Beruflich Dokumente

Kultur Dokumente

2AZ FE Starting

Hochgeladen von

Luks FernandezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2AZ FE Starting

Hochgeladen von

Luks FernandezCopyright:

Verfügbare Formate

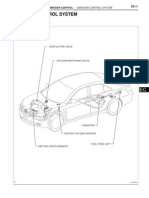

2AZ-FE STARTING STARTING SYSTEM

ST1

STARTING SYSTEM

2AZ-FE ENGINESTARTING

PARTS LOCATION

STARTER

AT: PARK/NEUTRAL POSITION SWITCH ECM

ENGINE ROOM R/B -STARTER RELAY -ST/AM2 FUSE -ALT FUSE

INSTRUMENT PANEL J/B -AM1 FUSE

ST

MT: CLUTCH START SWITCH IGNITION SWITCH

A135518E01

ST2

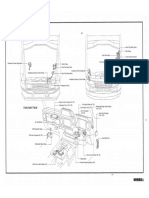

2AZ-FE STARTING STARTING SYSTEM

SYSTEM DIAGRAM

(*2) (*2) 4 C1 L B Park/Neutral P Position N Switch (*2) 48 A24 STA E23 Ignition Switch A22 Clutch Start Switch (*1) 1 ACC AM1 4 AM1 5 ST2 7 ALT ST/AM2 Starter FL MAIN 1 D1 M 1 1 C29 C3 (*1) (*2) 5 3 AM2 (*2) IG1 ST1 IG2 3 1 2 ST (*1) 2 52 C24 NSW ECM

ST

Battery

*1: M/T *2: A/T

A135060E01

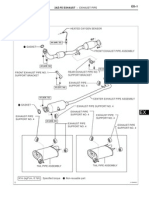

2AZ-FE STARTING STARTER

ST3

STARTER

2AZ-FE ENGINESTARTING

COMPONENTS

AIR CLEANER CAP SUB-ASSEMBLY AIR CLEANER FILTER ELEMENT

5.0 (51, 44 in.*lbf)

STARTER ASSEMBLY

9.8 (100, 87 in.*lbf)

x3

5.0 (51, 44 in.*lbf)

for Manual Transaxle:

12 (120, 9)

CLUTCH FLEXIBLE HOSE BRACKET

x2

37 (380, 28)

AIR CLEANER INLET ASSEMBLY

AIR CLEANER CASE SUB-ASSEMBLY

ST

N*m (kgf*cm, ft.*lbf) : Specified torque

A133564E01

ST4

2AZ-FE STARTING STARTER

STARTER ARMATURE ASSEMBLY STARTER COMMUTATOR END FRAME ASSEMBLY STARTER COMMUTATOR END FRAME COVER

6.0 (61, 53 in.*lbf)

SNAP RING

REPAIR SERVICE STARTER KIT -PLUNGER -RETURN SPRING -MAGNETIC SWITCH

WASHER

6.0 (61, 53 in.*lbf)

7.5 (76, 66 in.*lbf)

10 (102, 7)

ST

MOTOR TERMINAL STARTER KIT PLANETARY GEAR N*m (kgf*cm, ft.*lbf) : Specified torque Non-reusable part STARTER YOKE ASSEMBLY Apply High-temperature grease

A134900E01

STARTER ARMATURE PLATE

2AZ-FE STARTING STARTER

ST5

REMOVAL

1. 2. 3. 4. 5. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL REMOVE AIR CLEANER INLET ASSEMBLY (See page EM-94) REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page ES-416) REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See page EM-95) REMOVE STARTER ASSEMBLY (for Manual Transaxle) (a) Disconnect the terminal 50 connector from the starter assembly. (b) Remove the nut and disconnect the wire harness from terminal 30.

A133565

(c) Remove the 3 bolts, clutch flexible hose bracket and starter assembly.

Bracket

A133566E01

6.

REMOVE STARTER ASSEMBLY (for Automatic Transaxle) (a) Disconnect the terminal 50 connector from the starter assembly. (b) Remove the nut and disconnect the wire harness from terminal 30.

A134876

(c) Remove the 2 bolts and starter assembly.

ST

A134877

ST6

2AZ-FE STARTING STARTER

DISASSEMBLY

1. REMOVE REPAIR SERVICE STARTER KIT (a) Remove the nut and disconnect the lead wire from terminal C.

A079718E05

(b) Remove the 2 screws that hold the magnetic switch to the motor terminal starter kit. (c) Remove the repair service starter kit. (d) Remove the return spring and the plunger from the repair service starter kit.

A079719E05

2.

REMOVE STARTER YOKE ASSEMBLY (a) Remove the 2 through bolts and pull out the starter yoke assembly together with the starter commutator end frame assembly.

A079720E05

(b) Remove the starter yoke assembly from the starter commutator end frame assembly.

A079721E03

ST

3.

REMOVE STARTER ARMATURE PLATE (a) Remove the starter armature plate from the starter yoke assembly.

A079722E04

2AZ-FE STARTING STARTER

ST7

4.

REMOVE STARTER COMMUTATOR END FRAME COVER (a) Using a screwdriver, remove the starter commutator end frame cover.

A079723E03

5.

Snap Ring Pliers

REMOVE STARTER ARMATURE ASSEMBLY (a) Using snap ring pliers, remove the snap ring and plate washer. (b) Remove the starter armature assembly from the commutator end frame assembly.

A082440E07

6.

REMOVE PLANETARY GEAR (a) Remove the 3 planetary gears from the motor terminal starter kit.

A081167E03

ST

ST8

2AZ-FE STARTING STARTER

INSPECTION

1. INSPECT STARTER ASSEMBLY CAUTION: Make sure to complete each of the following tests within 5 seconds to prevent the coil from burning out. (a) Perform pull-in test: (1) Disconnect the lead wire from terminal C.

Terminal C

A133511E01

Terminal C

(2) Connect the battery to the magnetic switch as shown in the illustration. Check that the clutch pinion gear moves outward. If the clutch pinion gear does not move outward, replace the repair service starter kit.

Body Terminal 50

A133512E01

Terminal C

(b) Perform hold-in test: (1) Disconnect the negative (-) terminal lead from terminal C under the conditions for pull-in test. Check that the pinion gear remains out. If the clutch pinion gear moves inward, replace the repair service starter kit.

Body

Terminal 50

A133513E01

ST

Body Terminal 50

Terminal C

A133514E01

(c) Inspect clutch pinion gear return: (1) Disconnect the negative (-) lead from the starter body. Check that the clutch pinion gear moves inward. If the clutch pinion gear does not move inward, replace the repair service starter kit. (d) Perform no-load performance test: (1) Connect the field coil wire to terminal C with the nut. Make sure that the lead is not grounded. Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) (2) Clamp the starter in a vise.

2AZ-FE STARTING STARTER

ST9

Ammeter Terminal 30

(3) Connect the battery and an ammeter to the starter as shown in the illustration. (4) Check that the starter rotates smoothly and steadily with the clutch pinion gear extended. Check that the ammeter reads the specified current. Specified current

Condition at 11.5 V Specified condition 90 A or less

If the result is not as specified, overhaul the starter assembly.

Body Terminal 50

A133510E01

2.

INSPECT REPAIR SERVICE STARTER KIT (a) Check the plunger. (1) Push in the plunger and check that it returns quickly to its original position. If necessary, replace the repair service starter kit.

A058586E04

Terminal C

(b) Inspect the resistance of the pull-in coil. (1) Using an ohmmeter, measure the resistance between terminals 50 and C. Standard resistance

Tester connection Terminal 50 - Terminal C Specified condition Below 1

Terminal 50

Below 1

A079725E08

If the resistance is not as specified, replace the repair service starter kit.

Body Below 2

(c) Inspect the resistance of the hold-in coil. (1) Using an ohmmeter, measure the resistance between terminal 50 and the switch body. Standard resistance

Tester connection Terminal 50 - Switch body Specified condition Below 2

Terminal 50

A079726E07

If the resistance is not as specified, replace the repair service starter kit. 3. INSPECT STARTER ARMATURE ASSEMBLY (a) Check the commutator surface for dirt or burning. If the surface is dirty or burnt, smooth the surface with 400-grit sandpaper or leather.

ST

ST10

2AZ-FE STARTING STARTER

(b) Inspect the resistance of the commutator. (1) Using an ohmmeter, measure the resistance between the segments of the commutator. Standard resistance

Tester connection Specified condition Below 1

Below 1 Segment

A058372E04

Segment - Segment

If the resistance is not as specified, replace the starter armature assembly.

10 k or Higher

(2) Using an ohmmeter, measure the resistance between the commutator and armature coil core. Standard resistance

Tester connection Specified condition 10 k or higher Commutator - Armature coil core

Commutator Coil Core

A058373E04

If the resistance is not as specified, replace the starter armature assembly.

Depth

(c) Using vernier calipers, measure the commutator depth. Specified depth: 3.1 mm (0.122 in.) Maximum depth: 3.8 mm (0.150 in.) If the depth is greater than the maximum, replace the starter armature assembly.

A058584E09

4.

Length

A076677E10

INSPECT STARTER COMMUTATOR END FRAME ASSEMBLY (a) Check the brush length. (1) Using vernier calipers, measure the brush length. Specified length: 9.0 mm (0.354 in.) Maximum length: 4.0 mm (0.157 in.) If the length is less than the minimum, replace the starter commutator end frame assembly. (b) Check the resistance. (1) Using an ohmmeter, measure the resistance between the positive (+) and negative (-) brushes. Resistance: 10 k or higher If the resistance is not as specified, repair or replace the starter commutator end frame assembly.

ST

10 k or Higher

A079766E10

2AZ-FE STARTING STARTER

Lock

ST11

5.

Free

A081655E05

INSPECT MOTOR TERMINAL STARTER KIT (a) Check the starter clutch. (1) Rotate the clutch pinion gear counterclockwise and check that it turns freely. Try to rotate the clutch pinion gear clockwise and check that it locks. If necessary, replace the motor terminal starter kit.

REASSEMBLY

1.

Apply Grease

INSTALL PLANETARY GEAR (a) Apply high-temperature grease to the planetary gears and pin parts of the planetary shaft. (b) Install the 3 planetary gears to the motor terminal starter kit.

A081656E06

2.

Snap Ring Pliers

INSTALL STARTER ARMATURE ASSEMBLY (a) Apply high-temperature grease to the plate washer and the armature shaft. (b) Install the starter armature assembly to the starter commutator end frame assembly. (c) Using snap ring pliers, install the plate washer and a new snap ring.

A082440E08

Length

(d) Using vernier calipers, measure the snap ring. Maximum length: 5.0 mm (0.197 in.) If the length is greater than the maximum, replace the snap ring with a new one.

A058810E14

3.

INSTALL STARTER COMMUTATOR END FRAME COVER (a) Install the starter commutator end frame cover to the starter commutator end frame assembly.

ST

A081178E03

ST12

2AZ-FE STARTING STARTER

4.

Claw Groove

INSTALL STARTER ARMATURE PLATE (a) Align the claw of the armature plate with the groove inside the starter yoke assembly, and install the starter armature plate.

A073991E14

Rubber Groove

5.

A079727E08

INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY (a) Align the starter commutator end frame rubber with the groove of the starter yoke assembly. (b) Install the starter commutator end frame assembly to the starter yoke assembly. NOTICE: The magnet of the starter yoke assembly may attract the starter armature assembly when the starter commutator end frame assembly is installed, causing the magnet to break. INSTALL STARTER YOKE ASSEMBLY (a) Align the claw of the starter yoke with the groove inside the motor terminal starter kit.

6.

Claw

Groove

A079728E07

(b) Install the starter yoke with the 2 through bolts. Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

A079720E06

ST

7.

INSTALL REPAIR SERVICE STARTER KIT (a) Apply high-temperature grease to the plunger and the hook. (b) Hang the plunger hook of the repair service starter kit to the drive lever hook. (c) Install the plunger and the return spring.

A079729E03

2AZ-FE STARTING STARTER

ST13

(d) Install the repair service starter kit with the 2 screws. Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

A079719E06

(e) Connect the lead wire to terminal C with the nut. Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A079718E06

INSTALLATION

1.

B A

A Bracket

A133566E02

INSTALL STARTER ASSEMBLY (for Manual Transaxle) (a) Install the starter assembly and clutch flexible hose bracket with the 3 bolts. Torque: Bolt A 37 N*m (380 kgf*cm, 28 ft.*lbf) Bolt B 12 N*m (120 kgf*cm, 9 ft.*lbf) (b) Connect the wire harness to terminal 30 and install the nut. Then, attach the terminal cap. Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf) (c) Connect the terminal 50 connector to the starter assembly.

A133565

2.

INSTALL STARTER ASSEMBLY (for Automatic Transaxle) (a) Install the starter assembly with the 2 bolts. Torque: 37 N*m (380 kgf*cm, 28 ft.*lbf)

ST

A134877

ST14

2AZ-FE STARTING STARTER

(b) Connect the wire harness to terminal 30 and install the nut. Then, attach the terminal cap. Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf) (c) Connect the terminal 50 connector to the starter assembly. 3. 4.

A134876

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See page EM-120) INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page ES-419) INSTALL AIR CLEANER INLET ASSEMBLY (See page EM-120) CONNECT CABLE TO NEGATIVE BATTERY TERMINAL (See page EM-120)

5. 6.

ST

ST14

2AZ-FE STARTING STARTER RELAY

STARTER RELAY

ON-VEHICLE INSPECTION

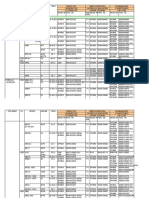

1. INSPECT STARTER RELAY ASSEMBLY (a) Using an ohmmeter, measure the resistance between each terminal. Standard resistance

Tester Connection

E034090E03

Specified Condition 10 k or higher Below 1 (when battery voltage is applied to terminals 1 and 2)

3-5

If the result is not as specified, replace the starter relay assembly.

ST

2AZ-FE STARTING IGNITION SWITCH

ST15

IGNITION SWITCH

LOCK ACC ON START

ON-VEHICLE INSPECTION

1. INSPECT IGNITION OR STARTER SWITCH ASSEMBLY (a) Check the resistance. (1) Using an ohmmeter, measure the resistance between the terminals. Standard resistance

Condition LOCK Tester Connection Between all terminals 2-4 1-2-4 5-6 1-3-4 5-6-7 Specified Condition 10 k or higher Below 1 Below 1 Below 1

AM1 ST1

ACC IG1

ACC ON

3 2 7 6 IG2

1 5 AM2

START

ST2

If the result is not as specified, replace the ignition or starter switch.

A119190E04

ST

Das könnte Ihnen auch gefallen

- 2AZ-FE Engine MechanicalDokument172 Seiten2AZ-FE Engine MechanicalWinnie Wan Huang100% (3)

- 2AZ-FE Emission ControlDokument25 Seiten2AZ-FE Emission ControlLuks FernandezNoch keine Bewertungen

- 2AZ-FE FuelDokument43 Seiten2AZ-FE FuelLuks Fernandez100% (1)

- 2AZ FE LubricationDokument22 Seiten2AZ FE LubricationLuks Fernandez100% (2)

- 2AZ-FE Engine HO2 Sensor Heater DTCsDokument6 Seiten2AZ-FE Engine HO2 Sensor Heater DTCslzengunitecNoch keine Bewertungen

- 2AZ FE CoolingDokument35 Seiten2AZ FE CoolingLuks Fernandez50% (2)

- 2AZ FE IgnitionDokument8 Seiten2AZ FE IgnitionLuks Fernandez100% (3)

- 2az-Fe Diagnostic Trouble Code ChartDokument6 Seiten2az-Fe Diagnostic Trouble Code ChartEdi Farnando100% (3)

- ENGINE INSPECTION AND TEST PROCEDURES (2AZ-FEDokument4 SeitenENGINE INSPECTION AND TEST PROCEDURES (2AZ-FEOlatunde OnakoyaNoch keine Bewertungen

- 2AZ FE IntakeDokument7 Seiten2AZ FE IntakeLuks Fernandez100% (2)

- Hyundai Chassis EPS - MDPS-Power SteeringDokument99 SeitenHyundai Chassis EPS - MDPS-Power SteeringDedi Suwasono100% (2)

- Ecs 2azDokument17 SeitenEcs 2azRoyer LRNoch keine Bewertungen

- 2az-Fe Engine Control System Sfi SystemDokument6 Seiten2az-Fe Engine Control System Sfi SystemMarcelo DecimaNoch keine Bewertungen

- 1kr Fe Starting Starting MotorDokument320 Seiten1kr Fe Starting Starting MotorTalleban Tal0% (1)

- 1mz Ecu Wiring DiagramDokument7 Seiten1mz Ecu Wiring Diagram12volt bayNoch keine Bewertungen

- LS600hL LS600h (Engine)Dokument36 SeitenLS600hL LS600h (Engine)Minh Nhat Phan100% (2)

- Ta1248 PDFDokument38 SeitenTa1248 PDFbad_boyz1989Noch keine Bewertungen

- 1 ZzfeDokument8 Seiten1 ZzfeScuderia Redin100% (1)

- General: Jengine Control SystemDokument29 SeitenGeneral: Jengine Control SystemJuan EspinoNoch keine Bewertungen

- Brake - Control of Toyota Yaris 2007 US PDFDokument105 SeitenBrake - Control of Toyota Yaris 2007 US PDFDavidTrevorPaul100% (2)

- Terminals of Ecm: E17 E16 E15 E14Dokument5 SeitenTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNoch keine Bewertungen

- Engine Control (1KR-FE) ECS-1KR PDFDokument1 SeiteEngine Control (1KR-FE) ECS-1KR PDFMuhammad Abbas Khan Niazi100% (1)

- 11a Engine 4g9-GdiDokument49 Seiten11a Engine 4g9-GdiAlexandre Da Silva Pinto100% (1)

- 3grfse 2 PDFDokument20 Seiten3grfse 2 PDFMarranNoch keine Bewertungen

- Toyota 2AZ-FE Engine Assemblyy InfoDokument10 SeitenToyota 2AZ-FE Engine Assemblyy Infomatderis100% (1)

- ABS, brake assist, EBD, TRC and VSC systems diagramDokument16 SeitenABS, brake assist, EBD, TRC and VSC systems diagramasfwsvgerNoch keine Bewertungen

- Toyota CorollaDokument166 SeitenToyota CorollaGjhgyhbgNoch keine Bewertungen

- 2AZ-FE FuelDokument43 Seiten2AZ-FE FuelAdedeji OluwatobilobaNoch keine Bewertungen

- Engine Bay Relay Locations GuideDokument82 SeitenEngine Bay Relay Locations GuidelukasNoch keine Bewertungen

- Toyota Noah AmDokument11 SeitenToyota Noah AmArchibold MachenaNoch keine Bewertungen

- Toyota Body Electrical SystemDokument95 SeitenToyota Body Electrical SystemNyhcnawNoch keine Bewertungen

- Camshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementDokument17 SeitenCamshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementMusat Catalin-Marian100% (5)

- Transmission Fluid PDFDokument5 SeitenTransmission Fluid PDFLv2mackNoch keine Bewertungen

- BeltsDokument89 SeitenBeltszul100% (2)

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDokument15 SeitenElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- BMC HiaceDokument396 SeitenBMC HiaceJerome Maminta100% (1)

- 3grfse 1pdf PDFDokument42 Seiten3grfse 1pdf PDFzerospace100% (4)

- Toyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineDokument5 SeitenToyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineMark Anthony Fletcher100% (1)

- Toyota 14Dokument76 SeitenToyota 14Dadang Lukmanul HakimNoch keine Bewertungen

- AE101 4AGE 20 Valve Pins 2019Dokument5 SeitenAE101 4AGE 20 Valve Pins 2019jorgeNoch keine Bewertungen

- Obd II CodesDokument21 SeitenObd II CodesObd King TgiNoch keine Bewertungen

- Engine 2JZ-GEDokument108 SeitenEngine 2JZ-GEroy.cheong900% (1)

- Corolla 00 02Dokument2.643 SeitenCorolla 00 02bobbie33389% (9)

- Corolla 4AfE 1 6 Ecu Pinout PDFDokument1 SeiteCorolla 4AfE 1 6 Ecu Pinout PDFWander Sarante100% (1)

- 1NZ Fe PDFDokument4 Seiten1NZ Fe PDFVinh PhạmNoch keine Bewertungen

- 2az FeDokument70 Seiten2az Fesayer2778100% (6)

- Mazda 5 EngineDokument143 SeitenMazda 5 EngineAngel CastNoch keine Bewertungen

- If Your Vehicle Needs To Be Towed: 5-1. Essential InformationDokument7 SeitenIf Your Vehicle Needs To Be Towed: 5-1. Essential InformationxsmartieNoch keine Bewertungen

- Power Steering PDFDokument93 SeitenPower Steering PDFWaldo Fuentes100% (1)

- Prado Manual SM - 2Dokument104 SeitenPrado Manual SM - 2jeddo2005100% (1)

- Ignition PDFDokument17 SeitenIgnition PDFtavi2meNoch keine Bewertungen

- Ignition PDFDokument16 SeitenIgnition PDFDoDuyBacNoch keine Bewertungen

- Terminals of Ecm: 2Gr-Fe Engine Control System - Sfi SystemDokument8 SeitenTerminals of Ecm: 2Gr-Fe Engine Control System - Sfi SystemMiguel ruiz100% (1)

- Honda Stream 18 i-VTEC PDFDokument5 SeitenHonda Stream 18 i-VTEC PDFFabian Carrasco NaulaNoch keine Bewertungen

- Toyota 1NZ-FE Wiring DiagramDokument6 SeitenToyota 1NZ-FE Wiring DiagramTomy100% (1)

- 19 - Starting and Charging PDFDokument22 Seiten19 - Starting and Charging PDFJen-Yung ChangNoch keine Bewertungen

- Starting System (2Az-Fe) : InspectionDokument40 SeitenStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- Charging System: PrecautionDokument17 SeitenCharging System: PrecautionlogammicNoch keine Bewertungen

- AlternatorDokument19 SeitenAlternatorcpgmotorsNoch keine Bewertungen

- Engine Mechanical PDFDokument115 SeitenEngine Mechanical PDFAndrey GladyshevNoch keine Bewertungen

- WITHJOYMYHEARTISLEAPING Albites1871GiojaDokument7 SeitenWITHJOYMYHEARTISLEAPING Albites1871GiojaLuks FernandezNoch keine Bewertungen

- Domenico Antenori-SonateGmollDokument9 SeitenDomenico Antenori-SonateGmollLuks FernandezNoch keine Bewertungen

- MAR 07 Shift PointersDokument4 SeitenMAR 07 Shift PointersVadim UrupaNoch keine Bewertungen

- Al To Heavyduty CatalogDokument54 SeitenAl To Heavyduty CatalogRoberto PerezNoch keine Bewertungen

- Dvorak Massind CredoDokument26 SeitenDvorak Massind CredoLuks FernandezNoch keine Bewertungen

- Andrew Loomis - Figure Drawing For All It's WorthDokument197 SeitenAndrew Loomis - Figure Drawing For All It's WorthManuel100% (26)

- DVK86B PDFDokument8 SeitenDVK86B PDFLuks FernandezNoch keine Bewertungen

- DVORAK MassInD Gloria PDFDokument18 SeitenDVORAK MassInD Gloria PDFLuks FernandezNoch keine Bewertungen

- DVORAK MassInD Gloria PDFDokument18 SeitenDVORAK MassInD Gloria PDFLuks FernandezNoch keine Bewertungen

- DVK86B PDFDokument8 SeitenDVK86B PDFLuks FernandezNoch keine Bewertungen

- Официальное руководство по ремонту АКПП ZF 4HP20Dokument140 SeitenОфициальное руководство по ремонту АКПП ZF 4HP20icechieff86% (7)

- 01J CodesDokument1 Seite01J CodesLuks FernandezNoch keine Bewertungen

- Hy-Vo Morse Chain CatalogueDokument20 SeitenHy-Vo Morse Chain CatalogueLuks FernandezNoch keine Bewertungen

- Vodka For BreakfastDokument11 SeitenVodka For BreakfastSetang Besar0% (1)

- 2GR-FE Emission ControlDokument23 Seiten2GR-FE Emission ControlLuks FernandezNoch keine Bewertungen

- 2GR-FE Engine MechanicalDokument156 Seiten2GR-FE Engine MechanicalLuks Fernandez100% (7)

- 2GR FE CoolingDokument36 Seiten2GR FE CoolingLuks FernandezNoch keine Bewertungen

- 2GR FE ExhaustDokument5 Seiten2GR FE ExhaustLuks FernandezNoch keine Bewertungen

- 2GR FE ChargingDokument25 Seiten2GR FE Chargingmink4uNoch keine Bewertungen

- 2AZ FE ExhaustDokument5 Seiten2AZ FE ExhaustLuks FernandezNoch keine Bewertungen

- 2AZ FE IntakeDokument7 Seiten2AZ FE IntakeLuks Fernandez100% (2)

- 2AZ FE IgnitionDokument8 Seiten2AZ FE IgnitionLuks Fernandez100% (3)

- 2011 Transtar Automatic Transmission CatalogDokument125 Seiten2011 Transtar Automatic Transmission Catalogshanestarbuck68100% (2)

- 2AZ FE CoolingDokument35 Seiten2AZ FE CoolingLuks Fernandez50% (2)

- Toyota Camry 2006-2011 2AZ-FE ChargingDokument21 SeitenToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNoch keine Bewertungen

- MR2520 DatasheetDokument7 SeitenMR2520 DatasheetOxkar YetiNoch keine Bewertungen

- Mobile Sniffer: D. Mohan KumarDokument2 SeitenMobile Sniffer: D. Mohan KumarIjjada VivekanandaNoch keine Bewertungen

- Electrical AnalysisDokument41 SeitenElectrical AnalysisAbinash MandalNoch keine Bewertungen

- Transistor Basics & DifferencesDokument2 SeitenTransistor Basics & DifferencesNayan AgrawalNoch keine Bewertungen

- PD DS5600 ManualDokument9 SeitenPD DS5600 ManualMichael RitzelNoch keine Bewertungen

- Re29583 (Servo)Dokument20 SeitenRe29583 (Servo)Putut SuprihartonoNoch keine Bewertungen

- Ec 8001 Unit 3Dokument26 SeitenEc 8001 Unit 3AlibabaNoch keine Bewertungen

- RCDokument7 SeitenRCadyro12Noch keine Bewertungen

- Measuring High Voltages and Currents (40Dokument21 SeitenMeasuring High Voltages and Currents (40Syed Z50% (8)

- AC Job CardDokument51 SeitenAC Job CardKashif SiddiquiNoch keine Bewertungen

- NEC Code Change: For Health Care FacilitiesDokument12 SeitenNEC Code Change: For Health Care FacilitiesJorge Buitrago100% (1)

- Sequence Impedances of a 3-φ TransformerDokument4 SeitenSequence Impedances of a 3-φ TransformerBhanu100% (1)

- LM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Dokument17 SeitenLM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Pravin MevadaNoch keine Bewertungen

- S05 Bias CKTDokument30 SeitenS05 Bias CKTAlperen ERNoch keine Bewertungen

- YASREF - QC QuestionaireDokument26 SeitenYASREF - QC Questionairevenkatesh100% (1)

- Guide To PatchbaysDokument6 SeitenGuide To PatchbaysPepe CocaNoch keine Bewertungen

- Project ProposalDokument4 SeitenProject ProposalSushrut BhatNoch keine Bewertungen

- Taikai Capacitor BanksDokument9 SeitenTaikai Capacitor Banksle hoai NamNoch keine Bewertungen

- Advances in Vector Control Ofac Motor Drives A Review PDFDokument24 SeitenAdvances in Vector Control Ofac Motor Drives A Review PDFBook4AllNoch keine Bewertungen

- Flyer Current TransformerDokument24 SeitenFlyer Current TransformerBash MatNoch keine Bewertungen

- Kolbeko PDFDokument68 SeitenKolbeko PDFDanh ThànhNoch keine Bewertungen

- Gutor UPS System GlossaryDokument33 SeitenGutor UPS System Glossarybookbum100% (4)

- TB6564AHQ (THB6064AH) : PWM Chopper-Type Bipolar Stepping Motor Driver ICDokument39 SeitenTB6564AHQ (THB6064AH) : PWM Chopper-Type Bipolar Stepping Motor Driver ICTran Duc IOTNoch keine Bewertungen

- Power Tool Switches: Catalog 1308650 Issued 1-01Dokument18 SeitenPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNoch keine Bewertungen

- Stator Winding Inter-Turn Short-Circuit ModellingDokument10 SeitenStator Winding Inter-Turn Short-Circuit Modellingronaldo rmaNoch keine Bewertungen

- Generic Remote For Logitech Z-2300Dokument1 SeiteGeneric Remote For Logitech Z-2300GiuseppeNoch keine Bewertungen

- DSE BC2410Ei Installation InstructionsDokument2 SeitenDSE BC2410Ei Installation InstructionsthaiNoch keine Bewertungen

- Electrical Power Transmission 7Dokument4 SeitenElectrical Power Transmission 7FaisalSoNoch keine Bewertungen

- SIRCOVERDokument12 SeitenSIRCOVERsaumya DuttaNoch keine Bewertungen

- P5500 Series RectifiersDokument4 SeitenP5500 Series RectifiersSME WJNoch keine Bewertungen