Beruflich Dokumente

Kultur Dokumente

D Kitting Process

Hochgeladen von

dharma2116272Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D Kitting Process

Hochgeladen von

dharma2116272Copyright:

Verfügbare Formate

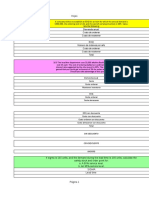

Title: Track k: edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

Introduc ction: e shed goods in nventory lying in FG stores This invent is accumulated becaus of cancella g s. tory se ation of We have different finis orders, Q Quality rejectio etc. Such FG codes ca ons h arrying multiples componen which can be used for manufacturing other nts n assemblies. This scena is mostly applicable in case of kitting activity. ario g By this process we can d-k finished goods at compo kit onent level. Th process ca also be use for d-kiting sales his an eful return go oods. Note: e y y. 1. D-kitting process should be handled very carefully, its generates Item in inventory e .to ave es y. 2. This process should handle properly w.r. India localization. You ha to maintaiin RG balance accordingly nsider same d department & resources for d-kitting which are available in Organisat e tion. 3. In this process we have con Run Transaction R Register Repo ort Step 1: R the Lot T on: orts y-> Requests -> Submit a New Request -> Single Request -> Name Lot w > e: Navigatio INV Repo & Enquiry View -> R Transact Register tion r Parameters: tion Give ed o rding to the Bu usiness require ements. Transact Dates: G the desire from and To Dates accor Item from & Item To: Mention the A m Assembly (Fin nished good It tem) or Job wh needs to be disassemb hich bled.[OK] Butt ton. View the output of the report, the re e eport contains the Link of t Sales orde Job Order / work order, Assembly Ite and s the er, r , em Inventory details. From this report fin out the job order numbe from which t assembly item is manuf y m nd er the factured and a the also corresponding sales or number through which this assembly item is shipp to the cust rder y ped tomer. erial o o ory Step 2: Find the Mate Requirement need to be Return to the Invento details of the components ne to be retu to the inventory after dis c eed urn sassembling th Assembly, from the discr job he rete Get the d (Example Job No 108974).This is basically requir for knowin actual cons e: red ng sumption in tha particular Jo at ob. on: iscrete -> Dis screte jobs. Navigatio WIP -> Di Give the job: 108974 (Example) utton. Under Components - > Quantit Tab, get the details of the list of components and Per As r s ties t f ssembly [Find] Bu requirement of the com mponent.

Page e1of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

Step 3: Non-standard Discrete job for disassem mbling the As ssembled / Pa arent Item (Ex AAA22160 x: 001) Define N on: iscrete -> Dis screte Jobs Navigatio WIP -> Di [NEW] Bu utton. B ual ording to the B Business requirement. (For example: 116 6947) Job: TAB OUT / Manu Entry Acco Type: No on-standard. Assembly: For examp (AAA2216 ple 6001), even th hough its not a mandatory field mention the assemblies name to p n perform e the Move Transaction operation. Class: Expense Unreleased. (D Dont change t Status unt Mentioned iin the future steps). the til Status: U Start: Nu umber of QTY need to be Disassemble ( In example it is considered as 2) MRP Net Zero (0). t:

Step 4 : A Material Requiremen for the Non Add nt n-Standard Discrete Job. P edule Details -> Material R Requirements s (N) : WIP -> Job/Sche Enter pus as the supp type and e sh ply enter the FGI s inventory in the supply sub inventory field sub s Check M net since you want to c MRP create demand for an assem that is supplied from th net table d mbly he FGI sub iinventory Create ne egative compo onent requirem ments for each of the major components you expect to return to h r o Inventory and check M Net so th the MRP planning proce sees these negative dem y MRP hat ess e mands as supply Supply Type for Paren Item Should be PUSH an the QTY NE TO BE M nt d nd EED MENTION IN P POSITIVE and Supply Type for the d e Child Ite ems or comp ponents need to return to t Inventory should be OP the PERATION P PULL and the QTY NEED TO BE e MENTIONED IN NEGA ATIVE Page e2of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

FG Part G

FG Part with G h Po ositive Qty y.

All RM/SFG P Part h with Negative Qty.

Page e3of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

FG Part with Push G type.

All RM/SF Part wit FG th operationa pull type al e.

Assign Stand dard Operatio for Disasse on embly defined in Step 4 fo the Non dis or screte Job Step 5: A on: ob/Schedule Details -> Op perations Navigatio WIP -> Jo Query the Non Standa Discrete Jo e ard ob Assign th Standard Operation for D he O Disassembly u under the main Tab. n [Button] S Select existing department or you can create new dep g partment & ass for d-kittin operation. Assign the Re sign ng equired Resource (existing res e source or you can create ne resource & assign for d-kitting operat under the same depart ew tion e tment)., Save the Form and Clo it. ose

Departmen required to capture over nt o rheads associated with d-k kitting proces ss

Page e4of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

Res source requir to capture cost red ass sociated with d-kitting pro h ocess

Step6: R Release the Non-standard Discrete job (N): WIP -> Discrete -> Discrete Jo Query the non-standar discrete job change the status to Rele obs, e rd b, s ease.

You can put RMA (Sales t s return) Sales order no here. r

Give the RMA Sales O Order Number(If any) . [Button] o save and c ok, close the form m

Page e5of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

Step 7: P Perform the WIP Material Transaction to WIP Issu the Assem / Parent Item from th Sub inventory to W n ue mbly he the SHOP FLOOR/Pro oduction Floo or. on: actions -> WIP Material Tran P nsactions. Navigatio WIP -> Material Transa Type: WIP ISSUE. [Bu utton] Continu ue

Page e6of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

Step 8 : Perform Mov Transactio for the No Standard D ve ons on Discrete Job on: tions -> Move Transaction e n. Navigatio WIP -> Move Transact Perform t Move Tran the nsaction from 10 Operation Queue to 10 operations TO Move O Do not u the Comp use pletions window since there is nothing to complete. window appear for Child co rs omponents, w which need to return to the Inventory, select the [Button] Save, Below Back flush w appropria Lot to store the components. ate e

The compone need to be return will be shown in the red color. ents e

Step 9: M Manually Cha ange the statu of Non Sta us andard Discre Job to Co ete omplete and C Complete N charges No Note: Do not use the Completions window sinc there is no o s ce othing to com mplete. on: crete Job -> Q Query the Non Standard Dis screte Job to Complete, C Navigatio WIP -> Diiscrete -> Disc Tools -> Change Statu -> select Co us omplete. -> Sa the form. ave For Complete No-charges us omplete-No ch harges -> Sav and close th form. ve he Tools -> Change Statu -> select Co

Page e7of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

on-standard D Discrete Job Step 10: Close the No Note : Do close the job if any pending transaction exist f the corres ont e for sponding job , make sure no pending b transaction are there for the closing job and su ubmit the req quest. on: se obs Discrete Job F Form, Query th Non-standa Discrete Job -> he ard Navigatio WIP -> Diiscrete -> Clos Discrete Jo -> Close D Tools ->C Close d. Request is submitted

Page e8of9

Title: k: Track edure Proce Name e:

Work In Pro ocess er Manufacturing WIP Use Manual ocess D Kitting pro

he d Check th following details 1. Job status. 2. Check the Ex xpense job value report for t full details of job. The en the nding balance of the job willl be equal to the resource and overhead cos incurred du sts uring the asse embly and disa assembly. The costs of mat e terials issued a and returned will b equal since all the compo be e onents were r returned to inv ventory. The re esource and o overhead are w written off as a varian when the job is closed o at period en when expe nce or nd ense type nons standard jobs are automatic cally expensed. 3. On-hand avaiilability and RG balance f the return c G23 for child compone ents.

Page e9of9

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- SRS For Sales ProjectDokument16 SeitenSRS For Sales ProjectHaile Michael100% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- MINOR PROJECT REPORT ON Indraprastha Gas Limited (Pulkit)Dokument65 SeitenMINOR PROJECT REPORT ON Indraprastha Gas Limited (Pulkit)Amit Jain50% (2)

- Final PlaneaciónDokument4 SeitenFinal PlaneaciónAdrianaNoch keine Bewertungen

- TIffany and Co. Competitive Analysis PresentationDokument52 SeitenTIffany and Co. Competitive Analysis Presentationlynklynk100% (1)

- Variable and Absorption CostingDokument3 SeitenVariable and Absorption CostingLiana Monica LopezNoch keine Bewertungen

- Tools and Techniques of Cost ReductionDokument27 SeitenTools and Techniques of Cost Reductionপ্রিয়াঙ্কুর ধর100% (2)

- Maintenance Practices in Cement IndustryDokument12 SeitenMaintenance Practices in Cement IndustryNayan DwivediNoch keine Bewertungen

- Information Technology in Supply Chain ManagementDokument15 SeitenInformation Technology in Supply Chain ManagementSiya Macwan100% (1)

- Mid Term Exam Auditing 2 2023Dokument2 SeitenMid Term Exam Auditing 2 2023ZakyaNoch keine Bewertungen

- Himson-Working Capital ManagemantDokument59 SeitenHimson-Working Capital ManagemantDipak DiyoraNoch keine Bewertungen

- Im CH 08Dokument16 SeitenIm CH 08Tanpo NomoNoch keine Bewertungen

- Long-Distance Freight Trucking in Canada Industry ReportDokument35 SeitenLong-Distance Freight Trucking in Canada Industry ReportBill LeeNoch keine Bewertungen

- L3 Fundamentals of LogisticsDokument40 SeitenL3 Fundamentals of LogisticsDu Lich Vung TauNoch keine Bewertungen

- THD Vs Lowes Balance Sheet &financial AnalysisDokument13 SeitenTHD Vs Lowes Balance Sheet &financial AnalysisR K Patham100% (2)

- MBA SIP Reports (Rani)Dokument35 SeitenMBA SIP Reports (Rani)Nikhil KulkarniNoch keine Bewertungen

- LSS Benefits of Kaizen To Business Excellence Evidence From A Case Study 2169 0316 1000251 (3197)Dokument15 SeitenLSS Benefits of Kaizen To Business Excellence Evidence From A Case Study 2169 0316 1000251 (3197)Dasa ShelkNoch keine Bewertungen

- Fin. Anal RafaelDokument6 SeitenFin. Anal RafaelMarjonNoch keine Bewertungen

- Lev Aloha Against Waiter ScamsDokument31 SeitenLev Aloha Against Waiter ScamsfedericusxNoch keine Bewertungen

- Cycle Selection, ProcurmentDokument18 SeitenCycle Selection, ProcurmentfikebatuNoch keine Bewertungen

- Stock Management and ControlDokument57 SeitenStock Management and ControlACCOMMODATION CENTRENoch keine Bewertungen

- InventoriesDokument22 SeitenInventoriesJane T.Noch keine Bewertungen

- EOQ With Quantity DiscountsDokument23 SeitenEOQ With Quantity DiscountsCarey HillNoch keine Bewertungen

- Sample Case Study (CD Warehouse Management)Dokument5 SeitenSample Case Study (CD Warehouse Management)Shreesh BasatwarNoch keine Bewertungen

- 110107074Dokument484 Seiten110107074anish jainNoch keine Bewertungen

- ECC 6 - Standard ReportsDokument7 SeitenECC 6 - Standard ReportsGulf CruiseNoch keine Bewertungen

- Week 1 Powerpoint SlidesDokument52 SeitenWeek 1 Powerpoint SlidesMichel BanvoNoch keine Bewertungen

- Eaton RFID Final ReportDokument18 SeitenEaton RFID Final ReportYaoxuekun HuNoch keine Bewertungen

- Warehousing, Inventory, and 3PLDokument9 SeitenWarehousing, Inventory, and 3PLMuhammed Shadab SazzadNoch keine Bewertungen

- Sample MAS 3rd Evals KEY Set ADokument10 SeitenSample MAS 3rd Evals KEY Set AJoanna MNoch keine Bewertungen

- Glovia KanbanDokument2 SeitenGlovia KanbandahboushNoch keine Bewertungen