Beruflich Dokumente

Kultur Dokumente

210 Bevel Gear Sets

Hochgeladen von

Fika PorieskaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

210 Bevel Gear Sets

Hochgeladen von

Fika PorieskaCopyright:

Verfügbare Formate

B.

Mroczkowski

12/5/2008

Mott, Robert L. Machine Elements in Mechanical Design Fourth Edition , Person Prentice Hall 2004

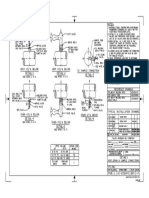

Problem 10-14 pg. 490

A straight bevel gear pair has the following data: Np=15; NG=45; Pd=6; 20 pressure angle.

If the pair is transmitting 3.0 hp, compute the forces on both the pinion and the gear. The pinion

is 300 rpm. The face width is 1.25 in. Compute the bending stress and the contact stress for

the teeth, and specify a suitable material and heat treatment. The gear are driven by a gasoline

engine, and the load is a concrete mixer providing moderate shock. Assume that neither gear

is straddle-mounted.

Concrete Mixer - Problem 10-14

3 hp

steps

1 Co=Ko, Service Factor

20 full depth teeth

2

3

300 rpm

100 rpm

1.5

Iteration:

T/in of dia

T

T

Pd

Np ( T min for Pinion)

Ng

Dimensions

Gear Ratio

Pitch diameter

13

mg=Ng/Np

Pinion d=Np/Pd

Gear D=Ng/Pd

Pinion g=tan^-1(Np/Ng)

Pitch cone angle

Pinion G=tan^-1(Ng/Np)

Ao=.5D/sin(G)

Outer Cone Distance

Face Width

F=

Nominal face Width

Fnom= .30Ao

Max Face Width

Fmax= Ao/3

Fmax=10/Pd

Mean Cone Distance

Am=Ao-.5F

pm=(p/Pd)(Am/Ao)

Mean Circular Pitch

Mean working depth

h= (2/Pd)(Am/Ao)

Clearance

c= .125h

Mean Whole Depth

hm= h+c

Mean addendum Factor c1=.210+.290/mg^2

ag=c1h

Gear Mean addendum

Pinion Mean addendum ap=h-ag

Gear deddendum

bg= hm-ag

Pinion deddendum

bp = hm-ap

Gear deddendum angle dg = tan^-1(bg/Amg

Pinion deddendum angle dp= tan^-1(bp/Amg

aog=ag+.5Ftandg

Gear Outer addendum

Pinion Outer addendum aop=ap+.5Ftandp

Do=D+2aogcosG

Gear Outer Diameter

do=d+2aopcosg

Pinion Outer Diameter

Output Speed

ng=(np*Np)/Ng

Center distance

C=(Do+ do)/2 =

Vt= (p*d*np)/12=

Tangent line speed

Tangential Force

Wt= ((63000*hp)/np)-(1/(d/2))=

Cp

Materials:

Quality # Qv=

HB of both Gears

Sat=

77.3(HB)+12800=

[Kz/(Kz+ Vt)]^u

Cv=Kv=

u=

(8/(2^.5*Qv))-Sat[125/(Ep+Eg)]

Kz=

85-10u

Geometry Factors:

14

15

16

Cm=Km =

Ks, Size factor

Kb,Rim thickness

18

19

20

21

22

23

24

Cb

SF, Saftey Factor

Ch, Hardness Ratio

Kr, Reliability

Design life

Ncp=

Ncg=

St=

Sc=

25

26

HBp/HBg =

Ch check If HBp/HBg < 1.2 then Ch=1.0

4

5

6

7

8

9

10

11

12

in

in

degrees

degrees

in

in

in

in

in

in

in

in

in

in

in

in

in

in

degrees

degrees

in

in

in

in

rpm

in

ft/min

pounds

Steel / Steel

HB

psi

J

I

Neither Straddle-mounted (GCQ)

Min Rim Thickness =

hours*60*rpm*cyc/rev

hours*60*rpm*cyc/rev

((Wt*Pd)/(F*Jp))(KoKsKm/Kv)

Cp*Cb(Wt/(F*d*I)*CoCm/Cv)

0.9999

hours

cycles

cycles

psi

psi

Pinion Su Reqd (ksi) =

Gear Su reqd (ksi) =

27

Material & heat Treat

Gasoline engine

Concrete Mixer

delivered hp = hp*Ko=

4.5

1 st

6

15

45

2 nd

6

15

45

3 rd

6

15

45

3.00

2.5

7.5

18.435

71.565

3.953

1.250

1.186

1.318

4.000

3.328

0.441

0.281

0.035

0.316

0.242

3.00

2.5

7.5

18.435

71.565

3.953

1.250

1.186

1.318

4.000

3.328

0.441

0.281

0.035

0.316

0.242

3.00

2.5

7.5

18.435

71.565

3.953

1.250

1.186

1.318

4.000

3.328

0.441

0.281

0.035

0.316

0.242

0.068

0.213

0.248

0.103

4.257

1.774

0.115

0.232

7.572

2.940

100.000

5.256

196.350

629.200

2300.000

6

293

35448.900

0.855

0.926

75.739

0.226

0.069

1.800

1.000

1.000

0.450

0.634

1.000

1.000

1.500

15600

280800000

93600000

42224.373

140017.636

0.068

0.213

0.248

0.103

4.257

1.774

0.115

0.232

7.572

2.940

100.000

5.256

196.350

629.200

2300.000

6

302

36144.600

0.855

0.925

75.753

0.226

0.069

1.800

1.000

2.000

0.450

0.634

1.000

1.000

1.500

15600

280800000

93600000

42212.819

139998.479

0.068

0.213

0.248

0.103

4.257

1.774

0.115

0.232

7.572

2.940

100.000

5.256

196.350

629.200

2300.000

6

341

39159.300

0.856

0.918

75.816

0.226

0.069

1.800

1.000

3.000

0.450

0.634

1.000

1.000

1.500

15600

280800000

93600000

42162.838

139915.573

1.000

No Change

1.000

No Change

141

141

AISI 4340

OQT 1100

146

146

AISI 4340

OQT 1100

4 th

164

164

AISI 6150

OQT 1100

Design Life

5

day/week

12

hr/day

5

years

52

weekk/year

15600 hr

Das könnte Ihnen auch gefallen

- Face WidthDokument24 SeitenFace WidthDipak100% (1)

- Review Problems Problem No.1: N D N D D DDokument7 SeitenReview Problems Problem No.1: N D N D D D3 stacksNoch keine Bewertungen

- Chapter 9 Spur Gear DesignDokument31 SeitenChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Machine Design & Drawing - II - GEARSDokument12 SeitenMachine Design & Drawing - II - GEARSSenthil KumarNoch keine Bewertungen

- Gear Force & StressDokument30 SeitenGear Force & StressRanjeethkumar JalalNoch keine Bewertungen

- Gears Types: Example: Car Differential Example: Car DifferentialDokument11 SeitenGears Types: Example: Car Differential Example: Car DifferentialAmal RadhakrishnanNoch keine Bewertungen

- Cement Concrete Road DesignDokument8 SeitenCement Concrete Road Designmdshah1308Noch keine Bewertungen

- References:: Third-All Branches Machine Design I (Lecture 28) Mechanical Eng. DeptDokument11 SeitenReferences:: Third-All Branches Machine Design I (Lecture 28) Mechanical Eng. DeptOmar loayzaNoch keine Bewertungen

- Worm GearsDokument27 SeitenWorm GearsDipakNoch keine Bewertungen

- Optimization of Gear Design and ManufactureDokument6 SeitenOptimization of Gear Design and Manufacturexijifa2368Noch keine Bewertungen

- Gears DesignDokument5 SeitenGears DesignSandy PandeNoch keine Bewertungen

- EG1020 Gear Drive HelpDokument4 SeitenEG1020 Gear Drive Helptimbs2004Noch keine Bewertungen

- Spur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDokument31 SeitenSpur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDipakNoch keine Bewertungen

- Gear BoxDokument16 SeitenGear BoxOmar AhmedNoch keine Bewertungen

- Stress Analysis of Drive ShaftDokument7 SeitenStress Analysis of Drive ShaftnachigansNoch keine Bewertungen

- Spur Gear DesignDokument51 SeitenSpur Gear Designmshebbal2212100% (1)

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDokument12 SeitenEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNoch keine Bewertungen

- DTS - Unit - 2 PDFDokument14 SeitenDTS - Unit - 2 PDFmani100% (1)

- MANE-4030: Elements of Mechanical Design: Worksheet #14Dokument3 SeitenMANE-4030: Elements of Mechanical Design: Worksheet #14azizieh5701Noch keine Bewertungen

- ch09 3Dokument155 Seitench09 3abdallah ghannamNoch keine Bewertungen

- Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and BrakesDokument17 SeitenPower Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakesrip111176Noch keine Bewertungen

- Design Calculation of Gearbox: ST ND RD TH THDokument50 SeitenDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNoch keine Bewertungen

- Spur GearDokument107 SeitenSpur GearMuhammadUmairShafiqNoch keine Bewertungen

- Machine DesignDokument15 SeitenMachine DesignYaNoch keine Bewertungen

- Tom 2Dokument16 SeitenTom 2Vaibhav Vithoba NaikNoch keine Bewertungen

- Tutorial MD II 2015 1Dokument2 SeitenTutorial MD II 2015 1rip111176Noch keine Bewertungen

- Planetery GearDokument19 SeitenPlanetery GearDipakNoch keine Bewertungen

- PM Synchronous MachineDokument14 SeitenPM Synchronous MachineNguyen Duy ChungNoch keine Bewertungen

- Theory of Metal Cuttingmechanics of Metal CuttingDokument18 SeitenTheory of Metal Cuttingmechanics of Metal Cuttingznovak77Noch keine Bewertungen

- Gears PDFDokument8 SeitenGears PDFmgualdiNoch keine Bewertungen

- Gear AnalysisDokument33 SeitenGear AnalysisRob Morien100% (1)

- Design of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byDokument4 SeitenDesign of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byLemi Chala BeyeneNoch keine Bewertungen

- Design of Spur Gear Tutorial No: - DateDokument18 SeitenDesign of Spur Gear Tutorial No: - DateAkhilesh NavikNoch keine Bewertungen

- Tutorial MD II 2015 1Dokument1 SeiteTutorial MD II 2015 1rip111176Noch keine Bewertungen

- 5 - Threaded Fasteners PDFDokument41 Seiten5 - Threaded Fasteners PDFViven Sharma100% (1)

- Design of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013Dokument3 SeitenDesign of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013bnkadia60% (5)

- Research PaperDokument10 SeitenResearch PaperGitesh SammalwarNoch keine Bewertungen

- Shaft AssignmentDokument7 SeitenShaft AssignmentdongNoch keine Bewertungen

- Ch08 - 5Dokument49 SeitenCh08 - 5abdallah ghannamNoch keine Bewertungen

- C504051018 PDFDokument9 SeitenC504051018 PDFlitonNoch keine Bewertungen

- Influence of Stresses in A Modified Non-Metallic Spur Gear PairDokument10 SeitenInfluence of Stresses in A Modified Non-Metallic Spur Gear PairTJPRC PublicationsNoch keine Bewertungen

- Gears PresentationDokument33 SeitenGears PresentationNaveen YadavNoch keine Bewertungen

- Machine Design IIDokument11 SeitenMachine Design IIExequiel MedinaNoch keine Bewertungen

- Bending Formulas For Tube Bending ToolsDokument3 SeitenBending Formulas For Tube Bending ToolsVikash SharmaNoch keine Bewertungen

- Design Data BookDokument20 SeitenDesign Data BookAtul Gaur100% (1)

- HES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)Dokument21 SeitenHES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)StephenPYBongNoch keine Bewertungen

- What We Need To Know About Them. Type of Gears Terminologies or Nomenclatures Forces Transmitted Design of A Gear BoxDokument33 SeitenWhat We Need To Know About Them. Type of Gears Terminologies or Nomenclatures Forces Transmitted Design of A Gear Boxfaith23dbagulNoch keine Bewertungen

- Shear - Torsion - HandoutDokument10 SeitenShear - Torsion - HandoutDirajen PMNoch keine Bewertungen

- Lecture 4 (EC4 Version)Dokument67 SeitenLecture 4 (EC4 Version)ikanyu79100% (1)

- The Influence of Pressure Angle of Spur Gears On Bending Stress Considering The Effect of Root Fillet RadiusDokument11 SeitenThe Influence of Pressure Angle of Spur Gears On Bending Stress Considering The Effect of Root Fillet RadiushaceneNoch keine Bewertungen

- Compound Epicyclic Gear TrainsDokument5 SeitenCompound Epicyclic Gear TrainsSezgin BayrakNoch keine Bewertungen

- Differential Forms on Electromagnetic NetworksVon EverandDifferential Forms on Electromagnetic NetworksBewertung: 4 von 5 Sternen4/5 (1)

- Dynamic Damage and FragmentationVon EverandDynamic Damage and FragmentationDavid Edward LambertNoch keine Bewertungen

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsVon EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- Interface / Interphase in Polymer NanocompositesVon EverandInterface / Interphase in Polymer NanocompositesAnil N. NetravaliNoch keine Bewertungen

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- Samson CatalogDokument170 SeitenSamson CatalogFelipe SalvatierraNoch keine Bewertungen

- Brake System: Irab 1Dokument15 SeitenBrake System: Irab 1Sk IrshadNoch keine Bewertungen

- Seated Valves: Type WV700Dokument14 SeitenSeated Valves: Type WV700John EvansNoch keine Bewertungen

- 6WG210变速箱操作保养手册Dokument87 Seiten6WG210变速箱操作保养手册Handoko Dwi raharjo100% (1)

- Drain ConnectionDokument1 SeiteDrain Connectionnas_mech8208Noch keine Bewertungen

- Valves Q.S For Fire Pump Room - Eng Ahmed HassanDokument1 SeiteValves Q.S For Fire Pump Room - Eng Ahmed Hassanmujassam noorNoch keine Bewertungen

- Design and Fabrication of Cycloidal Gear Box: A Project Report OnDokument25 SeitenDesign and Fabrication of Cycloidal Gear Box: A Project Report OnAjay NishadNoch keine Bewertungen

- Mercedes 9g-Tronic InfoDokument17 SeitenMercedes 9g-Tronic InfoRob LeaneyNoch keine Bewertungen

- LinkagesDokument30 SeitenLinkagesManoj AnandhanNoch keine Bewertungen

- Spare Parts List 2022: DS 610 2S - SLDokument6 SeitenSpare Parts List 2022: DS 610 2S - SLAle MattNoch keine Bewertungen

- Planetary Gearbox Adjustments - Overview: 1. I - Planet CarrierDokument11 SeitenPlanetary Gearbox Adjustments - Overview: 1. I - Planet CarrierВадим УрупаNoch keine Bewertungen

- 2021-07-15 Jadwal Ta-Npk1-07-2021.rev-0.3Dokument27 Seiten2021-07-15 Jadwal Ta-Npk1-07-2021.rev-0.3Heru Yulianto100% (1)

- RENR9980RENR9980 07 SIS - DesbloqueadoDokument13 SeitenRENR9980RENR9980 07 SIS - DesbloqueadoArturo AndNoch keine Bewertungen

- Actuated Ball Valve 357 D - BDKDokument5 SeitenActuated Ball Valve 357 D - BDKfarhanakhtar ansariNoch keine Bewertungen

- Fitting Catalog 1Dokument47 SeitenFitting Catalog 1Denny MahendraNoch keine Bewertungen

- Cat 307D Main Pump OperationDokument3 SeitenCat 307D Main Pump Operationkahandawala100% (1)

- Forester 19myty Pubno - G8240be Version - 008Dokument276 SeitenForester 19myty Pubno - G8240be Version - 008s.navarro.skcNoch keine Bewertungen

- XA Series 81Dokument1 SeiteXA Series 81RICHARDNoch keine Bewertungen

- 2 Interference in Spur GearsDokument2 Seiten2 Interference in Spur Gearschris100% (1)

- Theory of Machine-1 - PPTDokument224 SeitenTheory of Machine-1 - PPTHabib A BtooshNoch keine Bewertungen

- Manuals PDFDokument9 SeitenManuals PDFLuis Humberto Ruiz BetanzosNoch keine Bewertungen

- Smart Solution For Actuator: We Do Our Best To Full Fill Customer'S Needs With Trusted Product & Reliable PartnerDokument34 SeitenSmart Solution For Actuator: We Do Our Best To Full Fill Customer'S Needs With Trusted Product & Reliable PartnerIwan TirtaNoch keine Bewertungen

- Gardner Denver QD2500Q QD2500HD Fluid End Parts ListDokument37 SeitenGardner Denver QD2500Q QD2500HD Fluid End Parts ListG SchmidtNoch keine Bewertungen

- Calculo de Un Reductor de Dos EtapasDokument14 SeitenCalculo de Un Reductor de Dos EtapasPercy Huanca GutierrezNoch keine Bewertungen

- Catalog Pricelist: Periode: Oktober 2018Dokument22 SeitenCatalog Pricelist: Periode: Oktober 2018Arip Ace DuosNoch keine Bewertungen

- F4ael PDFDokument120 SeitenF4ael PDFPablo Cansas100% (2)

- Válvula de Control Fisher GXDokument2 SeitenVálvula de Control Fisher GXMartin AndradeNoch keine Bewertungen

- 07 - ValvesDokument31 Seiten07 - ValvesArdanNoch keine Bewertungen

- 21 SeareyLSA - Brake Line Install 2014-01-24 PDFDokument11 Seiten21 SeareyLSA - Brake Line Install 2014-01-24 PDFАлексей КрамарNoch keine Bewertungen

- Masson GearBox W7000Dokument137 SeitenMasson GearBox W7000Jesús Manuel Paz González100% (1)