Beruflich Dokumente

Kultur Dokumente

Equipment Repair Cost Reduced W Dirty Service Trim

Hochgeladen von

samy7354Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equipment Repair Cost Reduced W Dirty Service Trim

Hochgeladen von

samy7354Copyright:

Verfügbare Formate

METALS & MINING

Equipment Repair Costs Reduced using Fisher Valves with Dirty Service Anti-CavitationTrim

RESULTS The elimination of water hammer damage to equipment has saved the company over $80,000 in repair costs. Mine water pressure has been stable since installing the valves with no more overpressure situations.

APPLICATION

Pressure Reducing Valves

CUSTOMER

Large gold mining operation

CHALLENGE

The ground water at this gold mine, located in the most prolific gold producing area of North America, is about 145F (60C) due to deep hydrothermal activity. A large 10MW refrigeration plant was built to chill water and cool the mine ventilation air to provide sufficient cooling for the miners underground. The mine water distribution system was designed to supply up to 3,000 gpm of chilled water through an eight-inch steel pipeline in the production shaft to underground mining operations. Water hardness is in excess of 450 mg/L (ppm) resulting in severe scale buildup in pipes and valves. Scale can flake off the inside of pipes resulting in large particulate matter which can cause blockages in valves and instruments. Water pressure in the shaft is regulated using pressure regulators installed every 300 feet in elevation. The lowest mine level is 1925 feet below surface. Required pressure at the working areas should be no more than 100 psig. The eight-inch water supply line in the production shaft was sized for 3,000 gpm flow rate. However, typical service water consumption is only 300 to 600 gpm with a peak flow of 1,000 gpm. The eight-inch existing pressure reducing valves (PRVs) cannot control the pressure at low flow rates, become unstable, and open up resulting in severe water hammer at pressures greater than 500 psi.

Fisher Dirty Service Trim (DST) is a patented multi-stage, anticavitation control valve trim for use with fluids having entrained particulate.

Severe Service

METALS & MINING

The PRVs needed to be reset frequently and PRVs located in the shaft are difficult to access, since they are not all installed at convenient locations. Water hammer damages mining equipment such as jumbo drills. Flushing water passes through the rock drill (known as a drifter) and the drill steel to flush the holes. Water overpressure damages the rock drill seals and the drifter loses lubrication and is damaged. The cost to repair each unit is in excess of $40,000.

SOLUTION

The Emerson local business partner proposed using a Fisher six by fourinch EWT body globe valve with three-stage dirty service trim to be installed in-line with each PRV. The valves must handle the full head of water in case the PRVs fail and must be able to handle particulate matter and potential scale. The first valve was installed at 1,225 level (main working level) in 2004. Additional valves were installed at 925 Level in 2005 and at the 1,600 level in 2007. The dirty service trim is designed to protect against damaging cavitation up to 1,500 psi and can pass particulates up to 3/8 in diameter. It uses a protected seating surface and can be used in flow up or flow down applications in globe or angle bodies. Characterized trims are available.

RESULT

Since installing the dirty service trim valves, mine water pressure has been stable. The elimination of water hammer damage to equipment has saved the company over $80,000 in repair costs. For more information on severe service solutions, visit www.fishersevereservice.com.

Fisher Controls International LLC 2009 All Rights Reserved. Fisher is a mark owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end-user.

NORTH AMERICA Emerson Process Management Marshalltown, Iowa 50158 USA T 1 (641) 754-3011 F 1 (641) 754-2830

www.EmersonProcess.com/Fisher

LATIN AMERICA Emerson Process Management Sorocaba, Sao Paulo 18087 Brazil T +(55)(15)238-3788 F +(55)(15)228-3300

www.EmersonProcess.com/Fisher

EUROPE Emerson Process Management Cernay 68700 France T +(33) (0)3 89 37 64 00 F +(33) (0)3 89 37 65 18

www.EmersonProcess.com/Fisher

MIDDLE EAST & AFRICA Emerson FZE Dubai, United Arab Emirates T +971 4 883 5235 F +971 4 883 5315

www.EmersonProcess.com/Fisher

ASIA PACIFIC Emerson Process Management Singapore 128461 Singapore T +(65) 6777 8211 T +(65) 6777 0947

www.EmersonProcess.com/Fisher

Severe Service

D351718X012 / MV16 / CD204 / January 2009

Das könnte Ihnen auch gefallen

- API 650 Tank Design 1 1Dokument5 SeitenAPI 650 Tank Design 1 1samy7354100% (1)

- Orifice Plate DrawingsDokument11 SeitenOrifice Plate Drawingssamy7354Noch keine Bewertungen

- Ds EvmtDokument107 SeitenDs Evmtsamy7354Noch keine Bewertungen

- ALCONDokument5 SeitenALCONsamy7354Noch keine Bewertungen

- Welding SymbolsDokument26 SeitenWelding Symbolssamy7354Noch keine Bewertungen

- A135A135MDokument9 SeitenA135A135Msamy7354Noch keine Bewertungen

- Afua Kwatemaa Obeng 11-26-07Dokument1 SeiteAfua Kwatemaa Obeng 11-26-07samy7354Noch keine Bewertungen

- FGD Bid Preparation and Proposal Review Guideline EPRIDokument186 SeitenFGD Bid Preparation and Proposal Review Guideline EPRIivanjankov100% (6)

- Ali Jassim Concrete Firewater Tank For APD 12-15-09Dokument1 SeiteAli Jassim Concrete Firewater Tank For APD 12-15-09samy7354Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Vibration - Electrical or Mechanical - EASADokument3 SeitenVibration - Electrical or Mechanical - EASAGilbNoch keine Bewertungen

- Face Consultants Limited: Concrete Society'S Technical Report: 4 EditionDokument14 SeitenFace Consultants Limited: Concrete Society'S Technical Report: 4 EditionVincent_rko1Noch keine Bewertungen

- The Difference Between The Internet and World Wide WebDokument3 SeitenThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- Cbse PMT 2012Dokument33 SeitenCbse PMT 2012Vishal RamakrishnanNoch keine Bewertungen

- Using Dapper Asynchronously inDokument1 SeiteUsing Dapper Asynchronously inGiovani BrondaniNoch keine Bewertungen

- CH 4 Data CommDokument4 SeitenCH 4 Data CommHenna ShainaNoch keine Bewertungen

- zx350lc 3 InglesDokument6 Seitenzx350lc 3 InglesLuis Nahuelhuaique LemusNoch keine Bewertungen

- Solar Module CellDokument4 SeitenSolar Module CellVinod BabhaleNoch keine Bewertungen

- Colchicine - British Pharmacopoeia 2016Dokument4 SeitenColchicine - British Pharmacopoeia 2016Social Service (V)100% (1)

- SR No Co Name Salutation Person Designation Contact NoDokument4 SeitenSR No Co Name Salutation Person Designation Contact NoAnindya SharmaNoch keine Bewertungen

- Chapter 2 - 2 Plane Curvilinear MotionDokument37 SeitenChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaNoch keine Bewertungen

- WDU 2.5 enDokument14 SeitenWDU 2.5 enAhmadBintangNegoroNoch keine Bewertungen

- Help - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)Dokument8 SeitenHelp - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)ĐinhĐứcAnhNoch keine Bewertungen

- Deep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Dokument67 SeitenDeep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Tina CleoNoch keine Bewertungen

- Manual CRM-91H 93H 9SDokument2 SeitenManual CRM-91H 93H 9SFilip FilipovicNoch keine Bewertungen

- SdccmanDokument126 SeitenSdccmanGustavo A. Sarache MillanNoch keine Bewertungen

- Valve Body PDFDokument9 SeitenValve Body PDFTimur TOT100% (2)

- SMP Gateway SoftPLC Reference ManualDokument47 SeitenSMP Gateway SoftPLC Reference Manualswalker948100% (1)

- CLS 747 200Dokument158 SeitenCLS 747 200Rodrigo Adam100% (8)

- IEM PI A401 - ANNEXE - Design & Site ExperienceDokument5 SeitenIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNoch keine Bewertungen

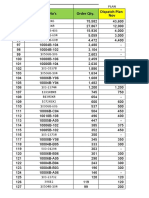

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- Calibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanDokument4 SeitenCalibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanJose Rafael Mora CasalNoch keine Bewertungen

- BD+ CD+ XD+ - tcm833-3534072Dokument20 SeitenBD+ CD+ XD+ - tcm833-3534072MisterMMNoch keine Bewertungen

- Oil & Gas Asset Integrity IssuesDokument15 SeitenOil & Gas Asset Integrity Issuesyogolain100% (2)

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDokument43 Seiten007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNoch keine Bewertungen

- ED ProcessDokument9 SeitenED ProcesskhanasifalamNoch keine Bewertungen

- Chapter 19A ConcreteDokument10 SeitenChapter 19A ConcreteMofasa ENoch keine Bewertungen

- Paket TrainingDokument20 SeitenPaket TrainingLukman AriyantoNoch keine Bewertungen

- Portland CementDokument46 SeitenPortland Cementni putu diah untariningsihNoch keine Bewertungen

- Differences Between VSI and CSI Converter Operation Modes.Dokument1 SeiteDifferences Between VSI and CSI Converter Operation Modes.Sushil NamoijamNoch keine Bewertungen