Beruflich Dokumente

Kultur Dokumente

37.RopeClamps en

Hochgeladen von

sadanand45Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

37.RopeClamps en

Hochgeladen von

sadanand45Copyright:

Verfügbare Formate

lhcne (US): 1.706.235.6315 : Tcll free: 866.54BRUCC (542.7844) : Fax: 1.706.235.6035 : lnfc: elevatcrrcpebrugg.ocm : www.bruggrcpe.

ocm

Telefcnc (L.U.): 1.706.235.6315 : Llamada gratulta: 866.54BRUCC (542.7844) : Fax: 1.706.235.6035 : lnfc: elevatcrrcpebrugg.ocm : www.bruggrcpe.ocm

B

r

u

g

g

L

i

f

t

i

n

g

_

B

f

u

g

g

W

i

r

e

R

o

p

e

1

1

1

0

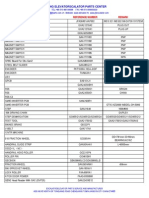

TECH TIPS: ROPE CLAMPS

PREPARATION AND USAGE

U-Bolt

Saddle

Nut

Securing A Clamp Properly

As can be seen in steps 1-3, the rope is passed around a thimble

forming a return loop, where its end is secured by rope grips.

Note how the saddle of the Crosby Clip is affixed over the rope

portion that carries the greatest load. Any other fashion is

unacceptable.

A

Proper Application Of Clamps

After the first wire rope clamp has been tightly applied at the thimble

area, a MINIMUM of one clamp width must be maintained between

the remaining wire rope clamps being used. Tighten nuts on each

U-Bolt evenly, alternating from one nut to the other until reaching rec-

ommended torque. After the first application of load check and, if

required, adjust torque again.

1 2

3

Preparation Of Rope Clamp

Prior to the application of rope clams to elevator ropes, Brugg strongly recommends

applying a lubricant to the bolt threads and collars of the nuts. A small step to be

sure, but one that can greatly facilitate installation and serve to reduce the time spent on

maintenance later.

Brugg Wire Rope, LLC Brugg Wire Rope, LLC

lhcne (US): 1.706.235.6315 : Tcll free: 866.54BRUCC (542.7844) : Fax: 1.706.235.6035 : lnfc: elevatcrrcpebrugg.ocm : www.bruggrcpe.ocm

Telefcnc (L.U.): 1.706.235.6315 : Llamada gratulta: 866.54BRUCC (542.7844) : Fax: 1.706.235.6035 : lnfc: elevatcrrcpebrugg.ocm : www.bruggrcpe.ocm

TECH TIPS: ROPE CLAMPS

PREPARATION AND USAGE

Incorrect Usage

WARNING: U-Bolts must never be applied on the loaded,

or "live" end of a hoist rope. Instead, the live end should

rest in the saddle of the Crosby clip as shown previously

in drawing A. Or to quote an old saw in the industry, "Never

saddle a dead horse."

B

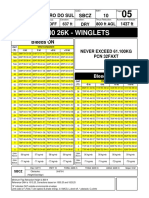

Part No. Rope Diameter

INsMM

Clamps

per loop

Torque

LBFTs.M

49459 3/16 in. (5,0 mm) 3 1.48 lb-ft (2,0 Nm)

01946 1/4 in. (6,5 mm) 3 2.58 lb-ft (3,5 Nm)

01947 5/16 in. (8,0 mm) 4 4.43 lb-ft (6,0 Nm)

01948 25/64 in. (10,0 mm) 4 6.65 lb-ft (9,0 Nm)

01950 15/32 in. (12,0 mm) 4 14.8 lb-ft (20,0 Nm)

78144 1/2 in. (13,0 mm) 4 24.3 lb-ft (33,0 Nm)

78145 35/65 in. (14,0 mm) 4 24.3 lb-ft (33,0 Nm)

01951 5/8 in. (16,0 mm) 4 36.1 lb-ft (49,0 Nm)

01952 3/4 in. (19,0 mm) 4 42.8 lb-ft (68,0 Nm)

01953 55/64 in. (22,0 mm) 5 78.9 lb-ft (107,0 Nm)

49525 1 1/64 in. (26,0 mm) 5 108 lb-ft (147,0 Nm)

49526 1 11/64 in. (30,0 mm) 6 156 lb-ft (212,0 Nm)

49527 1 21/64 (34,0 mm) 6 218 lb-ft (296,0 Nm)

49428 1 37/64 (40,0 mm) 6 268 lb-ft (363,0 Nm)

For intermediate rope diameter sizes use the next larger clamp size.

Torque

Wrench

Das könnte Ihnen auch gefallen

- Logging While Fishing Best Practices-2Dokument41 SeitenLogging While Fishing Best Practices-2aungwinnaingNoch keine Bewertungen

- Tautwire MK 15BDokument38 SeitenTautwire MK 15BValentin JonovNoch keine Bewertungen

- G5 Infinium: Service ManualDokument28 SeitenG5 Infinium: Service Manualne0botNoch keine Bewertungen

- 43.TechTips - Molten - Resin Babbit - EN Terminación de CableDokument3 Seiten43.TechTips - Molten - Resin Babbit - EN Terminación de CablerenesabaNoch keine Bewertungen

- 2010 Bear Archery SpecsDokument10 Seiten2010 Bear Archery SpecswiccanwaysNoch keine Bewertungen

- Siemens 3KL 3KM Fuseswitch 2009 PDFDokument19 SeitenSiemens 3KL 3KM Fuseswitch 2009 PDFragupathiNoch keine Bewertungen

- 04MSC7PODokument2 Seiten04MSC7POMokbelNoch keine Bewertungen

- Wireline Stripping OperationsDokument5 SeitenWireline Stripping OperationsDavid OrtegaNoch keine Bewertungen

- MBRD620CT, MBRD630CT, MBRD640CT, MBRD650CT, MBRD660CT Switchmode Power RectifiersDokument6 SeitenMBRD620CT, MBRD630CT, MBRD640CT, MBRD650CT, MBRD660CT Switchmode Power RectifiersAnderson Luis Do CarmoNoch keine Bewertungen

- T50 Infinium: Service ManualDokument22 SeitenT50 Infinium: Service Manualne0botNoch keine Bewertungen

- CM 003Dokument6 SeitenCM 003z01loNoch keine Bewertungen

- Strobex ManualDokument68 SeitenStrobex ManualMiguel Ramos75% (8)

- AM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDokument27 SeitenAM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDiego CorderoNoch keine Bewertungen

- SL No Equipment Name Equipment Model: 1 Current TransformerDokument4 SeitenSL No Equipment Name Equipment Model: 1 Current TransformerAnonymous vcadX45TD7Noch keine Bewertungen

- 2011 Bear Archery SpecsDokument8 Seiten2011 Bear Archery SpecswiccanwaysNoch keine Bewertungen

- Dumont 765 766 767 Oscilloscope FrameDokument63 SeitenDumont 765 766 767 Oscilloscope FrameRon LeonardNoch keine Bewertungen

- Opgw StringingDokument3 SeitenOpgw StringingNiraj SinhaNoch keine Bewertungen

- Architectural Products Group: C-APG08Dokument16 SeitenArchitectural Products Group: C-APG08lesgiuNoch keine Bewertungen

- h3c Nsq1tgs8ea0 Lpu Card Manual-6pw102Dokument5 Seitenh3c Nsq1tgs8ea0 Lpu Card Manual-6pw102Matthew MathewsNoch keine Bewertungen

- 497 Airfield LightingDokument4 Seiten497 Airfield LightingmolgarNoch keine Bewertungen

- Gis 02Dokument10 SeitenGis 02rasheed313Noch keine Bewertungen

- Superbay Eg Series: 19" Enclosed & GasketedDokument4 SeitenSuperbay Eg Series: 19" Enclosed & GasketedReginald D. De GuzmanNoch keine Bewertungen

- C&I Cable Schedule FormatDokument85 SeitenC&I Cable Schedule FormatVasu Dev0% (1)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Dokument18 SeitenOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNoch keine Bewertungen

- Gas Lift OperationsDokument4 SeitenGas Lift OperationsAbdelrahman AliNoch keine Bewertungen

- Sony Klv-26s550a 32s530a 32s550a-L-T 37s550a Chassis Ex2t SMDokument72 SeitenSony Klv-26s550a 32s530a 32s550a-L-T 37s550a Chassis Ex2t SMHarshad RathodNoch keine Bewertungen

- DC KaapelitaulukkoDokument1 SeiteDC KaapelitaulukkoJuotosKolviNoch keine Bewertungen

- Cable and Line RatingsDokument1 SeiteCable and Line RatingsEzekiel NyirendaNoch keine Bewertungen

- IBM P72 Service ManualDokument38 SeitenIBM P72 Service ManualMisko1978Noch keine Bewertungen

- Dock Leveller - Detailing SystemDokument21 SeitenDock Leveller - Detailing SystemEd Salanga100% (1)

- THRUST REDUCTION 800w 26k SBCZ Dry r2Dokument2 SeitenTHRUST REDUCTION 800w 26k SBCZ Dry r2cvelosoNoch keine Bewertungen

- SPE/IADC-173037-MS Recent Advances in Soft Torque Rotary SystemsDokument12 SeitenSPE/IADC-173037-MS Recent Advances in Soft Torque Rotary SystemsGreg CerrutiNoch keine Bewertungen

- 50110shl Load Chart ManitexDokument11 Seiten50110shl Load Chart ManitexvicvargNoch keine Bewertungen

- PowerCutter Assembly and Arming ProceduresDokument7 SeitenPowerCutter Assembly and Arming ProceduresmortizNoch keine Bewertungen

- CMP CW CX Installation Fitting Instructions FI416 Issue 3 0911Dokument2 SeitenCMP CW CX Installation Fitting Instructions FI416 Issue 3 0911Md Rodi BidinNoch keine Bewertungen

- IO List MRHSDokument52 SeitenIO List MRHSvinayjoshi2705Noch keine Bewertungen

- (12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1Dokument15 Seiten(12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1brig1960Noch keine Bewertungen

- Lista de Precios Publica NexansDokument10 SeitenLista de Precios Publica NexansSantiago Mejía RNoch keine Bewertungen

- 9 - Free Point and Backoff - (Houston)Dokument29 Seiten9 - Free Point and Backoff - (Houston)Usama Bin Sabir100% (2)

- SIMpull Cable Pull Calculator 4.2Dokument6 SeitenSIMpull Cable Pull Calculator 4.2John ElyNoch keine Bewertungen

- Capilla Huandoy GCM 06Dokument14 SeitenCapilla Huandoy GCM 06Sicologo CimeNoch keine Bewertungen

- Installation Manual Bandak Light Weight Taut Wire MK 15B: Kongsberg Part No.: 702788Dokument38 SeitenInstallation Manual Bandak Light Weight Taut Wire MK 15B: Kongsberg Part No.: 702788TEUKUNoch keine Bewertungen

- CBL, TCP, GR Flow OperationDokument49 SeitenCBL, TCP, GR Flow OperationAkol MajookNoch keine Bewertungen

- Wire Chart 12 Vol T: ExampleDokument1 SeiteWire Chart 12 Vol T: ExampleriosirrossiNoch keine Bewertungen

- HT Cable Schedule, R1Dokument16 SeitenHT Cable Schedule, R1kxalxoNoch keine Bewertungen

- PLT Line Thrower: Restech Norway AsDokument21 SeitenPLT Line Thrower: Restech Norway AsFreddy José CastroNoch keine Bewertungen

- Trex 01194Dokument136 SeitenTrex 01194OSDocs2012Noch keine Bewertungen

- WWH-IW-003 - A - Mounting and OperatingDokument24 SeitenWWH-IW-003 - A - Mounting and OperatingKevin CavanaughNoch keine Bewertungen

- Bushman C HookDokument2 SeitenBushman C Hookperdhana2000100% (1)

- HoppeckeDokument9 SeitenHoppeckeqodir_jaelaniNoch keine Bewertungen

- Otis Parts ListDokument48 SeitenOtis Parts ListMelina Labor92% (13)

- Reeving Information Grove CranesDokument19 SeitenReeving Information Grove CranesLouisAucamp100% (2)

- How To Make Disposable Silencers Vol IDokument86 SeitenHow To Make Disposable Silencers Vol IChris Breezley78% (9)

- MDR-8000 Parts ListDokument88 SeitenMDR-8000 Parts ListjuanNoch keine Bewertungen

- Brown's Knots and Splices - With Tables of Strengths of Ropes, Etc. and Wire RiggingVon EverandBrown's Knots and Splices - With Tables of Strengths of Ropes, Etc. and Wire RiggingBewertung: 5 von 5 Sternen5/5 (1)

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusVon EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusNoch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- 0100DB0604.R10-16.Selectivity Guidelines For SQD Pnbs PDFDokument26 Seiten0100DB0604.R10-16.Selectivity Guidelines For SQD Pnbs PDFKDANoch keine Bewertungen

- Welding Procedure Specification-1Dokument8 SeitenWelding Procedure Specification-1Suresh Rathod100% (1)

- 49 7 %-4-Zaaz: 24, %3 - ee-7-CC See 246Dokument3 Seiten49 7 %-4-Zaaz: 24, %3 - ee-7-CC See 246rovome3198Noch keine Bewertungen

- BRB Cables PVCDokument30 SeitenBRB Cables PVCMorsed Al Mamun75% (40)

- Electrical Licensing Test 01 March 2005Dokument6 SeitenElectrical Licensing Test 01 March 2005Courtney 'Jackworld' Jack100% (1)

- Falcon1 PDFDokument103 SeitenFalcon1 PDFZorrroNoch keine Bewertungen

- Paramhans Wires Pvt. Ltd. Rohtak: Project Report OnDokument70 SeitenParamhans Wires Pvt. Ltd. Rohtak: Project Report OnAnil BatraNoch keine Bewertungen

- Micro MT Laser Tag System V18-01Dokument19 SeitenMicro MT Laser Tag System V18-01Dylan SenkicNoch keine Bewertungen

- PCC PANEL POWER PACK P LTDDokument33 SeitenPCC PANEL POWER PACK P LTDmahidhar talapaneniNoch keine Bewertungen

- Firebird Mini Humbucker Pickup Kit: Assembly InstructionsDokument4 SeitenFirebird Mini Humbucker Pickup Kit: Assembly InstructionspsychpostersNoch keine Bewertungen

- Wire Rope Specification PDFDokument133 SeitenWire Rope Specification PDFjgtkd74100% (1)

- Accc/Tw Helsinki (160) : Data SheetDokument1 SeiteAccc/Tw Helsinki (160) : Data SheetkmiqdNoch keine Bewertungen

- Helvetas NepalDokument2 SeitenHelvetas NepalThapaliya BishalNoch keine Bewertungen

- Clinical Application of Loops in OrthodnticsDokument2 SeitenClinical Application of Loops in OrthodnticsMa Lyn GabayeronNoch keine Bewertungen

- Zinc-Coated Steel Chain-Link Fence Fabric: Standard Specification ForDokument5 SeitenZinc-Coated Steel Chain-Link Fence Fabric: Standard Specification ForRed RedNoch keine Bewertungen

- The Economical Solution To RockfallDokument8 SeitenThe Economical Solution To RockfallVince KongNoch keine Bewertungen

- Experimental Mechanics Laboratory ManualDokument76 SeitenExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- 2338133-1 - Terminator Overview CatalogDokument12 Seiten2338133-1 - Terminator Overview CatalogmacNoch keine Bewertungen

- Instrumentation Earthing System: - June 10, 2010Dokument14 SeitenInstrumentation Earthing System: - June 10, 2010indira_tungNoch keine Bewertungen

- Product Name Fb4Sdr70 Fit Off Guide: Electric Cable Duct Systems Pty. LTDDokument2 SeitenProduct Name Fb4Sdr70 Fit Off Guide: Electric Cable Duct Systems Pty. LTDSt. Laila QadriantiNoch keine Bewertungen

- Temperature Controls/ Thermometer/Timers: Technical Service Manual - All ModelsDokument24 SeitenTemperature Controls/ Thermometer/Timers: Technical Service Manual - All Models薛泽绵Noch keine Bewertungen

- Hengtong Short PresentationDokument17 SeitenHengtong Short PresentationRui BatistaNoch keine Bewertungen

- Loper - Unbonded Flexible Pipe ConstructionDokument18 SeitenLoper - Unbonded Flexible Pipe ConstructionChiemela Victor AmaechiNoch keine Bewertungen

- Development of A Virtual Wiredrawing Tool For Process Analysis and OptimizationDokument7 SeitenDevelopment of A Virtual Wiredrawing Tool For Process Analysis and OptimizationPhani KumarNoch keine Bewertungen

- Steel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForDokument3 SeitenSteel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForJosé Ramón GutierrezNoch keine Bewertungen

- Beetle Bot Design Engineering Build InstructionsDokument16 SeitenBeetle Bot Design Engineering Build InstructionsSusan KlimczakNoch keine Bewertungen

- The Complete Guide To Bead Jewelry and DecorationDokument452 SeitenThe Complete Guide To Bead Jewelry and DecorationLuana Araujo100% (5)

- Indian StandardsDokument101 SeitenIndian StandardsAanchal Srivastava100% (2)

- Catalogo NiedaxDokument58 SeitenCatalogo NiedaxCarlosNoch keine Bewertungen

- MS Cable Tray and Conduit InstallationDokument13 SeitenMS Cable Tray and Conduit InstallationJaafar LagayanNoch keine Bewertungen