Beruflich Dokumente

Kultur Dokumente

Welding Inspection

Hochgeladen von

Sreedhar Patnaik.MOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding Inspection

Hochgeladen von

Sreedhar Patnaik.MCopyright:

Verfügbare Formate

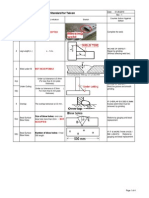

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Welding Inspection

1 - MOST COMMONLY USED INSPECTION TECHNIQUES Visual Inspection (VT) X-Rays (RT) Ultrasonic (UT) Magnetic Particle (MT) Liquid Penetrant (PT) Leak Testing 2 - THE VISUAL INSPECTION OF WELDS Defects and Causes classified by Welding Process Stick welding Gas welding Gas metal-arc welding with solid core wire Gas metal-arc welding with flux core wire 3 - WELDING TERMS AND DEFINITIONS 4 MORE ABOUT WELDING ON THE INTERNET

1 - MOST COMMONLY USED INSPECTION TECHNIQUES 1 - MOST COMMONLY USED INSPECTION TECHNIQUES

What an Inspector looks for... Welding inspection is based on visual inspection and other Non-Destructive Test (NDT) methods. They are used to find indications which have to be interpreted according to the inspection procedure for that particular job. Indications are inspection lingo for possible defects. These discontinuities (a fancier name for indications) have to be evaluated with reference to the acceptance criteria for that particular job. After comparison to the criteria are they considered acceptable or rejectable. These Non-Destructive Inspection (NDI) methods require special training and accumulation of experience. It is also important that both the inspector and the welder understand the flaw terminology and the welding terms and definitions. Visual Inspection (VT) The importance of visual inspection is often over looked. A visual test (VT) will provide a wealth of information about a weld. Many weld defects such as porosity, cracks, incomplete fusion, inclusions, overlap, edge melt, and incomplete penetration can be observed with just a simple visual exam. A weld that passes a visual exam has a much higher probability of passing further Non-Destructive Evaluation (NDE) methods. X-Rays (RT) Radiographic weld inspection is performed by pointing a radiographic source (an x-ray tube or a radioactive isotope) to the part of the weld to be inspected and by exposing for a

Guidelines for Shop Inspection Welding Page 1 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

predetermined time a radiographic film to the radiation on the opposite side of the source tip or tube. The resulting film contains information on the internal features of the weld. Variations in film density allow the film interpreter to accept or reject the weld based on comparison to specific hole or wire sizes in or on a penetrometer. These hole or wire sizes represent the largest acceptable defect size in a weld. Any indication that is larger than the acceptable wire or hole size is cause for rejection. All the relevant parameters including accept or reject are then recorded on an X-Ray Technique Sheet. The technique sheet and the processed film are usually turned over to the customer at the completion of the job. Ultrasonic (UT) Ultrasonic weld inspection is based on the fact that high frequency sound waves out of the range of human hearing can propagate in different materials, and be reflected by internal interfaces and opposite wall surfaces. These waves are generated by piezoelectric transducers of different sizes and frequencies which transform electrical vibrations into mechanical vibrations and vice-versa. These transducers are selected to match the thickness, type, temperature, and configuration of the material to be tested. Signal reflections are evaluated on a computer screen, and by making reference to standard reflectors (normally flat bottom holes carefully machined on specimens of the same material) of given shape and size, the qualified inspector can conclude that if an echo is present where it should not be and if its reflection is larger than that of comparison, then there is an indication that must be evaluated. Additional techniques may be required to determine acceptance or rejection. Ultrasonic testing is capable of detecting thin interfaces normal to the line of propagation of the wave (that X-Rays cannot detect) so that both testing methods complement each other. Ultrasonic testing is becoming one of the most widely used methods of nondestructive testing. Its primary purpose is to detect and characterize internal discontinuities. UT can also measure thickness, detect surface discontinuities, and define bond characteristics. Magnetic Particle (MT) Magnetic Particle weld inspection is used for locating surface or near surface discontinuities in ferro-magnetic material. It is based on the principals that magnetic lines of force will be distorted by a change in material continuity thereby creating a magnetic field or flux leak. Magnetic particles will assemble at the point of the leak. The particles are made visible by adding a colored dye to the dry powder method, and by using a black light with the wet method. The inspector has to interpret the indications formed by these particles. The most common equipment for this process is either an AC or DC yoke, or a DC prod. The AC yoke method will only detect surface discontinuities while the DC prod method may detect sub surface discontinuities to 3/16" deep. The powder or liquid is applied after magnetizing the material. The surface is then visually checked by the inspector to find suspicious areas of particle concentrations. Liquid Penetrant (PT) Liquid Penetrant weld inspection is a sensitive method of detecting and locating discontinuities that are clear and open to the surface. A penetrating liquid dye is applied to the cleaned surface. This dye will seep into surface discontinuities. After a certain amount of time(dwell time), the excess penetrant dye is removed. A developer is then applied that acts like a blotter and draws the remaining penetrant out of the discontinuity.

Guidelines for Shop Inspection Welding Page 2 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Liquid Penetrant inspection is used for both magnetic and non magnetic materials like aluminum, stainless steel, magnesium, titanium, bronze etc. and will detect extremely small cracks. There are three different types of penetrant used with both visible and flourescent methods. These are classified by how they are removed from the test surface: solvent removable, water washable, and post-emulsifiable. The solvent removable types are most common and highly portable making them ideal for "on site" inspections. Leak Testing Leak testing for weld inspection is done on containers and piping systems built to hold a liquid or a gas. The tank or piping system is usually pressurized above its design operating pressure and held at that pressure for a specific amount of time. The usual test mediums are air, gas(usually nitrogen), or water. These tests are performed mostly on new construction and are part of the ASME code.

Guidelines for Shop Inspection Welding Page 3 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

2 - THE VISUAL INSPECTION OF WELDS 2 - THE VISUAL INSPECTION OF WELDS

Defects and Causes classified by Welding Process

STICK WELDING STICK WELDING

INCOMPLETE PENETRATION This term is used to describe the failure of the filler and base metal to fuse together at the root of the joint. Bridging occurs in groove welds when the deposited metal and base metal are not fused at the root of the joint. The frequent cause of incomplete penetration is a joint design which is not suitable for the welding process or the conditions of construction. When the groove is welded from one side only, incomplete penetration is likely to result under the following conditions. a. The root face dimension is too big even though the root opening is adequate. b. The root opening is too small. c. The included angle of a V-groove is too small. d. The electrode is too large. e. The rate of travel is too high. f. The welding current is too low. LACK OF FUSION Lack of fusion is the failure of a welding process to fuse together layers of weld metal or weld metal and base metal. The weld metal just rolls over the plate surfaces. This is generally referred to as overlap. Lack of fusion is caused by the following conditions: a. Failure to raise to the melting point the temperature of the base metal or the previously deposited weld metal. b. Improper fluxing, which fails to dissolve the oxide and other foreign material from the surfaces to which the deposited metal must fuse. c. Dirty plate surfaces. d. Improper electrode size or type. e. Wrong current adjustment. UNDERCUTTING Undercutting is the burning away of the base metal at the toe of the weld. Undercutting may be caused by the following conditions: a. Current adjustment that is too high. b. Arc gap that is too long. c. Failure to fill up the crater completely with weld metal. d. Travel speed too fast.

Guidelines for Shop Inspection Welding Page 4 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

SLAG INCLUSIONS Slag inclusions are elongated or globular pockets of metallic oxides and other solids compounds. They produce porosity in the weld metal. In arc welding, slag inclusions are generally made up of electrode coating materials or fluxes. In multilayer welding operations, failure to remove the slag between the layers causes slag inclusions. Most slag inclusion can be prevented by: a. Preparing the groove and weld properly before each bead is deposited. b. Removing all slag. c. Making sure that the slag rises to the surface of the weld pool. d. Taking care to avoid leaving any contours such as a high crown which will be difficult to penetrate fully with the arc. e. Avoiding travel speed that is too slow. b. Avoiding current that is too low. POROSITY a. Porosity is the presence of pockets which do not contain any solid material. They differ from slag inclusions in that the pockets contain gas rather than a solid. The gases forming the voids are derived from: (1) Gas released by cooling weld because of its reduced solubility temperature drops. (2) Gases formed by the chemical reactions in the weld. b. Porosity is best prevented by avoiding: (1) Overheating and undercutting of the weld metal. (2) Too high a current setting. (3) Too long an arc.

GAS WELDING GAS WELDING

a. The weld should be of consistent width throughout. The two edges should form straight parallel lines. b. The face of the weld should be slightly convex with a reinforcement of not more than 1/16 in. (1.6 mm) above the plate surface. The convexity should be even along the entire length of the weld. It should not be high in one place and low in another. c. The face of the weld should have fine, evenly spaced ripples. It should be free of excessive spatter, scale, and pitting. d. The edges of the weld should be free of undercut or overlap. e. Starts and stops should blend together so that it is difficult where they have taken place. f. The crater at the end of the weld should be filled and show no holes, or cracks. (1) If the joint is a butt joint, check the back side for complete penetration through the root of the joint. A slight bead should form on the back side. (2) The root penetration and fusion of lap and T-joints can be checked by putting pressure on the upper plate until it is bent double. If the weld has not penetrated through the root, the plate will crack open at the joint as it is being bent. If it breaks, observe the extent of the penetration and fusion at the root. It will probably be lacking in fusion and penetration.

Guidelines for Shop Inspection Welding Page 5 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

GAS METAL-ARC WELDING (GMAW) WITH SOLID-CORE GAS METAL-ARC WELDING (GMAW) WITH SOLID-CORE WI R E WI R E

Lack of Penetration Lack of penetration or fusion in the root area. This poor penetration is the result of too little heat corrected by: (1) Increasing the wire-feed speed and reducing the stickout distance. (2) Making sure that the fit-up is correct. (3) Reducing the speed of travel. (4) Using proper welding techniques such as correct lead angle and making sure that both toes of the bead fuse to the base metal Excessive Penetration Excessive penetration usually causes burn through. It is the result of too much heat in the weld area. This can be corrected by: (1) Reducing the wire size. (2) Reducing the wire-feed speed and increasing the speed of travel. (3) Making sure that the root opening and root face are correct. (4) Increasing the stickout distance during welding and weaving the gun Whiskers Whiskers are short lengths of electrode wire sticking through the weld on the root side of the joint. They are caused by pushing the electrode wire past the leading edge of the weld pool. Whiskers can be prevented by: (1) Reducing the wire-feed speed and the speed of travel. (2) Increasing the stickout distance and weaving the gun Voids Voids are sometimes referred to as wagon tracks because of their resemblance to ruts in a dirt road. They may be continued along both sides of the weld deposit. They are found in multipass welding. Voids can be prevented by: (1) Avoiding a large contoured crown and undercut. (2) Making sure that all edges are filled in. (3) On succeeding passes , using slightly higher arc voltage and increasing travel speed Lack of Fusion Lack of fusion, also referred to as cold lap, is largely the result of improper torch handling, low heat, and higher speed travel. It is important that the arc be directed at the leading edge of the puddle. To prevent this defect, give careful consideration to the following: (1) Direct the arc so that it covers all areas of the joint. The arc, not the puddle, should do the fusing. (2) Keep the electrode at the leading edge of the puddle.

Guidelines for Shop Inspection Welding Page 6 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

(3) Reduce the size of the puddle as necessary by reducing either the travel speed or wire-feed speed. (4) Check current values carefully Porosity The most common defect in welds produced by any welding process is porosity. Porosity that exists on the face of the weld is readily detected, but porosity in the weld metal below the surface must be determined by x-ray or other testing methods. The causes of most porosity are: (1) Contamination by the atmosphere and other materials such as oil, dirt, rust, and paint. (2) Changes in the physical qualities of the filler wire due to excessive current. (3) Entrapment of the gas evolved during weld metal solidification. (4) Loss of shielding gas because of too fast travel. (5) Shielding gas flow rate too low, not providing full protection. (6) Shielding gas flow rate too high, drawing air into the arc area. (7) Wrong type of shielding gas being used. (8) Gas shield blown away by wind or drafts. (9) Defects in the gas system. (10) Improper welding technique, excessive stickout, improper torch angle, and too fast removal of the gun and the shielding gas at the end of the weld. Spatter Spatter is made up of very fine particles of metal on the plate surface adjoining the weld area. It is usually caused by high current, a long arc, an irregular and unstable arc, improper shielding gas, or a clogged nozzle Irregular Weld Shape Irregular welds include those that are too wide or too narrow, those that have an excessively convex or concave surface, and those that have coarse, irregular ripples. Such characteristics may be caused by poor torch manipulation, a speed of travel that is too slow, current that is too high or low, improper arc voltage, improper stickout, or improper shielding gas. Undercutting Undercutting is a cutting away of the base material along the edge of the weld. It may be present in the cover pass weld bead or in multipass welding. This condition is usually the result of high current, high voltage, excessive travel speed, low wire-feed speed, poor torch technique, improper gas shielding or the wrong filler wire. To correct undercutting, move the gun from side to side in the joint. Hesitate at each side before returning to the opposite side.

GAS METAL-ARC WELDING (GMAW) WITH FLUX-CORED GAS METAL-ARC WELDING (GMAW) WITH FLUX-CORED WI R E WI R E

Guidelines for Shop Inspection Welding Page 7 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Burn-Through Burn-through may be caused by the following: (1) Current too high. (2) Excessive gap between plates. (3) Travel speed too s1ow. (4) Bevel angle too large. (5) Nose too small. (6) Wire size too small. (7) Insufficient metal hold-down or clamping.

Crown Too High or Too Low The crown of the weld may be incorrect due to the following: (1) Current too high or low. (2) Voltage too high or low. (3) Travel speed too high or low. (4) Improper weld backing. (5) Improper spacing in welds with backing. (6) Workpiece not level. Penetration Too Deep or Too Shallow Incorrect penetration may be caused by any of the following: (1) Current too high or low. (2) Voltage too high or low. (3) Improper gap between plates. (4) Improper wire size. (5) Travel speed too slow or fast. Porosity and Gas Pockets These defects may be the results of any of the following: (1) Flux too shallow. (2) Improper cleaning. (3) Contaminated weld backing. (4) Improper fitup in welds with manual backing. (5) Insufficient penetration in double welds. Reinforcement Narrow and Steep-Sloped (Pointed) Narrow and pointed reinforcements may be caused by the following: (1) Insufficient width of flux. (2) Voltage too low.

Guidelines for Shop Inspection Welding Page 8 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Mountain Range Reinforcement If the reinforcement is ragged, the flux was too deep. Undercutting Undercutting may be caused by any of the following: (1) Travel speed too high. (2) Improper wire position (fillet welding). (3) Improper weld backing. (4) Current or voltage too high. Voids and Cracks These weld deficiencies may be caused by any of the following: (1) Improper cooling. (2) Failure to preheat. (3) Improper fitup. (4) Concave reinforcement (fillet weld). (5) Excessive convexity (full penetration weld). Practical Visual Inspection Tips (1) Know the code or codes that apply to the job you are working on. They go hand in hand with the design specifications. (2) Review all of the applicable weld procedures. (3) Check each welder's qualification to the welding procedure that they are currently working with. (4) Talk to the welders and fitters-not at them. Most of them already hate inspectors because of past bad experiences. They are your best source of information for potential quality problems because they are the ones actually doing the job. Be just as fast to tell welders when they have it right as you are when they have it wrong. (5) Always carry a flashlight, magnifier glass, and inspection mirror. You will eventually need them all. (6) Always inspect each weld 100% on both sides if possible. Clearly mark any defects on the work piece. (7) Reject welds professionally and not personally because you don't like the welder or the boss. (8) If you run into procedural problems or catch a blatant procedure deviation and it isn't corrected in a timely manner, do write an NCR (Non Conformance Report). Both the owner and design engineer have to sign it off. That relieves you of responsibility for the infraction if a failure should occur in the future. In today's finger pointing society you need to cover your butt.

Guidelines for Shop Inspection Welding Page 9 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

3 - Welldiing Terms and Defiiniitiions 3 - We d ng Terms and Def n t ons

Acceptable Weld A weld that meets all requirements and acceptance criteria of the design and welding specifications. Actual Throat The shortest distance between the weld root and face. Alloy Metal having different properties than the original base elements. Arc Blow The deflection or wandering of an electric welding arc from its normal path due to magnetism in the base metal. Arc Welding A group of welding processes wherein coalescence or complete fusion is produced by heating with an electric arc. Arc Strike A discontinuity on the surface of the base metal or weld consisting of pits, craters and/or re-melted metal. As-Welded The condition of weld metal after welding but prior to any thermal, mechanical, or chemical treatment. Automatic Welding Welding with equipment which performs the welding operation without adjustment of the controls by a welding operator. Back Bead A weld resulting from a back pass. Back Gouging The removal of weld and base metal by arc gouging or grinding from the other side of a partially welded joint to assure complete fusion and penetration upon subsequent welding from that side. Base Metal The material to be formed, welded, brazed, soldered, or cut. Butt Weld A weld joining two members laying in approximately the same plane. Cladding A relatively thick layer of (> 0.04" ) of different material applied by surface welding for the purpose of improving corrosion or heat resistance.

Guidelines for Shop Inspection Welding Page 10 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Complete Fusion Fusion occurring over the entire base metal surfaces intended for welding and between all joining weld beads and layers. Clad Vessel A vessel made from plate having a corrosion resistant material bonded to a base of less resistant material. Complete Joint Penetration Joint penetration in which the weld metal completely fills the groove and is fused to the base metal throughout its thickness. Concavity A weld that falls below the intended perpendicular plane. Convexity A weld that exceeds the intended perpendicular plane. Design Pressure The pressure used in the design of a vessel. It is recommended to design a vessel and its parts for a pressure 10% above its operating pressure. Design Temperature The maximum metal temperature expected under operating conditions. Defect A discontinuity or discontinuities that accumulate to render a weld or part unable to meet minimum acceptance standards or criteria of the design specifications. Fillet Weld A weld of approximately triangular cross section joining two surfaces at right angles to each other. Eddy Current Testing (ET) A non-destuctive test method that induces an electrical current into a test piece by an alternating magnetic field. This is accomplished by the use of different probes or coils and eddy current devices operating at frequencies that are appropriate for the material being tested. Filler Metal Metal added in making a welded, brazed, or soldered joint. FCAW Flux Cored Arc Welding. Welding process that uses a tubular weld wire with an internal flux with or without an externally supplied gas shielding. GMAC Gas Metal Arc Cutting. Metals are cut by the heat of an arc between a continuous filler metal electrode and the work piece with externally supplied shielding gas.

Guidelines for Shop Inspection Welding Page 11 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

GMAW Gas Metal Arc Welding. Metals are welded by the heat of an arc between a continuous filler metal electrode and the work piece with externally supplied shielding gas. GMAW-P (pulse arc) and GMAW-S (short arc) are variations of this method. GTAW Gas Tungsten Arc Welding. A gas shielded welding method where the heating is produced using a non-consumable tungsten electrode to transfer the arc to the work piece. Groove Weld A weld made in the groove between two plates to be joined. Head The end of a cylindrical shell. Types include flat, ellipsoidal, flanged and dished, conical and hemispherical. Heat-Affected Zone The portion of the base metal which has not been melted, but whose mechanical properties have been altered by the heat of welding or cutting. High-Alloy Steel Steel containing large percentages of elements other than carbon. Hydrostatic Test A vessel, pipe spool or piping system is completely filled with water and subjected to a test pressure which is equal to 1.5 times the design pressure. Impact Test Determination of the resistance of a material to breaking by impact. The test is measured by breaking the material by a single blow. Joint Efficiency The ratio of the strength of a joint to the strength of the base metal, expressed in percent. Lap Joint A welded joint in which two overlapping metal parts are joined by means of a fillet, plug or slot weld. Lethal Substance Substance that is of such a nature that a small amount of the substance is dangerous to life when absorbed by a human or animal. Liquid Penetrant Examination (PT) A method of non-destructive examination that uses three different chemicals to expose welding defects that are open to the surface. These chemicals are applied using an inspection procedure.

Guidelines for Shop Inspection Welding Page 12 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Magnetic Particle Examination (MT) A method of detecting cracks at or near the surface in magnetic alloys using a specially designed electro-magnet and a magnetic liquid or powder. Material Test Report (MTR) A document on which the material manufacturer records the results of test examinations or treatments required by the material specification. Operating Pressure The pressure at the top of a pressure vessel at which it normally operates. It can not exceed the maximum allowable working pressure (Stamped Pressure). Plug Weld A circular weld made through a hole in one member of a joint to fuse it to another member. Porosity A rounded or elongated cavity formed by gas entrapment during cool down or solidification. Postweld Heat Treatment Heating a weld or welded assembly to a sufficient temperature to relieve the residual stresses which are the result of welding and forming. Preheating Heat applied to base metal prior to welding. Procedure Qualification Record (PQR) The written demonstration record that welds made by a specific welding procedure can meet code standards. Radiography The process of passing radiation through a weld joint or base material to obtain a film record of its soundness. Seal Weld Weld used primarily to obtain complete tightness against leakage. SMAW Shielded Metal Arc Welding. Also known as stick welding. This process uses a powder coated welding rod placed in a holder that is arced against the base metal. Stud Welding Joining a metal stud to a work piece by welding with arc, friction, resistance, or other process. SAW

Guidelines for Shop Inspection Welding Page 13 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

Submerged Arc Welding. A bare metal electrode(s) method of welding where the arc and molten metal are shielded by a granular fusible blanket of material on the work piece. Tack Weld A weld made to hold parts of a weldment in proper alignment until final welds are made. Ultrasonic Testing (UT) A non-destructive inspection method using sound waves for surface or sub-surface welding or base material testing. Ultrasonics can also be used for thickness testing. Undercut A jagged groove melted into the base metal adjacent to the toe or root of a weld and left unfilled by weld metal. Also known as edge melt. WPS Weld Procedure Specification. A written document providing in detail the required variables for specific application to assure repeatability by properly qualified welders and welding operators.

Guidelines for Shop Inspection Welding Page 14 / 15

Guidelines for Shop Inspection Support Documents

Welding

_______________________________________________________________________________________________________

4 More about Welldiing on the Internet 4 More about We d ng on the Internet

Different Welding Processes Gas Metal Arc Welding (GMAW) Gas Torch Welding Oxygen Fuel Gas Welding Procedures Plasma Arc Welding (PAW) Stick Welding (SMAW) Submerged Arc Welding Thermite Welding (TW) Tig Welding (GTAW) Welding Codes & Uses Info

Guidelines for Shop Inspection Welding Page 15 / 15

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Visual Inspection Guide for WeldsDokument11 SeitenVisual Inspection Guide for WeldsAldy Bagus PratamaNoch keine Bewertungen

- Overview of NDT Methods & ApplicationsDokument7 SeitenOverview of NDT Methods & Applicationsgeorgescribd1103Noch keine Bewertungen

- RT Flash CardsDokument13 SeitenRT Flash CardsBalkishan DyavanapellyNoch keine Bewertungen

- ARTICLE - Considerations When Selecting An NDE Method (2010)Dokument2 SeitenARTICLE - Considerations When Selecting An NDE Method (2010)Sangameswaran RamarajNoch keine Bewertungen

- ARTICLE - Destructive Testing Basics (2012)Dokument4 SeitenARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNoch keine Bewertungen

- A General Review of The Causes and Acceptance of Shape ImperfectionsDokument7 SeitenA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNoch keine Bewertungen

- What Is Peening?: Frequently Asked QuestionsDokument2 SeitenWhat Is Peening?: Frequently Asked QuestionstuanNoch keine Bewertungen

- TGN-M-02 Voltage Reducing DevicesDokument11 SeitenTGN-M-02 Voltage Reducing Devicessalekojic5332Noch keine Bewertungen

- 3 Welding Imperfections and Materials InspectionDokument31 Seiten3 Welding Imperfections and Materials InspectionSamerNoch keine Bewertungen

- WPS - 008Dokument11 SeitenWPS - 008MAT-LIONNoch keine Bewertungen

- Identify Welding Defects & DiscontinuitiesDokument21 SeitenIdentify Welding Defects & DiscontinuitiesJoanna AprilNoch keine Bewertungen

- Kou2003 PDFDokument6 SeitenKou2003 PDFGe EffgenNoch keine Bewertungen

- TIG welding process technical capabilitiesDokument2 SeitenTIG welding process technical capabilitiestuanNoch keine Bewertungen

- Visual Examination Procedure: 1 - PurposeDokument4 SeitenVisual Examination Procedure: 1 - PurposeElvin MenlibaiNoch keine Bewertungen

- Importance of Visual Welding InspectionDokument4 SeitenImportance of Visual Welding Inspectionhekayat71Noch keine Bewertungen

- Welding Imperfection and Material InspectionDokument62 SeitenWelding Imperfection and Material Inspectionintfarha10Noch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- TWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanyDokument3 SeitenTWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanytuanNoch keine Bewertungen

- Geometric shape welding imperfections causes and typesDokument12 SeitenGeometric shape welding imperfections causes and typesbipete69Noch keine Bewertungen

- Welding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareDokument2 SeitenWelding Procedure Specification (Conform Cu /according To) : Specificatia Preliminara A Procedurii de SudareStoian ValentinNoch keine Bewertungen

- ARTICLE - Advancements in The Hardness Testing of Welds (2010)Dokument3 SeitenARTICLE - Advancements in The Hardness Testing of Welds (2010)Sangameswaran RamarajNoch keine Bewertungen

- Ie-Ndt Iqi En462-1 WireDokument2 SeitenIe-Ndt Iqi En462-1 Wiresamkarthik47Noch keine Bewertungen

- Fun With Civa Simulation Software for Ultrasonic NDT TrainingDokument12 SeitenFun With Civa Simulation Software for Ultrasonic NDT Trainingmusaismail8863Noch keine Bewertungen

- Weld DiscontinuityDokument61 SeitenWeld DiscontinuityEKKACHAI PRABNAKORN0% (1)

- Interpretation of Weld RadiographsDokument8 SeitenInterpretation of Weld RadiographsMyk MamykinNoch keine Bewertungen

- Learn Vertical Welding with WPSDokument3 SeitenLearn Vertical Welding with WPSFlorinda Gagasa100% (1)

- RT Interpretation-SignedDokument7 SeitenRT Interpretation-Signedhamdi hamdiNoch keine Bewertungen

- Native Inspection - Report - CleanedDokument6 SeitenNative Inspection - Report - CleanedPrathamesh OmtechNoch keine Bewertungen

- Ultrasonic Testing Level III Principles, Equipment, Techniques, InterpretationsDokument4 SeitenUltrasonic Testing Level III Principles, Equipment, Techniques, InterpretationsTrung Tinh HoNoch keine Bewertungen

- Pipeline Inspector 1667834732Dokument57 SeitenPipeline Inspector 1667834732Dhani de EngineurNoch keine Bewertungen

- Welding Standard Ver1Dokument4 SeitenWelding Standard Ver1Sowmen ChakrobortyNoch keine Bewertungen

- Ultrasonic Phased Array ApplicationsDokument26 SeitenUltrasonic Phased Array ApplicationsLương Hồ VũNoch keine Bewertungen

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Dokument29 SeitenVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- Radiographic Testing: Basic Principles and TechniquesDokument48 SeitenRadiographic Testing: Basic Principles and TechniquesArjun LalitNoch keine Bewertungen

- V+ 4.magnetic Particle ExaminationDokument12 SeitenV+ 4.magnetic Particle ExaminationAMAL VISHNUNoch keine Bewertungen

- What Is NDT ?: Detection of Damage Before BreakdownDokument40 SeitenWhat Is NDT ?: Detection of Damage Before BreakdownAnik hasan BadhonNoch keine Bewertungen

- CSWIP 3.1 Training Questions For Pipe Butt Weld 3Dokument5 SeitenCSWIP 3.1 Training Questions For Pipe Butt Weld 3ahmad fikrieNoch keine Bewertungen

- GEIT 40007EN NDT Film BrochureDokument56 SeitenGEIT 40007EN NDT Film BrochurevrapciudorianNoch keine Bewertungen

- Structural Steel Welded Connections Design ReportDokument4 SeitenStructural Steel Welded Connections Design ReportChris Paulo100% (1)

- Preventing Casting DefectsDokument7 SeitenPreventing Casting DefectsArun t nNoch keine Bewertungen

- Cordon Off - 4 (00000003)Dokument1 SeiteCordon Off - 4 (00000003)Anonymous PlyxbQ3tNoch keine Bewertungen

- Ir 5073 Ppa 005Dokument6 SeitenIr 5073 Ppa 005ValiNoch keine Bewertungen

- 4.7 Curs 2 VT - Alexandrina MihaiDokument51 Seiten4.7 Curs 2 VT - Alexandrina MihaiAlexandra Bolog100% (1)

- Welding Procedure Specification (WPS) : JointsDokument2 SeitenWelding Procedure Specification (WPS) : JointsNielNoch keine Bewertungen

- WE Inlastek 05A Visual ExaminationDokument30 SeitenWE Inlastek 05A Visual Examinationhafidhrahadiyan2100% (1)

- Interpretation of Weld RadiographsDokument14 SeitenInterpretation of Weld RadiographsJuliogNoch keine Bewertungen

- Wis5 TermsDokument29 SeitenWis5 Termsravi00098Noch keine Bewertungen

- API 1104 Welding Defect GuideDokument48 SeitenAPI 1104 Welding Defect GuidesbmmlaNoch keine Bewertungen

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDokument70 SeitenExample Slide of User Functions: Time Guide The Slide Should Be Finished byHskumarReddy KarriNoch keine Bewertungen

- Visual TestingDokument1 SeiteVisual TestingAnonymous GE8mQqxNoch keine Bewertungen

- Example Report TOFD 2 INT-GP1186-09-70 PDFDokument1 SeiteExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNoch keine Bewertungen

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDokument7 SeitenVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNoch keine Bewertungen

- Welding Inspection PDFDokument15 SeitenWelding Inspection PDFzsmithNoch keine Bewertungen

- Weld Inspection and RepairDokument23 SeitenWeld Inspection and RepairIlter KocamanNoch keine Bewertungen

- Module 9.qualification 1.welding PerformanceDokument6 SeitenModule 9.qualification 1.welding PerformanceMohd NizamNoch keine Bewertungen

- Destructive Testing of WeldsDokument4 SeitenDestructive Testing of Weldsvikram5211Noch keine Bewertungen

- NDT of Welded Steel Tanks1 PDFDokument4 SeitenNDT of Welded Steel Tanks1 PDFBulut Yildiz100% (1)

- The ABCs of Eddy Current Weld Inspection: A Guide to Surface Flaw DetectionDokument4 SeitenThe ABCs of Eddy Current Weld Inspection: A Guide to Surface Flaw Detectionpadmgovi23Noch keine Bewertungen

- Galvanizing Standards GuideDokument8 SeitenGalvanizing Standards GuideSreedhar Patnaik.MNoch keine Bewertungen

- Chemical Analysis Procedures For Galvanizing PlantsDokument32 SeitenChemical Analysis Procedures For Galvanizing PlantsSreedhar Patnaik.M100% (2)

- Material Check LestDokument2 SeitenMaterial Check LestSreedhar Patnaik.MNoch keine Bewertungen

- Directory of Galvanizing Association DirectoryDokument8 SeitenDirectory of Galvanizing Association DirectorySreedhar Patnaik.MNoch keine Bewertungen

- Galva ParametersDokument3 SeitenGalva ParametersSreedhar Patnaik.M100% (1)

- Anti-Blast Preparation and Adding Procedure: Startup QuantitiesDokument2 SeitenAnti-Blast Preparation and Adding Procedure: Startup QuantitiesSreedhar Patnaik.MNoch keine Bewertungen

- HDG Steel Combined With Al-AlloyDokument9 SeitenHDG Steel Combined With Al-AlloySreedhar Patnaik.MNoch keine Bewertungen

- Galvanizing and powder coating steel guideDokument4 SeitenGalvanizing and powder coating steel guideSaurabh SinghNoch keine Bewertungen

- Physical Properties of Hydrochloric Acid Chart: MolarityDokument1 SeitePhysical Properties of Hydrochloric Acid Chart: MolaritySreedhar Patnaik.MNoch keine Bewertungen

- Troubleshooting Guideline - Adjusting PH of Flux SolutionDokument4 SeitenTroubleshooting Guideline - Adjusting PH of Flux SolutionSreedhar Patnaik.MNoch keine Bewertungen

- Flux - InformationDokument9 SeitenFlux - InformationSreedhar Patnaik.M0% (1)

- Factors Affecting Hot Dip Galvanized CoatingsDokument9 SeitenFactors Affecting Hot Dip Galvanized CoatingsSreedhar Patnaik.M100% (1)

- B-Gas-Question & Answer PaparsDokument62 SeitenB-Gas-Question & Answer PaparsSreedhar Patnaik.MNoch keine Bewertungen

- Avoid Surprises at The Kettle & Vents & Holes Desigine GuideDokument27 SeitenAvoid Surprises at The Kettle & Vents & Holes Desigine GuideSreedhar Patnaik.MNoch keine Bewertungen

- Flux Skimming PDFDokument6 SeitenFlux Skimming PDFpbp2956Noch keine Bewertungen

- Surface Engineering For CorrosionDokument24 SeitenSurface Engineering For CorrosionSreedhar Patnaik.MNoch keine Bewertungen

- p09s128 PDFDokument8 Seitenp09s128 PDFAndiniPermanaNoch keine Bewertungen

- BGAS-CSWIP-BG-22-12 BGAS-CSWIP 2nd Edition April 2019 PDFDokument30 SeitenBGAS-CSWIP-BG-22-12 BGAS-CSWIP 2nd Edition April 2019 PDFEjazNoch keine Bewertungen

- Feed Cattle ProfitDokument5 SeitenFeed Cattle ProfitMd RaihanNoch keine Bewertungen

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDokument14 SeitenInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNoch keine Bewertungen

- p09s128 PDFDokument8 Seitenp09s128 PDFAndiniPermanaNoch keine Bewertungen

- Hot Dip GalvanizeDokument9 SeitenHot Dip GalvanizeSreedhar Patnaik.MNoch keine Bewertungen

- How to Titrate Zinc ChlorideDokument13 SeitenHow to Titrate Zinc ChlorideSreedhar Patnaik.MNoch keine Bewertungen

- Materials: Development of Bath Chemical Composition For Batch Hot-Dip Galvanizing-A ReviewDokument24 SeitenMaterials: Development of Bath Chemical Composition For Batch Hot-Dip Galvanizing-A ReviewkhurshedlakhoNoch keine Bewertungen

- Flux ControlDokument2 SeitenFlux ControlSreedhar Patnaik.M50% (2)

- Inspection & Testing of Galva-Products-Prepared by SreedharDokument5 SeitenInspection & Testing of Galva-Products-Prepared by SreedharSreedhar Patnaik.MNoch keine Bewertungen

- HDG Steel Combined With Al-AlloyDokument9 SeitenHDG Steel Combined With Al-AlloySreedhar Patnaik.MNoch keine Bewertungen

- Procedures For Preparation of Galva Solutions - SreedhrDokument5 SeitenProcedures For Preparation of Galva Solutions - SreedhrSreedhar Patnaik.MNoch keine Bewertungen

- Salt Spray TestDokument13 SeitenSalt Spray TestSreedhar Patnaik.M100% (1)

- Frequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing BarsDokument6 SeitenFrequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing Barsali tahaNoch keine Bewertungen

- RVX Upgrade Ps 100 7 Ea4Dokument8 SeitenRVX Upgrade Ps 100 7 Ea4Mark HydeNoch keine Bewertungen

- Tut3 - Bending Moment and Shear Force Diagrams - MemoDokument12 SeitenTut3 - Bending Moment and Shear Force Diagrams - MemoDazzle Njabs MbungeleNoch keine Bewertungen

- Your First Day Lifeguarding: How To Vacuum and Backwash A PoolDokument4 SeitenYour First Day Lifeguarding: How To Vacuum and Backwash A PoolMattMonroeNoch keine Bewertungen

- WL 856H PDFDokument16 SeitenWL 856H PDFrusydi raushan fikriNoch keine Bewertungen

- Summary On Uniaxial Ratchetting of 6061-T6 Aluminium AlloyDokument18 SeitenSummary On Uniaxial Ratchetting of 6061-T6 Aluminium AlloyautalNoch keine Bewertungen

- Unrestrained Beam With End MomentsDokument9 SeitenUnrestrained Beam With End MomentsNikos StathoulopoulosNoch keine Bewertungen

- CYTJ45-2 Specification - KAMACH 18UDokument8 SeitenCYTJ45-2 Specification - KAMACH 18UJhonatan rincon martinezNoch keine Bewertungen

- Kit de Joint de Verin CaterpillarDokument2 SeitenKit de Joint de Verin CaterpillarzephyrinNoch keine Bewertungen

- Progress on Equipment OverhaulDokument4 SeitenProgress on Equipment Overhaulaldy albarNoch keine Bewertungen

- Meca Mobilite Dev PDFDokument8 SeitenMeca Mobilite Dev PDFAyoubNoch keine Bewertungen

- Hiab 320Dokument152 SeitenHiab 320Jasbir Jammu Repairing & Maintence LLCNoch keine Bewertungen

- Design of Drag-Link Mechanisms With Optimum Transmission AngleDokument5 SeitenDesign of Drag-Link Mechanisms With Optimum Transmission AngleNigussie AdemNoch keine Bewertungen

- Minicrawler EnglishDokument24 SeitenMinicrawler EnglishXUAN LUUNoch keine Bewertungen

- Basement Car ParkDokument10 SeitenBasement Car ParkAnjali ParkheNoch keine Bewertungen

- Heat Flow Calculations Made Using The V C: Ventilation Test InstrumentsDokument6 SeitenHeat Flow Calculations Made Using The V C: Ventilation Test Instrumentsretrospect1000Noch keine Bewertungen

- Salient Features:: Crawler DozerDokument4 SeitenSalient Features:: Crawler DozerSAFE EARTHMOVERSNoch keine Bewertungen

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDokument43 SeitenAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraNoch keine Bewertungen

- SSC JE Mains Test Series ProblemsDokument6 SeitenSSC JE Mains Test Series ProblemsAble KuriakoseNoch keine Bewertungen

- GEO3701 Unit 3Dokument94 SeitenGEO3701 Unit 3Asithandile Punqunqu MpayipheliNoch keine Bewertungen

- Turbine Control Operation StrategyDokument16 SeitenTurbine Control Operation Strategykavish malakaNoch keine Bewertungen

- STB S19 00 Datenblatt - Scalpac - EN - v01 PDFDokument2 SeitenSTB S19 00 Datenblatt - Scalpac - EN - v01 PDFAnastasia PošaracNoch keine Bewertungen

- PSXX OMR0002 PDFDokument64 SeitenPSXX OMR0002 PDFLupeNoch keine Bewertungen

- TorqueDokument5 SeitenTorqueguillemirNoch keine Bewertungen

- Wiring Diagram V7Dokument1 SeiteWiring Diagram V7NadeeshNoch keine Bewertungen

- New Holland - Grader 156-7Dokument16 SeitenNew Holland - Grader 156-7Cristian Cernega100% (1)

- Mr-75-163-Tds Critical SparesDokument3 SeitenMr-75-163-Tds Critical Sparescmrig74Noch keine Bewertungen

- ME6404 Thermal EngineeringDokument21 SeitenME6404 Thermal EngineeringAnonymous mRBbdopMKfNoch keine Bewertungen

- 2-Theory of SedimentationDokument11 Seiten2-Theory of SedimentationSheeraz AhmedNoch keine Bewertungen

- Racor Oil Filtration Hydraulic Filter Cart 7768Dokument2 SeitenRacor Oil Filtration Hydraulic Filter Cart 7768sinter-musicNoch keine Bewertungen