Beruflich Dokumente

Kultur Dokumente

B0301-Microbial Bioreactor Engineering

Hochgeladen von

Boppani Ram ManoharOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

B0301-Microbial Bioreactor Engineering

Hochgeladen von

Boppani Ram ManoharCopyright:

Verfügbare Formate

www.jntuworld.

com

NR

Code No: B0301 JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY HYDERABAD M.Tech II - Semester Regular Examinations September, 2010 MICROBIAL BIOREACTORS ENGINEERING (Biotechnology) Time: 3hours Max. Marks: 60 Answer any five questions All questions carry equal marks --1.a) Write short note on: i) Yield ii) Selectivity. A batch Fermentor was operated for the production of alcohol from yeast. The rate of glucose conversion is measured and the data are presented below. Find the time taken in the batch fermentor when the concentration falls down to 12 kg mol/m3 when CA0 = 70 kg mol/m3 68 2.82 54.6 4.71 33.0 4.31 20.0 3.74 12.2 3.16

b)

Concentration (CA)kg mol/m3 Rate of reaction(-rA) kg mol/m3 h 2.

What is kLa ,What are the different methods available to measure kLa. Compare and contrast the static method and dynamic method for the measurement of kLa. Write about the effect of the following on oxygen transfer rate a) Bubble size b) Gas hold up c) Gas velocity d) Type of Gas sparger. Explain the theory of Power requirement for ungassed Newtonean fluids with neat diagram of Reynolds number and Power number for various impellers A fermentation broth containing a dilute pullalans culture is agitated in a 5 lit reactor containing rushton turbine impeller. The vessel geometry containing four baffles is as per the one described by Rushton. The impeller diameter is 16 cm and is rotating at 300 rpm. The apparent viscosity of the fluid is 8 cp and its density is 1010 kg/m3. Find the power required to run the agitator using the plots of power number versus Reynolds number. Describe the importance of mixing in bio processing. What are the different types of agitators used in bio processing? Mention five physical parameters to be monitored and explain in detail how they are monitored in the fermentation process? Contd -2-

3.

4.a) b)

T N

W U

R O

D L

7.4 2.46

4.5 1.91

2.7 1.4

5.a) b) 6.

www.jntuworld.com

www.jntuworld.com

-27. After a batch fermentation, the system is dismantled and approximately 75% of the cell mass is suspended in the liquid phase(2l), while 25% is attached to the reactor walls and internals in a thick film(0.3 cm). Work with radio active tracers shows that 50% of the target product (intracellular) is associated with each cell fraction. The productivity of this reactor is 2 g product/liter at the 2 l scale. What would be the productivity at 20,000 l scale if both reactors has a height to diameter ratio of 2 to 1? Compare various methods for the aeration of animal cell cultures. Comment on the advantages and disadvantages of each method?

8.

---o0o---

T N

W U

R O

D L

www.jntuworld.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Imprinting: Angelman, Prader-Willi, and Other Syndromes: Advanced Human Genetics Jonathan WolfeDokument22 SeitenImprinting: Angelman, Prader-Willi, and Other Syndromes: Advanced Human Genetics Jonathan WolfeBoppani Ram ManoharNoch keine Bewertungen

- r09 Plant Biotechnology4444Dokument1 Seiter09 Plant Biotechnology4444Boppani Ram ManoharNoch keine Bewertungen

- r09 Plant BiotechnologyDokument1 Seiter09 Plant BiotechnologyBoppani Ram ManoharNoch keine Bewertungen

- Downstream Processing4777Dokument1 SeiteDownstream Processing4777Boppani Ram ManoharNoch keine Bewertungen

- Single Cell Protein (SCP) Production by Bacillus Subtilis From Pineapple Fruit ExtractDokument42 SeitenSingle Cell Protein (SCP) Production by Bacillus Subtilis From Pineapple Fruit ExtractBoppani Ram ManoharNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- M2 Economic LandscapeDokument18 SeitenM2 Economic LandscapePrincess SilenceNoch keine Bewertungen

- Sweet Biscuits Snack Bars and Fruit Snacks in MexicoDokument17 SeitenSweet Biscuits Snack Bars and Fruit Snacks in MexicoSantiagoNoch keine Bewertungen

- Difference Between Mountain Bike and BMXDokument3 SeitenDifference Between Mountain Bike and BMXShakirNoch keine Bewertungen

- Electricity 10thDokument45 SeitenElectricity 10thSuryank sharmaNoch keine Bewertungen

- Seminar On Despute Resolution & IPR Protection in PRCDokument4 SeitenSeminar On Despute Resolution & IPR Protection in PRCrishi000071985100% (2)

- 90FF1DC58987 PDFDokument9 Seiten90FF1DC58987 PDFfanta tasfayeNoch keine Bewertungen

- EXTENDED PROJECT-Shoe - SalesDokument28 SeitenEXTENDED PROJECT-Shoe - Salesrhea100% (5)

- Cdi 2 Traffic Management and Accident InvestigationDokument22 SeitenCdi 2 Traffic Management and Accident InvestigationCasanaan Romer BryleNoch keine Bewertungen

- Basics: Define The Task of Having Braking System in A VehicleDokument27 SeitenBasics: Define The Task of Having Braking System in A VehiclearupNoch keine Bewertungen

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDokument3 SeitenWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdNoch keine Bewertungen

- MRT Mrte MRTFDokument24 SeitenMRT Mrte MRTFJonathan MoraNoch keine Bewertungen

- CIR Vs PAL - ConstructionDokument8 SeitenCIR Vs PAL - ConstructionEvan NervezaNoch keine Bewertungen

- What Caused The Slave Trade Ruth LingardDokument17 SeitenWhat Caused The Slave Trade Ruth LingardmahaNoch keine Bewertungen

- JAZEL Resume-2-1-2-1-3-1Dokument2 SeitenJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoNoch keine Bewertungen

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDokument3 SeitenMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezNoch keine Bewertungen

- Expense Tracking - How Do I Spend My MoneyDokument2 SeitenExpense Tracking - How Do I Spend My MoneyRenata SánchezNoch keine Bewertungen

- SPH4U Assignment - The Wave Nature of LightDokument2 SeitenSPH4U Assignment - The Wave Nature of LightMatthew GreesonNoch keine Bewertungen

- Guide For Overseas Applicants IRELAND PDFDokument29 SeitenGuide For Overseas Applicants IRELAND PDFJasonLeeNoch keine Bewertungen

- Tinplate CompanyDokument32 SeitenTinplate CompanysnbtccaNoch keine Bewertungen

- Experiment On Heat Transfer Through Fins Having Different NotchesDokument4 SeitenExperiment On Heat Transfer Through Fins Having Different NotcheskrantiNoch keine Bewertungen

- Audit On ERP Implementation UN PWCDokument28 SeitenAudit On ERP Implementation UN PWCSamina InkandellaNoch keine Bewertungen

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondDokument11 SeitenThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveNoch keine Bewertungen

- Hotel Reservation SystemDokument36 SeitenHotel Reservation SystemSowmi DaaluNoch keine Bewertungen

- Innovations in Land AdministrationDokument66 SeitenInnovations in Land AdministrationSanjawe KbNoch keine Bewertungen

- 4 Bar LinkDokument4 Seiten4 Bar LinkConstance Lynn'da GNoch keine Bewertungen

- Applied-Entrepreneurship PPTDokument65 SeitenApplied-Entrepreneurship PPTJanice EscañoNoch keine Bewertungen

- 1SXP210003C0201Dokument122 Seiten1SXP210003C0201Ferenc SzabóNoch keine Bewertungen

- Module 5 Data Collection Presentation and AnalysisDokument63 SeitenModule 5 Data Collection Presentation and AnalysisAngel Vera CastardoNoch keine Bewertungen

- Brand Positioning of PepsiCoDokument9 SeitenBrand Positioning of PepsiCoAbhishek DhawanNoch keine Bewertungen

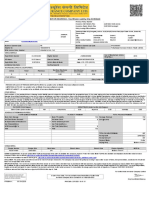

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDokument1 SeiteMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNoch keine Bewertungen