Beruflich Dokumente

Kultur Dokumente

2.16.1 Principles of Forced Induction

Hochgeladen von

stefanovicana1Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2.16.1 Principles of Forced Induction

Hochgeladen von

stefanovicana1Copyright:

Verfügbare Formate

116

Engines

Fundamentals of Motor Vehicle Technology: Book 1

2 3 4

5 6

fairly large amount of engine power. The cowling makes it difficult to get at certain parts of the engine. The engine is more liable to overheating under arduous conditions than a water-cooled engine. Mechanical engine noises tend to be amplified by the fins. The cylinders usually have to be made separately to ensure proper formation of the fins. This makes the engine more costly to manufacture. Cylinders must be spaced well apart to allow sufficient depth of fin. It is more difficult to arrange a satisfactory passenger compartment heating system.

4 There is no cowling to obstruct access to the engine. 5 The water and jackets deaden mechanical noise. 6 The engine is better able to operate under arduous conditions without overheating. The main disadvantages of water cooling are: 1 Weight, not only of the radiator and connections but also of the water. The whole engine installation is likely to be heavier than an equivalent air-cooled engine. 2 Because the water has to be heated, the engine takes longer to warm up after starting from cold. 3 If water is used, the maximum temperature is limited to about 85 to 90C to avoid the risk of boiling away the water. 4 If the engine is left standing in very cold weather, precautions must be taken to prevent the water freezing in the cylinder jackets and cracking them. 5 There is a constant risk of leaks developing. 6 A certain amount of maintenance is needed, e.g. checking water level, anti-frost precautions, cleaning out deposits, etc.

Liquid-cooled system The main points in favour of liquid or water cooling are: 1 Temperatures throughout the engine are more uniform, thus distortion is minimized. 2 Cylinders can be placed close together and the engine made more compact. 3 Although a fan is usually fitted to force air through the radiator, it is smaller than that required in an aircooled system and is thus quieter and absorbs less engine power.

2.16

SUPERCHARGING AND TURBOCHARGING (FORCED INDUCTION)

cause a much higher pressure to be created on the compression stroke. If pressures during the compression stroke are too high, this will increase the charge temperature, which can lead to premature or preignition of the fuel mixture. To overcome the problem, when an engine is supercharged, the compression ratio is usually reduced compared with a normally aspirated (un-supercharged) engine. Unfortunately, lower compression ratios usually result in lower combustion efficiency, which usually increases fuel consumption. Although combustion efficiency may be slightly lower, with regard to engine power, the advantage of having a much greater volume of air in the cylinder outweighs the disadvantage of lower combustion or thermal efficiency. Where a high power output is required from an engine of minimum size, there is no doubt that supercharging is a most effective approach, but fuel consumption can be high unless special arrangements are used to offset the lower compression ratio, and to allow for the energy needed to drive the unit. While the previous statement is generally true of older engines, modern electronic engine management systems enable very precise control of fuelling and ignition and this therefore allows supercharged engines to be efficient as well as powerful.

2.16.1 Principles of forced induction

Pumping air into the cylinder The power that any internal-combustion engine can develop depends fundamentally upon the mass of air it can consume per minute. The normal method of filling or charging the cylinders of a four-stroke engine consists of allowing the pressure of the atmosphere to force air into the combustion chambers. The downward movement of the piston on the intake stroke creates a partial vacuum, which is a lower pressure than that of the atmosphere. The amount of air entering the cylinder therefore depends on the difference in pressure between the atmospheric pressure and the lower pressure (vacuum) in the cylinder. If, however, air is forced into the cylinders under a pressure that is higher than atmospheric pressure, a greater mass of air will enter the cylinder and the engine will be supercharged. Forcing the air into the cylinders can be achieved by using some kind of air pump. Such a device is called a supercharger. Reducing the compression ratio It should be noted that a supercharger would cause the fresh charge to enter the cylinder at a much higher pressure than on a conventional (un-supercharged) engine. This increased fresh charge pressure would then

Supercharging and turbocharging (forced induction)

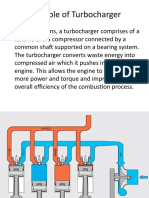

117

Position and drive arrangements of the supercharger The position of the supercharger in the induction system depends on the fuel system used. On early spark-ignition engines the supercharger (or blower as it is often called), forced the air into the carburettor where it then mixed with the petrol and passed into the engine. Many later designs for carburettor engines favoured an arrangement where the supercharger was fitted between the carburettor and the engine, therefore the supercharger pulled the petrol and air mixture from the carburettor and pumped the mixture into the engine. With the advent of petrol injection, the arrangement has reverted to a system in which the supercharger only pumps the air; the petrol is delivered independently by the injectors. A supercharger can be positively driven by belt, chain or gears from the engine crankshaft. Turbocharger A different type of supercharger, referred to as a Turbocharger is driven by energy contained within the exhaust gases as they flow from the engine. The turbocharger, has gained favour over recent years (although not universally), because it uses the energy in the exhaust gas instead of directly robbing the engine of some of its power. It is sometimes claimed that the turbocharger is the answer to emission problems as well as present day demands for better fuel consumption. However improved fuel efficiency is difficult to obtain from a spark-ignition engine unless the turbocharger is very carefully matched with the engine. This reservation is based on the fact that thermal efficiency (or fuel economy) depends on the compression ratio, and to avoid detonation, the ratio must normally be lowered slightly when a supercharger is fitted. However, as stated earlier, modern engine management systems do now allow higher compression ratios to be used on supercharged and turbocharged engines, than formerly. Supercharged compression-ignition engines (diesel) Supercharging is not limited to spark-ignition engines; compression-ignition engines may also be supercharged and in some ways are more suitable for supercharging and turbocharging. A typical example of the introduction of a supercharger into a CI engine is where there is a need to raise maximum engine power to meet a legally permitted increase in the load carried by a vehicle. Instead of fitting a larger engine, many manufacturers have uprated the power of the existing engine by using a turbocharger. In general, the CI engine is already constructed and designed to work at very high cylinder pressures with diesel fuel. The combustion chamber design and fuel delivery systems are therefore designed to reduce as far as possible the potential for pre-ignition. The

compression ratio problem does not therefore apply to CI engines. The following gives a rough guide to the advantages gained by turbocharging a CI engine: 1 A four-cylinder turbocharged engine gives the power output of a six-cylinder normally aspirated engine. 2 A six-cylinder turbocharged engine gives the fuel consumption of a four-cylinder normally aspirated engine. Two-stroke engines Note that a two-stroke engine does not have an induction stroke created by the downward movement of the piston, but relies upon air being forced into its cylinders by some kind of pump (usually the lower chamber beneath the piston). The two-stroke engine is therefore not supercharged unless the pressure of the air filling the cylinder is above atmospheric pressure. A two-stroke engine is normally pressure-charged (as opposed to supercharged) either by using by using the underneath of the working piston in the lower chamber or by using a separate cylinder as a charging cylinder. However, two-stroke engines have been supercharged using separate air pumps such as a Rootstype blower (covered in section 2.16.2). Strictly, a two-stroke engine cannot be supercharged unless the exhaust ports are arranged to close before the inlet ports close.

2.16.2 Types of direct drive superchargers

The Roots blower This device was patented about 1865 by F. M. and P. H. Roots in America and was used for a number of purposes including (in very large sizes) ventilating mines. Figure 2.167 illustrates the construction generally used for engine supercharging. Depending on the size of engine for which the blower is to be used, the width of the casing would be about 150300 mm (612 inches). It can be regarded as a form of gear pump in which each gear (called a rotor in the Roots blower) normally has two teeth or lobes. (Some Roots blowers have rotors with three or even four lobes.) The rotors have a small clearance inside the casing and are carried on shafts, which are geared together outside the casing; each rotor shaft is supported by a bearing at either end. One shaft is driven at approximate engine speed and drives the other at the same speed. The Roots blower is an air displacer and not a compressor. The air is not compressed within the blower but simply carried round from inlet side to outlet side in the spaces between the lobes and the casing. The pressure at the output side depends upon the relative swept volumes of the blower and the engine, and the speed at which the blower is driven.

118

Engines

Fundamentals of Motor Vehicle Technology: Book 1

The vane compressor In its simplest form a vane compressor consists of a cylindrical casing in which is mounted eccentrically a cylindrical rotor carrying protruding vanes. The vanes divide the space between the rotor and the casing into a number of compartments, which vary in volume as the rotor turns. In Figure 2.168a, the compartment shown shaded is in the position of maximum volume and the vane (1) has just cut off communication between this compartment and the inlet port. In Figure 2.168b the rotor has turned to the position where the vane (2) is just about to open the compartment to the outlet port, and it can be seen that the volume of the compartment is now smaller than it was in Figure 2.168a, which results in the air being compressed. The position of the leading edge of the outlet port dictates the amount of compression; this leading edge positioning would normally be arranged to correspond with the required delivery pressure for the engine to which the compressor is fitted.

Figure 2.167 A Roots blower

The rotors operate continuously against the full delivery pressure and thus more power is absorbed in driving this device than would be required if compression took place within the blower. At low pressures this disadvantage is small, but it increases rapidly as pressure rises. Owing to the rotor clearance there will be some back leakage of air, which increases as delivery pressure rises but this decreases as engine speed increases. Therefore, this type of supercharger is mostly used for high-speed engines and relatively low supercharge pressures. The operation of a Roots-type supercharger fitted to a modern engine is normally controlled by an electronic control unit (ECU). The ECU controls the operation of the supercharger by a magnetic clutch, which is fitted to the supercharger drive pulley. The supercharger is driven by the crankshaft, typically using a rubber belt. When the clutch is disengaged the supercharger is not driven; when the ECU operates the magnetic clutch, the drive is engaged and the supercharger then operates. The magnetic clutch is operated when the ECU senses that the throttle is open and the engine is also under load, such as during acceleration. To prevent the rotor gears from seizing they are supplied with oil. The oil level in the supercharger should be checked or renewed during routine maintenance.

Figure 2.168 Principle of the vane compression

Figure 2.169 shows one practical form of this device, which has, at various times, been marketed under the names of a Centric, Arnett and Shorrocks compressor. The vanes are mounted on a shaft, which is placed centrally in the casing, each vane being carried on two ball bearings so that the vanes are always radial to the casing. The vanes pass through slotted rods or trunnions carried in the rotor and there is a very small clearance between the tips of the vanes and the casing. The rotor is driven at approximately engine speed by a belt, chain or gears.

Figure 2.169 The trunnion-type radial vane compressor

Supercharging and turbocharging (forced induction)

119

One minor disadvantage of the vane compressor is the necessity for lubrication due to the sliding of the vanes in the rotor. While this is fairly easy to arrange it is undesirable because the oil mist carried into the engine may cause combustion difficulties, particularly in compression-ignition engines. The centrifugal blower If the Roots blower can be likened to a gear pump the centrifugal blower can be simply described as a glorified water pump (as used in an engine cooling system). The impeller is more carefully designed and made than the corresponding part of the water pump and is driven at considerably higher speed. Figure 2.170 illustrates the construction. The driving shaft is driven at some five to six times engine speed. Air is drawn in through the air inlet (intake), carried round between the vanes of the impeller and thrown outwards by centrifugal force into the volute casing; it exits via the outlet port, from which it passes to the inlet manifold.

other end of the shaft is the centrifugal compressor. The combination of centrifugal compressor and an exhaustdriven turbine is called a turbo-supercharger or turbocharger. Attempts to apply this principle to engines have been made from time to time since the early 1900s, but only within recent years has the method been successfully applied to motor vehicles. The blades of the turbine have to operate at the high temperature (about 1000C) of the exhaust gases, so only when a reasonably priced material became available for the blades was it possible to make an economical unit. Normally a turbine of the radial flow type is used to drive the compressor. It has a similar construction to a centrifugal blower but the gas flow through the unit is reversed (Figure 2.171). A special material, such as nickel or nickelchromium alloy iron, is used for the turbine; this is necessary because of the high temperatures. A cast iron casing, formed like a snails shell to feed the exhaust gas on to the periphery of the turbine blades, encloses the turbine. A flange on the part of the casing that forms the gas passage to the turbine connects the unit as closely as possible to the exhaust manifold of the engine. A connection to the gas outlet at the centre of the turbine casing allows the exhaust gas to be passed to the normal exhaust system.

Figure 2.170 A centrifugal blower Figure 2.171 A radial flow turbine

The advantage of this type of blower is that a small size of blower can deliver a considerable quantity of air. It has two main disadvantages for automobile use. The first is the very high speed at which it must be driven (which introduces problems in the drive arrangements during rapid acceleration and deceleration) and the second is that it is only efficient over a very narrow impeller speed range. When the unit is in operation, the exhaust gas expelled from the engine cylinders at high temperature and velocity is delivered into the casing and the gas is then directed to the turbine rotor. Before the gas flows from the casing to the turbine it first has to pass through either specially shaped passages or a ring of guide vanes; these ensure that the gas strikes the outer tips of the turbine blades tangentially so that the turbine can be driven in the required direction. As the gas flows towards the centre of the turbine, the blades slow down the gas velocity. This action extracts energy from the gas and causes the turbine to spin at a high speed. This can be in excess of 100,000 revolutions per minute under engine conditions in which the temperature and/or velocity of the exhaust gas is high. The exhaust-driven turbine is supported by a shaft, which transmits the drive to the centrifugal compressor.

2.16.3 Turbo-type supercharger (turbocharger)

The difficulties of driving a centrifugal blower at very high speeds, and the loss of up to 35% of the engines power to provide this drive, can be overcome by using the energy contained in the exhaust gas to drive a centrifugal blower or compressor. A turbine on one end of a shaft is driven by the flow of exhaust gas; on the

120

Engines

Fundamentals of Motor Vehicle Technology: Book 1

The casings of aluminium alloy and cast iron for compressor and turbine respectively are bolted together to form a single unit; it is this assembly that is called a turbocharger or turbo for short (Figure 2.172). In view of the high speed of operation, two plain floating bearings (often made of cast iron) are needed to support the shaft (Figure 2.173). This type of bearing requires a pressurized supply of clean oil to resist wear and an adequate flow of oil to keep the bearings cool. The bearings are supplied with oil by a pipe connected to the engines lubrication system. After passing through the bearings the oil is collected in a cavity, formed in the casing between the compressor and turbine, from where it is allowed to drain back naturally into the engine sump. Gas and oil sealing are very important. Oil must not enter the compressor and exhaust gas must not pass to the bearings. The onset of either condition soon becomes apparent to the driver. Oil passing the compressor seal, especially when it is being pumped through by exhaust gas that is escaping from the turbine, produces a vast quantity of blue smoke. Any defect in the turbocharger that disturbs the action of the seals, such as shaft movement caused by worn bearings, soon shows up. Poor lubrication, caused by a lack of pressure or dirty oil, is a common cause of rapid bearing wear; this is accelerated when the shaft movement allows hot exhaust gas to escape into the bearings. When this occurs the life of the unit is limited to a few seconds. Figure 2.173 also shows the bearing-and-seal arrangement. This design uses cast iron sealing rings similar to a piston ring. Special care of the turbocharger is needed to ensure that the bearings are not starved of oil when the engine is either started or stopped. The engine should not be accelerated either immediately after it has been started or just prior to switching off (it should be noted that it takes a long time for the turbine to come to rest).

Figure 2.173 Section through a turbocharger

Turbocharging for diesel and petrol engines Fitting a turbocharger to an engine, which originally was normally aspirated, gives the following advantages: 1 Greater torque and power. Since the power increase can be as high as 60%, the engine is smaller and lighter than a non-turbocharged unit of equal power. 2 Fuel consumption is improved by about 10%. 3 Exhaust noise is reduced owing to the smoothing out of the exhaust pulsations. Diesel engine applications Turbocharging has been commonly used on large CI engines (diesel) for many years, since this type of engine is particularly suited to pressure charging or forced induction. Unlike the spark-ignition type, the CI engine does not suffer from compression limitations and, in addition, the air-only induction system of a CI unit (no fuel in the intake airflow) makes the fitting of a turbocharger much easier.

Figure 2.172 A turbocharger

Supercharging and turbocharging (forced induction)

121

More recently, diesel engine cars with small and large capacity engines have become increasingly popular across Europe and other markets. Due to the advances in diesel engine management systems, turbocharging has proven to be an extremely efficient way of producing high power outputs along with excellent fuel economy. Even some sports saloons are now fitted with turbocharged diesel engines. Petrol engine applications A car fitted with a turbo is generally associated with top-of-the-range models designed to give a performance, especially acceleration in mid-range, far above the normal levels of non-turbocharged engines. Engines that are suitable for turbocharging conversion must be structurally strong to withstand the extra load and higher speeds. Also if the turbocharged engine was originally designed as a normally aspirated engine, it will probably require a lowering of the compression ratio to avoid mechanical damage caused by combustion problems such as detonation. Virtually all modern petrol engines are fuel-injected, and this suits the process of turbocharging. The complexity of turbocharging carburettor engines restricted the use of turbochargers, but fitting turbochargers to fuel-injected engines is a relatively simple arrangement. Careful matching of the turbocharger to a given engine ensures that the maximum boost (pressure above atmospheric) is limited to about 1.5 bar, i.e. the maximum pressure in the inlet manifold is 1.5 times atmospheric pressure. Boost limitation and boost control The exhaust gas temperature of a petrol engine is much hotter than that of a diesel engine, so this places extra stress on the turbocharger. Furthermore, current emission regulations relating to the discharge of NOx (oxides of nitrogen refer to section 2.30 in this chapter) mean that the boost may need to be reduced at times when this pollutant would normally be produced in unacceptable quantities. This occurs at high engine speed and/or at certain load conditions. To meet emissions requirements and also to minimize the risk of engine damage, a boost-limiting valve is fitted (Figure 2.174). Under high load conditions, this poppet-type valve, often called a wastegate, is opened mechanically so as to allow some of the exhaust gas to by-pass the turbine, which therefore reduces its pumping action. Modern engines use an electronic engine management system to set the ignition timing and control fuelling and it is therefore logical to use the same engine management system to monitor and regulate the boost pressure. Such systems can control the boost pressure very accurately throughout all engine speed and load conditions, and this allows the boost pressure to be maintained at the optimum value with regard to power, economy and emissions. The electronically controlled waste-gate systems make use of engine vacuum and boost pressure to

Figure 2.174 A turbocharger with boost limiting valve

actuate the waste-gate, as illustrated in Figure 2.174. However, an additional valve is positioned in the pipe, which passes the boost pressure to the waste-gate. The valve is controlled by the engine management computer, which is able to sense the boost pressure via a signal passed from a pressure sensor. The computer or ECU is then able to control the valve, which in turn regulates waste-gate operation. An alternative method of limiting boost pressure is to use a pressure relief valve in the induction manifold; this opens when the boost reaches a predetermined maximum and allows air in the manifold to bleed to the atmosphere. This type of system is now not so widely used due to the superior efficiency of electronically regulated waste-gate systems. Charge-air coolers (intercoolers) Compression of the charge and its passage through a hot turbocharger raises the temperature of the air; this results in a reduction of the density of the charge as well as increasing the chance that premature detonation will occur. To overcome the problem, some petrol and diesel engines have a heat exchanger fitted between the turbocharger and engine (Figure 2.175). This unit, often called an intercooler, is generally an air-to-air heat exchanger, although some systems use a separated portion of the cooling system radiator as a means of dissipating the heat from the intake air. By lowering the air temperature to around 5060C volumetric efficiency is improved and detonation tolerance is increased.

122

Engines

Fundamentals of Motor Vehicle Technology: Book 1

emissions, improved engine power and torque with lower fuel consumption. A variable-geometry turbo (Figure 2.176) is normally used in conjunction with a diesel engine or with high performance petrol engines.

Figure 2.176 A variable-vane turbocharger

Figure 2.175 A turbocharger with an intercooler

Advantages and disadvantages of turbocharging petrol engines The advantages of turbocharging petrol engines include: 1 Higher torque for acceleration from low speed. 2 Lower exhaust noise and emission. 3 Better fuel economy due to a reduction in the pumping energy expended during the induction stroke. (This advantage is seldom achieved in practice because many drivers alter their driving technique to take full advantage of the extra power of a turbocharged engine.) The main disadvantages of a turbocharged petrol engine (apart from the extra hazards created when inexperienced drivers attempt to demonstrate the extra performance) are: 1 The higher initial cost of turbocharger and allied equipment. 2 The higher repair and servicing costs especially when other engine components are damaged by a defective unit. 3 At low engine speeds, a delay in engine response after depressing the accelerator. Since the turbine takes a time to reach its effective speed, an acceleration delay occurs with older type units often referred to as turbo-lag. Variable-geometry turbos A turbocharger is associated with turbo-lag, noise and high emissions, especially NOx. With advances in engine technology and computer-controlled engine management systems it has been possible to alter the geometry within the turbocharger during engine operation. The variable-geometry turbo provides lower

By altering the flow of the exhaust gases at the inlet port of the exhaust turbine, it is possible to optimize the speed of the turbine during low and high engine loads. During low engine loads, the vanes of the turbo nozzle are closed (Figure 2.177), which directs a minimal flow of exhaust gas across the turbine impellor. The turbine spins relatively slowly producing very little turbo charging effect in the inlet manifold.

Figure 2.177 A variable-vane turbocharger at low load

When the load applied to the engine is high, the flow of exhaust gas at the turbine inlet port is also high. The nozzle vanes are opened by the ECU via the operation of the actuator (Figure 2.178) and flow of high-speed exhaust gases passing over the turbine, driving the impellor at high speed. The high speed of the turbine

The petrol four-stroke cycle in detail: valve and ignition timing

123

drives the compressor, which provides a high boost pressure in the inlet manifold. The engine management ECU monitors engine operating conditions, such as engine speed and engine load using information from sensors, and the ECU then controls the position of the nozzle vanes via the actuator. Variable geometry turbochargers provide a faster response to throttle opening, reducing the effect of turbo-lag. The ECU can accurately control the turbo boost pressure using a variable-geometry turbocharger; a traditional poppet valve waste-gate is no longer required to reduce or regulate the boost pressure. When boost pressure is too high, the nozzle vanes are closed thus reducing the speed of the turbine, resulting in a reduction of boost pressure. The ECU controls the nozzle actuator with the use of either a solenoid-operated vacuum valve or electrical stepper motor.

Figure 2.178 A variable-vane turbocharger at high load

2.17

THE PETROL FOUR-STROKE CYCLE IN DETAIL: VALVE AND IGNITION TIMING

Consider an engine running reasonably fast; the most suitable point at which to open the inlet port depends upon conditions at the end of the exhaust stroke, and we will begin our study with the piston moving down the cylinder on the induction stroke and the inlet port already wide open (Figure 2.179).

Note: In section 2.2 (especially 2.2.3), the general principles of operation of an engine on the four-stroke cycle was described. The following section provides further detail on the four-stroke cycle in relationship to the petrol engine, particularly in connection with ignition and valve timing, and the opening and closing of the inlet and exhaust valves.

2.17.1 Valve operation and the fourstroke engines

The first point to be appreciated is that it is not possible for a valve to move from closed to fully open (or vice versa) instantaneously. The opening and the closing movements are each spread over a considerable angle of crankshaft rotation. Thus, if a valve is required to be effectively open at the beginning of a stroke (TDC or BDC) it must begin to open before the dead centre. Similarly, if a valve is required to be open at the end of a stroke, it must not close completely until after the dead centre. Even if the valves could be opened and closed instantaneously, the dead centres would not be the best points at which to open and close them, except at very low engine speeds. The engine gives its best performance when the greatest mass of air and fuel is passed through the combustion chamber and burnt effectively.

Figure 2.179 Induction stroke

Induction stroke The downward movement of the piston reduces the pressure inside the cylinder so that the pressure of the atmosphere (or supercharge pressure) forces air

Das könnte Ihnen auch gefallen

- Diesel CycleDokument10 SeitenDiesel CycleSri Ram VikasNoch keine Bewertungen

- Auto Vehicle Dealer - Valid - 07-20-2017 PDFDokument261 SeitenAuto Vehicle Dealer - Valid - 07-20-2017 PDFDavid PalanukNoch keine Bewertungen

- 4 Stroke Petrol EngineDokument11 Seiten4 Stroke Petrol EngineAnkit Joshi50% (4)

- Quattro The Evolution of Audi All-Wheel DriveDokument50 SeitenQuattro The Evolution of Audi All-Wheel Drivestefanovicana1100% (1)

- TurbochargerDokument10 SeitenTurbochargernavle krushnaNoch keine Bewertungen

- What Are The Functions of An Exhaust ManifoldDokument5 SeitenWhat Are The Functions of An Exhaust Manifoldjameel babooram100% (1)

- VW Touran Electrical SystemDokument23 SeitenVW Touran Electrical SystemZoltan Szekely75% (4)

- GM & FordDokument118 SeitenGM & FordmalescaNoch keine Bewertungen

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Four-Stroke Diesel EngineDokument18 SeitenFour-Stroke Diesel Enginebs esliye me aap ka fan ho gya100% (2)

- Turbocharger PresentationDokument18 SeitenTurbocharger PresentationShrwan Gyawali100% (3)

- Turbocharger 4Dokument18 SeitenTurbocharger 4safwansd750% (2)

- Nissan Cd17 Diesel Engine ManualDokument2 SeitenNissan Cd17 Diesel Engine ManualMiguel Chinchay Cueva44% (9)

- Chapter 3 SuperchargingDokument16 SeitenChapter 3 Superchargingmustafa1011100% (1)

- Super ChargingDokument23 SeitenSuper Charginghirenbabaji100% (2)

- BWM 0000004 01Dokument54 SeitenBWM 0000004 01stefanovicana1Noch keine Bewertungen

- Daewoo Doosan D20S 5 PARTSDokument386 SeitenDaewoo Doosan D20S 5 PARTSBRETT HOLLINGSWORTHNoch keine Bewertungen

- SuperchargerDokument24 SeitenSuperchargerpravat dalai100% (1)

- 03 Principle of TurbochargerDokument19 Seiten03 Principle of TurbochargerSky RNoch keine Bewertungen

- Pilot Hydraulic System M315CDokument6 SeitenPilot Hydraulic System M315CMEULEYE100% (1)

- Turbochargers, Final Report of The SeminarDokument19 SeitenTurbochargers, Final Report of The SeminarMuddukrishna C Shetty91% (22)

- Wa380-7 Venss04200 1212 PDFDokument24 SeitenWa380-7 Venss04200 1212 PDFRicardo SanzanaNoch keine Bewertungen

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesDokument9 SeitenEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceNoch keine Bewertungen

- What Is Forced Induction?Dokument15 SeitenWhat Is Forced Induction?Fugaru Paul - AlexandruNoch keine Bewertungen

- Air and Fuel Induction - FiveDokument35 SeitenAir and Fuel Induction - FiveasfsaedgarNoch keine Bewertungen

- 6 TURBOCHARGING v2Dokument27 Seiten6 TURBOCHARGING v2Tuan Linh VoNoch keine Bewertungen

- Supercharging and TurbochargingDokument8 SeitenSupercharging and TurbochargingMudassir Hussain100% (1)

- 8 1turbochargerDokument24 Seiten8 1turbochargerkedir67Noch keine Bewertungen

- Induction SystemDokument6 SeitenInduction SystemDaniel MkandawireNoch keine Bewertungen

- Ch-12 - Turbocharger & Super MecDokument29 SeitenCh-12 - Turbocharger & Super Mecahmed jemalNoch keine Bewertungen

- 17ME655-Module 4 PDFDokument40 Seiten17ME655-Module 4 PDFVinayakNoch keine Bewertungen

- Ic Engine: Assignment#02Dokument9 SeitenIc Engine: Assignment#02Jawad ZafarNoch keine Bewertungen

- TURBOCHARGERDokument5 SeitenTURBOCHARGERAnand Raju100% (1)

- SuperchargerDokument27 SeitenSuperchargerRamachandran SubburathinamNoch keine Bewertungen

- Lec-9 - MCE 4805 - Diesel Power PlantDokument44 SeitenLec-9 - MCE 4805 - Diesel Power PlantWinden CaveNoch keine Bewertungen

- Air Induction For Diesel Engines3Dokument8 SeitenAir Induction For Diesel Engines3Musa TandiarrangNoch keine Bewertungen

- Turbocharging & SuperchargingDokument2 SeitenTurbocharging & SuperchargingAndrei JatariuNoch keine Bewertungen

- Chapter 12 Supercharging TurbochargingDokument33 SeitenChapter 12 Supercharging Turbochargingdesie yalewNoch keine Bewertungen

- Supercharging and TurbochargingDokument3 SeitenSupercharging and Turbocharging13311A0341 S SHIVA SAI KIRANNoch keine Bewertungen

- Super ChargingDokument24 SeitenSuper ChargingGagan KaushikNoch keine Bewertungen

- What Is Stratified Charge Engine?Dokument18 SeitenWhat Is Stratified Charge Engine?ÅBin PÅulNoch keine Bewertungen

- Himanshu Singh Turbocharger-SeminarDokument20 SeitenHimanshu Singh Turbocharger-SeminarHimanshu SinghNoch keine Bewertungen

- Turbo NotesDokument18 SeitenTurbo NotescleousNoch keine Bewertungen

- Supercharger VS TurbochargerDokument25 SeitenSupercharger VS TurbochargerAllen CastorNoch keine Bewertungen

- The BG Tuning ManualDokument7 SeitenThe BG Tuning ManualNidhin JoseNoch keine Bewertungen

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDokument6 SeitenKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindreNoch keine Bewertungen

- Chapter 1Dokument61 SeitenChapter 1anup chauhanNoch keine Bewertungen

- Turbocharger and SuperchargerDokument16 SeitenTurbocharger and SuperchargerPrajwal ZinjadeNoch keine Bewertungen

- Turbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Dokument25 SeitenTurbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Vinod SubramaniamNoch keine Bewertungen

- GDI Stratified Charge Engine 1Dokument9 SeitenGDI Stratified Charge Engine 1Jasdeep SandhuNoch keine Bewertungen

- Turbo ChargerDokument18 SeitenTurbo ChargerRangappa swamyNoch keine Bewertungen

- Turbo ChargerDokument19 SeitenTurbo ChargerHamimi AkmalNoch keine Bewertungen

- Air EngineDokument5 SeitenAir EngineVinay MohanNoch keine Bewertungen

- SuperchargingDokument44 SeitenSuperchargingbslawsNoch keine Bewertungen

- Types of Jet Engines: 6.1 TurbojetDokument20 SeitenTypes of Jet Engines: 6.1 Turbojetapi-376777497Noch keine Bewertungen

- Turbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDokument19 SeitenTurbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDeepak Satpathy0% (1)

- AEMSDokument28 SeitenAEMSGARVIT SRIVASTAVANoch keine Bewertungen

- AGK Final QuestionsDokument17 SeitenAGK Final Questionsİrem DdNoch keine Bewertungen

- Operating PrincipleDokument6 SeitenOperating PrincipleGedan CristianNoch keine Bewertungen

- 5 2020 10 06!03 05 20 AmDokument10 Seiten5 2020 10 06!03 05 20 AmHakim ChelghamNoch keine Bewertungen

- Diesel EngineDokument5 SeitenDiesel EnginejaftcolNoch keine Bewertungen

- Turbocharging of Ic EnginesDokument5 SeitenTurbocharging of Ic EnginesKrishna MurthyNoch keine Bewertungen

- Automotive Superchargers and Turbochargers: U.S. Air Force, Colorado Springs, Colorado, U.S.ADokument48 SeitenAutomotive Superchargers and Turbochargers: U.S. Air Force, Colorado Springs, Colorado, U.S.APatricia LozerNoch keine Bewertungen

- Turbo PDFDokument16 SeitenTurbo PDFAdnin HakeemNoch keine Bewertungen

- Natural Aspirated EnginesDokument10 SeitenNatural Aspirated EnginesakshithaNoch keine Bewertungen

- IC Engine QuestionsDokument18 SeitenIC Engine QuestionswasemNoch keine Bewertungen

- EMEg 5221 Chapter 12 13 14Dokument51 SeitenEMEg 5221 Chapter 12 13 14Yoseph MershaNoch keine Bewertungen

- Lubrication: Source - WikipediaDokument3 SeitenLubrication: Source - WikipediaWolfMensch1216Noch keine Bewertungen

- Tank Container Relief Vent Valve RV 30, RV 40 RV 30 RV 40: GestraDokument2 SeitenTank Container Relief Vent Valve RV 30, RV 40 RV 30 RV 40: Gestrastefanovicana1Noch keine Bewertungen

- A Topology Based Approach For Exploiting Sparsity in Multibody Dynamics in Cartesian FormulationDokument18 SeitenA Topology Based Approach For Exploiting Sparsity in Multibody Dynamics in Cartesian Formulationstefanovicana1Noch keine Bewertungen

- Tank ComponentsDokument12 SeitenTank Componentsstefanovicana1Noch keine Bewertungen

- Frequently Asked Questions (FAQ) Regarding WP.29: (Updated On May 2005)Dokument17 SeitenFrequently Asked Questions (FAQ) Regarding WP.29: (Updated On May 2005)stefanovicana1Noch keine Bewertungen

- Text With EEA RelevanceDokument26 SeitenText With EEA Relevancestefanovicana1Noch keine Bewertungen

- Volvo Sept 2011 PV776-K-BodyBuilder Kit TOCDokument1 SeiteVolvo Sept 2011 PV776-K-BodyBuilder Kit TOCstefanovicana1Noch keine Bewertungen

- Vehicle Sideslip and Roll Parameter Estimation Using GPSDokument8 SeitenVehicle Sideslip and Roll Parameter Estimation Using GPSstefanovicana1Noch keine Bewertungen

- 7series Sedan CatalogueDokument9 Seiten7series Sedan Cataloguestefanovicana1Noch keine Bewertungen

- x3 CatalogueDokument10 Seitenx3 Cataloguestefanovicana1Noch keine Bewertungen

- BWM 0000002 01Dokument28 SeitenBWM 0000002 01stefanovicana1Noch keine Bewertungen

- Adjoint Sensitivity Analysis For Differential-Algebraic Equations: The Adjoint Dae System and Its Numerical SolutionDokument14 SeitenAdjoint Sensitivity Analysis For Differential-Algebraic Equations: The Adjoint Dae System and Its Numerical Solutionstefanovicana1Noch keine Bewertungen

- Engine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and ControlDokument6 SeitenEngine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and Controlstefanovicana1Noch keine Bewertungen

- YTR4105G69 YTO Part List EngineDokument75 SeitenYTR4105G69 YTO Part List Enginericardobarreto10Noch keine Bewertungen

- HYSTER GPS - Hyster (W40XL) (W40XT) Parts ManualDokument13 SeitenHYSTER GPS - Hyster (W40XL) (W40XT) Parts ManualMelwyn FernandesNoch keine Bewertungen

- Insurance Bidder Margin Tax Transportation RC Charges Warranty Parking Charges Total Cost DisclaimerDokument3 SeitenInsurance Bidder Margin Tax Transportation RC Charges Warranty Parking Charges Total Cost Disclaimersaurabh singhNoch keine Bewertungen

- Classified: Your Local MarketplaceDokument5 SeitenClassified: Your Local MarketplaceDigital MediaNoch keine Bewertungen

- Upah Machine Operator Jan 12 - SabahuploadDokument2 SeitenUpah Machine Operator Jan 12 - SabahuploadJayson TeeNoch keine Bewertungen

- 1-Nguyen Ly Cua OBD (English)Dokument9 Seiten1-Nguyen Ly Cua OBD (English)Thanh Tùng HuỳnhNoch keine Bewertungen

- Ashok LeylandsDokument24 SeitenAshok Leylandsbhavna100% (4)

- MG Motors Updated 1Dokument9 SeitenMG Motors Updated 1Shivam JadhavNoch keine Bewertungen

- FlexiLite Minibus Brochure April17 WEB PDFDokument8 SeitenFlexiLite Minibus Brochure April17 WEB PDFLee JonesNoch keine Bewertungen

- TDC-15-S-02 Road and Traffic RulesDokument7 SeitenTDC-15-S-02 Road and Traffic RulesSanty UyNoch keine Bewertungen

- Genuine Buddy 50 125 150 170 Owners Manual ENDokument44 SeitenGenuine Buddy 50 125 150 170 Owners Manual ENTerrence JonesNoch keine Bewertungen

- Alternator and Starter Quick Reference GuideDokument545 SeitenAlternator and Starter Quick Reference GuideRodrigo Alejandro Ramírez ZamoraNoch keine Bewertungen

- Cat De88 GC: ® Diesel Generator SetsDokument2 SeitenCat De88 GC: ® Diesel Generator SetsApo ghasan Al shargapiNoch keine Bewertungen

- 6001 - 24' Dry Box Truck 2019 Hino 268: Cap Cost: $81,728.00Dokument5 Seiten6001 - 24' Dry Box Truck 2019 Hino 268: Cap Cost: $81,728.00Mwita william josephNoch keine Bewertungen

- KIA Cerato - From 2011 - Fuse Box Diagram - Auto GeniusDokument6 SeitenKIA Cerato - From 2011 - Fuse Box Diagram - Auto Geniusromance.cavalier1Noch keine Bewertungen

- Wheel and Rim Truing - WWW - Parktool - ComDokument5 SeitenWheel and Rim Truing - WWW - Parktool - ComJose Luis SabinoNoch keine Bewertungen

- Geely 7DCT TransmissionDokument4 SeitenGeely 7DCT Transmissionsebaa taha amineNoch keine Bewertungen

- Electric Hoist CatalogDokument2 SeitenElectric Hoist Catalogsaddam4everNoch keine Bewertungen

- Spacex Dragon: Us Commercial Servicing and Logistic VehicleDokument4 SeitenSpacex Dragon: Us Commercial Servicing and Logistic VehicleSafi Ullah WarraichNoch keine Bewertungen

- 2007-08 IQ Service Manual PDFDokument325 Seiten2007-08 IQ Service Manual PDFBrianCookNoch keine Bewertungen

- PM Clinic WA500-3LEDokument3 SeitenPM Clinic WA500-3LEJheison ValenciaNoch keine Bewertungen

- Principles of MarketingDokument5 SeitenPrinciples of MarketingAman Ahmad UrfiNoch keine Bewertungen

- Productivity For A World That'S Always N.: X12 For Truck ApplicationsDokument6 SeitenProductivity For A World That'S Always N.: X12 For Truck ApplicationsOscar CampoNoch keine Bewertungen