Beruflich Dokumente

Kultur Dokumente

Cold Applied

Hochgeladen von

Rakesh PandeyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cold Applied

Hochgeladen von

Rakesh PandeyCopyright:

Verfügbare Formate

108

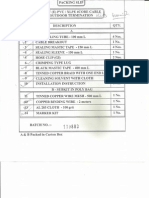

COLD APPLIED

Energy Division

Cold Applied

Page

TFTI / TFTO Push-on Terminations up to 42 kV

110

TFTI / TFTO Pre-expanded Terminations up to 42 kV

112

MVTI / MVTO Silicone Push-on Termination

115

CSJR / CSJH Straight Joint up to 36 kV

120

CSJH Straight Joint up to 36 kV

123

CSJA All in One Joint up to 36 kV

124

109

Raychem TFTI/TFTO Push-on elastomeric medium voltage terminations for indoor and outdoor applications for single core polymeric cables up to 42 kV

Product range The product line is designed for single core plastic cables up to 42 kV cables. This coverage is completed with a minimum number of designs. Pre-expanded versions are available. The products are fully tested to CENELEC specification HD 629 and to IEEE Std. 48-1996 which encompasses international standards such as IEC, British Standard (BS) and VDE. For cable box applications TFT can be combined with either Raychem bushing boot (RCAB) or Raychem insulated connection system (RICS) to fit most types of switchgear currently available in todays market place. For pole top applications we can supply TFT along with polymeric insulators (EPBI), Polygarde surge arresters and most fittings required for installation. Under regular circumstances, all of the TFT components have full traceability back to the origin of manufacture and raw materials. The TFT includes: a non-tracking, silicone-based elastomeric body a stress control patch self amalgamating sealant tape These components combine to provide the same important functions as heat-shrink products: electrical performance, stress control, and moisture sealing. Because of the inherent physical property differences between semi-crystalline and rubbery polymers, the TFT stress control and sealant materials are tailored to achieve optimum performance with an elastomeric system.

Kit content Each TFT product will generally consist of the termination body unexpanded or expanded, a stress control patch, sealant tapes, silicone grease, a small PE bag as assembly tool and installation instructions. For special applications contact your local sales representative. The right kit for your cable range can be selected with the help of the selection table. Installation Each kit contains an easy to follow installation instruction with excellent visual displays of the installation steps. Installation is both fast and simple.

Raychem TFTO out termination

A Sealant tape B Termination body C Stress control patch D Sealant tape

110

Energy Division

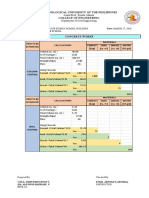

TFT Terminations Pre-Expanded version Cross sections in mm2 12 kV 17.5 kV Indoor/Outdoor Indoor/Outdoor 1 25 70 2 50 185 3 150 400* 4 5 *Larger on request **Three shed housing 25 95 95 300 240 400 500 630

24 kV Indoor/Outdoor 25 95 70 240 240 400 500 630**

36 kV Indoor/Outdoor 35 120 95 300* 240 400*

42 kV Indoor/Outdoor mm 35 95 95 185 240 400*

Diameter over insulation in 12.5 16.0 21.5 27.0 37.0 20.0 27.0 36.0 45.0 56.0

TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 12 kV Cross Section Kit Number Indoor TFTI-E3122 TFTI-E3132 TFTI-E3142 TFTI-E3152 Kit Number Outdoor TFTO-E3122 TFTO-E3132 TFTO-E3142 TFTO-E3152

TFTI/TFTO termination family 1 2 Indoor up to 17.5 kV Outdoor up to 12 kV Indoor up to 24 kV Outdoor up to 17.5 kV Outdoor up to 24 kV Indoor up to 42 kV Outdoor up to 42 kV

25 95 95 185 300 400 500 630

3 4

5 TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 24 kV Cross Section Kit Number Indoor TFTI-E5122 TFTI-E5132 TFTI-E5142 TFTI-E5152 Kit Number Outdoor TFTO-E5122 TFTO-E5132 TFTO-E5142 TFTO-E5152 1

25 95 95 300 300 400 500 630

TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 36 kV Cross Section Kit Number Indoor TFTI-E6132 TFTI-E6142 TFTI-E6152 Kit Number Outdoor TFTO-E6132 TFTO-E6142 TFTO-E6152

95 240 300 400 500 630

111

Raychem TFTI/TFTO Pre-expanded elastomeric medium voltage terminations for indoor and outdoor applications for single core polymeric cables up to 42 kV

Benefits Compact design Few components Simple and fast to install Re-positioning after installation possible Superior application ranges Designed for both indoor and outdoor use in all climate conditions, the TFT range covers applications on single core plastic cables up to 42 kV. The TFT has been developed to complement the Raychem termination product line. TFT includes an elastomeric body material in contrast to the semi-crystalline polymeric body of the heat-shrink terminations. Both types of bodies consist of crosslinked polymer networks and both types of terminations are easy to install over a range of cable sizes.

The TFT includes: a non-tracking, silicone-based, pre-expanded elastomeric body a stress control patch self amalgamating sealant tape These components combine to provide the same important functions as heat-shrink products: electrical performance, stress control, and moisture sealing. Because of the inherent physical property differences between semi-crystalline and rubbery polymers, the TFT stress control and sealant materials are tailored to achieve optimum perfor-mance with an elastomeric system.

Raychem TFTO out termination

Kit content Each standard TFT product consists of an outer elastomeric termination body on a pre-lubricated, crush resistant core (holdout), a stress control patch, sealant tapes and installation instructions. For special applications contact your local sales representative. The right kit for your cable range can be selected with the help of the selection table on next page. Installation Each kit contains an easy to follow installation instruction with excellent visual displays of the installation steps. Installation is both fast and simple.

A Sealant tape B Termination body

Raychem TFT components

C Stress control patch D Sealant tape

112

Energy Division

TFTI/TFTO Selection Table

Application

Voltage in kV

[Um]

I O

Cores

Indoor Outdoor Single core polymeric cable

3 4 5 6

12 17.5 24 36 + 42

TFT Terminations Pre-Expanded version Cross sections in mm2

12 kV 17.5 kV 24 kV Indoor/Outdoor Indoor/Outdoor Indoor/Outdoor 1 2 3 4 5

*Larger on request **Only indoor

36 kV Indoor/Outdoor 35 150 150 400 400 630*

25 70 70 185 150 400 400*

25 50** 50 150 120 300 300 400*

25 95 95 300 240 400*

42 kV Indoor/Outdoor mm 35 120 95 240*

Diameter over insulation in 13.5 17.0 23.0 30.0 42.0 21.0 28.0 37.0 46.0

60.0

TFT x - x x x x

TFT Application

Elastomeric Termination I = Indoor O = Outdoor 3 4 5 6 = = = = 12 kV 17.5 kV 24 kV 36 kV + 42 kV

Voltage

Cores Cross-sections Delivery

1 = single core cable see above table 2

For example: TFTI-5132 Indoor termination for single core polymeric cable 24 kV, 95 300 mm2 (Pre-Expanded version) TFTI-5131 Indoor termination for single core polymeric cable 24 kV, 95 240 mm2 (Push-On version)

113

Energy Division

TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 12 kV Cross Section Kit Number Indoor Kit Number Outdoor

25 95 95 185 300 400 500 630

TFTI-E3122 TFTI-E3132 TFTI-E3142 TFTI-E3152

TFTO-E3122 TFTO-E3132 TFTO-E3142 TFTO-E3152

TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 24 kV Cross Section Kit Number Indoor Kit Number Outdoor

25 95 95 300 300 400 500 630

TFTI-E5122 TFTI-E5132 TFTI-E5142 TFTI-E5152

TFTO-E5122 TFTO-E5132 TFTO-E5142 TFTO-E5152

TFTI-E/TFTO-E Pre-expanded termination single core plastic cable Voltage 36 kV Cross Section Kit Number Indoor Kit Number Outdoor

95 240 300 400 500 630

TFTI-E6132 TFTI-E6142 TFTI-E6152

TFTO-E6132 TFTO-E6142 TFTO-E6152

TFTI/TFTO termination family

1 2

Indoor up to 17.5 kV Outdoor up to 12 kV Indoor up to 24 kV Outdoor up to 17.5 kV Outdoor up to 24 kV Indoor up to 42 kV Outdoor up to 42 kV

3 4

114

Raychem MVTI/MVTO silicone push-on termination with integrated stress control for single core polymeric cables up to 36/42kV

Features: One piece termination Integrated geometrical stress cone Suitable for hexagonal/deep indentcrimp and mechanical lugs according to IEC 61238 Compact design Long creepage distance Easy to install Reduced waste for disposal Tested in accordance to CENELEC HD.629.1.S2:2006 and IEC 60502-4 Manufactured according to ISO 9001 and ISO 14001

Benefits: Outstanding weathering, UV and Ozone Resistance Chemically resistant Resistant to fungi Excellent electrical properties including good tracking resistance and high dielectric strength Hydrophobic (water hating/repelling) Non-Flammable Self Extinguishing Retains performance over wide temperature range 55 to +180C Highly elastic material with good resistance to permanent set No shelf-life issues All components have full traceability of raw materials Application range The product line is designed for polymer cables from 25 to 300 mm2 and up to 42 kV. This coverage is achieved with only two sizes of termination bodies on each voltage class.

Insulation material The material used in the MVTI/MVTO generation have undergone many years of development to yield a high performance, next generation liquid silicone rubber, with exceptional electrical and weathering properties. The formulation is based on proven silicone compounds, exhibiting excellent thermal stability and longterm performance, under severe environmental conditions. It delivers outstanding tracking and erosion resistance, very high dielectric strength combined with good mechanical strength and high elasticity. Integrated stress control cone It has an optimal geometrical shape and is made of a similar high performance liquid silicone rubber which has been tailored to be conductive. The excellent bonding to the insulation material has been carefully designed to achieve the necessary high electrical performance. The cone is located at the end of the cables outer conductive layer, during installation, to relieve any electrical stresses in this area.

115

Energy Division

Kit content Each MVTI/MVTO kit consists of the termination body, sealant tapes, installation aid PE bag, silicone lubricant and installation instruction. Optionally mechanical lugs and compression lugs are available. The brochure EPP-1233 exhibits more details on mechanical connections. For special applications contact your local sales representative.

Technical Data Cable insulation diameter Cross section range Max system voltage Um Basic impulse level Partial discharge at 2 U0 AC Voltage withstand, 5 min DC Voltage withstand, 15min

[mm] [mm2] [kV] [kV] [pC] [kV] [kV]

12kV 13.7 30.4 25 300 12 95 <5 28.5 38

24kV 17.0 34.6 25 300 24 125 <5 57 76

36/42kV 24.0 39.6 35 300 36/42 194/200* <5 81/94 108/120

The terminations meet the CENELEC HD 629.1.S2:2006 specification *170kV BIL for 35 150mm2 Indoor termination MVTI-6121, 81kV AC, 108kV DC

Dimensions as delivered Termination Height housing [mm] 276 276 276 355 355 355 Creepage Flashover distance distance [mm] [mm] 412 412 412 675 676 676 284 284 284 368 369 369 Diameter Installed over sheds length L1* [mm] [mm] 76.3 76.3 80.1 97.3 101.1 101.1 265 265 285 345 365 365

12kV MVTO-3131 24kV MVTI-5121 MVTI-5131 MVTO-5121 MVTO-5131 36/42kV MVTI-6121

* Terminations with mechanical lug type BLMT, and depending on cable construction Application ranges for Indoor and Outdoor Cable cross section [mm2] 12kV MVTO-3131 24kV MVTI-5121/MVTO-5121 MVTI-5131/MVTO-5131 36/42kV MVTI-6121 95 - 300 25 95 95 - 300 35 150 Diameter over insulation [mm] 18.6 30.4 17.9 25.0 23.5 34.6 24.0 33.5 Application range termination body [mm] 17 - 30 17 - 30 21 - 37 21 - 37

L1

The application range given in the table is based on polymeric insulated cables according to HD 620 A2: (2004) with stranded circular conductors. Due to different conductor dimensions and/or cable constructions the minimum and maximum application range may be extendable. Please contact your local sales representative.

116

Energy Division

MVTO Push-on Termination with mechanical lug BLMT Cross Section [mm2] 95 150 95 150 95 240(300)* 95 240(300)* Kit Number Outdoor MVTO-3131-ML-2-13 MVTO-3131-ML-2-17 MVTO-3131-ML-4-13 MVTO-3131-ML-4-17 Diameter over insulation [mm] 18.6 30.4 18.6 30.4 18.6 30.4 18.6 30.4

MVTO Push-on Termination for crimp lug Cross Section [mm2] 95 240 300 Kit Number Outdoor MVTO-3131 MVTO-3141 Diameter over insulation [mm] 18.6 30.4 28.0 30.4

MVTI Push-on Termination with mechanical lug BLMT Cross Section [mm2] 25 95 25 95 95 240(300)* 95 240(300)* 120 300** 120 300** Kit Number Indoor MVTI-5121-ML-1-13 MVTI-5121-ML-1-17 MVTI-5131-ML-4-13 MVTI-5131-ML-4-17 MVTI-5131-ML-5-13 MVTI-5131-ML-5-17 Diameter over insulation [mm] 17.9 25.0 17.9 25.0 23.5 34.6 23.5 34.6 24.3 34.6 24.3 34.6

MVTO Push-on Termination with mechanical lug BLMT Cross Section [mm2] 25 95 25 95 95 240(300)* 95 240(300)* 120 300** 120 300** Kit Number Outdoor MVTO-5121-ML-1-13 MVTO-5121-ML-1-17 MVTO-5131-ML-4-13 MVTO-5131-ML-4-17 MVTO-5131-ML-5-13 MVTO-5131-ML-5-17 Diameter over insulation [mm] 17.9 25.0 17.9 25.0 23.5 34.6 23.5 34.6 24.3 34.6 24.3 34.6

* the kits suits 300mm2 solid Al conductor ** the kit suit 300mm2 round stranded conductor -13 = hole for M12 -17 = hole for M16

117

Energy Division

MVTI Push-on Termination for crimp lug Cross Section [mm2] 25 95 95 300 Kit Number Indoor MVTI-5121 MVTI-5131 Diameter over insulation [mm] 17.9 25.0 23.5 34.6

MVTO Push-on Termination for crimp lug Cross Section [mm2] 25 95 95 300 Kit Number Outdoor MVTO-5121 MVTO-5131 Diameter over insulation [mm] 17.9 25.0 23.5 34.6

MVTI Push-on Termination with mechanical lug BLMT Cross Section [mm2] 35 150 35 150 -13 = hole for M12 -17 = hole for M16 Kit Number Indoor MVTI-6121-ML-2-13 MVTI-6121-ML-2-17 Diameter over insulation [mm] 21 37.0 21 37.0

MVTI Push-on Termination for crimp lug Cross Section [mm2] 35 150 Kit Number Indoor MVTI-6121 Diameter over insulation [mm] 21 37.0

118

Energy Division

119

CSJR / CSJH Cold shrinkable straight joints for polymeric insulated cables up to 36 kV

Features Pre-expanded, single piece silicone rubber joint body with high mechanical expansion capability allows a wide application range Electrical stress control of the screen cut area by integrated conductive geometrical stress cones Electrical stress control of the connector area by an integrated screened connection area (Faraday cage) Pre-expansion on a well-known and easy-to-install holdout system Choice of outer sealing and protection systems Easy-to-install joint system with short installation time Exceeds CENELEC HD 629.1, requirements which include IEC, BS, VDE and other international specifications

Mechanical shear bolt connectors to IEC 61238-1 with wide application range for conductor and wire shield can be supplied with the kit Proven shield continuity concept General CSJR/CSJH joints offer a reliable, fast and easy-to-install jointing system to assure and maintain high network reliability. A silicone rubber joint body with integrated geometrical stress cones and Faraday cage provides excellent electrical stress control. CSJR/CSJH joints are designed to cover a wide range of applications and to accommodate the variety of cable and conductor types in the networks. Rangetaking mechanical connectors ensuring reliable installation and service can be supplied with the kit.

1 Mechanical shear bolt connectors CSJR/CSJH joints are available with Tyco Electronics BSM mechanical connectors fitted with shear head bolts to ensure a reliable connection for different conductor materials, shapes and types used in todays network. The pre-set shear torque of the bolts ensures that the correct contact pressure is always achieved. The specially designed contact surface on the inside of the connector breaks up any oxide layer and ensures reliable service over the entire life of the joint. Different sizes of mechanical connectors with wide application ranges are available. The connectors have been tested in accordance with IEC-61238-1 class A.

120

Energy Division

2 Pre-expanded silicone joint body The silicone rubber joint body is delivered in a pre-expanded condition on a spiral holdout system. Silicone materials with excellent mechanical properties allow high expansion forces and therefore guarantee a wide application range. Integrated stress control mechanism and conductive outer layer provide exceptional electrical performance. The joint body can be easily removed from the spiral holdout with low release forces, particularly designed for joint applications.

3 Electrical stress control Electrical stress control is fully integrated in the silicone joint body by well defined conductive areas. Conductive cones with an exactly defined geometrical design over the screen cut area provide excellent electrical stress control. The electrical stress control of the connector area is made with an integrated conductive screen performing as a Faraday cage. The coverage of voids and edges at the connection area with void fillers is not necessary.

4 Shield continuity Typical shield wire cross sections up to 35 mm2 can easily be connected by either mechanical or compression connectors. Positioned at the oversheath cut-back, the connection provides a smooth profile resistant to mechanical damage. For kits with Tyco Electronics BSM mechanical connectors a mechanical shield wire connector is supplied. The two shear bolts of the shield connector provide the required contact force in order to ensure secure installation and reliable performance. Additional layers of copper mesh are applied around the joint to provide shielding and protection Cordless impact wrench For the installation of mechanical connectors a cordless impact wrench is available. This tool allows simpler, safer and faster installation compared with manual installation. It can be used for shear-head bolts up to 100 Nm torque. The motor is constructed with heavy gauge copper coils and the striker is designed to deliver maximum power output while withstanding extreme heat and stress. This tool has externally accessible and replaceable carbon brushes, thereby guaranteeing long service life. The machine comes in a rigid compartmented carrying case with all hexagon sockets and keys necessary for standard mechanical connectors and lugs. The powerful battery is sufficient for approximately 20 four-bolted connectors per battery charging cycle.

the joint system. Rayvolve sleeves have more than 20 years service experience in cable rejacketing systems worldwide. On CSJH joints the outer sealing and protection is provided by a thick-wall, heat-shrinkable tubing. Effective moisture seal and corrosion protection for the joint is ensured by the co-extruded hot melt adhesive. When installed, the heat-shrinkable tubing provides a similar level of protection as the PE oversheath of modern cables. 5 Outer sealing and protection CSJx joints are available with alternative re-jacketing methods. CSJR joints include a dual-wall Rayvolve sleeve with entrapped lubricant. The elastomeric sleeve rolls onto the cable and over the joint area. The gripping force of the specially formulated EPDM elastomer combined with a high performance sealant forms a reliable moisture seal and corrosion protection for

121

Energy Division

CSJR joint with mechanical connector Application range* [mm2] 95 185 240 500 630 35 95 120 185 500 630 95 240 500 630 240 300 400 CSJR-12B/1XU-1XU-M CSJR-12C/1XU-1XU-M CSJR-12D/1XU-1XU-M CSJR-12E/1XU-1XU-M1 CSJR-12E/1XU-1XU-M2 CSJR-24B/1XU-1XU-M CSJR-24C/1XU-1XU-M1 CSJR-24C/1XU-1XU-M2 CSJR-24D/1XU-1XU-M CSJR-24E/1XU-1XU-M1 CSJR-24E/1XU-1XU-M2 CSJR-36D/1XU-1XU-M CSJR-36E/1XU-1XU-M1 CSJR-36E/1XU-1XU-M2 CSJR-36E/1XU-1XU-M3 Kit description Diameter over core insulation [mm] 18.6 23.2 25.7 34.4 38.0 18.9 23.5 24.3 27.4 37.9 41.0 27.8 34.9 42.6 45.8 28.4 32.6 33.6 36.2 40.0 28.5 32.6 34.6 37.8 40.6 44.0 37.6 42.8 45.6 49.2 Diameter over outer sheath [mm] 26.0 30.0 33.0 43.0 47.0 26.0 30.0 32.0 35.0 46.0 56.0 35.0 42.0 51.0 56.0 39.0 44.0 45.0 48.0 52.0 39.0 44.0 46.0 49.0 52.0 57.0 48.0 54.0 57.0 61.0 Diameter over conductor ** [mm] 11.0 15.5 17.8 25.7 29.3 6.8 11.0 12.5 15.5 25.7 29.3 11.0 17.8 25.7 29.3 19.2 23.1 24.6 27.6 32.5 19.2 19.2 21.6 24.6 27.6 32.5 19.2 24.6 27.6 32.5

12 kV

24 kV

150 240 300 400

36 kV

240 400

CSJH joint with mechanical connector Application range* [mm2] 95 185 240 500 630 35 95 120 185 500 630 95 240 500 630 240 300 400 CSJH-12B/1XU-1XU-M CSJH-12C/1XU-1XU-M CSJH-12D/1XU-1XU-M CSJH-12E/1XU-1XU-M1 CSJH-12E/1XU-1XU-M2 CSJH-24B/1XU-1XU-M CSJH-24C/1XU-1XU-M1 CSJH-24C/1XU-1XU-M2 CSJH-24D/1XU-1XU-M CSJH-24E/1XU-1XU-M1 CSJH-24E/1XU-1XU-M2 CSJH-36D/1XU-1XU-M CSJH-36E/1XU-1XU-M1 CSJH-36E/1XU-1XU-M2 CSJH-36E/1XU-1XU-M3 Kit description Diameter over core insulation [mm] 18.6 23.2 25.7 34.4 38.0 18.9 23.5 24.3 27.4 37.9 41.0 27.8 34.9 42.6 45.8 28.4 32.6 33.6 36.2 40.0 28.5 32.6 34.6 37.8 40.6 44.0 37.6 42.8 45.6 49.2 Diameter over outer sheath [mm] 26.0 30.0 33.0 43.0 47.0 26.0 30.0 32.0 35.0 46.0 56.0 35.0 42.0 51.0 56.0 39.0 44.0 45.0 48.0 52.0 39.0 44.0 46.0 49.0 52.0 57.0 48.0 54.0 57.0 61.0 Diameter over conductor ** [mm] 11.0 15.5 17.8 25.7 29.3 6.8 11.0 12.5 15.5 25.7 29.3 11.0 17.8 25.7 29.3 19.2 23.1 24.6 27.6 32.5 19.2 19.2 21.6 24.6 27.6 32.5 19.2 24.6 27.6 32.5

12 kV

24 kV

150 240 300 400

36 kV

240 400

122

CSJH Raychem MV cold shrinkable joint for 3-core cables with heat shrinkable protection

Features Pre-expanded, single piece silicone rubber joint body with high mechanical expansion capability allows a wide application range Electrical stress control of the screen cut area by integrated conductive geometrical stress cones

Electrical stress control of the connector area by an integrated screened connection area (Faraday cage) Pre-expansion on a well-known and easy-to-install holdout system Proven shield continuity concept The WCSM heat shrinkable outer protection provides effective impact resistance.

Hot melt adhesive ensures an effective moisture seal and corrosion protection Exceeds CENELEC HD 629.1, requirements which include IEC, BS, VDE and other international specications

CSJH 3-core joint without connector Application range* [mm2] 95 - 240 185 - 300 35 - 185 95 - 300 Kit description Diameter over core insulation [mm] 18.6 - 28.4 23.2 - 32.6 18.9 - 30.1 23.5 - 34.6 Diameter over outer sheath [mm] 50.0 - 120.0 50.0 - 120.0 50.0 - 120.0 50.0 - 120.0 Admissible connector dimensions Max. length Max. dia [mm] [mm] 145.0 33.0 145.0 37.0 145.0 33.0 145.0 37.0

12 kV 24 kV

*

CSJH-12B/3XU-3XU CSJH-12C/3XU-3XU CSJH-24B/3XU-3XU CSJH-24C/3XU-3XU

The application range given in the table is based on polymeric insulated cables according to IEC 60502 with stranded circular conductors. Due to different conductor dimensions and/or cable constructions the minimum and maximum application range may be extendable. Please contact your local sales representative.

Note: CSJH 3-core joints can be supplied with compression connectors or Tyco Electronics mechanical BSM connectors. CSJH 3-core joints can be modied for armoured and/or wire shield cables. Please contact your local sales representative. Test Report PPR-2180 Qualication of CSJH-24C/3XU-3XU-M for application up to 24 kV

123

CSJA Raychem MV cold shrinkable All-In-One straight joint for polymeric insulated cables

Features Joint body, earthing system and rejacketing pre-expanded on one holdout system Single piece silicone rubber joint body with high mechanical expansion capability allows a wide application range Electrical stress control of the screen cut area by integrated conductive geometrical stress cones Electrical stress control of the connector area by an integrated screened connection area (Faraday cage) Well-known and easy-to-install holdout system Short parking distance required Easy-to-install joint system with short installation time Exceeds CENELEC HD 629.1, requirements which include IEC, BS, VDE and other international specifications Mechanical shear bolt connector to IEC 61238-1 is supplied with the kit Proven shield continuity concept

General CSJA joints offer a reliable, fast and easyto-install jointing system to assure and maintain high network reliability. All key components are pre-expanded on one holdout system, allowing a very short parking length during cable preparation. A silicone rubber joint body with integrated geometrical stress cones and Faraday cage provides excellent electrical stress control. CSJA joints are designed to cover a wide range of applications and to accommodate the variety of cable and conductor types in the networks. Range-taking mechanical connectors ensuring reliable installation and service are supplied with the kit. 1 Mechanical shear bolt connectors CSJA joints are provided with Tyco Electronics BSM mechanical connectors fitted with shear head bolts to ensure a reliable connection for different conductor materials, shapes and types used in todays network. The pre-set shear torque of the bolts ensures that the correct contact pressure is always achieved. The specially designed contact surface on the inside of the connector breaks up any oxide layer and ensures reliable service over the entire life of the joint.

Different sizes of mechanical connectors with wide application ranges are available. The connectors have been tested in accordance with IEC-61238-1 class A. For the installation of mechanical connectors using shear-head bolts a cordless impact wrench can be supplied (IT-1000-023). 2 Pre-expanded silicone joint body The silicone rubber joint body is delivered in a pre-expanded condition on a spiral holdout system. Silicone materials with excellent mechanical properties allow high expansion forces and therefore guarantee a wide application range. Integrated stress control mechanism and conductive outer layer provide exceptional electrical performance. The joint body can be easily removed from the spiral holdout with low release forces, particularly designed for joint applications.

124

Energy Division

3 Electrical stress control Electrical stress control is fully integrated in the silicone joint body by well defined conductive areas. Conductive cones with an exactly defined geometrical design over the screen cut area provide excellent electrical stress control. The electrical stress control of the connector area is made with an integrated conductive screen performing as a Faraday cage. The coverage of voids and edges at the connection area with void fillers is not necessary.

4 Shield continuity The integrated pre-expanded copper mesh is connected to the cable screens by constant force roll springs. This connection method reliably operates during loadcycling and thermal short circuits of the conductors on all cable types regardless of whether the oversheath is PVC or PE. It provides a smooth profile which is resistant to mechanical impacts. The solderless earth connection has more than 25 years service experience in Tyco Electronics Raychem joint systems used worldwide.

5 Outer sealing and protection The CSJA joint has an integrated outer protection system which is already expanded onto the joint body and requires no additional parking distance. The EPDM sleeve combined with a high performance sealant forms a reliable moisture seal and corrosion protection. It is easy to install by just rolling out the flipped back rejacketing.

CSJA joint with mechanical connector Application range* [mm2] 95 - 240 185 - 300 240 - 400 500 630 35 - 150 95 - 240 120 - 300 185 - 400 500 630 95 - 240 240 - 400 500 630 Kit description Diameter over core insulation [mm] 18.6 - 28.4 23.2 - 32.6 25.7 - 33.6 34.4 - 36.2 38.0 - 40.0 18.9 - 28.5 23.5 - 32.6 24.3 - 34.6 27.4 - 37.8 37.9 - 40.6 41.0 - 44.0 27.8 - 37.6 34.9 - 42.8 42.6 - 45.6 45.8 - 49.2 Diameter over outer sheath [mm] 26.0 - 39.0 30.0 - 44.0 33.0 - 45.0 43.0 - 48.0 47.0 - 52.0 26.0 - 39.0 30.0 - 44.0 32.0 - 46.0 35.0 - 49.0 46.0 - 52.0 56.0 - 57.0 35.0 - 48.0 42.0 - 54.0 51.0 - 57.0 56.0 - 61.0 Diameter over conductor*** [mm] 11.0 15.5 17.8 25.7 29.3 6.8 11.0 12.5 15.5 25.7 29.3 11.0 17.8 25.7 29.3 -

12 kV

24 kV

36(42) kV

CSJA-12B/1XU-1XU-M CSJA-12C/1XU-1XU-M CSJA-12D/1XU-1XU-M CSJA-12E/1XU-1XU-M1 CSJA-12E/1XU-1XU-M2 CSJA-24B/1XU-1XU-M CSJA-24C/1XU-1XU-M1 CSJA-24C/1XU-1XU-M2 CSJA-24D/1XU-1XU-M CSJA-24E/1XU-1XU-M1 CSJA-24E/1XU-1XU-M2 CSJA-36D/1XU-1XU-M CSJA-36E/1XU-1XU-M1 CSJA-36E/1XU-1XU-M2 CSJA-36E/1XU-1XU-M3

19.2 23.1 24.6 27.6 32.5 15.0 19.2 23.1 24.6 27.6 32.5 19.2 24.6 27.6 32.5

* The application range given in the table is based on polymeric insulated cables according to IEC 60502 with stranded circular conductors. Due to different conductor dimensions and/or cable constructions the minimum and maximum application range may be extendable. Please contact your local sales representative. ** Max. block thickness of connector 10 mm ***

3

The diameter over conductor is needed only for kits including Tyco Electronics BSM connectors. The values given in the selection table refer to aluminium circular conductors and may change for other materials and shapes.

3 4 5

125

Das könnte Ihnen auch gefallen

- Term in Ales Premoldeadas para 15 KV y 34.5 KVDokument4 SeitenTerm in Ales Premoldeadas para 15 KV y 34.5 KVFranz Montero RamirezNoch keine Bewertungen

- Raychem TerminalesDokument26 SeitenRaychem TerminalesAcuario Chable Gomez100% (1)

- Cold Shrink Termination MVTI - MVTODokument6 SeitenCold Shrink Termination MVTI - MVTOdes1982Noch keine Bewertungen

- Trfricate Kit For 3C Cold Shrink TerminationDokument4 SeitenTrfricate Kit For 3C Cold Shrink Terminationdes1982Noch keine Bewertungen

- Anexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFDokument20 SeitenAnexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFAnonymous zd86j8vVNoch keine Bewertungen

- Hot oil resistant 150°C automotive engine wireDokument2 SeitenHot oil resistant 150°C automotive engine wireanna_malai078351Noch keine Bewertungen

- Cinta HVBTDokument2 SeitenCinta HVBTFaVCMNoch keine Bewertungen

- 3m qtII 5623kDokument4 Seiten3m qtII 5623kcerachuckNoch keine Bewertungen

- OFFSHORE CABLES CATALOGUEDokument88 SeitenOFFSHORE CABLES CATALOGUEErstendrain EngNoch keine Bewertungen

- Catalogo Cables Prysmian OffshoreDokument86 SeitenCatalogo Cables Prysmian OffshoreJuanNoch keine Bewertungen

- Heat-Shrink Terminations Selection GuideDokument3 SeitenHeat-Shrink Terminations Selection Guideminitaur8Noch keine Bewertungen

- CM Cc9000 Eng Int C Comp Catalogue - 6Dokument36 SeitenCM Cc9000 Eng Int C Comp Catalogue - 6Amauri SilvaNoch keine Bewertungen

- Ti SPC Ohe Inscom 107Dokument44 SeitenTi SPC Ohe Inscom 107mukeshhNoch keine Bewertungen

- TCJDokument12 SeitenTCJThilina Dhanushka GuluwitaNoch keine Bewertungen

- 01 66 KV 300 SQ MM 1 C POWER CABLEDokument27 Seiten01 66 KV 300 SQ MM 1 C POWER CABLETarun AggarwalNoch keine Bewertungen

- Micrometal CatalogDokument72 SeitenMicrometal Catalogdinu petreNoch keine Bewertungen

- Raychem Catalogue - APKT - 7.2kV To 36kVDokument2 SeitenRaychem Catalogue - APKT - 7.2kV To 36kVdes1982100% (2)

- Nexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFDokument25 SeitenNexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFnicesreekanthNoch keine Bewertungen

- Trihal Catalogue EN - 04062015Dokument29 SeitenTrihal Catalogue EN - 04062015César Luis Castillo Chilet100% (1)

- Shrink Polymer System - 24V To 36kV Cable Installation Materials PDFDokument68 SeitenShrink Polymer System - 24V To 36kV Cable Installation Materials PDFMichael Parohinog Gregas100% (1)

- Tyco Raychem Termination KitDokument6 SeitenTyco Raychem Termination Kitperumal1312Noch keine Bewertungen

- HVBT - Bus Bar Insulation Tape - 25 KVDokument2 SeitenHVBT - Bus Bar Insulation Tape - 25 KVLakshmi NarayananNoch keine Bewertungen

- Hauptkatalog 12-42kv GBDokument64 SeitenHauptkatalog 12-42kv GBrabchabNoch keine Bewertungen

- BushingDokument8 SeitenBushingrasheed313Noch keine Bewertungen

- Siemens Flex Cable PDFDokument107 SeitenSiemens Flex Cable PDFeliahud100% (1)

- LVIT DatasheetDokument2 SeitenLVIT DatasheetFaVCMNoch keine Bewertungen

- Telegatner Catalog Conectori RFDokument32 SeitenTelegatner Catalog Conectori RFcodrelluNoch keine Bewertungen

- TLC PDFDokument2 SeitenTLC PDFrahul05singhaNoch keine Bewertungen

- Section 6:: Insulators & Insulating CoversDokument20 SeitenSection 6:: Insulators & Insulating CoversAnonymous XS9jAhY1pENoch keine Bewertungen

- Recotec Rotafil enDokument16 SeitenRecotec Rotafil enJordan RileyNoch keine Bewertungen

- Teldor Instrumentation Cable CatalogueDokument40 SeitenTeldor Instrumentation Cable CatalogueGiraldoCarpioRamosNoch keine Bewertungen

- Tri CastDokument2 SeitenTri CastyoongleiNoch keine Bewertungen

- 3mtm Bpeo s1 Evolution 12 Tray Org Anise PDFDokument4 Seiten3mtm Bpeo s1 Evolution 12 Tray Org Anise PDFVinothchellappan VinothNoch keine Bewertungen

- Catalogues Phụ Kiện Cap Ngầm RaychemDokument44 SeitenCatalogues Phụ Kiện Cap Ngầm RaychemHo Jun Xian100% (1)

- PFISTERER CableSystems 300kV PDFDokument12 SeitenPFISTERER CableSystems 300kV PDFHashimAmrNoch keine Bewertungen

- NEXANS - Motionline - GB - 19nov10 - 1 Cabos PDFDokument102 SeitenNEXANS - Motionline - GB - 19nov10 - 1 Cabos PDFFernando BenzecryNoch keine Bewertungen

- Terminales y EmpalmesDokument167 SeitenTerminales y EmpalmesJose Luis Limongi VeltriNoch keine Bewertungen

- KACO 02xi Series Grid-Tied Inverters High Efficiency, FlexibilityDokument2 SeitenKACO 02xi Series Grid-Tied Inverters High Efficiency, FlexibilityKirsten HernandezNoch keine Bewertungen

- Amp Cat 6Dokument12 SeitenAmp Cat 6Rene BarbozaNoch keine Bewertungen

- Mufas DatatronixDokument3 SeitenMufas DatatronixChristianNoch keine Bewertungen

- Technical Specification For 11kv PanelDokument48 SeitenTechnical Specification For 11kv PanelCharles Benwari100% (1)

- Olex Cables PDFDokument116 SeitenOlex Cables PDFwillieferreiraNoch keine Bewertungen

- P.1.87.01 Linear Heat Detection CableDokument5 SeitenP.1.87.01 Linear Heat Detection CableMartin LlontopNoch keine Bewertungen

- Raychem-Cata MV TerminationDokument16 SeitenRaychem-Cata MV TerminationKeshab ShresthaNoch keine Bewertungen

- Innovations For The Contactors DIL.: Product InformationDokument6 SeitenInnovations For The Contactors DIL.: Product InformationnikrouNoch keine Bewertungen

- XLPE Cable Technical SpecificationDokument18 SeitenXLPE Cable Technical SpecificationSandipNanawareNoch keine Bewertungen

- Aislador Epoxi Catalogo 2011 ENG PDFDokument56 SeitenAislador Epoxi Catalogo 2011 ENG PDFWalter CataldoNoch keine Bewertungen

- Energy RV-K Foc PDFDokument8 SeitenEnergy RV-K Foc PDFJulio Vega AngelesNoch keine Bewertungen

- FluokitDokument8 SeitenFluokitJoaquim SantanaNoch keine Bewertungen

- 3M-EMD High Voltage CableAss PBDokument8 Seiten3M-EMD High Voltage CableAss PBLiz Vilela ArízagaNoch keine Bewertungen

- Manual Universal II Level Transmitter - EnglishDokument40 SeitenManual Universal II Level Transmitter - EnglishFernando Alves PereiraNoch keine Bewertungen

- Amphenol Connex Broadcast SolutionsDokument20 SeitenAmphenol Connex Broadcast SolutionsAmphenolConnexNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsVon EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNoch keine Bewertungen

- Bom of 400 LT TerminationDokument2 SeitenBom of 400 LT TerminationRakesh PandeyNoch keine Bewertungen

- Tender Notification-Cable Jointing Work BYPL-NIT-073Dokument95 SeitenTender Notification-Cable Jointing Work BYPL-NIT-073Rakesh PandeyNoch keine Bewertungen

- Tricks For Cable Accessories InstallationDokument30 SeitenTricks For Cable Accessories InstallationcxfuentesNoch keine Bewertungen

- Ferro ResonanceDokument30 SeitenFerro ResonanceAlex GeorgescuNoch keine Bewertungen

- Press Release Stevi0calDokument11 SeitenPress Release Stevi0calRakesh PandeyNoch keine Bewertungen

- Schneider Electric - Chapter G - Sizing and Protection of ConductorsDokument50 SeitenSchneider Electric - Chapter G - Sizing and Protection of ConductorsRobert MarkovskiNoch keine Bewertungen

- Avogadro's Law ExplainedDokument18 SeitenAvogadro's Law ExplainedNico Van De CasteeleNoch keine Bewertungen

- CS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)Dokument36 SeitenCS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)don2hmrNoch keine Bewertungen

- Air-coupled ultrasonic measurements in compositesDokument100 SeitenAir-coupled ultrasonic measurements in compositeswc_11111Noch keine Bewertungen

- Training Overview: Presented by Akash KarpeDokument22 SeitenTraining Overview: Presented by Akash KarpeMukesh Kumar VaishnavNoch keine Bewertungen

- Semiconductor FabricationDokument6 SeitenSemiconductor FabricationSyed Raheel AdeelNoch keine Bewertungen

- Awwa C115 - A2c115 (1999)Dokument23 SeitenAwwa C115 - A2c115 (1999)kumarvizayin100% (1)

- Oxidation and Reduction SPM Form 5Dokument63 SeitenOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- Macrostructure Defect in Continuous Steel CastingDokument13 SeitenMacrostructure Defect in Continuous Steel CastingHasna RiazNoch keine Bewertungen

- Smart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganDokument1 SeiteSmart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganKathy Irene ReganNoch keine Bewertungen

- All ElementsDokument392 SeitenAll ElementsWilliam Bataluna100% (1)

- UTP A 8051 Ti: ClassificationsDokument1 SeiteUTP A 8051 Ti: ClassificationsGustavo OrozcoNoch keine Bewertungen

- Fathima Nasir Material StudyDokument6 SeitenFathima Nasir Material StudyfathimanasirNoch keine Bewertungen

- Microstructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsDokument244 SeitenMicrostructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsJH ShinNoch keine Bewertungen

- Flexible Pavement Design SK RaoDokument62 SeitenFlexible Pavement Design SK Raokrishnarao krishnarao329100% (3)

- 1Dokument29 Seiten1عبدربه منصورNoch keine Bewertungen

- Cmos Process FlowDokument25 SeitenCmos Process FlowSHAIK MUSTHAFANoch keine Bewertungen

- Polyurethanes From Renewable ResourcesDokument46 SeitenPolyurethanes From Renewable ResourcesMohammad R ChandanNoch keine Bewertungen

- 1a. Lion Titco Company ProfileDokument12 Seiten1a. Lion Titco Company ProfileIFTIKUETNoch keine Bewertungen

- Final Drawing - Operation Manual - K.C Ltd. Co.Dokument19 SeitenFinal Drawing - Operation Manual - K.C Ltd. Co.pdimizasNoch keine Bewertungen

- Alkali-Activated Fly Ash-Based Geopolymers With Zeolite or BentoniteDokument7 SeitenAlkali-Activated Fly Ash-Based Geopolymers With Zeolite or BentoniteSo Thu DaiNoch keine Bewertungen

- WFO Global Foundry Report 2018 PDFDokument107 SeitenWFO Global Foundry Report 2018 PDFMonisha SharmaNoch keine Bewertungen

- Spectre M 1 Ds EnglishDokument2 SeitenSpectre M 1 Ds EnglishOgbedande Awo OrunmilaNoch keine Bewertungen

- Non-Destructive Testing: Laboratory ManualDokument65 SeitenNon-Destructive Testing: Laboratory ManuallokendraNoch keine Bewertungen

- DIPRA Member Companies Design Ductile Iron Pipe Thrust Restraint SystemsDokument10 SeitenDIPRA Member Companies Design Ductile Iron Pipe Thrust Restraint SystemsSaravanan MuthuramanNoch keine Bewertungen

- Rigid Pavement: Postgraduate Studies Highways EngineeringDokument15 SeitenRigid Pavement: Postgraduate Studies Highways EngineeringHANAN HUSSNoch keine Bewertungen

- Multi-stage centrifugal pumps for clean water applicationsDokument6 SeitenMulti-stage centrifugal pumps for clean water applicationsazze bouzNoch keine Bewertungen

- CV Curriculum Vitae Mechanical EngineerDokument3 SeitenCV Curriculum Vitae Mechanical Engineerkalpesh yadavNoch keine Bewertungen

- Staircase AssignmentDokument10 SeitenStaircase AssignmentNabila Faiqah Zayn100% (1)

- Heat TreatmentDokument32 SeitenHeat TreatmentMradul ChaudharyNoch keine Bewertungen

- 2 Concrete Works CompuDokument14 Seiten2 Concrete Works CompuALFONSO RAPHAEL SIANoch keine Bewertungen