Beruflich Dokumente

Kultur Dokumente

E2 Coupl Ident Chart

Hochgeladen von

aerohead34Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

E2 Coupl Ident Chart

Hochgeladen von

aerohead34Copyright:

Verfügbare Formate

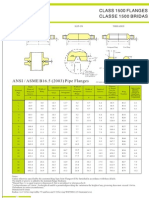

E2/50101

Hydraulic coupling identification chart

Determine seal

Mated angle

seat with

O-ring

Visual identification

AO-ring

BNose seat CSeat angle D

Measure

Dash size

Coupling termination

location

-4

-6

-8

-10

-12

-16

-20

-24

-32

British Standard Pipe Parallel

55

This type of seal is found

on BSP and DIN terminations.

It uses both the O-ring

and the mated angle

to make the seal.

Inside

Inverted

30

60 Inclusive

O-ring

Thread

O.D.

Thread

I.D.

Male (MBSPP)

30

O-ring

24 Inclusive

Thread 12

I.D.

Tube O.D.

Male (MDL/MDH)

This type of seal is found on

O-ring boss, flat-face O-ring,

British flat-face O-ring and

O-ring flange couplings.

O-ring boss couplings have

straight threads with the

O-ring on the outside of the

threads next to the large hex

nut. Generally the O-ring will

not be present on a used

coupling but the groove for

the O-ring will be present.

Flat-face and British flat-face

O-ring couplings have

straight threads. The female

has a flat face; the male has

a flat face with a groove

to accept the O-ring.

Differences between flat-face

and British flat-face are

determined when measuring

thread size.

O-ring flange couplings have

no threads but do have a flat

face with a groove to accept

the O-ring. The connection

is made with two flange half

boots that go over the O-ring

flange and are bolted to

the port.

Mechanical

joint or

mated angle

AO-ring

BNose seat CSeat angle D

Female (FDLORX/FDHORX)

Dash size

Coupling termination

Nominal

size

Flange O.D. Flange head

(mm)

thickness

(mm)

E

location

Tube O.D. Heavy Series

(mm)

6

8

10

12

14

15

18

22

28

35

42

8

10

12

14

16

20

25

30

38

A

(mm)

B

(mm)

C

(mm)

S.A.E. O-ring flange

flat face

Flange O.D.

Flange head

-8

-12

-16

-20

-24

-32

1/2"

3/4"

1"

1.1/4"

1.1/2"

2"

S.A.E. O-ring boss

O-ring located

outside

Thread

O.D.

flat face

Thread

I.D.

Male (MB)

Female (FB)

Thread

O.D.

flat face

This type of seal is found

on National Pipe Straight

Mechanical (NPSM), British

Standard Pipe Parallel (BSPP),

JIC, SAE, JIS, Komatsu, DIN,

North American Stand Pipe,

Metric Stand Pipe, Inverted

Flare and Kobelco. Different

angles are used to create

the seal, but the angles are

cut two different ways,

Standard and Inverted.

BNose seat CSeat angle D

Inverted seat couplings

contain the nose angle of the

male on the inside bore of

the coupling. These

couplings are: (NPSM)

National Pipe Straight

Mechanical, (BSPP) British

Standard Pipe Parallel, DIN,

North American Stand Pipe,

Metric Stand Pipe, Inverted

Flare and Kobelco.

Female Swivel (FSX)

Japanese Industrial Standard & Komatsu

30

30

None

Standard

30

Thread

I.D.

Thread

O.D.

Male (MJIS or MK)

Female (FJISX or FKX)

60

None

Inverted

30

Thread

O.D.

Male (MP)

Female (FPX)

14.1

17.3

22.0

25.3

30.0

36.3

42.6

50.6

12.9

15.9

19.1

23.6

28.0

34.4

40.5

48.5

Dash size

Nominal size

No. Threads

per inch

Male thread O.D. (mm)

MJ

Female thread I.D. (mm)

FJX

-4

-5

-6

-8

-10

-12

-14

-16

-20

-24

-32

1/4"

5/16"

3/8"

1/2"

5/8"

3/4"

7/8"

1"

1.1/4"

1.1/2"

2"

20

20

18

16

14

12

12

12

12

12

12

11.0

12.5

14.1

18.9

22.1

26.9

30.0

33.2

41.2

47.6

63.3

9.9

11.5

12.9

17.5

20.5

25.0

28.2

31.3

39.2

45.5

61.4

MS

FSX

11.0

12.5

15.9

19.1

22.1

26.9

9.9

11.5

14.3

17.5

20.5

25.0

1/4"

5/16"

3/8"

1/2"

5/8"

3/4"

Dash size

Nominal size

-4

-6

-8

-10

-12

-16

-20

-24

-32

1/4"

3/8"

1/2"

5/8"

3/4"

1"

1.1/4"

1.1/2"

2"

45

None

Inverted

42

45

Thread

O.D.

Thread

I.D.

Male (MIX)

Female (FI)

20

20

18

16

14

14

No. Threads

per inch

Male thread

O.D. (mm)

MJIS

Female thread

I.D.(mm)

FJISX

19

19

14

14

14

11

11

11

11

13.5

16.7

20.5

23.1

26.3

33.4

42.1

47.6

59.6

11.7

15.2

18.9

20.5

24.4

30.6

38.9

45.3

56.4

Inverted

24 Inclusive

Male (MFG)

Female (FFGX)

-2

-3

-4

-5

-6

-7

-8

-10

-12

Standard

24 Inclusive

Male (MPFL)

Thread

interface

60

This type of seal is found

on the (NPTF) National Pipe

Tapered for Fuel or the (BSPT)

British Standard Pipe Taper.

Characteristics of this thread

is the male has a smaller

diameter at the end,

tapering to a larger diameter

at the hexagon. When the

male is screwed into the

female the thread deforms,

thus creating the seal.

Female (FPFL)

Dash size

National Pipe Tapered

-2

-4

-6

-8

-12

-16

-20

-24

-32

30

Thread

I.D.

Thread

O.D.

NPTF Solid Male (MP)

NPTF or NPSP Solid Female (FP)

British Standard Pipe Tapered

55

Thread

O.D.

Male (MBSPT)

MALE

(Outside diameter)

FEMALE

(Inside diameter)

M14 x 1.5

M18 x 1.5

M22 x 1.5

M24 x 1.5

M30 x 1.5

M33 x 1.5

M36 x 1.5

M42 x 1.5

14.0

18.0

22.0

24.0

30.0

33.0

36.0

42.0

12.5

16.5

20.5

22.5

28.5

31.5

34.5

40.5

6.0

8.0

10.0

12.0

15.0

16.0

18.0

20.0

22.0

25.0

28.0

30.0

35.0

38.0

42.0

M12 x 1.5

M14 x 1.5

M16 x 1.5

M18 x 1.5

M22 x 1.5

M26 x 1.5

M30 x 2.0

M36 x 2.0

M45 x 2.0

M52 x 2.0

M16 x 1.5

M18 x 1.5

M20 x 1.5

M24 x 1.5

M30 x 2.0

M36 x 2.0

M45 x 2.0

M52 x 2.0

No. Threads

per inch

Male thread

O.D. (mm)

MP

Female thread

I.D. (mm)

FPX

10.3

13.9

17.3

21.6

27.0

33.7

42.5

48.6

60.7

9.1

11.9

15.1

19.0

24.2

30.6

38.9

45.2

57.2

Female thread

I.D. (mm)

FI

Male thread

O.D. (mm)

MIX

7.9

9.5

11.0

12.5

15.7

17.4

18.9

22.1

26.8

7.1

8.3

9.9

11.5

14.7

15.9

17.9

20.6

25.4

Metric thread size

Male thread

O.D. (mm)

MFG

Female thread

I.D. (mm)

FFGX

M20 x 1.5

M20 x 1.5

M20 x 1.5

M24 x 1.5

M30 x 1.5

M36 x 1.5

M45 x 1.5

M52 x 1.5

20.0

20.0

20.0

24.0

30.0

36.0

45.0

52.0

18.5

18.5

18.5

22.5

28.5

34.5

43.5

50.5

No. Threads

per inch

27

18

18

14

14

11.1/2

11.1/2

11.1/2

11.1/2

X Dia (mm)

MPFL

X Dia (mm)

FPFL

17.0

21.0

27.0

34.0

42.0

17.0

21.0

27.0

34.0

42.0

Male thread

O.D. (mm)

MP

Female thread

I.D. (mm)

FP

10.3

13.9

17.3

21.6

27.0

33.7

42.5

48.6

60.7

9.1

11.9

15.1

19.0

24.2

30.6

38.9

45.2

57.2

MBSPT

-2

-4

-6

-8

-10

-12

-16

-20

-24

-32

Measuring threads

With the calliper measure the thread diameter of the largest point.

(Outside diameter (O.D.) of male threads. Inside diameter

(I.D.) of female threads.)

Female thread

I.D. (mm)

FKX

Metric Nut

Thread - Heavy

1/2"

5/8"

3/4"

1"

1.1/4"

1/8"

1/4"

3/8"

1/2"

3/4"

1"

1.1/4"

1.1/2"

2"

Male thread

O.D. (mm)

MK

Metric Nut

Thread - Light

Nominal size

Nominal size

Metric thread size

Metric Stand Pipe

DIN Tube O.D. (mm)

MSP

28

24

24

20

18

18

18

18

16

1/4"

5/16"

3/8"

1/2"

5/8"

3/4"

1"

1.1/4"

Coupling termination

6.3

9.5

13.0

16.0

19.0

25.0

32.0

38.0

No. Threads

per inch

Nominal size

-8

-10

-12

-16

-20

Nominal size

Dash size

Nominal size

(mm)

27

18

18

14

14

11.1/2

11.1/2

11.1/2

11.1/2

1/8"

3/16"

1/4"

5/16"

3/8"

7/16"

1/2"

5/8"

3/4"

-4

-5

-6

-8

-10

-12

-16

-20

French Gaz 24 high pressure flange

None,

except -20

Nominal size

1/8"

1/4"

3/8"

1/2"

3/4"

1"

1.1/4"

1.1/2"

2"

Dash size

French Gaz 24 cone

None

-2

-4

-6

-8

-12

-16

-20

-24

-32

Dash size

S.A.E. Inverted Flare

1/8"

1/4"

3/8"

1/2"

5/8"

3/4"

1"

1.1/4"

1.1/2"

2"

28

19

19

14

14

14

11

11

11

11

10.1

13.6

17.1

21.5

23.4

27.0

33.9

42.6

48.5

60.5

Measuring seat angles

Using the thread gauge, determine the number

of threads per inch. Comparison of gauge and

coupling threads against a lighted background

will ensure an accurate reading.

Centrelines

are parallel

Right

10.9

12.9

14.9

17.2

21.2

18

16

16

14

12

12

12

12

Dash size

Thread 30

I.D.

11.9

13.9

15.9

18.2

22.2

1/4"

3/8"

1/2"

5/8"

3/4"

1"

1.1/4"

1.1/2"

Stand Pipe Fitting

30

50.8

57.1

66.7

79.4

96.8

-4

-6

-8

-10

-12

-16

-20

-24

Solid Male (MFA)

National Pipe Straight

14.2

14.2

14.2

14.2

14.2

Female thread I.D. (mm)

FFORX

Thread O.D.

Nut

41.4

47.6

54.0

63.5

79.5

Male thread O.D. (mm)

MFFOR

Tube

O.D.

Bite Sleeve

40.5

50.8

57.1

66.7

79.4

96.8

No. Threads per inch

12

Inverted

7.7

8.8

9.5

10.3

12.6

12.6

Nominal size

Metric Stand Pipe

None

31.8

41.3

47.6

54.0

63.5

79.4

Dash size

-4

-5

-6

-8

-10

-12

Thread

I.D.

Male (MS)

7.7

10.1

12.1

14.1

16.9

20.4

6.0

7.6

8.9

10.5

11.9

16.3

19.2

23.5

26.6

29.7

37.5

43.7

59.4

45

Standard seat couplings have

the nose angle of the male

on the outer surface of the

coupling. These couplings

are: JIC, SAE, JIS, Komatsu.

8.7

11.1

13.1

15.1

17.8

20.4

6.8

8.3

9.9

11.5

12.9

17.5

20.5

24.9

28.2

31.3

39.2

45.5

61.4

Thread

I.D.

Thread

O.D.

38.1

47.6

52.3

58.7

69.8

77.7

7.9

9.5

11.0

12.5

14.1

18.9

22.1

26.9

30.0

33.2

41.2

47.6

63.5

Female Swivel (FJX)

45

8.1

10.9

12.9

14.9

17.3

21.1

Code 62 - FLH

C

(mm)

24

24

20

20

18

16

14

12

12

12

12

12

12

SAE 45 Flare45

Standard

9.1

11.9

13.9

15.9

18.2

22.2

Flange O.D. Flange head

A

B

(mm)

thickness

(mm)

(mm)

(mm)

E

Caterpillar Code 62 - FLC

1/8"

3/16"

1/4"

5/16"

3/8"

1/2"

5/8"

3/4"

7/8"

1"

1.1/4"

1.1/2"

2"

37

None

C

(mm)

-2

-3

-4

-5

-6

-8

-10

-12

-14

-16

-20

-24

-32

37

Male (MJ)

B

(mm)

O-ring I.D. (mm)

Female Swivel (FFORX)

Thread

O.D.

A

(mm)

10.5

12.5

14.5

16.5

18.5

20.5

22.5

24.5

28.0

34.0

40.0

43.0

50.0

Female thread I.D. (mm)

FB

Coupling termination

37

6.7

6.7

8.0

8.0

8.0

9.7

Female thread I.D. (mm)

FDLORX/FDHORX

Male thread O.D. (mm)

MB

JIC 37 Flare

Standard

30.2

38.1

44.5

50.8

60.3

71.4

Male thread O.D. (mm)

MDL/MDH

No. Threads per inch

location

None

11.7

15.2

18.9

20.9

24.4

30.6

39.3

45.2

59.5

Nominal size

Thread

I.D.

Male (MFFOR)

AO-ring

13.0

16.5

20.8

22.8

26.3

33.1

41.8

47.7

59.5

Dash size

O-ring face seal

O-ring located at

nose seat

Female thread I.D. (mm)

FBSPORX

12.0

14.0

16.0

18.0

20.0

22.0

24.0

26.0

30.0

36.0

42.0

45.0

52.0

Flange O.D. Flange head

(mm)

thickness

(mm)

E

Code 61 - FL

O-ring located in

flange

groove

Male thread O.D. (mm)

MBSPP

19

19

14

14

14

11

11

11

11

Tube O.D. Light Series

(mm)

M12 x 1.5

M14 x 1.5

M16 x 1.5

M18 x 1.5

M20 x 1.5

M22 x 1.5

M24 x 1.5

M26 x 1.5

M30 x 2.0

M36 x 2.0

M42 x 2.0

M45 x 2.0

M52 x 2.0

Thread O.D.

O-ring

face seal

1/4"

3/8"

1/2"

5/8"

3/4"

1"

1.1/4"

1.1/2"

2"

Metric thread size

12

Inverted

No. Threads per inch

Female (FBSPORX)

DIN 24 cone

Inside

Nominal size

Using the seat gauge, determine the angle of the seat, as illustrated. When the centreline of the seat gauge extends parallel

with the projected longitudinal axis of the coupling, then the angles of the gauge and seat match.

Centrelines

Compare the measurements taken to a coupling shown in the tables above that appear to be similar.

at an angle

NOTE: Thread binding will occur when different thread configurations are used.

DO NOT mix thread configurations.

Coupling thread identification kits containing reference charts, vernier,

seat gauges and thread gauges are available.

Wrong

Order reference: 7369-04318.

Centrelines

are parallel

DIN 24

JIC 37

The manufacturers reserve the right to amend details where necessary.

Gates Europe nv 2004

Printed in Belgium - 03/04.

Das könnte Ihnen auch gefallen

- Thread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1Dokument4 SeitenThread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Identificación de RoscasDokument7 SeitenIdentificación de RoscasEduNoch keine Bewertungen

- 35Dokument10 Seiten35phankhoa83Noch keine Bewertungen

- Lista de Normas para Roscas PDFDokument1 SeiteLista de Normas para Roscas PDFdelpfe delpdeNoch keine Bewertungen

- Thread Guides PDFDokument6 SeitenThread Guides PDFFelix RanillaNoch keine Bewertungen

- CP96-C96 Eng TDS NewDokument48 SeitenCP96-C96 Eng TDS NewSang ElangNoch keine Bewertungen

- Identifying Threads Identifying Threads: How To Use The CaliperDokument6 SeitenIdentifying Threads Identifying Threads: How To Use The CaliperkyletgerberNoch keine Bewertungen

- ContinentalDokument76 SeitenContinentalVIVEK UPADHYAYNoch keine Bewertungen

- 10Z 3Dokument95 Seiten10Z 3ZMCONTROLNoch keine Bewertungen

- Catalogo Pistones SMCDokument151 SeitenCatalogo Pistones SMCCarlos Gonzalez100% (1)

- Teknopoli: North American ConnectionsDokument39 SeitenTeknopoli: North American ConnectionsKishor JadhavNoch keine Bewertungen

- Flange BS10 AS2129 ANSIBS4504Dokument0 SeitenFlange BS10 AS2129 ANSIBS4504Vivek DukareNoch keine Bewertungen

- Medida PGDokument2 SeitenMedida PGluanfaleNoch keine Bewertungen

- Hydraulic AdapterswebpageDokument48 SeitenHydraulic AdapterswebpageBilly ZununNoch keine Bewertungen

- Grundfos InstructionDokument22 SeitenGrundfos InstructionSajeev NerurkarNoch keine Bewertungen

- Flanges 2Dokument15 SeitenFlanges 2chicotonyxdNoch keine Bewertungen

- British Standard PipeDokument3 SeitenBritish Standard PipeskluxNoch keine Bewertungen

- American Standard ThreadDokument30 SeitenAmerican Standard ThreadsoparlNoch keine Bewertungen

- Stepped Couplings OD355.6 - 1222: Large DiameterDokument1 SeiteStepped Couplings OD355.6 - 1222: Large DiameterAnonymous 48jYxR1CNoch keine Bewertungen

- Threading Tools (SST Series)Dokument8 SeitenThreading Tools (SST Series)Gilberto ManhattanNoch keine Bewertungen

- Thread and Port GuideDokument44 SeitenThread and Port GuidejlrdlgNoch keine Bewertungen

- Pasos de HilosDokument13 SeitenPasos de HilosRoberto Vera RamosNoch keine Bewertungen

- The Most Economical Solution For Drilling!: Indexable DrillDokument20 SeitenThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNoch keine Bewertungen

- As (One Touch)Dokument105 SeitenAs (One Touch)carlos223344Noch keine Bewertungen

- U Bolt StandardDokument1 SeiteU Bolt StandardcocoNoch keine Bewertungen

- Flange Dimensions PDFDokument4 SeitenFlange Dimensions PDFSRINIVASNoch keine Bewertungen

- Metric STD ThreadDokument4 SeitenMetric STD ThreadmayurNoch keine Bewertungen

- Metric Section BDokument26 SeitenMetric Section BniladriprasadrNoch keine Bewertungen

- Threads in Pneumatics - FestoWiki - EnglishDokument3 SeitenThreads in Pneumatics - FestoWiki - EnglishSaeed QahremaniNoch keine Bewertungen

- Cat Needle Valve11Dokument13 SeitenCat Needle Valve11Nilesh MistryNoch keine Bewertungen

- NPT Thread ChartDokument2 SeitenNPT Thread Chartprabu_v50% (2)

- 6 Series Tube Fittings 131119Dokument46 Seiten6 Series Tube Fittings 131119Brunno Vasques100% (1)

- GWC Valve International Threaded & Socketweld Ball ValveDokument16 SeitenGWC Valve International Threaded & Socketweld Ball ValveGWC Valve InternationalNoch keine Bewertungen

- BSP Identification PDFDokument3 SeitenBSP Identification PDFrefaeNoch keine Bewertungen

- Tube Pipe FittingDokument36 SeitenTube Pipe Fittingnbngoc012Noch keine Bewertungen

- Bernard Q - Gun Parts Break DownDokument13 SeitenBernard Q - Gun Parts Break DownullwnNoch keine Bewertungen

- Thread GaugesDokument8 SeitenThread GaugesJohn MuellerNoch keine Bewertungen

- British Standard Pipe ThreadDokument3 SeitenBritish Standard Pipe ThreaduttampokharkarNoch keine Bewertungen

- erm3.CHAPTER 13 - Flow Controls and Flow DividersetoDokument17 Seitenerm3.CHAPTER 13 - Flow Controls and Flow DividersetoVinod YbNoch keine Bewertungen

- SMC KJSDokument3 SeitenSMC KJSvictor_hptn7305Noch keine Bewertungen

- ThreadingDokument8 SeitenThreadingVivek SDNoch keine Bewertungen

- NPT Pipe SizesDokument3 SeitenNPT Pipe SizesGMHHENoch keine Bewertungen

- Entrelec DIN RailsDokument5 SeitenEntrelec DIN RailsFelipe Soares MaiaNoch keine Bewertungen

- Hydraulics (Eaton) - How To Identify Fluid Ports and ConnectorsDokument48 SeitenHydraulics (Eaton) - How To Identify Fluid Ports and ConnectorsDoug RoordaNoch keine Bewertungen

- PDMSDokument39 SeitenPDMSprathikNoch keine Bewertungen

- Flange Drilling StandardDokument4 SeitenFlange Drilling StandardNitin Aggarwal100% (1)

- 37° Tube Fittings: Instrumentation SolutionsDokument9 Seiten37° Tube Fittings: Instrumentation SolutionsNilesh MistryNoch keine Bewertungen

- 13 Threading PDFDokument46 Seiten13 Threading PDFrefaeNoch keine Bewertungen

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionVon EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNoch keine Bewertungen

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 32nd EditionVon EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 32nd EditionNoch keine Bewertungen

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersVon EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Manual of Engineering Drawing: British and International StandardsVon EverandManual of Engineering Drawing: British and International StandardsBewertung: 3.5 von 5 Sternen3.5/5 (4)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Super ComputersDokument9 SeitenSuper Computers/ditya JadhavNoch keine Bewertungen

- Sony Alpha A1 Press ReleaseDokument7 SeitenSony Alpha A1 Press ReleaseNikonRumorsNoch keine Bewertungen

- Datasheet of DS-2DF8236IX-AEL (W) - 20170911Dokument5 SeitenDatasheet of DS-2DF8236IX-AEL (W) - 20170911gohilnarendraNoch keine Bewertungen

- B1 Speaking SuggestionsDokument20 SeitenB1 Speaking SuggestionsCường NguyễnNoch keine Bewertungen

- Tottenham Hotspur Brand Identity v2Dokument15 SeitenTottenham Hotspur Brand Identity v2hgoughNoch keine Bewertungen

- American English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartDokument6 SeitenAmerican English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartIsmael Shahamat100% (1)

- Email MarketingDokument1 SeiteEmail MarketingRoss BeadmanNoch keine Bewertungen

- Today Forecast: Mature Young Cumulative 80 1000 1250Dokument4 SeitenToday Forecast: Mature Young Cumulative 80 1000 1250Bruno NunesNoch keine Bewertungen

- Explanation, Apology, and RantDokument8 SeitenExplanation, Apology, and RantAnonymous xV9mg4vPG0Noch keine Bewertungen

- Piano TheoryDokument51 SeitenPiano Theorychica liberato100% (2)

- XVR User's Manual V1.0.0 201703Dokument303 SeitenXVR User's Manual V1.0.0 201703Hipolito Delgado100% (1)

- Manual de Servicio SRPT 30 and SRPT 40A RPU Transmitters ManualDokument129 SeitenManual de Servicio SRPT 30 and SRPT 40A RPU Transmitters Manualcarlos enriqueNoch keine Bewertungen

- AX2a Sandbox Resources Hex Map Pack (6550904)Dokument9 SeitenAX2a Sandbox Resources Hex Map Pack (6550904)Kryptton100% (2)

- Networks: - Jeslin JojuDokument12 SeitenNetworks: - Jeslin Jojujeremy jacobNoch keine Bewertungen

- 4 ConversationDokument12 Seiten4 Conversationehajer186Noch keine Bewertungen

- Presentation On Hawaii: Soumik Dey Anudeep T Sudip Chhetri Rajeev Gunjan Goutam KumarDokument8 SeitenPresentation On Hawaii: Soumik Dey Anudeep T Sudip Chhetri Rajeev Gunjan Goutam KumarAnudeep TantravahiNoch keine Bewertungen

- Development of A Mobile Airline Reservation Application: January 2012Dokument10 SeitenDevelopment of A Mobile Airline Reservation Application: January 2012JakezWeruNoch keine Bewertungen

- MrtlistDokument141 SeitenMrtlistManish sharmaNoch keine Bewertungen

- Preschool Cascade Training HandoutsDokument55 SeitenPreschool Cascade Training Handoutsskbtblog100% (2)

- Christmas Games AnswersDokument9 SeitenChristmas Games AnswersDavid BrownNoch keine Bewertungen

- Jewell Hill ResumeDokument2 SeitenJewell Hill ResumeJewell HillNoch keine Bewertungen

- Jennifer Gliere - Chapter05ExercisesDokument4 SeitenJennifer Gliere - Chapter05ExercisesAnthony BoldenNoch keine Bewertungen

- Old English, Norwegian, Islandic Rune PoemsDokument6 SeitenOld English, Norwegian, Islandic Rune Poemsseixxx666Noch keine Bewertungen

- Ielts Writing Task 1 Maps Introductory SentencesDokument2 SeitenIelts Writing Task 1 Maps Introductory SentencesPhùng ThúyNoch keine Bewertungen

- DCN Case StudyDokument8 SeitenDCN Case Studyhimanshu guptaNoch keine Bewertungen

- Winter Dubai Turki 2-11 Maret 2023Dokument4 SeitenWinter Dubai Turki 2-11 Maret 2023Hukma ShabiyyahNoch keine Bewertungen

- Wedding DanceDokument1 SeiteWedding Dancezionselegna012808Noch keine Bewertungen

- Fallout New Vegas - Lonesome Road DLCDokument23 SeitenFallout New Vegas - Lonesome Road DLCIan CampNoch keine Bewertungen

- BackgammonDokument12 SeitenBackgammonfPH80c9BK100% (1)

- EADHS KJ and RL The Good The Bad and The Very UnfortunateDokument30 SeitenEADHS KJ and RL The Good The Bad and The Very UnfortunateValemoralesVNoch keine Bewertungen