Beruflich Dokumente

Kultur Dokumente

Production Automation (Lecture 8)

Hochgeladen von

Nauman KhanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Production Automation (Lecture 8)

Hochgeladen von

Nauman KhanCopyright:

Verfügbare Formate

PRODUCTION AUTOMATION (Lecture 8) REASONS FOR AUTOMATION 1.

Increase Production Rate Eliminates portions of processes that directly increase production time (Machine Processing Time, Handling Time, Setup Times)

2. Removes Human from hazardous environments Exposure to (Chemicals, Fumes, Temperatures and Radiations) Robotic Applications (Furnaces, Spray Painting, Welding)

3. Remove Humans from Processes that requires extremely clean environments (Semiconductors, Drugs) 4. Reduce number of defective products 5. Reduce Direct labor One worker monitors a large number of machines

6. Reduce W.I.P (Better control and Scheduling) 7. Reduce Manufacturing Lead Time M.L.T (Processing times, Setup times, Waiting Times) Setup Time (Flexible Automation, common Fixtures and Tooling) Processing Time (Combining or Eliminating Operations) Waiting Time (Increased Speeds)

8. Increase Quality Repeatable operations through every cycle (Tighter and Controlled) Easier detection (when process is out of control limits)

9. Increase Productivity 10. Reduce Labor Costs 11. Address Labor Shortages 12. Health and Safety

Dr. S.A. Shah

Page 1

PRODUCTION AUTOMATION (Lecture 8) STRENGTHS OF COMPUTER BASED MACHINES Performs repetitive tasks consistently Store large amount of Data Retrieve data from memory reliably Performs multiple tasks simultaneously Apply high forces and powers Performs computations quickly

MANUAL LABOR IN AUTOMATED SYSTEMS Even if all of the Manufacturing System in a Factory are automated, still there will be a need of the following work to be performed by humans Equipment maintenance (maintain and repair, improve the reliability of automated system) Programming and computer operations Engineering project works (Upgrades, Design Tooling, Continuous improvement) Plant Management

REASONS FOR AUTOMATION Automated Manufacturing Systems are expensive comparing to Conventional Manufacturing, still the manufacturers prefer to have an Automated systems. If cost a lot, why should we go for Automation?? Because there are various advantages associated with Automation, they are: 1. Increase Labor Productivity With automated machines the Production Rate of the system increases and number of labor decreases, conversely, the labor productivity increases Greater output per hour with less labor input

2. Reduce Labor Cost Manual operations are replaced by computer programs Computer control reduces the number of labor, meaning labor cost per unit will reduce, hence Unit product cost will be reduced Page 2

Dr. S.A. Shah

PRODUCTION AUTOMATION (Lecture 8) 3. Levels the Effect of Labor Shortages Labor shortages (In some advanced nations) Automated operations (Are substitute for labor)

4. Reduce Routine Tasks Routine operations causes fatigue and sometimes lead the workers to a boring situations (May result in lack of concentration) General level of working conditions (are improved by automation as routine works are done automatically)

5. Improved Worker Safety Role of worker (supervisory instead of Active participation in a process) Hence the work is made safer

6. Improve Product Quality Defect Rates (Reduced) Accuracy of Machines (High) Fatigue due to repetition work (Eliminated) Manufacturing Processes (Performed with greater uniformity)

7. Reduce Manufacturing Lead Time (MLT) MLT is the time between the customer order and Delivery of the product Operations (Fast and Accurate) Reduced MLT will reduce the WIP Inventory

8. Complex Operations Precision and Complex Geometries (Sometimes difficult to achieve manually) Complex Contours (Mathematically defined surfaces can only be understand by computer controlled systems Examples: Integrated circuits fabrication, Blades Profiles (Turbines and Aircrafts)

9. Flexibility increases Dr. S.A. Shah Page 3

PRODUCTION AUTOMATION (Lecture 8) DISADVANTAGES 1. High initial costs 2. Job cuts of labor 3. Requires skilled labors 4. Maintenance costs are higher

Dr. S.A. Shah

Page 4

Das könnte Ihnen auch gefallen

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowVon EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowBewertung: 4 von 5 Sternen4/5 (1)

- Unit 1 Introduction To AutomationDokument19 SeitenUnit 1 Introduction To Automationshadow.thevolcanoNoch keine Bewertungen

- AutomationDokument9 SeitenAutomationPrincy AgrawalNoch keine Bewertungen

- Unit 1Dokument7 SeitenUnit 1GajananNoch keine Bewertungen

- Ghrce - Final Aip Lab Manual (Viii Sem)Dokument89 SeitenGhrce - Final Aip Lab Manual (Viii Sem)Jyotiraman De100% (1)

- AIM All Units - 3122018Dokument91 SeitenAIM All Units - 3122018Čhęťãń ĶNoch keine Bewertungen

- AUTOMATION IN PRODUCTION SYSTEMS Unit 1Dokument12 SeitenAUTOMATION IN PRODUCTION SYSTEMS Unit 1compras.seaagsNoch keine Bewertungen

- Production Line Instant NoodleDokument13 SeitenProduction Line Instant NoodleAnisah Aniz100% (1)

- IIA Module 5Dokument48 SeitenIIA Module 5TeenaNoch keine Bewertungen

- Industrial Automation: David O'Sullivan WWW - Owl.ieDokument33 SeitenIndustrial Automation: David O'Sullivan WWW - Owl.ieruby_evangelinNoch keine Bewertungen

- Automation: Fixed Automation. Fixed Automation Is A System in Which The Sequence of ProcessingDokument7 SeitenAutomation: Fixed Automation. Fixed Automation Is A System in Which The Sequence of ProcessingBalu ZerofourNoch keine Bewertungen

- SEMESTER 1 (2020/2021) SMJE 4293 Assignment 1: LECTURES: Profesor Madya DR Mohd Fauzi Bin OthmanDokument7 SeitenSEMESTER 1 (2020/2021) SMJE 4293 Assignment 1: LECTURES: Profesor Madya DR Mohd Fauzi Bin OthmanBrian LaiNoch keine Bewertungen

- Ebroand Seya-1Dokument19 SeitenEbroand Seya-1wabdushukurNoch keine Bewertungen

- MADA DDokument11 SeitenMADA DHimanshu JaiswalNoch keine Bewertungen

- Notes Unit 1Dokument7 SeitenNotes Unit 1Sooraj ThakurNoch keine Bewertungen

- Automation in ManufacturingDokument89 SeitenAutomation in ManufacturingPassmore DubeNoch keine Bewertungen

- Pom PDFDokument11 SeitenPom PDFPINTU TOMARNoch keine Bewertungen

- Assignment Advance ManufacturingDokument3 SeitenAssignment Advance ManufacturingMuhammad Fizree Ashraf100% (1)

- CH 01Dokument33 SeitenCH 01muniraju mNoch keine Bewertungen

- UNIT-1 Manufacturing AutomationDokument46 SeitenUNIT-1 Manufacturing AutomationPradyumna DharmadhikariNoch keine Bewertungen

- AutomationDokument2 SeitenAutomationpavankumar72Noch keine Bewertungen

- 4 - IB-CIM Lecture 4Dokument59 Seiten4 - IB-CIM Lecture 4عبدالرحمن سليمانNoch keine Bewertungen

- Unit 8 - AutomationDokument24 SeitenUnit 8 - Automationlamao123Noch keine Bewertungen

- Computer Integrated Manufacturing.Dokument29 SeitenComputer Integrated Manufacturing.cooldude2000Noch keine Bewertungen

- The Advantages and Disadvantages of Automation in ManufacturingDokument2 SeitenThe Advantages and Disadvantages of Automation in ManufacturingSujan ChapagainNoch keine Bewertungen

- GROUP NO 17 - Advantages of Automation SystemDokument4 SeitenGROUP NO 17 - Advantages of Automation SystemAnurag Chadha100% (1)

- AIM (Unit 1)Dokument46 SeitenAIM (Unit 1)0iamkaran0Noch keine Bewertungen

- AUTOMATION For Learnig Session in SEMINARSDokument8 SeitenAUTOMATION For Learnig Session in SEMINARSandrei CalloNoch keine Bewertungen

- Rapid PrototypingDokument70 SeitenRapid PrototypingRamesh KumarNoch keine Bewertungen

- Automation in ManufacturingDokument128 SeitenAutomation in ManufacturingMsNoch keine Bewertungen

- ReportDokument8 SeitenReportWaqas AhmedNoch keine Bewertungen

- Automation ProductionDokument6 SeitenAutomation ProductionGhilman HabibNoch keine Bewertungen

- Automation in Production Systems PDFDokument10 SeitenAutomation in Production Systems PDFMrRulesGta0% (1)

- DR Rabie 331S06 Introd Mod1Dokument31 SeitenDR Rabie 331S06 Introd Mod1AlucardAtemNoch keine Bewertungen

- Automation in ManufacturingDokument20 SeitenAutomation in ManufacturingSunkeswaram Deva PrasadNoch keine Bewertungen

- TurbineDokument8 SeitenTurbineBhbNoch keine Bewertungen

- Industrial AutomationDokument21 SeitenIndustrial Automationsanju245100% (1)

- Ebroand SeyaDokument19 SeitenEbroand SeyawabdushukurNoch keine Bewertungen

- Total Productive Maintenance Theoretical Aspect:A Journey Towards Manufacturing ExcellenceDokument9 SeitenTotal Productive Maintenance Theoretical Aspect:A Journey Towards Manufacturing ExcellenceDũng TNNoch keine Bewertungen

- سلايدات اتمتةDokument612 Seitenسلايدات اتمتةAbdul-Aziz MasadNoch keine Bewertungen

- Lecture 3Dokument21 SeitenLecture 3Himanshu JaiswalNoch keine Bewertungen

- Automation - Lecture 01Dokument6 SeitenAutomation - Lecture 01Sudhir KumarNoch keine Bewertungen

- Lecture 4Dokument3 SeitenLecture 4Nauman KhanNoch keine Bewertungen

- Industrial AutomationDokument6 SeitenIndustrial AutomationCamyChin50% (4)

- Aim NotesDokument90 SeitenAim NotesSanketh SNoch keine Bewertungen

- What Is The Differences Between Product Layout and Process LayoutDokument4 SeitenWhat Is The Differences Between Product Layout and Process LayoutConstance ChoiNoch keine Bewertungen

- Unit 3Dokument34 SeitenUnit 3Mohammad MunniNoch keine Bewertungen

- 10) What Is Automation and How Is It Different From Mechanization??Dokument4 Seiten10) What Is Automation and How Is It Different From Mechanization??Rohan KawediyaNoch keine Bewertungen

- Real Time Production Monitoring SystemDokument27 SeitenReal Time Production Monitoring SystemMuhd MuzzammilNoch keine Bewertungen

- Automation and CIMSDokument27 SeitenAutomation and CIMSgavin_d265Noch keine Bewertungen

- Process Selection and Facility LayoutDokument55 SeitenProcess Selection and Facility LayoutJosart TubayNoch keine Bewertungen

- Introduction To Production Planning and ControlDokument28 SeitenIntroduction To Production Planning and ControlDr. Mahmoud Abbas Mahmoud Al-NaimiNoch keine Bewertungen

- 1 Unit1Dokument18 Seiten1 Unit1mathankumarjkkNoch keine Bewertungen

- 3 2 2 P 604764a9e8de5 FileDokument13 Seiten3 2 2 P 604764a9e8de5 FileKunal AhiwaleNoch keine Bewertungen

- 761words-Fakhrul Hafizi-Chapter1.aDokument6 Seiten761words-Fakhrul Hafizi-Chapter1.aUina JoNoch keine Bewertungen

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneVon EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNoch keine Bewertungen

- How to Create Continuous Production Flow?: Toyota Production System ConceptsVon EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsBewertung: 5 von 5 Sternen5/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- Workshop:Bicycle Frame Design (Optimization) : University of Puerto Rico at Mayagüez Department of Mechanical EngineeringDokument12 SeitenWorkshop:Bicycle Frame Design (Optimization) : University of Puerto Rico at Mayagüez Department of Mechanical EngineeringNauman KhanNoch keine Bewertungen

- C ProgramDokument1 SeiteC ProgramNauman KhanNoch keine Bewertungen

- Dot Product: Today's ObjectiveDokument22 SeitenDot Product: Today's ObjectiveNauman KhanNoch keine Bewertungen

- Cam DesignDokument19 SeitenCam DesignNauman KhanNoch keine Bewertungen

- Statement of Problem: Methodology/ProcedureDokument1 SeiteStatement of Problem: Methodology/ProcedureNauman KhanNoch keine Bewertungen

- Chemical Reactions: Thermodynamics IIDokument29 SeitenChemical Reactions: Thermodynamics IINauman KhanNoch keine Bewertungen

- Understanding Scientific Progress Aim-OrDokument3 SeitenUnderstanding Scientific Progress Aim-OrNauman KhanNoch keine Bewertungen

- CAM and Follower LectureDokument61 SeitenCAM and Follower LectureNauman KhanNoch keine Bewertungen

- Heat Transfer and Mass Transfer: 6 SemesterDokument9 SeitenHeat Transfer and Mass Transfer: 6 SemesterNauman KhanNoch keine Bewertungen

- Assignment No 2Dokument1 SeiteAssignment No 2Nauman KhanNoch keine Bewertungen

- Tutorial DrawingDokument19 SeitenTutorial DrawingNauman KhanNoch keine Bewertungen

- Thermo AssignmentDokument1 SeiteThermo AssignmentNauman KhanNoch keine Bewertungen

- Assignment # 2Dokument5 SeitenAssignment # 2Nauman KhanNoch keine Bewertungen

- Practice ProblemsDokument1 SeitePractice ProblemsNauman KhanNoch keine Bewertungen

- Determination of Stress and Strain: Machine Design-IDokument66 SeitenDetermination of Stress and Strain: Machine Design-INauman KhanNoch keine Bewertungen

- Machine Design Property TablesDokument7 SeitenMachine Design Property TablesNauman KhanNoch keine Bewertungen

- Power Point PresentationDokument5 SeitenPower Point PresentationNauman KhanNoch keine Bewertungen

- Deming 14 PointsDokument28 SeitenDeming 14 PointsNauman KhanNoch keine Bewertungen

- Clutches, Brakes and FlywheelsDokument23 SeitenClutches, Brakes and FlywheelsNauman KhanNoch keine Bewertungen

- Heat and Mass Transfer Course Outline: Week No. 9/4 1 16/4 2 23/4 3 30/4 4Dokument2 SeitenHeat and Mass Transfer Course Outline: Week No. 9/4 1 16/4 2 23/4 3 30/4 4Nauman KhanNoch keine Bewertungen

- TQM Concept and Principles (Lecture 2)Dokument31 SeitenTQM Concept and Principles (Lecture 2)Nauman KhanNoch keine Bewertungen

- Pneumatically Actuated PDMS FingersDokument10 SeitenPneumatically Actuated PDMS FingersNauman KhanNoch keine Bewertungen

- Keys, Shafts and CouplingsDokument26 SeitenKeys, Shafts and CouplingsNauman KhanNoch keine Bewertungen

- Lista de AccesoriosDokument8 SeitenLista de AccesoriosRONALDNoch keine Bewertungen

- Voltas Case StudyDokument26 SeitenVoltas Case StudyVarsha MalviyaNoch keine Bewertungen

- Select Subjetcts of MetallurgyDokument3 SeitenSelect Subjetcts of MetallurgyRenato BarretoNoch keine Bewertungen

- Catalogo HispaniaDokument58 SeitenCatalogo Hispaniapiscobar67% (6)

- Fragrance Vessel Design ProcessDokument37 SeitenFragrance Vessel Design ProcessCameronFiliauNoch keine Bewertungen

- 14 Management Principles of TOYOTADokument8 Seiten14 Management Principles of TOYOTAgergis50% (2)

- MC LANAHAN ScrubbersDokument4 SeitenMC LANAHAN ScrubbersTsakalakis G. KonstantinosNoch keine Bewertungen

- Amplify Io 3701Dokument2 SeitenAmplify Io 3701Julio GarcíaNoch keine Bewertungen

- CH 13Dokument20 SeitenCH 13Johan GutierrezNoch keine Bewertungen

- Design and Operation of A Gimbal Top Charging System: Peter Whitfield - Siemens VAI Metals Technologies LTDDokument4 SeitenDesign and Operation of A Gimbal Top Charging System: Peter Whitfield - Siemens VAI Metals Technologies LTDklaus4321Noch keine Bewertungen

- Preventing Mechanical FailuresDokument15 SeitenPreventing Mechanical Failuresmarcalasan0% (1)

- Economic Structure of IndiaDokument22 SeitenEconomic Structure of IndiaShreedhar DeshmukhNoch keine Bewertungen

- VP Director Supply Chain Logistics in United States Resume David StonichDokument2 SeitenVP Director Supply Chain Logistics in United States Resume David StonichDavid StonichNoch keine Bewertungen

- Kaowool Paper 1260Dokument2 SeitenKaowool Paper 1260praveentienNoch keine Bewertungen

- GRE PipeDokument4 SeitenGRE PipeMohamed GuezguezNoch keine Bewertungen

- Resources and Trade: The Heckscher-Ohlin Model: Eleventh EditionDokument24 SeitenResources and Trade: The Heckscher-Ohlin Model: Eleventh EditionJonny FalentinoNoch keine Bewertungen

- 1 An Introduction To Project Management: 2007 Dennis Lock and His Licensors. All Rights ReservedDokument32 Seiten1 An Introduction To Project Management: 2007 Dennis Lock and His Licensors. All Rights ReservedOmar Ahmed ElkhalilNoch keine Bewertungen

- Unit 4 Sandwich Composite Materials and StructuresDokument43 SeitenUnit 4 Sandwich Composite Materials and StructuresprsnthNoch keine Bewertungen

- Philippine Agribusiness: An Introduction: Vicky GuiebDokument21 SeitenPhilippine Agribusiness: An Introduction: Vicky GuiebMaria Charlene Grace AringoNoch keine Bewertungen

- Pattern AllowanceDokument14 SeitenPattern AllowancesudhirNoch keine Bewertungen

- Foundry LabDokument24 SeitenFoundry LabthodatisampathNoch keine Bewertungen

- Uops On Purpose Propylene ProductionDokument4 SeitenUops On Purpose Propylene ProductionaminNoch keine Bewertungen

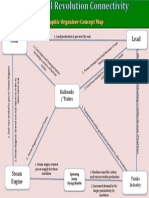

- Graphic OrganizerDokument1 SeiteGraphic Organizerapi-270328839Noch keine Bewertungen

- Basic Engineering DesignDokument4 SeitenBasic Engineering DesignSopi LabuNoch keine Bewertungen

- Gabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDDokument12 SeitenGabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDSab RiNoch keine Bewertungen

- CHAPTER 1 - History of Kaizen & Lean ManagementDokument8 SeitenCHAPTER 1 - History of Kaizen & Lean Managementsam100% (1)

- Director Engineering Electronics Operations in Phoenix AZ Resume Ronald MuellerDokument2 SeitenDirector Engineering Electronics Operations in Phoenix AZ Resume Ronald MuellerRonaldMueller1Noch keine Bewertungen

- Comptibility by Maesh Cone-1Dokument5 SeitenComptibility by Maesh Cone-1Rajesh KumarNoch keine Bewertungen

- Turning N Milling FormulaDokument2 SeitenTurning N Milling FormulaHaris SetiawanNoch keine Bewertungen