Beruflich Dokumente

Kultur Dokumente

Evason Hideaway at Con Dao - STP

Hochgeladen von

tpqnhatOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Evason Hideaway at Con Dao - STP

Hochgeladen von

tpqnhatCopyright:

Verfügbare Formate

CONTENTS

A. DESIGN BASIC ...................................................................................................................................................... 1

1. WATER DEMAND .........................................................................................................................1 2. WASTEWATER FLOWRATE ............................................................................................................1 3. TREATMENT PROCESS ..................................................................................................................1

B. EFFLUENT STANDARD....................................................................................................................................... 2 C. OPERATION TIME............................................................................................................................................... 2 D. THE PROPOSED SEWAGE TREATMENT PROCESS ................................................................................... 3

1. STP PROCESS .............................................................................................................................3 2. STP DESCRIPTION ......................................................................................................................4 3. STP SPECIFICATIONS .................................................................................................................7

a. b. c. d. e. f. g. h. i. j. k. l. Grease trap ................................................................................................................................................. 7 Septic tank................................................................................................................................................... 7 Equalization tank ....................................................................................................................................... 7 Anoxic 1 ...................................................................................................................................................... 8 Aeration tank............................................................................................................................................... 8 Anoxic 2 ...................................................................................................................................................... 8 Aeration tank 2............................................................................................................................................ 8 Clarifier ...................................................................................................................................................... 9 Disinfection tank ......................................................................................................................................... 9 Treated water storage tank ......................................................................................................................... 9 Anaerobic sludge digester........................................................................................................................... 9 Belt filter press........................................................................................................................................... 9

E. ODOR CONTROL SYSTEM .............................................................................................................................. 11 F. SOLID WASTE DISPOSAL ................................................................................................................................ 13 G. EQUIPMENT........................................................................................................................................................ 14 J. OPERATION COST.............................................................................................................................................. 17

1. SEWAGE TREATMENT PLANT (A).................................................................................................17

a. Electric consumption rate ......................................................................................................................... 17 b. Chemical consumption rate ........................................................................................................................... 18 c. Labor cost ................................................................................................................................................. 18

2. ODOR CONTROL SYSTEM (B)......................................................................................................18

a. Electric consumption rate............................................................................................................................... 18 b. Chemical consumption.............................................................................................................................. 18

3. SOLID WASTE PROCESSING SYSTEM (C) .....................................................................................19

a. Electric consumption rate ......................................................................................................................... 19 b. Chemical consumption.............................................................................................................................. 19 Total operation cost............................................................................................................................................ 19

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

A. DESIGN BASIC 1. Water demand 24 villas (2 beds/villa) x 1 m3/villa.day1 71 room building x 800l/room.day Restaurant 200 guests x 35 l/guest.day2 Other services (spa, gym, shops, etc.) Washing = 24 m3/day = 57 m3/day = 7 m3/day = 10 m3/day = 80 m3/day

Maximum water consumption is about 180 m3/day. 2. Wastewater flowrate In general, wastewater flowrate can be assumed as total water demand. Therefore, wastewater flow for designing the STP is 180 m3/day. 3. Treatment process The treatment process includes the following steps: - Pre-treatment by septic tank and equalization tank. - Biological treatment with denitrification process. - Biological and mechanical sludge treatment process.

1 2

Water demand is 400-600l/bed.day. Water demand for restaurant is 35l/guest.day

31-Mar-08

Page |1

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

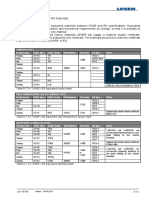

B. EFFLUENT STANDARD The selection of wastewater treatment processes is based on: Quality of the influent The Vietnamese Standards of domestic wastewater (TCVN 6772 - 2000, level I) Table 1. Effluent standards for domestic uses

No. 1 2 3 4 5 6 7 8 9 10 Parameter pH BOD Suspended solid Settable solid Total solid Sulfur (H2S) Nitrate (NO3-) Oil and grease Phosphate (PO43-) Total coliform Unit Value Level Level III IV 59 59 40 50 60 100 0,5 0,5 500 500 3.0 4.0 40 50 20 20 10 10 5000 5000

mg/l mg/l mg/l mg/l mg/l mg/l mg/l mg/l MPN/100ml

Level I 59 30 50 0,5 500 1.0 30 20 6 1000

Level II 59 30 50 0,5 500 1.0 30 20 6 1000

Level V 59 200 100 100 10000

Source: www.nea.gov.vn C. OPERATION TIME Operation time: - 24 hours/day. - 7 days per week.

31-Mar-08

Page |2

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

D. THE PROPOSED SEWAGE TREATMENT PROCESS 1. STP Process

Figure 1. The proposed STP process

31-Mar-08

Page |3

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

2. STP Description The Sewage Treatment Plant (STP) is proposed to treat wastewater which generates from facilities of the resort. Wastewater from villas and hotel building is collected to the STP by the separate sewer system. Wastewater from restaurant kitchen containing high oil and grease is pretreated by oil trap before entering the sewer. In STP, wastewater at first flows to septic tank which includes three chambers: (i) anaerobic chamber, (ii) settling chamber and, (iii) anaerobic filtration chamber. In septic tank, settleable solids in the incoming wastewater settle and form a sludge layer at the bottom of tank. Greases and other light materials float to the surface where a scum layer is formed as floating materials accumulate. Settled and skimmed wastewater flows from the clear space between the scum and sludge layer to the downstream treatment facilities. The organic material retained in the bottom of the tank undergoes facultative and anaerobic decomposition and is converted to more stable compounds and gases such as carbon dioxide (CO2) methane (CH4) and hydrogen sulfide (H2S). After coming out the septic tank, wastewater flows pass over fine screening bar in order to protect pumps, valves, pipe lines and other appurtenances from damage or clogging by rags and large objects and then wastewater flows to equalization tank. The equalization tank is used to overcome the operational problems caused by flow rate variations, to improve the performance of the downstream processes, and to reduce the size and the cost of downstream facilities. Besides, the equalization tank has the function to reduce an amount of BOD/COD in waste water. In equalization tank there are two submersible pumps are installed to transfer wastewater to the anoxic and aerobic processes There are five chambers in anoxic and aerobic processes, the first chamber is anoxic No.1 chamber, the second chamber is aeration chamber, the third chamber is anoxic No.2 chamber, the fourth chamber is oxic chamber and finally is the clarifier chamber. The anoxic and aerobic processes are used to remove BOD and ammonia. BOD is converted to CO2 and NH3 by equation (1). Organic matter + C5H7NO2 + O2 + nutrients products (1) CO2 + NH3 + C5H7NO2(new cells) +other

Various forms of nitrogen can deplete dissolved oxygen levels in receiving waters, exhibit toxicity toward aquatic life, affect chlorine disinfection efficiency, present public health hazards, and affect the suitability of waste water reuse. To treat nitrogen in water, nitrification and denitrification are applied.

31-Mar-08

Page |4

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

And, ammonia is oxidized to nitrite (NO2-N) and nitrite is oxidized to nitrate ((NO3-N) and then N2

+ NH 4 + 1.83O2 + 1.98 HCO3 0.021C5 H 7 O2 + 0.98 NO3 + 1.041H 2O + 1.88 H 2 CO3

NO3 NO2 NO N 2 O N 2

The term nitrification is the biological oxidation of ammonium (NH4+) first to the nitrite (NO2-) then to the nitrate (NO3-) form. The conversion of ammonium to nitrite is caused by Nitrosomonas bacteria: 2 NH4+ + 3 O2 Nitrosomon as 2 NO2- + 4 H+ + 2 H2O The nitrite in turn are oxidized by the bacteria Nitrobacter according to the following: 2 NO2- + O2 Nitrobacte r 2 NO3 The overall nitrification reaction is as follow: NH4+ + 2 O2 Bacteria NO3- + 2H+ + H2O The term denitrification is biological process is used to remove nitrate and nitrite forms of nitrogen in water. The produced nitrate nitrogen in the nitrification process is converted to a gaseous form of nitrogen. Pseudomonas, Micrococcus, Achromobacter, and Bacillus are pricipal nitrate reducing bacteria that accomplish denitrification. Using methanol as the carbon source, the energy reaction is represented as follows: 6 NO3- + 2 CH3OH 6 NO2- + 2 CO2 + 4 H2O 6 NO2- + 3 CH3OH 3 N2 + 3 CO2 + 3 H2O + 6 OH- + 3 O2 The overall energy reaction: 3 NO3- + 14 CH3OH + CO2 + 3 H+ 3 C5H7O2N + 19 H2O In the anoxic tank 1, the denitrification is conducted. As mentioned above, the removal of nitrogen gas can be accomplished biologically under anoxic conditions. The last product of this process is nitrogen gas. This gas is produced as buddle attached with sludge particles and can be removed by mixing The wastewater is pumped to the aeration tank 1 for decomposing an amount of BOD in the waste water under oxic conditions. In this tank, the aerobic bacteria use organic contaminants as influent substances to form simpler compounds.

31-Mar-08

Page |5

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

For the complete transformation of nitrogen in waste water, the anoxic tank 2 is necessary. The using of this tank has two reasons: (i) change ammonia and various organic nitrogen forms into nitrate and, (ii) elimination the residual nitrate to nitrogen gas. After nitrogen treatment, wastewater is flowed into the other oxic tank for decomposing all residual BOD. The biomass informed by activated sludge is separated by clarifier. The function of the sedimentation tank is to separate the activated-sludge solids from the mixed liquor. The sludge in the inlet wastewater is precipitated to the bottom of the clarifier by gravity. The sludge layer thickens during the operation process of wastewater treatment plant. It is collected continuously by scraper. The outlet water after separation from sludge flows through effluent trough surround top of four walls tank. The effluent trough is designed as V-notch shape to ensure that the outlet water from clarifier does not contain a large amount of biological sludge. The disinfection process is used to sterilize water before the utilization. Disinfection tank is provided by a Sodium Hypochlorite dosing system downstream of the clarifier. A contact tank of 20 minutes minimum retention is provided. This contact tank will achieve a chlorine residual of 1 ml before reuse. This chlorine residuals function is maintaining the microorganism inactivation activities of sterilizing chemical.

31-Mar-08

Page |6

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

3. STP specifications 180m 3 / day = 9m 3 / h Design flowrate Q = 20h / day Peak flow: 64 m3/h Capacity: 180 m3/day a. Grease trap Grease trap is located near the restaurant to remove oil and grease in kitchen wastewater. Table 2. Specification of Grease trap

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 4 2 8 10 2x 2 x 2.0 2 x 2 x 2.5 Reinforce concrete

b. Septic tank Table 3. Specification of Septic tank

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Vworking Volume Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 13.5 24 179 204.5 15 x 4 x 4.0 15 x 4 x 4.5 Reinforce concrete

c. Equalization tank Table 4. Specification of Equalization tank

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Vworking Volume Vtotal L x W x Hworking Dimension L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 9 9.5 85.4 96 6.2 x 3.8 x 4.0 6.2 x 3.8 x 4.5 Reinforce concrete

31-Mar-08

Page |7

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

d. Anoxic 1 Table 5. Specification of Anoxic 1

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Vworking Volume Vtotal L x W x Hworking Dimension L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 9 2.33 21 24 3.8 x 1.7 x 4.0 3.8 x 1.7 x 4.5 Reinforce concrete

e. Aeration tank Table 6. Specification of Aeration Tank 1

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal L x W x Hworking Dimension L x W x Htotal Material Unit m3/hour Hour m3 m3 M M Value 5 6.22 56 63 4.2 x 3.8 x 4.0 4.2 x 3.8 x 4.5 Reinforce concrete

f. Anoxic 2 Table 7. Specification of Anoxic 2

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 M M Value 9 2.33 21 24 3.8 x 1.7 x 4.0 3.8 x 1.7 x 4.5 Reinforce concrete

g. Aeration tank 2 Table 8. Specification of Aeration tank 2

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 9 3.11 28 31.5 3.8 x 2.3 x 4.0 3.8 x 2.3 x 4.5 Reinforce concrete

31-Mar-08

Page |8

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

h. Clarifier Table 9. Specification of Clarifier

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Vworking Volume Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 18 2.64 54 48 3.8 x 3.8 x 4 3.8 x 3.8 x 4.5 Reinforce concrete

i. Disinfection tank Table 10. Specification of Disinfection tank

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal L x W x Hworking Dimension L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 9 1.77 16 20 4.2 x 2.4 x 2.0 4.2 x 2.4 x 2.5 Reinforce concrete

j. Treated water storage tank Table 11. Specification of Treated water storage tank

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal Dimension L x W x Hworking L x W x Htotal Material Unit m3/hour Hour m3 m3 m m Value 9 6 54 48 7.9 x 2.4 x 4.0 7.9 x 2.4 x 4.5 Reinforce concrete

k. Anaerobic sludge digester Table 12. Specification of Anaerobic sludge digester

No. 1 2 3 4 5 Parameter Design flowrate Q Hydraulic retention time (HRT) Volume Vworking Vtotal L x W x Hworking Dimension L x W x Htotal Material Unit m3/hour day m3 m3 m m Value 1 6.25 150 167 8.1 x 5.5 x 4.5 8.1 x 5.5 x 5.0 Reinforce concrete

l. Belt filter press - Belt Filter press: o Capacity: 1m3/h

31-Mar-08

Page |9

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

o Manufacture: Shun-Huei, Taiwan, Accessories: electric control panel, handrail, washing pump, compressor, recycle system, polymer solution tank, mixer, electric wire

31-Mar-08

Page |10

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

E. ODOR CONTROL SYSTEM All tanks have internal vent holes through the tank walls above water level and are vented into the same line to allow the excess air in the STP to absorber to remove odor before discharged. The odor control system consists of three parts: (1) deodorization column, (2) exhaust fan and, (3) chemical mixing tank. The chemical mixing tank contains NaOCl 10% solution for absorption process. The exhaust fan collects contaminated air from tanks and houses of the STP into the absorber. The air from these tanks has many components with various ratios, such as: CH4, H2S, CO2, H2O Polluted air stream enters the absorber from the bottom and passes upward through a wetted plastic packed bed. This packed bed in the odor control system has two functions: (i) lengthening the contact time between polluted air and deodorized solution, thus, the deodorization efficiency will be higher and, (ii) widespread distribution the solution from the top of the absorber. To treat foul gases in the inlet air stream, NaOCl is used as deodorized chemical. The liquid - NaOCl 10% solution enters the top of the column and is uniformly distributed over the column packing through spray nozzles.

Figure 2. Odor control system Sodium hypochloride is a pale greenish liquid also known as soda bleach or liquid bleach. As a powerful oxidative qualities and slight alkalinity, NaOCl is used to mitigate odor problems in wastewater collection and treatment facilities. NaOCl oxidizes pollutants in the air inlet stream to simpler compounds that have less uncomfortable smell. For example, with hydrogen sulfide (H2S) gas - one of the most common causes of foul odor in wastewater, NaOCl oxidizes it into the last form sulfate ion H2SO4 as the following reaction:

31-Mar-08 Page |11

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

H2S + 4 NaOCl

4 NaCl + H2SO4

In this deodorization system, the NaOCl concentration is 10%. NaOCl is contained in chemical tank for stabilization concentration. When the odor treatment system works, NaOCl solution is pumped into the absorber and distributed by sprayers from top as droplets. After contacting and reacting with contaminated gases in the inlet air, the solution is collected at the bottom of the absorber. Then, it is circulated into the chemical tank for the next treatment circle. The outlet gas after treatment that is odorless goes to the atmosphere from the top of the absorber.

31-Mar-08

Page |12

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

F. SOLID WASTE DISPOSAL The solid waste in Con Dao Resort should be separated into two main types (a) biodegradable waste including wasted food, vegetables, sludge from the STP and garden waste (b) nonbiodegradable wastes such as plastics, paper, plastic bottles and cans. Due to the fact that Con Dao has no sanitary landfill, all the solid waste must be reasonably treated on-site. Biodegradable and non-biodegradable waste shall be handled in two different ways. The biodegradable waste will be degraded in a anaerobic digester and the compost will be used as fertilizer for garden in the resort or selling to local farmers. The non-biodegradable waste will be separated into the following types: papers, plastic bags, plastic bottles, glasses and metal cans. Packaging machine will be used for compaction each waste. The compacted waste packages will be stored in the ware house and transported to the recycling facilities in the inland or Con Dao Island. The solid waste generation rate is about 1 kg/guest.day (chosen of generation rate based on Table 13) Thus, the maximum solid waste quantity is about: (24 villas+ 71 hotel rooms) x 2 guest/unit x 1 kg/guest.day = 190 kg/day. Assume solid waste contains 50% biodegradable waste. Therefore, the quantity of waste to be digested is approximately 100 kg/day. Sludge from the CSTP is around 180 kg/day. Total solid waste is 280 kg/day. Table 13 Municipal solid water generation in Viet Nam, 2003

Generation rate (kg/person.day) 0.7 1.3 1.0 0.9 0.3 % organic 55

Urban areas Ho Chi Minh city Ha Noi Da Nang Rural areas

60-55

Source: Urban data by consulting data group survey 2004.Rural data calculated using studies by NEA (2000) and Agriculture University No.1(2003)

31-Mar-08

Page |13

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

The treatment of solid waste is given in Figure 2.

Biodegradable waste Storage and transfer to Shredding Slurry tank Anaerobic Digester

Sludge pump

Reuse for agriculture Non-biodegradable waste

Belt Filter press

Packaging

Ware house

Recycling facilities

Figure 3. Schematic diagram of solid waste management system

31-Mar-08

Page |14

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

G. EQUIPMENT

No. 1 2 3 4 5 6 7 8 Description Macerator Submersible sludge pumps Submersible pump Submersible mixer Drive and mixer Air blowers Return flow pump Drive and mixer Location TK-101A TK-101A/B TK-102 TK-102 TK-201 TK-202 TK-202 TK-203 Tag number M-101 P-101A/B P-102A/B SM-102 M-201 A/B BL-202A/B P-202A/B M-203 A/B Brand Specification Quantity 1 2 2 2

SEWAGE TREATMENT PLANT Tsurumi Japan Tsurumi Japan Tsurumi Japan Sumitomo-japan Anlet Japan Ebara Italy Sumitomo-japan 0.75 KW, 3-ph.380V/50Hz 1.5 kW, 3-ph.380V/50Hz , Q = 10 3 m /h, H = 8m 0.4 kW, 2.8m3/min 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM. Mixer and shaft: SUS 304 5.1 kW, Model: BE80E, 4.04m3/min, 50kPa, ANLET Roots type 0.75kW ,Q = 5 m3/h, H = 8m 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM. Mixer and shaft: SUS 304 0.039 rpm, 0.2 kW SUS 304 1.1kW, Q = 8 m3/h, H = 10m 0.15kW, Q= 0-> 50l/h, H =10psi 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM PE, V=200 L 0.4 kW, 2.8m /min

3

2

2 2

2

1 1 2 2 1 1 2 2 2

9 10 11 12 13 14 15 16 17

Gear motor of sludge scraper Sludge scraper Return sludge pump Chlorine dosing pump Chemical mixer: drive and mixer Chlorine tank Treated water pump Submersible mixer Air Diaphragm Pump

TK-205 TK-205 TK-205 TK-301 TK-301 TK-301 TK-302 TK-401 TK-401

M-205 SCP-205 P-205A/B DP-301A/B M-301 T-301 P-302A/B SM-401A/B SDP-401A/B

Sumitomo-japan Vietnam Ebara Italy Blue White-USA Sumitomo-japan Vietnam Tsurumi Japan Sandpiper - USA

31-Mar-08

Page |14

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

0.4kW, 380V/3phase/50Hz, Disposal capacity: 30-80kg-D.S/hr, Fiter cloth width: 800mm 5.25kW, 8kg/cm2, 75l/ph, 160l 0.15kW, Q= 0-> 50l/h, H =10psi =34mm PE, V=200 L 2.5, H=4m, SS 304 PE, V=1000 L 5.25kW SUS 304 1.1kW, Q = 8 m3/h, H = 10m Motor 2.25 kW 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM. Mixer and shaft: SUS 304

18 19 20 21 22 23 24 25 26 27 28 29 30

Fiter belt press Air compressor Polymer dosing pump Air Diaphragm Pump Polymer tank Deordorization column Air Diaphragm Pumps NaOCl tank Fan for Deodorization column Pick up hoods Sludge pump Grinder Mixer

TK-401 TK-401 TK-401 TK-401 TK-401 DC-500 DC-500 DC-500 DC-500 FP-401 TK-600 TK-600 TK-600

SP-401 CR-401 DP-401A/B SDP-401A/B T-401 DC-500 CDP-500A/B CT-500 FAN-500

Shun Huei Puma - Taiwan Blue White-USA Sandpiper - USA Vietnam Vietnam Sandpiper - USA Vietnam Vietnam Vietnam

1 1 2 2 1 1 2 1 1 2 1 1 1

ODOR CONTROL SYSTEM

SOLID WASTE PROCESSING SP-600A/B Ebara Italy G-600 M-600 Vietnam Sumitomo-japan

31-Mar-08

Page |15

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

I. CONSTRUCTION WORKS

No. 1 2 3 Item Grease trap Septic tank Equalization tank Quantity 1 1 1 Specifications - HRT: 2h - Material: reinforced concrete - HRT: 24h - Material: reinforced concrete - Hydraulic retention time (HRT): 9.5 h. - Material: reinforced concrete - HRT: 2.33h - Material: reinforced concrete - HRT: 6.22 hours. - Material: reinforced concrete - HRT: 3.11 hours - Material: reinforced concrete - HRT: 2.64 hours - Overflow rate: 17 m3/m2.h. - Material: reinforced concrete - HRT: 1.77 hours - Material: reinforced concrete - HRT: 6 hours - Material: reinforced concrete - HRT: 1days - Material: reinforced concrete - Material: reinforced concrete And bricks Dimension - L x W x Htl= 2mx2mx2.5m - L x W x Htl = 15mx4mx4.0m - L x W x Htl = 6.2mx3.8mx4.5m - L x W x Htl = 3.8mx1.7mx4.5m - L x W x Htl = 4.2mx3.8mx4.5m - L x W x Htl = 3.8mx2.3mx4.5m - L x W x Htl = 3.8mx3.8mx4.5m - L x W x Htl = 4.2mx2.4mx2.5m - L x W x Htl = 7.9mx2.4mx4.5m - L x W x Htl = 8.1mx5.5x5.1m - L x W x Htl = 6.5m*5.5m*3.4m Volume, (Vtl) m3 10 246 106

4 5

Anoxic 1,2 Aeration tank 1

2 1

29 72

6 7

Aeration tank 2 Clarifier

1 1

31.5 65

8 9 10 11

Disinfection tank Treated wastewater storage tank Anaerobic sludge digester Control house

1 1 1 1

25.2 86 227

31-Mar-08

Page |15

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

J. OPERATION COST 1. Sewage treatment plant (A) a. Electric consumption rate

Motor capacity (kW) 0.75 1.5 0.45 0.75 Operation time (hr/day) 8 8 24 8 Power consumption (kWh/day) 6 12 10.8 6

No. 1 2 3 4

Equipment

Code

Manufacturer Tsurumi Japan Tsurumi Japan Tsurumi Japan Sumitomo-japan

Specification 0.75 KW, 3ph.380V/50Hz 1.5 kW, 3-ph.380V/50Hz ( run in shifts), Q = 10 m3/h, H = 8m 0.4 kW, 2.8m3/min 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM 5.1 kW, Model: BE80E, 4.04m3/min, 50kPa, ANLET Roots type 0.75kW , ( run in shifts), Q = 5 m3/h, H = 8m 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm, Output Speed: 58 RPM. Mixer and shaft: SUS 304 0.039 rpm, 0.2 kW 1.1kW, ( run in shifts), Q = 8 m3/h, H = 10m 0.15kW, ( run in shifts), Q= 0-> 50l/h, H =35m 0.75 kW, 380V/3phase/50Hz , Output Torque: 98.5 Nm,

Quantity 2 1 2 1

SEWAGE TREATMENT PLANT Submersible sludge P-100A/B pumps Submersible pump Submersible mixer Drive and mixer P-102A/B SM-102 M-201A/B BL202A/B P-202A/B

5 6

Air blowers Return flow pump

Anlet Japan Ebara Italy

2 2

5.1 0.75

24 8

122.4 6

Drive and mixer

M-203 A/B

Sumitomo-japan

0.75

8 9 10 11

Gear motor of sludge scraper Return sludge pump ChlorineDosing pump Chemical mixer: drive and mixer

M-205 P-205A/B DP301A/B M-301

Sumitomo-japan Ebara Italy Blue White-USA Sumitomo-japan

1 2 2 1

0.2 1.1 0.15 0.75

24 8 8 8

4.8 8.8 1.2 6

31-Mar-08

Page |17

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

Output Speed: 58 RPM

12 13 14

Treated water pump Submersible mixer Polymer dosing pump

P-302A/B SM401A/B DP401A/B Tsurumi Japan Blue White-USA

1.1 kW, ( run in shifts), Q = 8m3/h, H = 20m 0.4 kW, 2.8m3/min 0.15kW, ( run in shifts), Q= 0-> 50l/h, H =35m 0.4kW, 380V/3phase/50Hz, Disposal capacity: 3080kg-D.S/hr, Fiter cloth width: 800mm 5.25kW, 8kg/cm2, 75l/ph, 160l

2 1 2

1.1 0.4 0.15

8 8 8

8.8 3.2 1.2

15

Fiter press

SP-401

Shun Huei

0.4

1.6

16

Air compressor

CR-401

Puma - Taiwan

5.25

4 Total

21 225.8

31-Mar-08

Page |18

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

Assuming electric tariff: 1,000 VND/kWh 225,80 kWh/day x 1,000 VND/kWh = 225,800 VND b. Chemical consumption rate

N0 1 2 Chemical Chlorine Polymer Total Consumption 1,2 kg 500 gram Unit price 30,000/kg 70,000/kg Total 36,000 35,000 71,000

c.

Labor cost

Salary: 50,000 VND/worker.day x 2 workers = 100,000 VND/day Total cost (Total A): 225,800 + 71,000 + 100,000 = 396,800 VND/day Operation cost for 1 m3 treated wastewater: 396,800/180 = 2,200 VND /m3 2. Odor control system (B) a. Electric consumption rate

Motor capacity (kW) 5.25 Operation time (hr/day) 8 Power consumption (kWh/day) 42

No. 1 2

Equipment Fan for Deodorization column Air Diaphragm Pumps

Code FAN-500 CDP500A/B

Manufacturer Vietnam Sandpiper USA -

Specification 5.25kW

Quantity 1

Total

42

b. Chemical consumption

N0 1 Chemical NaOCl Total Consumption 3 kg Unit price 15,000/kg Total 45,000 45,000

Total cost (Total B): 42,000 + 45,000 = 87,000 VND/day

31-Mar-08

Page |18

EVASON HIDEAWAY AT CON DAO

Sewage Treatment Plant: General Description

3. Solid waste processing system (C) a. Electric consumption rate

No. 1 2 3 Equipment Sludge pump Mixer Grinder Code SP600A/B M-600 G-600 Manufacturer Ebara Italy Sumitomojapan Vietnam Specification 1.1kW, ( run in shifts), Q = 8 m3/h, H = 10m 0.75kW, 58RPM Motor 2.25 kW Quantity 1 1 1 Motor capacity (kW) 1.1 0.75 2.2 Operation time (hr/day) 4 4 4 Total Power consumption (kWh/day) 4.4 3 8.8 16.2

Assuming electric tariff is: 1,000 VND/ kWh 27 kW.h/day x 1000 VND/kWh =27,000 VND Total cost ( Total C): 27,000 VND/day b. Chemical consumption

N0 1 Chemical C-polymer Total Consumption 1 kg Unit price 30,000/kg Total 30,000 30,000

Total C = 27,000 + 30,000 = 57,000 VND Total operation cost = Total A + Total B + Total C = 225,800 VND/day + 87,000 VND/day + 57,000 VND/day = 369,800 VND/day

31-Mar-08

Page |19

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Morley Fire Panels Installation ManualDokument55 SeitenMorley Fire Panels Installation Manualtpqnhat100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Sys-Am-14 Designing An 'Iaq Ready' Air Handler SystemDokument71 SeitenSys-Am-14 Designing An 'Iaq Ready' Air Handler SystemtpqnhatNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Astm A53Dokument22 SeitenAstm A53Islavy NguyenNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Green Building User GuideDokument22 SeitenGreen Building User Guidetpqnhat50% (2)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Green Building: Christin Jose S7 Ce Roll No: 14Dokument32 SeitenGreen Building: Christin Jose S7 Ce Roll No: 14tpqnhat100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Honeywell DDC Panel ManualDokument512 SeitenHoneywell DDC Panel ManualSyed ZakiuddinNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Magnetic Bearing Oil Free Technology MN Ashrae PDFDokument27 SeitenMagnetic Bearing Oil Free Technology MN Ashrae PDFtpqnhat100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Building Commission and Plumbing Industry Commission Agreement 20102Dokument34 SeitenBuilding Commission and Plumbing Industry Commission Agreement 20102tpqnhatNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- (McQuay Incorporated) Geothermal Heat Pump Design ManualDokument70 Seiten(McQuay Incorporated) Geothermal Heat Pump Design Manualtpqnhat100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Wind & Solar Power: Environmental Spring Festival - Macksville Adventist SchoolDokument34 SeitenWind & Solar Power: Environmental Spring Festival - Macksville Adventist SchooltpqnhatNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- MS For Painting Marina MallDokument5 SeitenMS For Painting Marina MalltpqnhatNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Report Ohwt 2011Dokument71 SeitenReport Ohwt 2011tpqnhatNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- FIDIC IV - Design & Build (Turnkey) ContractDokument70 SeitenFIDIC IV - Design & Build (Turnkey) Contractlittledragon0110100% (6)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Final Wake SW Tool v22Dokument17 SeitenFinal Wake SW Tool v22tpqnhatNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Gso 987 2012Dokument9 SeitenGso 987 2012Mani KandanNoch keine Bewertungen

- WaterAnalyses PDFDokument2 SeitenWaterAnalyses PDFZenga Harsya PrakarsaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Flame-Retardant Mechanisms and Preparation ofDokument23 SeitenThe Flame-Retardant Mechanisms and Preparation ofbrilyan muhammadNoch keine Bewertungen

- High Speed SteelDokument2 SeitenHigh Speed SteeljerfmosNoch keine Bewertungen

- Asme Sa 240 PDFDokument16 SeitenAsme Sa 240 PDFqaNoch keine Bewertungen

- Far04410 PDFDokument9 SeitenFar04410 PDFAlfred FonsecaNoch keine Bewertungen

- DFL E-31Dokument16 SeitenDFL E-31Fersan AngelesNoch keine Bewertungen

- Effect of Variation in LPG Composition On Heating Value Using Aspen HYSYSDokument7 SeitenEffect of Variation in LPG Composition On Heating Value Using Aspen HYSYSIstiak HussainNoch keine Bewertungen

- PQR Al 6xxxDokument7 SeitenPQR Al 6xxxAmin ThabetNoch keine Bewertungen

- Week 3 - Reactive DyesDokument7 SeitenWeek 3 - Reactive DyesRR TNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Text ReportDokument6 SeitenText ReportokibanaNoch keine Bewertungen

- Alloy 59 - Alfa Laval Olmi Aprile 2018 PDFDokument12 SeitenAlloy 59 - Alfa Laval Olmi Aprile 2018 PDFfabianoNoch keine Bewertungen

- Wang Et Al 2008Dokument14 SeitenWang Et Al 2008Venkata KrishnaNoch keine Bewertungen

- NSPS LitDokument4 SeitenNSPS Litnermeen ahmedNoch keine Bewertungen

- QCS 2010 Section 26 Part 3 Primers, Paints and CoatingsDokument4 SeitenQCS 2010 Section 26 Part 3 Primers, Paints and Coatingsbryanpastor106Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Chemistry Chapter 4 PDFDokument16 SeitenChemistry Chapter 4 PDFMin Thade DeeNoch keine Bewertungen

- TafelDokument33 SeitenTafelMadhur Raj NNoch keine Bewertungen

- 3.3a VSEPR Theory PDFDokument21 Seiten3.3a VSEPR Theory PDFSarvesh Kanaujia100% (8)

- Gas Turbine GEK28143aDokument10 SeitenGas Turbine GEK28143aDede Maulana100% (1)

- SizingDokument22 SeitenSizingFaisal AnsariNoch keine Bewertungen

- Abe. Proof PU ECO: PolyurethaneDokument2 SeitenAbe. Proof PU ECO: Polyurethanecremildo maetinhoNoch keine Bewertungen

- Manual HP700 2020Dokument11 SeitenManual HP700 2020Jefril SiruNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 15 - Memo - No.261, dt.16.7.07Dokument10 Seiten15 - Memo - No.261, dt.16.7.07anreddyharishNoch keine Bewertungen

- EHB en File 9.7.3 Equivalent ASME en MaterialsDokument3 SeitenEHB en File 9.7.3 Equivalent ASME en MaterialsAdhitya DarmadiNoch keine Bewertungen

- Chemistry Jan 2021 (2C)Dokument14 SeitenChemistry Jan 2021 (2C)zaraNoch keine Bewertungen

- Using PVC and CPVC Piping For Chemical ApplicationsDokument3 SeitenUsing PVC and CPVC Piping For Chemical ApplicationsmrpalmistNoch keine Bewertungen

- CAPE Chemistry 2011 U1 P1 PDFDokument12 SeitenCAPE Chemistry 2011 U1 P1 PDFIsmadth2918388Noch keine Bewertungen

- United States Patent: Kwolek (45) June 20, 1972Dokument58 SeitenUnited States Patent: Kwolek (45) June 20, 1972Bala RajuNoch keine Bewertungen

- Marine Geochemistry 1Dokument19 SeitenMarine Geochemistry 1Juliano CordeiroNoch keine Bewertungen

- Gen Chem Activity (Week 3)Dokument2 SeitenGen Chem Activity (Week 3)Jane GanadoNoch keine Bewertungen

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontVon EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontBewertung: 4.5 von 5 Sternen4.5/5 (18)