Beruflich Dokumente

Kultur Dokumente

SpecTehnice Eng (1) .Montaj

Hochgeladen von

Eduard Gabriel VipelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SpecTehnice Eng (1) .Montaj

Hochgeladen von

Eduard Gabriel VipelCopyright:

Verfügbare Formate

12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

TableofContents

5.1 ProcedureDescription....................................................................................... 1

5.2 ProductDescription.......................................................................................... 2

5.3 PE100RC

plus

QualityAssurance........................................................................ 3

5.4 TechnicalInformation........................................................................................ 8

5.4.1 ProductDataSheetforSLM

2.0DrinkingWaterPipes........................................................................8

5.4.2 ProductDataSheetforSLM

2.0GasPipes........................................................................................9

5.4.3 ProductDataSheetforSLM

2.0SewagePressurePipes.................................................................... 10

5.4.4 ProtectionfromAbrasionduringTrenchlessInstallation....................................................................... 11

5.4.5 DoubleProtectionagainstPointLoads.............................................................................................. 11

5.5 InstallationGuidelinesforSLM

2.0Pipes.........................................................12

5.5.1 GeneralInformationonInstallation.................................................................................................. 12

5.5.2 JoiningTechniques.......................................................................................................................... 13

5.5.3 SystemTechniques.......................................................................................................................... 19

5.5.4 Tables...........................................................................................................................................20

5.6 RFPForms.......................................................................................................24

5.6.1 RFPFormforegeplastSLM

2.0DrinkingWaterPipe........................................................................ 24

5.6.2 RFPFormforegeplastSLM

2.0GasPipe........................................................................................25

5.6.3 RFPFormforegeplastSLM

2.0SewagePressurePipe......................................................................26

5.7 RecyclingandEnvironmentalProtection............................................................27

12/05

1 12/05

5 TrenchlessInstallation

andRenovation

Trenchlessinstallation:

Veryhighdemandsonpipelines

Open-trench pipe installation not

only represents a hazard to traffc

and causes annoyance to local resi-

dents but also permanently damages

the road surface. This has resulted in

a growing acceptance of trenchless

pipe installation methods, which can

alsobeusedtolaypipesunderrivers,

lakesortraffcroutes.

Atthesametime,thesemethodssave

timeandmoney.Costsavingsofupto

50 percent can be achieved accord-

ing to a publication by the Bavarian

State Ministry for Regional Develop-

ment and Environmental Affairs of

September 11, 1996 - a powerful ar-

gument in view of the high cost pres-

sureonthepublicpurse.

Various options are available for

trenchless pipe installation. With all

these methods, there is an increased

risk of pipe damage. The extent of

this damage cannot be determined

oncethepipeislaid(blackboxinstal-

lation!). For this reason, pipes with

a protective outer layer are required

and are therefore recommended by

the DVGW (German Association of

GasandWaterEngineering)fordirec-

tional drilling (Code of Practice GW

321) and for pipe bursting (Code of

PracticeGW323).

5.1ProcedureDescription

Fig5-4

This method is technically challenging. Depending on the

materialfromwhichtheoldpipeismadeandthecondition

oftheoldpipe,thenewpipeissusceptibletoscratchesand

scoring.Shardsandstonescangiverisetoincreasedpoint

loadsduringservice.

Fig5-3

Thismethodisusedforrenovatingdefectivepipelines.De-

pending on the condition of the old pipe, scratches and

scoring can be caused in the new pipe. Steel pipes with

V-weldsposeaparticularlyhighrisk.Increasedpointloads

arenotlikelywiththismethod.

Scoredepth

Pointload

Relining(longpipe) Pipebursting

Fig5-2

Using an impact mole, pipes - generally domestic serv-

ice connections - are fred over a few metres through

theground.Surroundingstonesscratchthenewpipeand

causepointloads.

Soildisplacement

Fig5-1

Horizontal directional drilling is a steerable wet drilling

method.Dependingonthenatureofthesoilandborehole

radius,scratches,scoringandpointloadingbystonescan

damagethenewlyinstalledpipe.

Horizontaldirectionaldrilling(HDD)

Scoredepth

Pointload

Scoredepth

Pointload

Scoredepth

Pointload

2 12/05

5 TrenchlessInstallation

andRenovation

5.2ProductDescription

Protectivefunction1

Protectionfromscoring

andnotching

Protectivefunction2

Weakeningoffastcrack

propagation

Protectivefunction4

Hightearstrengthgives

cracksnochance

Protectivefunction5

Highcrackresistancepro-

tectsagainstcrackforma-

tionthroughpointloads

Protectivefunction3

Distributionofpoint

loads

TheSLM

2.0pipeoffersthefollowingprotectivefunctions:

egeplast SLM

2.0 DrinkingWaterPipesGasPipes

SewagePressurePipes

Trenchlessinstallationmethodsimpose

higherdemandsonthepipematerial.

Thepressure-bearingpipewallofthe

SLM

2.0 is produced from modern

PE100RC

plus

pipe materials (Resist-

ancetoCrack),andthepipealsohas

an extremely abrasion-resistant outer

layer to protect it from scratches and

scoring. This hard outer layer is es-

sential for black box installation and

therefore recommended by the Ger-

manDVGWfortrenchlessinstallation

techniques.

Protectivefunction1

Inordertopreventpipefailure,theEN

standardsandDVGWWorksheetsG

472 and W 400-2 permit abrasions

onlyto10%oftheminimumwallthick-

ness. Furthermore, the damage must

run out smoothly so as to prevent

crackinitiation.

To reliably protect HDPE pipes from

scoring during trenchless installation,

egeplasthas,therefore,addedtheex-

traprotectivecoatingoftheSLM

2.0

pipe.Thesecureprotectionfromscor-

ingandnotchingreliesonanaddition-

allayermadeofamineral-reinforced

polypropylene.Thispreventsdamage

from reaching the pressure bearing

pipecore.

Protectivefunction2

The double layer constructioninhibits

fastcrackgrowth.

Protectivefunction3

In operation, the protective coating

preventsdirectcontactbetweenstones

or old pipe shards and the pressure

bearing HDPE pipe. The point loads

which arise are distributed by the

protective coating, thereby distinctly

reducingthestresspeaks.

Protectivefunction4

The modern, crack resistant sub-

stance of the core pipe, made of

PE100RC

plus

, provides the protec-

tion against crack propagation. The

tearstrengthofthismaterialhasbeen

demonstratedbyitshighvaluesinthe

FNCTtest.

Protectivefunction5

The material of the core pipe has a

very high resistance to stress crack-

ing;thispreventscracksontheinside

of the pipe from being generated by

thestresspeakswhichresultfrompoint

loads.

3 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.3PE100RC

plus

QualityAssurance

Fig5-6:

FullnotchcreeptestFNCT(ISO16770)

Fig5-5:

Notchtest(ISO13479)

Fig5-7:

PointloadtestusingtheDr.Hesselmethod

Moderninstallationproceduresmake

special demands of pipe material.

The materials used must satisfy addi-

tional requirements, over and above

the material properties monitored ac-

cording to the applicable standards

andDVGWWorksheetGW335Part

A2. The resistance of the pipe mate-

rial to slow crack growth is critical

for the lifespan of the pipe under ex-

tremeoperatingconditions,ifthepipe

istoachievethestandardservicelife

of100yearsinspiteoftheincreased

demands. In particular, resistance to

stress-induced cracking can be im-

provedenormouslythroughoptimised

polymerisation. The qualities of to-

daysPE100RC

plus

allowittoalmost

reach the resistance to stress-induced

cracking of cross-linked polyethylene

PEX,whichhasbeenusedforyearsin

harshconditions.

ThenotchtestandtheFNCTtestpro-

vide information about the stress-in-

ducedcrackingbehaviour(slowcrack

growth)ofapipematerial.

In the notch test according to ISO

13479,asectionofpipeisnotchedas

specifed,andafterwardstestedtode-

structionatatesttemperatureof80C

andtestpressureof9.2bar(SDR11,

PE100).

ISO16770describesafurtherdevel-

opmentofthenotchtest.IntheFNCT,

small test bars of the material to be

tested are incised with a sharp edge

and,at80C(+2%ArkopalN100),

subjectedtoaconstanttensileloadof

4N/mm

2

untiltheyfail.Thetestsimu-

lateslocalisedstressconcentrations.

An additional check is the point load

test using the Dr. Hessel method. This

test reproduces very well the effect of

a stone pressing against the pipe. An

pipe, which has been internally pres-

surised,isalsodentedinwardsusinga

roundpunchasapointload(penetra-

tiondepth:8.2%oftheexternaldiame-

ter)inordertosimulatethestresscaused

byastone.Thetestiscarriedoutata

temperatureof80C(+2%ArkopalN

100).

So as to be able

to make estimates

of the service life

of pipes under

additional point

loading, Dr. Hes-

sel Ingenieurtech-

nik compared tests

of pipes under internal

pressure, and with additional point

loading,totheresultsfromtheFNCT

test (3R international 4/2001 and

6/2001). With this comparison, the

stressestowhichapipeinstalledwith-

out a sand bed is exposed during its

operating life may be related to the

results of FNCT testing, and thus the

FNCTtestmaybeadoptedforregular

qualitymonitoring.

Performedwithintheframeworkofthe

full quality testing cycle are: monitor-

ing of the material properties of all

PE100RC

plus

rawmaterialchargesby

FNCTtests,andmonitoringofthema-

terial properties after processing of

therawmaterial.Thelatteriscarried

outontheproducedpipebyatesting

laboratorywhichisaccreditedtoper-

formsuchanalyses.ThePE100RC

plus

materialsperformdistinctlybetterthan

thestandardPE100typesinboththe

notch and FNCT tests, with values

thatliewellabovethosestipulatedfor

pipeswithprotectiveproperties.

4 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Tab5-1 1)Valuesfrom3R-international4/2001and6/2001

2)ThePE100+Associationisanamalgamationofpolyethylenemanufacturerswhovoluntarilyexceedthestandardrequirements

3)Datafromafewmanufacturers

The quality of the material utilised can

be documented on request with a 3.1

Bcertifcate.

egeplastusesonlyselectedPE100ma-

terials (PE 100 RC

plus

) for the egeplast

SLM

2.0 pipe. These materials must

demonstrateatimetofailureofatleast

3300hintheFNCT.Asanadditional

control, the quality of PE 100 RC

plus

is

monitored within the framework of the

full quality testing cycle. The quality of

thesematerialsissuchthattheirsuitabil-

ityfora100yearservicelifeforapipe

underpointloadingmaybeconfrmed

bystructuraltesting.egeplastSLM

2.0

pipes are subjected regularly to such

structural testing: an internal pressure

creeptestlastingforoneyear,withad-

ditional point loading, at 80C (+2%

ArkopalN100).

ThePE100RC

plus

materialsperformdis-

tinctlybetterthanthestandardPE100

typesinboththenotchandFNCTtests,

with values that lie well above those

stipulatedforpipeswithprotectiveprop-

erties.

InternalPressure

CreepTest

S4Test

(FastCrackGrowth)

110x10mm

NotchTest FNCT

PointLoadTest,

Dr.HesselMethod

PEasper

GW335PartA2

s=12,4N/mm

2

;

20C

100h

asperDIN8075

pc8bar

80C;9.2bar

500h

250-800h1) 10003000h1)

PE100+2)

s=12,4N/mm

2

;

20C

200h

pc10bar

80C;9.2bar

500h

250800h1)

>300h3)

10003000h1)

PE100RC

plus

s=12,4N/mm

2

;

20C

200h

pc10bar

80C;9.2bar

5000h

3300 h 8760 h

Monitoring

agreement

Testcertificates

KIWA

VGW

DVGW

Certifyingbodies

Monitoringreports

Continuousqualitymonitoring

Internalandexternal

qualitychecking

Qualityand

systemaudits

Productionand

processmonitoring

Customerrequirements

Monitoring

HesselIngenieurtechnikGmbH

Continualchargetesting

forRC

plus

materials

Materialtestingafter

pipemanufacture

Regularstructuraltesting

ofpipesbymeansof

pointloadingexperiments

Testcertificate

Contractuallyagreed:

Full Quality Testing Cycle

Checkingofgoods

received

Productionchecking

Producttesting

Confirmationof

thesuitabilityof

theSLM

2.0pipe

forinstallation

withoutasand

bed,andfortren-

chlessinstallation

5 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Tab5-2

TestingoftheMaterialPE100RC

plus

Property Requirement TestProcedure Frequency

Meltindex asperspecifcations

ENISO1133:1999ConditionT

5kg,190C10minutes

Min.1xperweekaswellason

everychangeofmaterialandon

everydimensioncheck

Lossondrying 0.1% Infraredmethod percharge

Homogeneity grade3 ISO18553 percharge

Density 930kg/m

3

DINENISO1183-2,

DINENISO1872-1

percharge

Colour asperDVGWGW335PartA2 regularly

Resistancetoweathering

asperDVGWGW335PartA2

DINEN12201-1

DINEN1555-1

BlackasperISO6964,

blueandyellowasperDINEN921

andfollowingDINENISO6259-1

regularly

Thermalstability >20minutesat200C DINEN728 percharge

Microbiology

asperKTWrecommendationas

wellasDVGWGW335PartA2

DVGWW270 approvaltesting

Fastcrackgrowth

asperDVGWGW335PartA2

DINEN12201-1

DINEN1555-1

ISO13477 1xannually

Gasresistance

asperDVGWGW335PartA2

DINEN12201-1

DINEN1555-1

DVGWGW335PartA2 approvaltesting

Hygiene

asperKTWrecommendationas

wellasDVGWGW335PartA2

DINEN10204 approvaltesting

Odourandtaste

asperKTWrecommendationas

wellasDVGWGW335PartA2

DINEN10204 percharge

Slowcrackgrowth

asperDVGWGW335PartA2

DINEN12201-1

DINEN1555-1

NotchtestDINENISO13479 1xannually

Slowcrackgrowth

>3300h

asperFullQualityTestingCycle

FNCT

ISO16770

80C,4N/mm

2

,2%Arkopal

percharge

6 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

TheegeplastSLM

2.0pipeis,asaconsequenceofitsexcellentresistancetostress-inducedcracking,insensitivetopoint

loadsandthereforeneednotbebeddedinsand.Itissuitableforinstallationwithoutasandbed,andfortrenchlessinstal-

lation.

Tab5-3

AdditionalTestingoftheFinishedPE100RC

plus

Piping

Property Requirement TestProcedure Frequency

Labelling

asperDVGWGW335PartA2

DINEN12201-2

DINEN1555-2

visualinspection regularlyevery2hours

Texture asperDVGWGW335PartA2 visualinspection regularlyevery2hours

Colour asperDVGWGW335PartA2 visualinspection regularlyevery2hours

Warmstorage asperDVGWGW335PartA2 1xperweek

Homogeneity asperDVGWGW335PartA2 visualinspection 1xperweek

Thermalstability >20minutesat200C DINEN728 1xperweek

Internalpressurecreeptest

asperDVGWGW335PartA2

DINEN12201-2

DINEN1555-2

80C,165h;

PE80s =4.6N/mm

2

PE100s =5.5N/mm

2

oneverystart

atleast1xperweek

Meltindex

max.20%variation

fromtherawmaterial

ENISO1133:1999ConditionT

5kg,190C10minutes

oneverychangeandonevery

dimensioncheck

atleast1xperweek

Hygiene

asperKTWrecommendationas

wellasDVGWGW335PartA2

DVGWW270 1xannually

Labelling

asperDVGWGW335PartA2

DINEN12201-2

DINEN1555-2

visualinspection regularlyevery2hours

Slowcrackgrowth

>3300h

asperFullQualityTestingCycle

FNCT

ISO16770

80C,4N/mm

2

,2%Arkopal

6xannually

Pointloadingtest

>8760h

asperFullQualityTestingCycle

HESSEL

PAPLP2.2-22004-05

80C,4N/mm

2

,2%Arkopal

3xannually

7 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

It is not allowed to multiply this confirmation or parts of this confirmation without written permission of HESSEL

Ingenieurtechnik.

Confirmation of continuous Quality Inspection

Subject: Inspection of pipes made from PE 100 RC

plus

within the scope of

the Full Quality Testing Cycle

Product: egeplast SLM

2.0-pipe for drinking water, gas supply and waste

water for non-conventional pipe installation

Manufacturer: egeplast Werner Strumann GmbH & Co. KG

Robert-Bosch-Str. 7, DE-48268 Greven, Germany

Scope of inspection: 1. Prove of the transfer-function from testing to service conditions

(Full Quality Testing Cycle) 2. Inspection of the materials properties of all raw material

batches designated as PE 100 RC

plus

using the FNCT

3. Inspection of the materials properties after processing

4. Prove of the expected minimum service life using pipes under

point load in type tests every year

5. Statistical validation of the minimum requirements of

PE 100 RC

plus

HESSEL Ingenieurtechnik GmbH

Am Vennstein 1a

D-52159 Roetgen

Tel.: +49 2471/ 920 220

Fax: +49 2471/920 2219

E-Mail: info@hessel-ingtech.de

Net: www.hessel-ingtech.de

Date: 16.07.2004

Authorized to sign: (Dr.Ing. Joachim Hessel)

Officially approved as a test, inspection and certification facility (NRW 37).

DAP-PL-3760.00

According to DIN EN ISO/IEC 17025 accredited Test-Laboratory by

DAP Deutsches Akkreditierungssystem Prfwesen GmbH

This is to certify that due to the above mentioned inspections the following minimum requirements

are fulfilled:

FNCT (PA FNCT 2.1-3 2004-03): 4 N/mm, 80 C, 2% Arkopal N-100 testing time: >3300 h

Point loading test (PA PLP 2.2-2 2004-05): 4 N/mm, 80 C, 2% Arkopal N-100 testing time: >8760 h

The egeplast SLM

2.0-pipes made from PE 100 RC

plus

are qualified for sandless and trenchless

installation techniques.

Fig5-8

8 12/05

5 TrenchlessInstallation

andRenovation

5.4TechnicalInformation

5.4.1ProductDataSheetforSLM

2.0DrinkingWaterPipes

Dimension: OD25mmOD1200mm

Pipeconstruction:

Medium-bearingpipeblack

Protectivecoatingontheoutsidebluetoidentifythemediumasdrinkingwater

with4greendoublestripestosignifyapipewithaprotectivecoating

SDR17;SDR11;SDR7.4

Material: Medium-bearingpipe:PE100RC

plus

(ResistancetoCrack)

Protectivecoating: Patented, mineral-reinforced polypropylene coat, con-

tinuouslyextrudedonduringthemanufacturingprocess

Approval: DVGW*,SVGW,VGW*,DIN-Gost*,IGNG*,DWI*

*Theapprovalspertaintothemedium-bearingpipe

Standards: DVGWGW335;DIN8074/75;DINEN12201

Weldinggroup: 003

Labelling: With coloured metre marking on the medium-bearing pipe and additional

markingoftheprotectivecoating

Deliveryform: 6,12or20mstraightlengths(uptomax.30m)

Bundledcoilsof100m(uptoOD160/180mm)

Customlengthsonrequest

Largerlengthsondrums

Regulatorycode/installationmethods: DVGWW400-1/2,GW320,GW321,GW323;DINEN805;DIN4124

Materialtesting: HESSELIngenieurtechnik

egeplast SLM

2.0

12/05

5 TrenchlessInstallation

andRenovation

5.4.2ProductDataSheetforSLM

2.0GasPipes

Dimension: OD25mmOD1200mm

Pipeconstruction:

Medium-bearingpipeblack

Protectivecoatingontheoutsideorangetoidentifythemediumasnatural

gaswith4greendoublestripestosignifyapipewithaprotectivecoating

SDR17;SDR17.6;SDR11

Material: Medium-bearingpipe:PE100RC

plus

(ResistancetoCrack)

Protectivecoating: Patented, mineral-reinforced polypropylene coat, con-

tinuouslyextrudedonduringthemanufacturingprocess

Approval: DVGW*,SVGW,VGW*,DIN-Gost*,IGNG*

*Theapprovalspertaintothemedium-bearingpipe

Standards: DVGWGW335;DIN8074/75;DINEN1555

Weldinggroup: 003

Labelling: With coloured metre marking on the medium-bearing pipe and additional

markingoftheprotectivecoating

Deliveryform: 6,12or20mstraightlengths(uptomax.30m)

Bundledcoilsof100m(uptoOD160/180mm)

Customlengthsonrequest

Largerlengthsondrums

Regulatorycode/installationmethods: DVGWG472,GW320,GW321,GW323;DINEN805;DIN4124

Materialtesting: HESSELIngenieurtechnik

egeplast SLM

2.0

10 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.4.3ProductDataSheetforSLM

2.0SewagePressurePipes

Dimension: OD25mmOD1200mm

Pipeconstruction:

Medium-bearingpipeblack

Protectivecoatingontheoutsidebrowntoidentifythemediumassewage

with4greendoublestripestosignifyapipewithaprotectivecoating

SDR17;SDR11;SDR7.4

Material: Medium-bearingpipe:PE100RC

plus

(ResistancetoCrack)

Protectivecoating: Patented, mineral-reinforced polypropylene coat, con-

tinuouslyextrudedonduringthemanufacturingprocess

Approval: TheegeplastSLM

2.0sewagepressurepipesaremanufacturedaccordingto

ZP14.3.1andbeartheDINCertcomarkofconformity

Standards: DVGWGW335;DIN8074/75;DINEN13244

Weldinggroup: 003

Labelling: With coloured metre marking on the medium-bearing pipe and additional

markingoftheprotectivecoating

Deliveryform: 6,12or20mstraightlengths(uptomax.30m)

Bundledcoilsof100m(uptoOD160/180mm)

Customlengthsonrequest

Largerlengthsondrums

Regulatorycode/installationmethods: Recommended:byanalogytoDVGWW400-1/2,GW320,GW321,GW

323;DINEN805;DIN4124

Materialtesting: HESSELIngenieurtechnik

11 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Like a hard shell, the protective

coatingkeepsthedirectloadaway

fromthepressurebearingpipeand

distributes the additional stress.

Analyses using the fnite element

method show what advantages a

pipe with a protective coating has

withregardtoitsresiliencetopoint

loading. No stress concentration

actsonthecorepipeintheimmedi-

ateareaofcontact.

Theselectedhigh-quality,extremely

crack resistant PE 100 RC

plus

poly-

ethylene materials of the pressure

bearingcorepipegivecrackforma-

tion no chance. For pipe bursting,

the DVGW demands FNCT values

of2700hfordrinkingwaterpipes

and3300hforgaspipesinitsWork-

sheetGW323.PE100RC

plus

-mate-

rialsarecheckedduringtheincom-

ing goods inspection for >3300h.

These requirements are met by the

corepipesoftheSLM

2.0.

Fig5-11:Finiteelementmethod(FEM)computa-

tionalmodel,MuensterUniversityofAppliedSci-

ences,stressconcentration:pointandlinearload

safetylineforcoatedpipe

Fig5-12:Pointloadtestusingthe

Dr.Hesselmethod

5.4.5DoubleProtectionagainstPointLoads

Pipeswithprotectivecoatingsofferdoubleprotectionagainstpointloads:

TheSLM

2.0istheresultofconsistent

andsteadyfurtherdevelopmentofthe

well proven SLM

pipe. Confrmation

of its improved quality has been pro-

videdbyestablished,independenttest-

inginstitutes.

Thepressurebearingpipewallconsists

of PE 100 RC

plus

(optionally PE 80),

whichguardsreliablyagainstdamage

by virtue of its excellent crack resist-

ance.

The protective coating of polypropyl-

enereliablyprotectsthemedium-bear-

ingpipeagainstscratchesandscoring

fromoutside.Inaddition,pointloads,

suchasthosewhichcanarisethrough

stones or shards, are spread over a

greatersurfaceareabytheprotective

coating,soreducingthestressconcen-

tration.

Thehardnessofthepipecoatingresults

fromthespecialcompositionofthema-

terial. egeplast incorporates mineral

microparticles into the polypropylene

protectivecoating;thesepermitnotice-

ablylessscoringandabrasion.

Theseclearimprovementsintheprod-

uct characteristics have been verifed

throughscratchtestingbytheMaterial-

prfanstalt (Materials Testing Institute)

inHanover,amongstothers(Fig5-9).

Scratchdepthinmm

SLM

-2.0 PPnotreinforced PEX PE100RC

plus

PE80

Fig5-10: Mineralmicroparticlesinthe

coatingmaterial

5.4.4ProtectionfromAbrasionduringTrenchlessInstallation

Fig5-9:Resultsofscratchtesting,offcialmaterialstestinginstituteattheUniversityofHanover

12 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.5.1 GeneralInformation

onInstallation

TheSLM

2.0consistsofacorepipe

in accordance with DIN 8074/75,

uponwhichaprotectivecoatingisad-

ditionallyextrudedinordertoincrease

its scratch and abrasion resistance.

Thefourgreendoublestripesserveto

identifyitasamultiplelayerpipe.

Scopeofapplication

The installation instructions apply to

soilcoveredegeplastSLM

2.0pipes

withcorepipesmadeofHDPEinac-

cordance with DIN 8074 and DIN

8075foruseasdrinkinganddomestic

waterpipelines,andasgaspipelines.

The pipe joints and pipeline compo-

nentsmustberatedforusewiththeir

respectiveoperatingpressures.

Installation,opentrenchmethod

egeplast SLM

2.0

pipes are suited for

installation without a

sand bed because they are made of

PE100RC

plus

,whichishighlyresistant

to stress-induced cracking. Their suit-

ability for installation without a sand

bedisverifedbyanindependenttest-

ing institute on the basis of continual

qualitychecks.

Theexcavatedsoilissuitableforback-

fllingifitcanbecompacted.egeplast

does not make any provisos for its

composition in terms of grain size.

Considerable cost savings result from

eliminatingtheneedtodisposeofthe

excavatedsoil.

For assessment of individual cases,

it is necessary to determine the total

cost of soil replacement and weigh

thatagainsttheadditionalcostofthe

SLM

2.0pipe.

Thestandardsforassessmentofthefll

basearesetbyZTVA-StB97fromthe

GermanRoadandTransportationRe-

searchAssociationinCologneaswell

asbyDIN4022andDIN18196.

Thepipetrenchistobedugoutinac-

cordancewithDIN4124(trenchpro-

fleandsheeting)andDIN1998(lay-

out of pipelines in public areas). The

minimumcoveringforgaspipelinesis

0.6 to 1.0 m, although the covering

canbereducedto0.5mforsections

up to ca. 2.0 m long which do not

carry a heavy load (front gardens,

pavements).Drinkingwaterandsew-

agepressurepipelinesaretobelaid

atadepthof1.0to1.8m(according

toclimateandgroundconditions)safe

fromfrost.Applicabletotheconstruc-

tionofwaterconduitsis,furthermore,

DVGWWorksheetW400-2.

Installation,ploughingandcutting

TheegeplastSLM

2.0

pipe is flexible and

manoeuvrable. These

attributes make installation using the

ploughing or cutting procedures pos-

sible.Theminimumallowablebendra-

diusshouldbeobserved.Thebendra-

dius can, however, be under-stepped

forashorttimeduringtheinstallation

process,providedthatthepipestring

issupportedbysomemechanism,e.g.

guiderollers,thatmakeskinkingofthe

pipeimpossible.

The increased stretching of the outer

fbreswhichresultsfromthisisnotcriti-

calforPE100RC

plus

,thematerialused

here.

Installation,trenchlessmethod

There is a higher risk

of damage during

trenchless installation

and renovation pro-

cedures. The extent

of this damage to the

pipecannotbedeterminedafterwards

(blackboxinstallation)!

For this reason, pipes with a protec-

tive coating are essential. Multiple

layer pipes such as the egeplast

SLM

2.0constituteapracticableso-

lution here: they allow continued use

of the approved and tested egeplast

gas, drinking water, and sewage

pipes, while ensuring that the outer

surfaces of the pipes are abrasion

resistantforusewithinnovativeinstal-

lation methods. DVGW Worksheets

GW 321 (water-jet drilling) and GW

323 (pipe bursting) recommend the

useofpipeswithprotectivecoatings.

The DVGW regulations specify the

maximum permitted tractive forces

for trenchless installation procedures;

these may not be exceeded. Over-

shooting these limits leads to per-

manent damage to the new piping.

egeplast recommends the use of suit-

abledataloggersforcompletedocu-

mentation of the construction project.

The minimum allowable bend radius

shouldbeobserved.

Longitudinal force-locked joining pro-

ceduresmustbecarriedoutaccording

to the current regulatory codes of the

DVGWandDVS.

The egeplast installation guidelines

shouldbefollowedsoastoavoidsteps

atthejointsduetomisalignment.

5.5InstallationGuidelinesforSLM

2.0Pipes

SupplementtotheinstallationinstructionsforPEpressurepipesA135andA435

fromtheKunststoffrohrverbande.V.inBonn

Openwith

sandbed

Openwithout

sandbed

Soildisplace-

ment

Relining

Waterjet

drilling

Pipebursting

Ploughing Cutting

13 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.5.2JoiningTechniques

Opentrenchinstallation,ploughingandmillingelectrofusionwelding

Fig5-15:Markingtheareafromwhichthe

coatingistobestripped

Fig5-18:Weldinginaccordancewith

DVS2207,Part1

Fig5-16:Removaloftheprotectivecoating

withtheegeplastcoatingcutteror

withtheegeplastM10strippingtool

Fig5-17:Removaloftheoxidelayerusinga

rotaryscraper

egeplastSLM

2.0pipesmaybeweld-

edtoallthecommonlyusedmoulded

fttingsmadefromPE100andPE80

for electrofusion welding, after strip-

ping the coating from the pipe ends.

The guidelines and specifcations giv-

en by the fttings manufacturers must

alsobefollowed.

Before electrofusion welding of

SLM

2.0 pipes can take place, the

protective coating must be removed

using an egeplast coat stripping tool

(Fig 5-15/16). Coat stripping of the

pipeendscanbecarriedoutbyege-

plastonrequest.

The length of coating to be stripped

correspondstoatleasthalfthelength

ofthesleeveftting(seeTab5-4).The

contact surfaces must be prepared

by scraping and/or cleaning before

welding(Fig5-17).

For stress free welding of pipe sup-

plied as bundled coils, egeplast rec-

ommends use of the egeplast pipe-

heatersystem(Fig5-13/14).

Once the sleeve fttings have been

mounted, the treated areas are heat-

ed to fusion temperature by passing

electric current though integrated

resistance wires (heating coil) in the

sleevefttings,andtherebyweldedto-

gether(Fig5-18).Theweldingprocess

takesplaceautomaticallyifthedevice

issetupappropriately.Theassembly

instructions given by the respective

manufacturers are to be followed.

Standards for workmanship are laid

outinDVS2207,Part1.

Fig5-13:Straighteningbundledcoiland

drumendswiththeegeplastpipe-

heatersystem

Fig5-14:Thepipeendsarepreparedopti-

mallyforsecurewelding

14 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

egeplast SLM

2.0 pipes are manu-

factured from PE 100 RC

plus

materials

belongingtoweldinggroup003.The

protectivecoatingisextrudedontothe

medium-bearingpipe,andisremoved

according to the egeplast installation

instructions before joining. After this,

welding with one another and with

any other approved material is pos-

sible.

BeforebuttfusionweldingofSLM

2.0

cantakeplace,theprotectivecoating

must be removed using an egeplast

coat stripping tool (Fig 5-21-23). It is

advisable to use the M10 stripping

toolandthecoatingcutterforthis.Ro-

tary scrapers are not recommended.

Coat stripping of the pipe ends can

becarriedoutbyegeplastonrequest.

Welding should be carried out in

compliancewithDVS2207,Part1in

standardweldingmachines,inwhich

theuseofskimmedweldingshoesad-

justedtothespecifcexternaldiameter

isrecommended.Clampingjawssuit-

able for welding machines from the

Widoscompanycanbesuppliedfree

ofchargebyegeplast(Tab5-5).

Forstressfreeweldingofpipesupplied

as bundled coils, egeplast recom-

mendsuseoftheegeplastpipe-heater

system (Fig 5-19/20). The sequence

ofoperationscontinuesasspecifedin

DVS2207,Part1,untiltheformation

ofauniformlycircularweldbead(Fig

5-25/26).

For open trench installation, and for

ploughing and cutting using egeplast

pipes with protective coatings, cover-

ing of the welded joint afterwards is

notnecessary.

Exception:

When using the mole ploughing meth-

od, the joints must be covered after

welding as per the instructions Pipe

burstingbuttfusionwelding.

Opentrenchinstallation,ploughingandmillingbuttfusionwelding

Fig5-21:Markingtheareafromwhich

thecoatingistobestripped

(seeTable5-4)

Fig5-25:Weldinginaccordancewith

DVS2207,Part1

Fig5-26:Removaloftheweldbeadwithan

externalbeadremover

Fig5-22:Removaloftheprotectivecoating

withtheegeplastcoatingcutter

Fig5-23:Removaloftheprotectivecoating

withtheegeplastM10strippingtool

Fig5-24:Fasteningthespecialclamping

jawsavailablefromegeplast

(seeTable5-5)

Fig5-19:Straighteningbundledcoiland

drumendswiththeegeplastpipe-

heatersystem

Fig5-20:Thepipeendsarepreparedopti-

mallyforsecurewelding

15 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

egeplast SLM

2.0 pipes are manufac-

turedfromPE100RC

plus

materialsbelong-

ingtoweldinggroup003.Theprotective

coating is extruded onto the medium-

bearingpipe,andisremovedaccording

totheegeplastinstallationinstructionsbe-

forejoining.Afterthis,weldingwithone

another and with any other approved

materialispossible.

Before butt fusion welding of SLM

2.0

can take place, the protective coating

mustberemovedforatleast20mmus-

ing an egeplast coat stripping tool (Fig

5-29-31).ItisadvisabletousetheM10

stripping tool and the coating cutter for

this.Rotaryscrapersarenotrecommend-

ed.Coatstrippingofthepipeendscan

be carried out by egeplast on request.

Weldingshouldbecarriedoutincompli-

ancewithDVS2207,Part1instandard

welding machines, in which the use of

skimmed welding shoes adjusted to the

specifcexternaldiameterisrecommend-

ed. Clamping jaws suitable for welding

machinesfromtheWidoscompanycan

be supplied free of charge by egeplast

(Tab5-5).Forstressfreeweldingofpipe

supplied as bundled coils, egeplast rec-

ommendsuseoftheegeplastpipe-heater

system(Fig5-27/28).

Thesequenceofoperationscontinuesas

specifedinDVS2207,Part1,untilthefor-

mationofauniformlycircularweldbead

(Fig5-33/34).

According to DVGW Worksheet GW

323, suitable external protection is re-

quiredforpipesmadeofPE100installed

bymeansoftrenchlessmethodsusingthe

pipe bursting procedure. The pipes ex-

ternalprotectionmustbereconstitutedto

giveafushoutsidesurface.Itistherefore

mandatory with SLM

2.0 to protect the

areaabouttheweldseparatelyforpipe

bursting installation. If the formation of

theweldbeadshouldreachbeyondthe

thickness of the protective coating, then

thebeadistoberemovedusinganexter-

nalbeadremover.

Continuedonthenextpage

Pipeburstingbuttfusionwelding

Fig5-29:Markingtheareafromwhichthe

coatingistobestripped

(seeTable5-4)

Fig5-33:Weldinginaccordancewith

DVS2207,Part1

Fig5-34:Removaloftheweldbeadwithan

externalbeadremover

Fig5-30:Removaloftheprotectivecoating

withtheegeplastcoatingcutter

Fig5-31:Removaloftheprotectivecoating

withtheegeplastM10strippingtool

Fig5-32:Fasteningthespecialclamping

jawsavailablefromegeplast

(seeTable5-5)

Fig5-27:Straighteningbundledcoiland

drumendswiththeegeplastpipe-

heatersystem

Fig5-28:Thepipeendsarepreparedopti-

mallyforsecurewelding

16 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Continued:pipeburstingbuttfusionwelding

Fig5-35:CoatingwithDensolidHK7

Fig5-37:Smoothingoutthefllermaterial

Fig5-36:Layingdownthefabrictape

Fig5-38:Smoothersurfaceby

wrappingwithadhesivetape

Densolid HK7 is a fast curing, impact

resistant two-component fller material

based on polyurethane. To reduce the

curing time at lower temperatures, the

fasterreactingDensolidHK7-Wshould

beusedinwinter.Theflledringshould

be reinforced additionally with polyes-

ter fabric mesh (e.g. Densolan ES) for

externalpipediameters110mm(Fig

5-36). A single layer wrapping is suff-

cientfordimensionsof110-180mm;for

dimensions180mm,thefabricshould

belaiddownintwolayersintheflling

coatbeforeithashardened.Whenus-

ingfabrictape,careshouldbetakento

pressthetapewellintotheresinsothat

thefllermaterialpermeatesthemeshof

the fabric well. The manufacturers rec-

ommendations for handling are to be

observed.

As an alternative to Densolid HK7,

egeplastoffersresin-impregnatedglass

fbre wrappings. These are activated

with water. After soaking in clear wa-

ter for ca. 10-15 sec, the wrapping is

woundaroundtheareatobeinsulated.

Indoingso,careshouldbetakenthat

this area is fully wrapped, and that it

iswrappeduntilitisfushwiththepro-

tective coating. The wrappings are

obtainable in widths between 2.5 cm

and12.5cm,accordingtotheexposed

areatobecovered.Thefnishedarea

is bound liberally with adhesive tape

afterwardsforamoreevenhardening

ofthewrapping.

Nostrainshouldbeputonthepipeline

untilthewrappinghasfullyhardened.

The manufacturers instructions are to

befollowedindoingso.

Thecontinuouslyfushexternalsurface

required for pipe strings intended for

useintrenchlessinstallationprocedures

isguaranteedbythecoveringprocess

describedabove.

AlternativeB:Coveringwithresin-impregnatedglassfbrewrapping

Fig5-39:Soakthewrappinginclearwater

for10-15sec.accordingtothe

manufacturersinstructions

Fig5-41:Bindthecoveredarealiberally

withadhesivetapeforamoreeven

hardening

Fig5-40:Windthewrappingtautlyaround

theweldareauntilitisfushwith

theprotectivecoating

Fig5-42:Donotputanystrainonthe

pipelineuntilthewrappinghasfully

hardened

Theunprotectedareabetweenthestrippedendsofthecoatingistobeevenedoutandprotected.Inthisway,asmooth

pipesurfaceiscreatedwhichdoesnotofferanypointofmechanicalcontact.TheexposedPEpipeistoberoughened

withsandpaper(orsimilar)toguaranteestrongbonding.egeplastrecommendsthefollowingalternativeproceduresfor

coveringafterwards:

AlternativeA:CoveringwithDensolidHK7

17 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Water-jetdrillingandreliningbuttfusionwelding

Fig5-45:Markingtheareafromwhichthe

coatingistobestripped

Fig5-46:Removaloftheprotectivecoating

withtheegeplastcoatingcutter

Fig5-47:Removaloftheprotectivecoating

withtheegeplastM10strippingtool

Fig5-49:Weldinginaccordancewith

DVS2207,Part1

Fig5-50:Thefnishedweld

BeforebuttfusionweldingofSLM

2.0

pipescantakeplace,theprotectivecoat-

ingmustberemovedusinganegeplast

coatstrippingtool.Forreliningandwa-

ter-jetdrillingundereasysoilconditions,

theweldbeadcanbesuffcientaspro-

tectionfortheweldzone.Inthiscase,

it is, however, necessary that the weld

beadfllsoutcompletelytheunprotected

area between the polypropylene coat-

ings.Fixedcoatstrippinglengthscannot

be specifed due to varying conditions

atconstructionsites.Someguidanceis

offeredbyAppendix1ofDVS2202-1

(AcceptableWeldBeadWidthsforButt

Fusion Weld Seams on Pipes made of

PEandPP);seealsoFig5-57.

Oversized gap widths, which are not

flledoutbyformationoftheweldbead,

must be covered over in accordance

with the guidelines for pipe bursting

buttfusionwelding(seepage15/16).

Theuseofspecialclampingjawsisre-

quiredtomakesurethatthepipeends

areproperlyclampedinthebuttweld-

ingmachineandtopreventdamageto

theprotectivecoating(Fig5-48).These

areadjustedexactlyforthethicknessof

theprotectivecoating,whichvariesac-

cordingtothecorepipediameter,and

areavailablefromegeplast.

Forstressfreeweldingofpipesupplied

asbundledcoils,egeplastrecommends

use of the egeplast pipe-heater system

(Fig5-43/44).

Thesequenceofoperationscontinuesas

specifedinDVS2207,Part1,untilthe

formation of a uniformly circular weld

bead (Fig 5-49/50). The weld bead

mustfllouttheannulargapbetweenthe

protectivecoatingssothatprotectionis

providedforthecorepipeduringwater-

jetdrillingorrelining.

Fig5-43:Straighteningbundledcoiland

drumendswiththeegeplastpipe-

heatersystem

Fig5-44:Thepipeendsarepreparedopti-

mallyforsecurewelding

Fig5-48:Fasteningthespecialclamping

jawsavailablefromegeplast

(seeTable5-5)

18 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Thereare,ingeneral,twomethodsof

mountingtappingfttings:

Mounting of tapping valves with

drill hole sealing bushes, System

EWEfordrinkingwater.Theseseal

in the tapping hole and can there-

forebeusedforpipeswithmultiple-

layerprotectivecoatings.

When mounting welded tapping ft-

tings, the protective coating on the

relevant length of pipe must be re-

moved.

Useoftheegeplastcoatstrippingtool

Coatstrippingcanbecarriedoutwiththe

egeplast M10 stripping tool (Fig 5-52).

ForODabove160mm,egeplastrecom-

mendsthecombineduseofthecoatstrip-

pingtoolandthecoatingcutter.

Astartingpointmustfrstbeformedwhen

using the M10 coat stripping tool. This

canbedonee.g.usingastandardfle.

Greatcareshouldbetakentoonlyflea

holeinthecoatingandnotthedamage

thecorepipe.Itisthenpossible,begin-

ningfromthepreparedstartingpoint,to

cutbackasectionforthetappingftting

using the M10 stripping tool. Welding

ofthetappingfttingistobecarriedout

inaccordancewithDVS2207-1andthe

technicalguidelinesgivenbythemanu-

factureroftheweldedftting.

Fig5-51:Markingtheareafromwhichthe

coatingistobestripped

Fig5-54:Mountingthetappingftting

accordingtothemanufacturers

installationinstructions

Fig5-52:Removaloftheprotectivecoating

withtheegeplastM10strippingtool

orwiththeegeplastcoatingcutter

Fig5-55:Weldingthetappingfttinginac-

cordancewithDVS2207,Part1

Fig5-53:Removaloftheoxidelayerusinga

suitablescrapingtool

Fig5-56:Thetappingfttingisweldedsecure-

lytotheegeplastSLM

2.0pipe

Weldingoftappingfttings

Screw-clampjoints

PipesmadeofHDPEcanbejoinedus-

ingclampconnectorsmadeofplastic

or metal. Clamp connectors made of

plasticmustconformtoDIN8076Part

3;thosemadeofmetalmustconform

toDIN8076Part1or2.

The pipe end must be fared when

using clamp joints with support bush-

ings. This is usually accomplished by

drivinginthesupportbushings.

When assembling clamp joints, the

pipeendshouldbechamferedonthe

inside without notching, and the pro-

tective coating is to be removed ap-

propriately.

Flangedjoints

Thefollowingtypesofdesignarecom-

monlyusedformakingfangedjoints

(seeDIN16963Parts4and8):

Stubendforelectrofusionwelding

Stubendforbuttfusionwelding

Theaxesofthepipelinesectionstobe

joinedmustbealignedwhenmaking

fangejoints.Theboltsshouldbetight-

enedevenlyinacrosswisesequence.

Note: Use lapped fanges with steel

inserts.

1 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.5.3SystemTechniques

egeplastSLM

2.0pipescanbeinte-

grated into the pipeline network with

allthemouldedfttingsandjoiningele-

mentsnormallyusedinthetrade.The

manufacturers instructions should be

followedindoingso.

MouldedfttingsofPE100RC

plus

qual-

ityarealsoofferedaspartoftheege-

plastproductrange.

Aselectionofcommonlyusedmould-

ed fttings is shown for illustration be-

low.

Seamlesslydrawnelbow

madeofPE100RC

plus

Constructedaccording

torequirements

Segmentedelbow

madeofPE100RC

plus

Constructedaccording

torequirements

SegmentedT-Pieces

madeofPE100RC

plus

Constructedaccording

torequirements

BranchesmadeofPE100RC

plus

Constructedaccording

torequirements

20 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Before electrofusion welding or butt

fusionweldingofSLM

2.0pipescan

takeplace,theprotectivecoatingmust

be removed with egeplast coat strip-

pingtool.

Coat stripping of the pipe ends can

becarriedoutbyegeplastonrequest.

Forthisweneedanindicationofthe

weldingproceduretobeused.

5.5.4Tables

Coatingbackcutrequiredforthepipeburstinginstallationprocedure,opentrenchinstallation,ploughing,andcutting

Tab5-4:*DimensionsspecifedfortheproductrangesoftheGeorgFischer,Friatec,andPlassoncompanies

L

o

n

g

s

l

e

e

v

e

f

t

t

i

n

g

s

a

r

e

n

o

t

c

o

n

s

i

d

e

r

e

d

.

P

r

e

f

e

r

r

e

d

e

q

u

i

p

m

e

n

t

s

i

z

e

s

f

o

r

t

h

e

W

i

d

o

s

e

x

t

e

r

n

a

l

b

e

a

d

r

e

m

o

v

e

r

a

r

e

g

i

v

e

n

CoatingBackcutfortheSLM

2.0

Medium-BearingPipe

DIN8074

OD[mm]

ButtFusionWelding

[mm]

ElectrofusionWelding*

[mm]

WhenUsingWidosExternal

BeadRemovers

[mm]

25 20 40 - -

32 20 45 - -

40 20 50 - -

50 20 55 - -

63 20 65 - -

75 20 70 - -

90 20 80 - -

110 20 90

35 Size1

125 20 95

35 Size1

140 20 100

35

40

Size1

Size2

160 20 105

35

40

Size1

Size2

180 20 110

40

Size2

Size3

200 20 115

40

Size2

Size3

225 20 125

40

Size2

Size3

250 20 135

40 Size3

280 20 140

40

50

Size3

Size4

315 20 150

40

50

Size3

Size4

355 20 155

50 Size4

400 20 165

50 Size4

450 20 175

50 Size4

500 20 185

60 Size5

560 20 190

60 Size5

630 20 205

5060

Size5

Size8

21 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

b

s

A

Wer|ebereiche

C

0 10

W

e

r

k

s

|

o

|

|

d

i

c

k

e

s

i

n

m

m

1 20 2 30 3 40 4 0 mm

Abmon|ellnqe 5chweibwols|brei|e b

0

10

1

20

2

30

3

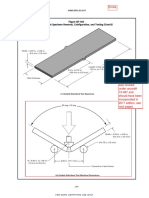

Fig5-57:BeadwidthaccordingtoDVSGuideline2202-1

Guidingvaluesforthecoatingbackcutrequiredforbuttfusionweldingwater-jetdrillingandrelining

Forreliningandwater-jetdrillingunder

easy soil conditions, the weld bead

canbesuffcientasprotectionforthe

weldzone.Inthiscase,itis,however,

necessarythattheweldbeadfllsout

completely the unprotected area be-

tween the polypropylene coatings.

Fixedcoatstrippinglengthscannotbe

specifedduetovaryingconditionsat

construction sites. Overly wide gaps,

inwhichsoilorstonescouldbecome

trapped as the pipe is drawn in, are

to be avoided. Some guidance is of-

feredbyAppendix1ofDVS2202-1

(Acceptable Weld Bead Widths for

Butt Fusion Weld Seams on Pipes

madeofPEandPP).Thediagrampro-

vides guiding values; these must be

adjusted by carrying out test welds.

egeplast applications engineering is

pleasedtoassistwithdeterminingthis

adjustment.

Note:

22 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Overviewofexternalandmedium-bearingpipediametersforSLM

2.0clampingjawsforbuttweldingmachines

Forwelding,thepipeendsaregrippedwithclampingjaws*whicharespeciallyadjustedtotheSLM

2.0outerdiameter

sothatthepipeendstobeweldedcanbefxedsecurely.

Tab5-5 *SpecialclampingjawsforWIDOSweldingmachinesareavailablefromegeplastforthispurpose

Medium-BearingPipe

DIN8074

OD

[mm]

OuterDiameterofthe

SLM

2.0PipewithProtectiveCoating

[mm]

25 26,9

32 34,3

40 42,6

50 52,8

63 66,1

75 78,3

90 93,6

110 114,2

125 129,5

140 145,0

160 165,6

180 187,0

200 207,0

225 232,0

250 257,0

280 287,0

315 322,0

355 362,0

400 410,0

450 460,0

500 510,0

560 570,0

630 640,0

710 720,0

800 810,0

900 910,0

1000 1010,0

1200 1210,0

Subjecttomanufacturingtolerances

23 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

DensolidHK7/HK7-W

For a layer thickness of 3 mm, one

dual pack is suffcient for an area of

ca.600cm2.

Therequirementsgivenarebasedon

abackcutof20mmtotheprotective

layer, on both sides, for SLM

2.0

pipes.

DensolanESfabrictape

TheapproximatequantityofDENSO-

LANEStapeisgivenfor

dimensionsuptoOD160mmby

OD 3.2 running metres

dimensionsfromOD180mmby

OD 6.4 running metres

DENSOLANESissuppliedasrollsof

15minwidthsof35mmand60mm.

MaterialrequirementsforcoveringwithDENSOLIDHK7/HK7-WandDENSOLANES

Tab:5-6

OD

[mm]

SLM

2.0

QuantityofHK7/HK7-W

Units/WeldSeam

SLM

2.0

QuantityofDensolanESTape

Metres/WeldSeam

25 0.20

32 0.20

40 0.20

50 0.20

63 0.20

75 0.25

90 0.35

110 0.50 0.40

125 0.50 0.40

140 0.50 0.50

160 1.00 0.60

180 1.00 1.20

200 1.00 1.40

225 1.00 1.60

250 2.00 1.60

280 2.00 1.80

315 2.00 2.10

355 2.00 2.30

400 3.00 2.60

450 3.00 2.90

500 3.00 3.20

560 3.00 3.60

630 4.00 4.10

710 4.00 4.60

800 5.00 5.20

900 5.00 5.80

1000 6.00 6.40

1200 7.00 7.70

24 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Preliminarynote:

DrinkingwaterpipeinaccordancewithDIN8074/8075,DINEN12201,made

ofPE100RC

plus

withthehighestresistancetoslowcrackgrowth(FNCTminimum

requirement:3300hinaccordancewithDVS2203-4;T=80C,s=4

N

mm

2

,2%

Arkopal),pipecolourblack.VerifedinaccordancewithbothDIN8075and

DVGWGW335PartA2,withacontinuouslyextrudedprotectivecoating,add-

edsubsequently,madeofmineral-reinforcedsignalbluepolypropyleneakinto

RAL5005,with4yellow-greendoublestripesakintoRAL6018,inaccordance

withtherecommendationsofDVGWWorksheetsGW321andGW323.

Monitoringofconstantmaterialqualityaswellasregularstructuraltestingiscar-

riedoutbyanindependenttestinginstitutewhichisaccreditedaccordingtoDIN

ENISO/IEC17025toperformsuchanalyses.

Thesuitabilityoftheproductforinstallationwithoutasandbed,andfortrench-

lessinstallation,isverifedbyanindependentassessor.

All necessary pipeline joints created by means of either electrofusion welding

orbuttfusionweldingaretobemadeaccordingtotherequirementsoftheap-

plicable DVS technical guidelines. The pipeline junctions are to be completed

according to the pipe manufacturers current technical manual. The piping is

to be stored and transported on the building site in compliance with the KRV

guidelines.

Product: egeplastSLM

2.0drinkingwaterpipe

madeofPE100RC

plus

orequivalent

Manufacturer: egeplastWernerStrumannGmbH&Co.KG

Robert-Bosch-Str.7 48268Greven,Germany

Tel.:+49.2575.9710-0 Fax:+49.2575.9710-110

e-mail:info@egeplast.de http://www.egeplast.de

Specifcationofservices: egeplast-SLM

2.0drinkingwaterpipe

madeofPE100RC

plus

withdimensions:

mm,SDR

Odeliveredasstraightlengthsof6/12m

Odeliveredasbundledcoilsinlengthsofm

Deliverrunningmetresandinstallprofessionally

accordingtoDINandappropriateinstallationguidelinesas

drinkingwaterpipe:/runningmetre

5.6.1RFPFormforegeplastSLM

2.0DrinkingWaterPipe

5.6RFPForms

25 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Preliminarynote:

GaspipeinaccordancewithDIN8074/8075,DINEN1555,madeofPE100

RC

plus

withthehighestresistancetoslowcrackgrowth(FNCTminimumrequire-

ment:3300hinaccordancewithDVS2203-4;T=80C,s=4

N

mm

2

,2%Arkopal),

pipecolourblack.VerifedinaccordancewithbothDIN8075andDVGWGW

335PartA2,withacontinuouslyextrudedprotectivecoating,addedsubsequent-

ly, made of mineral-reinforced yellow-orange polypropylene akin to RAL 1033,

with4yellow-greendoublestripesakintoRAL6018,inaccordancewiththerec-

ommendationsofDVGWWorksheetsGW321andGW323.

Monitoringofconstantmaterialqualityaswellasregularstructuraltestingiscar-

riedoutbyanindependenttestinginstitutewhichisaccreditedaccordingtoDIN

ENISO/IEC17025toperformsuchanalyses.

Thesuitabilityoftheproductforinstallationwithoutasandbed,andfortrench-

lessinstallation,isverifedbyanindependentassessor.

All necessary pipeline joints created by means of either electrofusion welding

orbuttfusionweldingaretobemadeaccordingtotherequirementsoftheap-

plicable DVS technical guidelines. The pipeline junctions are to be completed

according to the pipe manufacturers current technical manual. The piping is

to be stored and transported on the building site in compliance with the KRV

guidelines.

5.6.2RFPFormforegeplastSLM

2.0GasPipe

Product: egeplastSLM

2.0gaspipe

madeofPE100RC

plus

orequivalent

Manufacturer: egeplastWernerStrumannGmbH&Co.KG

Robert-Bosch-Str.7 48268Greven,Germany

Tel.:+49.2575.9710-0 Fax:+49.2575.9710-110

e-mail:info@egeplast.de http://www.egeplast.de

Specifcationofservices: egeplast-SLM

2.0gaspipe

madeofPE100RC

plus

withdimensions:

mm,SDR

Odeliveredasstraightlengthsof6/12m

Odeliveredasbundledcoilsinlengthsofm

Deliverrunningmetresandinstallprofessionally

accordingtoDINandappropriateinstallationguidelinesas

gaspipe:/runningmetre

26 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Preliminarynote:

Sewage pressure pipe in accordance with DIN 8074/8075, DIN EN 13244,

madeofPE100RC

plus

withthehighestresistancetoslowcrackgrowth(FNCTmini-

mumrequirement:3300hinaccordancewithDVS2203-4;T=80C,s=

N

mm

2

,

2%Arkopal),pipecolourblack.VerifedinaccordancewithDIN8075aswellas

DINCertcoinaccordancewithZP14.3.1,labelledwiththeDINCertcoDINplus

markofconformity,withacontinuouslyextrudedprotectivecoating,addedsubse-

quently,madeofmineral-reinforcedbrownpolypropyleneakintoRAL8017,with

4yellow-greendoublestripesakintoRAL6018,inaccordancewiththerecom-

mendationsofDVGWWorksheetsGW321andGW323.

Monitoringofconstantmaterialqualityaswellasregularstructuraltestingiscar-

riedoutbyanindependenttestinginstitutewhichisaccreditedaccordingtoDIN

ENISO/IEC17025toperformsuchanalyses.

Thesuitabilityoftheproductforinstallationwithoutasandbed,andfortrenchless

installation,isverifedbyanindependentassessor.

Allnecessarypipelinejointscreatedbymeansofeitherelectrofusionweldingorbutt

fusionweldingaretobemadeaccordingtotherequirementsoftheapplicableDVS

technicalguidelines.Thepipelinejunctionsaretobecompletedaccordingtothe

pipemanufacturerscurrenttechnicalmanual.Thepipingistobestoredandtrans-

portedonthebuildingsiteincompliancewiththeKRVguidelines.

5.6.3RFPFormforegeplastSLM

2.0SewagePressurePipe

Product: egeplastSLM

2.0sewagepressurepipe

madeofPE100RC

plus

orequivalent

Manufacturer: egeplastWernerStrumannGmbH&Co.KG

Robert-Bosch-Str.7 48268Greven,Germany

Tel.:+49.2575.9710-0 Fax:+49.2575.9710-110

e-mail:info@egeplast.de http://www.egeplast.de

Specifcationofservices: egeplast-SLM

2.0sewagepressurepipe

madeofPE100RC

plus

withdimensions:

mm,SDR

Odeliveredasstraightlengthsof6/12m

Odeliveredasbundledcoilsinlengthsofm

Deliverrunningmetresandinstallprofessionally

accordingtoDINandappropriateinstallationguidelinesas

sewagepressurepipe:/runningmetre

27 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

5.7RecyclingandEnvironmentalProtection

Polyethylene is an organic material

and consists only of carbon and hy-

drogen. It has a wholly neutral im-

pact on the environment. PE, being

a thermoplastic, can be remelted an

almostunlimitednumberoftimesand

processedintonewproducts.Pipeoff-

cutsanddiscardedplasticpipemate-

rial, which, for example, accumulate

during the installation of plastic pipe

systems,shouldthereforeberecycled

ifatallpossible.

At the start of 1994, the Kunststoffro-

hrverband (KRV), together with the

Gtegemeinschaft Kunststoffrohre

(GKR),hadalreadyintroducedana-

tionalcollectionandrecyclingsystem

for plastic materials, which is free of

chargeforthetradeanditscustomers

andincorporatesanobligationtotake

back these materials. This environ-

mentally conscious system eliminates

dumpingorincinerationtogetherwith

thehighcostswhicharisefromdispos-

albythesemethods.

Recycling boxes are provided on a

loan basis to the customer as collec-

tioncontainers.Theplasticpipemate-

rial,atleastpartiallycleaned,isthen

thrown into these boxes. Once the

boxes have been flled, their collec-

tionandexchangeforemptyboxesis

arranged.Onlyboxeswhichareflled

exclusively with plastic pipe material

are taken. The recycling boxes are

then brought, via regional collection

points, to a recycling plant in which

the collected pipe material is sorted,

cleaned, and cut into small pieces to

be employed subsequently for other

uses.

Fig5-58 Fig5-59:Recyclingbox

28 12/05

5 TrenchlessInstallation

andRenovation

egeplast SLM

2.0

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Failure PVC PipeDokument31 SeitenFailure PVC PipeHAJEYYNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Zip GunDokument7 SeitenZip Gunbtbam11222Noch keine Bewertungen

- TDP-502 Water Piping and PumpsDokument63 SeitenTDP-502 Water Piping and PumpsAmr HeshamNoch keine Bewertungen

- Acidizing With CTUDokument6 SeitenAcidizing With CTUMuhammad ShahrukhNoch keine Bewertungen

- Evaluation of The Bolting and Flanges of Ansi B16.5 Flanged JointsDokument184 SeitenEvaluation of The Bolting and Flanges of Ansi B16.5 Flanged Jointsila_368684492100% (2)

- BS 5041-3-1975 Fire Hydrant Systems EquipmentDokument10 SeitenBS 5041-3-1975 Fire Hydrant Systems EquipmentTrần Khắc ĐộNoch keine Bewertungen

- Absolute LYFT Pulsed Eddy CurrentDokument2 SeitenAbsolute LYFT Pulsed Eddy CurrentgulmuhrNoch keine Bewertungen

- Pipeline Isolating Joints (Amendments - Supplements To ISO 15590-2 - 2003)Dokument18 SeitenPipeline Isolating Joints (Amendments - Supplements To ISO 15590-2 - 2003)Jacob PhilipNoch keine Bewertungen

- Pyrolysis PlantDokument14 SeitenPyrolysis PlantElie AbNoch keine Bewertungen

- Hyd Book 11Dokument300 SeitenHyd Book 11hanifpanjaNoch keine Bewertungen

- Process Industry Practices Process Control: Pip Pcign300 General Instrument Accessory DetailsDokument10 SeitenProcess Industry Practices Process Control: Pip Pcign300 General Instrument Accessory DetailsEr Bishwonath ShahNoch keine Bewertungen

- Berat BajaDokument25 SeitenBerat BajaAchmad Zaki ZulkarnainNoch keine Bewertungen

- Importance of Dedusting Pipe LayoutDokument4 SeitenImportance of Dedusting Pipe LayoutManoj ThakurNoch keine Bewertungen

- ArioshDokument14 SeitenArioshumer shafiqueNoch keine Bewertungen

- Steelmark ProfileDokument14 SeitenSteelmark ProfileAzizul KhanNoch keine Bewertungen

- Lista ProductosDokument133 SeitenLista ProductosmangalamtestingbureaNoch keine Bewertungen

- Lession 1 Materials and Sanitary Features of The Dairy EquipmentDokument77 SeitenLession 1 Materials and Sanitary Features of The Dairy EquipmentRajat Jain100% (1)

- 2013.03.11 Ssi2000 2010 HDDokument28 Seiten2013.03.11 Ssi2000 2010 HDdanko826Noch keine Bewertungen

- Chapter-7: Imported MachineriesDokument16 SeitenChapter-7: Imported MachineriesSim Khoon AunNoch keine Bewertungen

- Orifice Fittings Brochure PDFDokument10 SeitenOrifice Fittings Brochure PDFisukuruNoch keine Bewertungen

- PVM Ms 4749 BDokument48 SeitenPVM Ms 4749 BabdelillahNoch keine Bewertungen

- Instruction Manual: Phosphate AnalyzerDokument39 SeitenInstruction Manual: Phosphate AnalyzerdhitanandaNoch keine Bewertungen

- Memorandum Circular No. 22-18Dokument66 SeitenMemorandum Circular No. 22-18Marce MangaoangNoch keine Bewertungen

- VRF Indoor Unit Four Way Cassette (2 Generation DC Series, 50/60Hz)Dokument2 SeitenVRF Indoor Unit Four Way Cassette (2 Generation DC Series, 50/60Hz)JAQANoch keine Bewertungen

- As 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsDokument7 SeitenAs 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsSAI Global - APACNoch keine Bewertungen

- EHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Dokument2 SeitenEHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Rene ParedeschaconNoch keine Bewertungen

- Figure QF-463 Bend Test Specimen Removal, Configuration, and Testing (Cont'd)Dokument7 SeitenFigure QF-463 Bend Test Specimen Removal, Configuration, and Testing (Cont'd)Gangadhar SahuNoch keine Bewertungen

- Leda Industrial Gates and Perimeter Security HandbookDokument160 SeitenLeda Industrial Gates and Perimeter Security HandbookJessicaNoch keine Bewertungen

- Material Assessment Report - Mis ArabiaDokument6 SeitenMaterial Assessment Report - Mis ArabiaBALAKRISHANANNoch keine Bewertungen

- PDFDokument52 SeitenPDFzhobeysNoch keine Bewertungen