Beruflich Dokumente

Kultur Dokumente

ACMV

Hochgeladen von

x3350Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ACMV

Hochgeladen von

x3350Copyright:

Verfügbare Formate

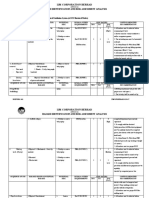

TECHNICAL SPECIFICATION FOR THE SUPPLY AND INSTALLATION OF MVAC SYSTEM

FOR PROJECT SAI GON M&C TOWER At No 34 TON DUC THANG, DISTRICT 1 HO CHI MINH CITY VIETNAM

REV. A

DECEMBER 2005

Page 1 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

CONTENTS

CENTRIFUGAL WATER CHILLER............................................................................4 PUMPS&EXPANTION TANK .................................................................................... 20 COOLING TOWERS ...................................................................................................22 FANS............................................................................................................................26 AIR COILS................................................................................................................... 35 AIR CONDITIONING EQUIPMENT.........................................................................39 AIR FILTERS..............................................................................................................45 DUCTWORK................................................................................................................49 MECHANICAL PIPING .............................................................................................67 ACOUSTICS & VIBRATION CONTROL...................................................................87 MECHANICAL INSULATION ................................................................................... 92 MECHANICAL COMMISSIONING ........................................................................ 104

Page 2 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Page 3 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

SECTION B01

CENTRIFUGAL WATER CHILLER

PART 1 GENERAL 1.01 Section Includes A. Chiller package. B. Charge of refrigerant and oil. C. Controls and control connections. D. Chilled water connections. E. Condenser water connections. F. Starters. G. Electrical power connections. 1.02 References A. ANSI/ASHRAE STANDARD 15-1994 - Safety Code for Mechanical Refrigeration. B. ANSI/ASHRAE 90A - Energy Conservation in New Building Design. C. ASME SEC VIII - Boiler and Pressure Vessel Code. D. ANSI/UL 465 - Central Cooling Air Conditioners. E. ARI STANDARD 550/590-98 - Centrifugal, Helical rotary, scroll, and reciprocating water chillers. F. ARI Standard 575-94 Sound G. AFBMA 9 - Load Ratings and Fatigue Life of Roller Bearings. H. ASHRAE STANDARD 34 - Number Designation and Safety Classification of Refrigerants

Page 4 of 110

SAIGON M&C TOWER 1.03 Submittals

MVAC SPECIFICATIONS

A. Acceptable Refrigerants on which chiller performance is based are: HCFC123, HFC-134a. All proposals for chiller performance must include a 50 Hz ARI approved selection method for the specified refrigerants. The manufacturer shall provide 50 Hz ARI certified data or provide actual data from a performance test done at a factory. An original copy of an ARI certified computerized selection shall also be provided to display the performance of the machine with the applicable alternative refrigerant. Capacity and efficiency are to meet the scheduled performance. B. Submit drawings indicating components, assembly, dimensions, weights and loading, required clearances, and location and size of field connections. Indicate equipment, piping and connections, valves, strainers, and thermostatic valves required for complete system. C. Submit product data indicating rated capacities, weights, specialties and accessories, electrical requirements and wiring diagrams. D. Submit manufacturer's installation instructions. E. Submit performance data indicating energy input versus cooling load output from 100 to 20 percent of full load With Constant Entering condenser Water Temperature. F. Submit load stability data with constant entering condenser water temperature down to 20 Percent Load Stability.

G. Submit product data in table form indicating impeller speed (RPM), number of bearings, type of bearings, high speed impeller shaft RPM, sound level per ARI 575-94 (dB), number of stages, number of sets of inlet guide vanes, amount of refrigerant charge (lbs.), and amount of oil required (lbs.). 1.04 Operation And Maintenance Data A. Submit operation data. B. Include start-up instructions, maintenance data, controls, and accessories. Include trouble-shooting guide. C. Submit maintenance data. 1.05 Verification Of Chiller Capacity And Efficiency

Page 5 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

A. One of each size chiller shall be FACTORY PERFORMANCE TESTED with the proposed refrigerant under full load conditions in a 50Hz ARI certified test facility. The manufacturer shall supply a certified test report to confirm performance as specified. Proper a 50Hz ARI certification documents for the test loop shall be made available upon request from the manufacturer for inspection. B. Stable operation at a minimum load of 25 % shall be demonstrated during the factory performance test with constant entering condenser water temperature. The machine shall be modified to include hot gas bypass if the minimum load cannot be demonstrated. C. The performance test shall be run with clean tubes in accordance with ARI 550/590-98 to include the following: 1. A downward temperature adjustment per Section A6.3 shall be made to the design leaving evaporator water temperature to adjust from the design fouling to the clean tube condition. 2. An upward temperature adjustment per Section A6.3 shall be made to the design entering condenser water temperature to adjust from the design fouling to the clean tube condition. 3. There shall be no exceptions to conducting the performance test with clean tubes and with temperature adjustments in (1) and (2). The manufacturer shall clean tubes, if necessary, prior to test to obtain a test-fouling factor of .0000 hr. sq. ft. F/BTU. D. The factory test instrumentation shall be per 50 Hz ARI Standard 550/59098, and the calibration of all instrumentation shall be traceable to the National Institute of Standards and Technology (formerly NBS). E. Factory Performance Test shall be conducted in accordance with ARI Standard 550/590-98 procedures and tolerances. F. A certified test report of all data shall be submitted to the Contracting Officer prior to completion of the project. The factory certified test report shall be signed by an officer of the manufacturer's company. Preprinted certification will not be acceptable; certification shall be in the original. G. The equipment will be accepted if the test is conducted in conformance with ARI Standard 550/590-98 and the proposed tolerances are met. 1.06 Sound Data Page 6 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

A. The Centrifugal Chiller Sound Pressure Level (SPL), in decibels (dB), with a reference pressure of 20 micropascals, shall not exceed Sound Levels: Load % Decibels (A Weighted) 100 _____________________(dB) 50 (option _____________________(dB) 25 (option _____________________(dB) All ratings shall be in accordance with ARI Standard 575-94. 1. To represent the chiller's loudest operating condition and uncover any sound problems, reducing the temperature of the entering condenser water and/or raising the leaving chilled water temperature is not allowed when determining the Sound Pressure Levels. B. Sound Pressure Test - One of each size chiller shall have a sound test conducted at the factory prior to shipment to confirm the submitted Sound Pressure Levels. All data must be measured and presented in strict accordance with ARI Standard 575-94. 1. The sound data points shall be measured simultaneously during the verification of capacity and efficiency as outlined in Section 1.06. 2. In the event that a chiller does not meet the submitted dBA sound pressure level, sufficient funds will be deducted from the purchase order to cover materials and labor for jobsite attenuation, and to cover expenses of a retest to insure that the submitted levels are met. This attenuation shall be applied in such a manner that it does not hinder trhe operation or routine maintenance procedures of the chiller. 1.07 Regulatory Requirements A. Conform to 50 Hz ARI Standard 550/590-98 code for rating and testing of water chillers. B. Conform to ANSI/UL 465 for construction of centrifugal chillers. C. Conform to ANSI/ASME SECTION VIII Boiler and Pressure Vessel Code for construction and testing of centrifugal chillers as applicable. D. Conform to ANSI/ASHRAE STANDARD 15-1994 code for construction and operation of centrifugal chillers. E. Unit shall bear the 50 Hz ARI Certification Label for Water Chillers as Page 7 of 110

SAIGON M&C TOWER applicable. 1.08 Handling And Equipment Room Requirements

MVAC SPECIFICATIONS

A. Comply with manufacturer's installation instructions for rigging, unloading, and transporting units. B. Protect units from physical damage. Leave factory shipping covers in place until installation. C. Equipment Room Requirements 1. Follow minimum standards for refrigeration systems as required by ANSI/ASHRAE Standard 15-1994 paying special attention to requirements for air monitoring, ventilation, self-contained breathing apparatus, for leak detection and insuring the safety of chiller plant operating personnel. 2. Install local exhaust at relief device discharge headers and purge units. Route exhaust to the outside of the building and away from all air intakes. 3. Install a refrigerant monitor that can be calibrated for appropriate refrigerant, capable of detecting concentrations of ten ppm for low level leak detection and for insuring the safety of operators. 4. Refrigerant Monitor concentration output shall be integrated into the chiller control panel. 5. Install suitable alarms that activate well below the Acceptable Exposure Level (AEL) of the refrigerant and alert persons inside and outside of the equipment room that a leak condition exists.

1.09 Warranty A. Provide Whole Unit Parts warranty (less refrigerant) for the duration of 1 year. 1.10 Maintenance Service A. Furnish service and maintenance of chillers for period of one year from Date of Substantial Completion. B. A minimum of one inspection is required the first year with two inspections

Page 8 of 110

SAIGON M&C TOWER for each subsequent year. PART 2 PRODUCTS 2.01 Summary

MVAC SPECIFICATIONS

A. The contractor shall furnish and install centrifugal water chillers as shown and scheduled in the plans and specifications. The units shall produce the specified tonnage per the scheduled data in accordance with ARI 550/590-98. The unit shall bear the ARI certification label as applicable. B. Approved Manufacturers: 1. Trane 2. Carrier 3. York 2.02 Compressor And Motor A. The compressor shall be centrifugal with multiple stages. The single stage compressors are not allowed. B. Low pressure refrigerant machines must be provided as follows: Pressure at 40oF = 18.1Hg o Pressure at 82 F = 0 PSIG o Pressure at 100 F = 6.08 PSIG

C. Chiller should be able to unload to 20 percent of design tonnage with constant entering water temperature. D. Compressor assembly shall be run-tested at the factory. Vibration shall not exceed 0.15 inches per second. The test data shall be recorded and provided to the customer in report form for approval. E. The motor shall be hermetic and either suction or liquid refrigerant cooled. Hot gas motor cooling is not acceptable. The Open drives are not acceptable due to the potential for refrigerant and oil leakage associated with the mechanical shaft seal and the coupling between an open motor and the compressor. F. The compressors must be direct drive type. The gear-drive compressors are not accepted. Manufacturers with speed increasing transmissions shall

Page 9 of 110

SAIGON M&C TOWER not exceed 3,000 RPM compressor speeds G.

MVAC SPECIFICATIONS

The impellers shall be fully shrouded and made of a high strength aluminum alloy. Impellers shall be dynamically balanced and over speed tested at 1.25 times impeller shaft speed.

2.03 Evaporator And Condenser A. The evaporator and condenser shall be built in accordance with ANSI/ASHRAE 15-1994 Safety Code for Mechanical Refrigeration. The water piping connections shall be victaulic. B. Evaporator and condenser tubes shall be internally enhanced. The minimum tube wall thickness shall be 0.028 inch. C. Units with multi-stage compressors shall incorporate an interstage flash vessel "economizer". D. Supply and return head water boxes shall be designed for a working pressure of 300 psig and shall be factory hydrostatic pressure tested at 150 percent of the design pressure. Provide drain and vent connections in water boxes.

E. If marine water boxes are required, side connections of the condenser and evaporator shall be provided such that the water piping of both the entering and leaving sides shall not be disconnected for mechanical cleaning. The water piping connections shall be in a direction perpendicular to the shells to allow full unblocked access to the tubes. F. Insulation will be 3/4" insulation and cover all low temperature surfaces to include the evaporator, water boxes, and suction elbow. Economizer and motor cooling lines are insulated with 3/8" and 1/2" insulation respectively. 2.04 Purge System A. The manufacturers of low pressure machines, must provide a purge system. Acceptable purges are the Trane Purifier Purge and the York Skyguard Purge. The Turboguard Purge is not acceptable. B. The purge must be ARI Standard 580 listed. C. The purge efficiency must meet ASHRAE Guideline 3-1996 paragraph 4.4.1.1.

Page 10 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

D.

The purge shall be capable of operating when the chiller is idle in accordance with ASHRAE Guideline 3-1996, paragraph 4.4.1.2. At standard room operating conditions and with a condensing refrigerant temperature > 80 degrees F, the purge system shall be rated for no more than .0049 lb. of refrigerant per 1 lb. non-condensable. The purge efficiency must not deteriorate over time. The purge unit must be met the following features: 1. 2. 3. 4. 5. 6. 7. 8. 9. Purge must be able to operate while chiller is not running. Next time purge is to run ) auto adaptive mode Purge adaptive cycle time Purge operating mode status Purge pumpout rate Purge pumpout time this/last cycle Purge refrigerant compressor suction temp Total purge pumpout time Total purge run time.

E.

F.

2.05 Controls A. The chiller shall be controlled by a stand-alone direct Digital Control (DDC) System. A dedicated chiller microprocessor control panel is to be supplied with each chiller by the chiller manufacturer. The Direct Digital Control (DDC) can perform in clear language display, 2 lines by 40 characters. 16 function keypad. Diagnostic summary with time/date stamp and help message, programmable soft loading, modular flexibility, non-volatile memory, saves machine setups on power loss. The capabilities of DDC includes: 1. 2. Super-twist LCD display with backlighting for readability. Access to all available chiller data: a. Status b. Setpoints

B.

C.

Page 11 of 110

SAIGON M&C TOWER c. d. e. 3. Field start-up items Machine configuration items Service test items

MVAC SPECIFICATIONS

Status reports, in logical groupings, including: a. Chiller Report b. c. d. Refrigerant Report Compressor Report Custom report capability for data arranged the way the operator wants to see it.

4.

Alarm and diagnostic capability including: a. At least 100 different diagnostic messages b. c. History log of the last 20 diagnostics An indicator to let the operator knows when an alarm is present. Expanded help messages for each alarm to let the operator knows what action to take Operator security Internationally recognized symbols.

d.

e. f.

C. The chiller control panel shall provide control of chiller operation and monitoring of chiller modules, sensors, actuators, relays and switches and shall include controls to safely and efficiently operate the chiller. D. Safeties - the chiller control panel shall monitor the following safeties: start and running time between compressor/motor starts, low chilled water temperature, low evaporator refrigerant temperature or pressure, high condenser refrigerant pressure, evaporator and condenser water flow status, low oil pressure, low oil temperature, high oil temperature, high motor winding temperatures, sensor faults, and proper operation of unit controls. 1. To monitor bearing temperatures, all of the compressor and motor bearings, (including high speed, low speed, and thrust bearings) Page 12 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

shall have factory installed separate temperature sensors installed in the bearing or the oil return lines of each bearing. If any oil temperature reaches or exceeds a set value, the chiller control panel shall shut down the chiller, display the diagnostic, and light the front panel alarm LED. 2. The chiller control panel shall incorporate advanced motor protection to safeguard the motor throughout the starting and running cycles from the adverse affects of: a. Phase loss b. Phase imbalance c. Phase reversal d. Under voltage e. motor overload f. motor overload protection incorrectly set g. momentary power loss protection with auto restart consisting of three-phase current sensing devices that monitor the status of the current h. starter contactor fault protection i. starter transition failure 3. Alternately, the advanced motor protection system can be furnished in the starter. E. The chiller control panel shall be capable of displaying system data in English or Metric units. F. The chiller control panel is to be provided with a starts counter and running time counter. G. The front of the chiller control panel shall display the following in clear language, without the use of codes, look-up tables, or gauges: 1. Entering and leaving evaporator water temperatures 2. Entering and leaving condenser water temperatures 3. Compressor Motor Winding Temperature 1,2,3 4. Saturated evaporator and condenser refrigerant temperatures

Page 13 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

5. Evaporator and condenser refrigerant pressure 6. Oil Temperature 7. Oil Tank pressure 8. Oil pump discharge pressure 9. Differential oil pressure 10. Compressor motor starts and running hours 11. Compressor motor current, by phase 12. Compressor motor percent RLA 13. Purge compressor suction temperature 14. Purge pumpout rate 15. Purge pumpout time last or current cycle 16. Total Purge pumpout time 17. Total Purge run time 18. Chilled water set point and set point source 19. Electrical current limit set point and set point source 20. Current chiller operating mode 21. Equipment room refrigerant monitor ppm levels 22. Chiller diagnostics including a time and date of occurrence (minimum 20 historical diagnostics stored in non-volatile chiller panel memory) 23. Bearing Oil Temperatures 24. Discharge Temperature (compressor) 28. Compressor motor voltage, by phase, KW, power factor

Page 14 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

H. The chiller control panel shall provide evaporator freeze protection and low limit control to avoid low evaporator refrigerant temperature trip-outs during critical periods of chiller operation. The control shall take action in response to the actual value of the evaporator refrigerant temperature. A diagnostic message shall be automatically displayed at the front panel whenever this control is in effect, and if the condition exists for more than 20 minutes, a limit warning alarm relay shall energize. I. The chiller control panel shall provide individual relay outputs to start/stop the evaporator and condenser water pumps. The condenser water pump relay output can be used to enable the cooling tower temperature controls. J. The chiller control panel shall provide a relay output that shall energize whenever the compressor is running. K. The chiller control panel shall provide an alarm relay output that shall energize whenever a fault requiring manual reset is detected by the panel. L. The chiller control panel shall provide a relay output that shall energize whenever the chiller is operating at maximum capacity. M. The chiller control panel shall provide a head relief request relay output to indicate that the chiller is in condenser limit mode and thereby requesting condenser water temperature relief. N. The chiller control panel shall provide an analog output signal that shall indicate the Compressor Motor Percent RLA. O. The chiller control panel shall provide an analog output signal that shall indicate the condenser refrigerant pressure or condenser/evaporator differential refrigerant pressure. P. The chiller control panel shall provide condenser limit control to include a pressure transducer and interconnecting piping and wiring. This control shall be used to avoid high condenser refrigerant pressure tripouts. The control shall take action in response to the condenser refrigerant pressure. A diagnostic message shall be automatically displayed at the front panel whenever this control is in effect, and if the condition exists for more than 20 minutes, a limit warning alarm relay shall energize. Q. The chiller control panel shall provide leaving chilled water temperature reset based upon return water temperature or ambient temperature.

Page 15 of 110

SAIGON M&C TOWER R.

MVAC SPECIFICATIONS

The chiller control panel shall be capable of providing short cycling protection. The chiller control panel shall be capable of independently invoking password protection of the entire display and keypad, operator settings (e.g. chilled water set point), machine configuration settings, and service start-up settings. The above specified items are required as a minimum. The contractor may select which items are covered by the equipment supplier and which are covered by the controls contractor. A combined submittal will be required where the contractor will identify which items are covered by each supplier. The manufacture has to provide remote monitoring service function via telephone system from their site, which alarm and display panel with a minimum of the following features: 1. Leaving chiller water temperature setpoint adjustment. 2. Display diagnostics in 2.05 G. 3. Display entering and leaving water temperatures. 4. Display active chilled water and current limit setpoint. 5. Display parts failures: a. Water temperature sensors b. Motor contactors c. Unit Controller d. Evaporator [and condenser] refrigerant temperature sensors.

S.

T.

U.

2.06 Starter - Star Delta (Low Voltage) A. Motor starter shall be a Star-Delta Closed Transition and shall have a NEMA 1A gasketed enclosure. B. The starter enclosure shall have a withstand rating of 380-400V/3P/50Hz. If the starter enclosure does not have this withstand rating, then a device shall be provided upstream of the starter to limit the fault current at the starter to be equal or less than the withstand rating of the starter. Page 16 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

C. Motor starters shall include incoming line provisions for the number and size cables shown on the drawings. Incoming line lugs shall be copper mechanical type. D. Contactors shall be sized properly to the chiller full load currents. E. Each motor starter shall include a 3 KVA control power transformer with fused primary and secondary. Control relays shall be provided within the motor starter to interface with the control panel. F. Starter shall include an advanced motor protection system incorporating electronic three phase overloads and current transformers. This electronic motor protection system shall monitor and protect against the following conditions: 1. Phase loss 2. Phase imbalance 3. Phase reversal 4. Under voltage 5. Motor overload 6. Motor overload protection incorrectly set 7. Momentary power loss protection with auto restart consisting of threephase current sensing devices that monitor the status of the current. 8. Starter contactor fault protection 9. Starter transition failure 10. Distribution fault protection. 11. Under/over voltage relay shall be provided. Alternately, this protection can be integrated with the chiller controls.

G. Alternately the advanced motor protection system can be furnished in the chiller control panel. H. The starter shall be able to operate in temperatures up to 120 degrees F.

Page 17 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

I. All field supplied wires, bus bars, and fittings shall be copper only.

PART 3 EXECUTION 3.01 Installation A. Install in accordance with manufacturer's instructions. B. Provide for connection to electrical service. Include for connection of oil pump. C. Provide for connection of electrical wiring between starter and chiller control panel, oil pump, and purge unit.

D. Furnish and install necessary auxiliary water piping for oil cooling units and purge condensers if required. E. Arrange piping for easy dismantling to permit tube cleaning. F. Provide piping from chiller relief device to outdoors. Size as recommended by manufacturer. G. Chiller vibration isolation and the base type (i.e. floor pad) will be in accordance with ASHRAE Handbook, 1995, HVAC Applications, Chapter 43 Table 42. Open centrifugal chillers shall require installation onto a base type "C" as defined by ASHRAE. This concrete base type "C" shall consist of a steel pouring form with welded-in reinforcing bars, provision for equipment hold-down, and isolator brackets. Hermetic centrifugal chillers require installation onto a base type "A" as defined by ASHRAE. 3.02 Manufacturer's Field Services A. Manufacturer shall furnish a factory trained service engineer without additional charge to start the unit(s). Representatives shall provide leak testing, evacuation, dehydration, and charging of the unit(s).

B. A start-up log shall be furnished by the manufacturer to document the chiller's start-up date and shall be signed by the owner or his authorized representative prior to commissioning the chillers. C. The manufacturer shall furnish an alternate price for:

Page 18 of 110

SAIGON M&C TOWER 1. Extended parts warranty for five years.

MVAC SPECIFICATIONS

2. Extended parts and labor warranty for five years. D. The manufacturer shall furnish complete submittal wiring diagrams of the centrifugal chiller(s) starter(s) and associated components like cooling towers, pumps, interlocks, etc. as applicable. Part 4 Sequence Of Operations A. The chiller plant shall start in response to the optimum start, night setback or timed override operation of any system air handler. B. Chiller Status Report - Provide an operating status report for each chiller. The report(s) shall provide the present status of all binary information and for analog information present value, today's average, and the month to date average for the following information to provide the operator with critical chiller operating data. 1. Compressor On/Off Status. 2. Compressor Starts/Run Hours 3. Active Chiller Diagnostics or Alarms 4. Leaving Chilled Water Temperature 5. Entering Chilled Water Temperature 6. Chilled Water Setpoint. 7. Operating Mode 8. Chiller Model and Serial Number 9. Outside Air Temperature 10. Zone Temperature END OF SECTION

Page 19 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

SECTION B02

PUMPS&EXPANTION TANK

1. Cooling / Chilled/ Secondary Water Pumps a) The cooling / chilled water system includes cooling / chilled water pumps, directly connected to motor by coupling and mounted on a base plate. b) Component specification of pumps is as follows: i) Casings shall be cast iron conforming to JIS G 5501 or JIS G 5502. Impellers shall be cast bronze conforming to JIS H 5120, class 2 or class 6, or approved equivalent. Main shafts shall be stainless steel, conforming to JIS G 4303, or carbon steel conforming to JIS G 4051 when shafts sleeves are provided; and shall be of construction that will prevent oil from mixing with supply water. Base plate shall be cast iron or steel frame with a raised lip at all edges. Rotating parts shall be well balanced and with no vibration. Vibration isolators (rubber pad) shall be provided for each pump, and shall be selected for location and weight of pump and its expected vibration. Vibration isolators (rubber pad) shall require the approval of the Engineer prior to installation.

ii)

iii) iv) v)

c) Pumps shall be provided with following accessories for each unit. i) Globe valve for discharge piping and gate valve or butterfly valve for suction piping. Check valve (hammerless type) with by-pass valve Y-type strainer (to be used only at cooling water circulating pumps) Air cock and drain cock Pressure gauge with SUS made siphon tube and gauge valve Compound gauge with SUS made siphon tube and gauge valve Priming water funnel with cock Companion flanges, bolts, washers, nuts and packing for piping connections

ii) iii) iv) v) vi) vii) viii)

Page 20 of 110

SAIGON M&C TOWER

ix) x) xi) Vibration isolators (rubber pad)

MVAC SPECIFICATIONS

Flexible joints for discharge and suction piping (rubber type FJ) Anchor bolts with washers and nuts and foundations

2. Expansion Tank a) Expansion tanks shall be constructed for a working pressure of 150 psi and shall comply with the Japanese boiler and pressure vessel codes or international recognized codes and standards. b) Expansion vessel shall be installed and fitted with all necessary equipment to achieve a proper operation of the Plant and to comply with manufacturers instructions. c) Tank requirements shall be as follows:i) Closed type expansion tanks with complete accessories shall have make-up water introduced directly into the tank by means of a combination pressure regulating and relief valve. The material of body shall be steel sheet complying to JIS G 3101, G 3141, G 3454, G 3457 and G 3131. The membrane shall be diaphragm type. The membrane material shall be butyl rubber, natural rubber, etc., complying to JIS K 6200. The valve core of air pressure adjusting valve shall comply with JIS D 4211. Accessories to be provided shall include: pressure gauge Foundations and foundation bolts name plate

ii)

iii)

iv)

v)

END OF SECTION

Page 21 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

SECTION B03

COOLING TOWERS

3. COOLING TOWERS a) General i) Cooling towers shall be open type, counter flow (or cross flow), factory or field assembled of low noise level type and shall consist of tower body, pan, fan, motor and accessories. The cooling tower shall be suitable for use with city water and well water in Vietnam. All materials used for the cooling tower shall be non-inflammable.

ii)

iii)

b) Tower Body i) The tower body shall be made by glass fibre reinforced polyvinyl chloride sheet, or rigid polyvinyl chloride sheet (JIS K 6745). The structure of tower body shall be provided with access opening for inspection and easy maintenance and cleaning inside. Water distribution device shall be made of stainless steel sheet or aluminium cast metal or synthetic resins and the water spray distribution should be uniform. The louver or wire to be set at air inlet shall be the same materials above or steel sheet with hot dip galvanizing (JIS H 8641), and the air flow should be well ventilated, and should not have water spray out The structure of filler shall be provided to make that the water flow in the filler is equally distributed.

ii)

iii)

iv)

v)

c) Pan i) ii) The pan shall be constructed of stainless steel sheet (JIS G4303, G4305). The pan shall consist of drain pipe, overflow pipe, and make-up water pipe. The water inlet shall be provided with wire that is made of stainless steel sheet or steel sheet with hot dip galvanizing (JIS H 8641) or synthetic resins for removing dust.

d) Fan

Page 22 of 110

SAIGON M&C TOWER

i) ii)

MVAC SPECIFICATIONS

Fan shall be heavy-duty axial propeller type statically balanced. The protecting cover of air outlet shall be stainless steel sheet, or steel sheet with hot dip galvanizing (JIS H 864) or synthetic resins. The casing material shall be the same as the tower body. The propeller shall be made of steel with hot dip galvanizing (JIS H 8641) or aluminium alloy or synthetic resins.

iii) iv)

e) Motor i) Motor shall comply with Japan Industrial Standard.

f) Painting i) ii) Painting shall be manufacturers standard,. Steel parts shall generally be hot dipped galvanised.

g) Accessories i) ii) iii) iv) Ball Tap (Float Ball) Ladder and Hand Rail: stainless steel Foundations and foundations bolts Nameplate

4. WATER TREATMENT EQUIPMENT FOR COOLING WATER a) General The water treatment equipment shall consist of conductivity control equipment with plastic box for outdoor use type, chemical storage tank and high performance chemical injection pump. b) Conductivity Control Equipment The Conductivity Control Equipment shall be as follows i) ii) iii) Power source : Power consumption 1 50Hz 85~250V : Less than 10VA 5 electrode method/5m

Electrode/cable length :

Page 23 of 110

SAIGON M&C TOWER

iv) v) vi) vii) Measurement range Control Range : Measurement Error Single Output : : 0~19,999 mS/m

MVAC SPECIFICATIONS

100~12,000 mS/m : within +3 % of an indicated value

4~20mA DC

c) Chemical Storage Tank i) ii) iii) iv) v) Capacity : 100 L Rectangular/Polyethylene : 500 x 1020 x 300H (for reference)

Type/Material : Outer dimensions Accessories Cover :

Lead switch level switch, transparent PVC pump

d) High Performance Chemical Injection Pump i) ii) iii) Power Source : Capacity Stroke : : 1 220V 50Hz 38ml/min, 10 kg/cm2

Stroke of slide: 0 to 100 %, Stroke per min.: 0 to 360 spm Electromagnetic driving diaphragm type : 4 x 6 polyethylene tube with a siphon

iv) v)

Type

Connecting tube backstop chuck valve

e) Chemicals Dosing For Cooling Tower Water Quality i) The contractor shall collect and analyse the proposed make up water system and shall also study the specification of the cooling water system. From this information, the Contractor shall propose a suitable and comprehensive water treatment chemical for the proper, efficient and economic operation of the cooling water system. Treated water quality for cooling water shall be in accordance with the guideline JRA-GA-02-1994 issued by the Japan Refrigeration and Air conditioning Industry Association. The water shall be introduced through a water meter coupled to a chemical injection pump so that the prcised quantity of chemical required is injected.

ii)

iii)

Page 24 of 110

SAIGON M&C TOWER END OF SECTION

MVAC SPECIFICATIONS

Page 25 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

SECTION B04

FANS

GENERAL Functional Description The fans scope of work covers the ventilation fans for distributing outside air to certain fan coil units, various toilet exhaust fans and the fans within the primary air units and fan coil units. The products shall be M&Y.(Matthews & Yates). Standards Comply with the following standards: Fan performance: To BS 848:1. Fan sound power levels: To BS 848:2. ASHRAE 51 Fans AMCA 210 Laboratory Methods Of Testing Fans For Rating Purposes AMCA 301 Method Of Calculating Fan Sound Rating From Laboratory Test Data Design (a)

Centrifugal fans

Select for maximum fan static efficiency at 100% of design air flow.

(b) Axial

flow fans

Select at pitch angle 90% of maximum recommended by manufacturer for impeller and speed. (c)

Fans with multi-speed motors

Select for required duty at "medium" or second highest speed.

(d) Noise

Page 26 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Contractor to select fans to ensure that required noise levels are achieved. QUALITY 1 Pre-Completion Tests (a) Tests Fan performance: To BS 848:1. Fan sound power levels: To BS 848:2. 2 Submissions (a) Product Data & Literature Submit - Generic product data - Fan technical data - Fan curves, with duty point marked - Acoustic Performance FANS CENTRIFUGAL - GENERAL PURPOSE (a) General Provide fans with non-overloading power characteristics. (b) Casings Construction: Welded steel scroll and side plates, reinforced to prevent flexing and drumming. Inlet bells: Removable, shaped for aerodynamically efficient air entry and close approach to impeller. Access panels: Provide inspection/access panels to casings of fans with impellers 650 mm diameter. Seal panels airtight with neoprene gaskets. Outlets: Provide flanged outlets to casings of fans with impellers 250 mm diameter or greater. Guards: For fans not connected to ductwork provide removable inlet guards, discharge guards or both.

Page 27 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

(c)

Minimum casings thickness table

Impeller diameter (mm) =450 > 450, =800 > 800, =1000 > 1000 Side plates (mm) 2 2.5 3 4 Scroll (mm) 1.6 2 2.5 3

(d) Bases General: Form from fully welded steel sections integral with or bolted to casings. Mounting brackets: Provide at least 4 height saving mounting brackets. (e)

Impellers

Blade type: Backward inclined aerofoil or laminar single thickness type, flat or curved section, with non-overloading power characteristics. Characteristics: Provide the following: - Statically and dynamically balanced. - Keyed to drive shafts by means of taper-lock fixing devices or taper keys. - For overhung driven fans, retained onto drive shafts by means of positive devices such as washers and set screws into tapped holes in shaft ends.

(f)

Bearings

For single width fans with impellers < 1.25 mm diameter and double width fans with impellers < 950 mm diameter: Provide pillow-block mounted, self aligning ball bearings, sealed for life, with a minimum rating fatigue life of 12,000 hours. For larger fans: Provide plummer-block mounted roller bearings to AS 2729, with seals and grease relief, with a minimum rating fatigue life of 20,000 hours. Extend grease nipples for ready access.

(g)

Motors

General: Provide electric motors which are compatible with fan requirements, providing efficient non-overloading fan units. Power rating: At least the power required by the fan when the air flow is increased by 10% above the specified design air flow rate, against the corresponding increased system resistance. Minimum degree of protection: IP54. Page 28 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

(h) Belt

drives

Drive sizing: To suit a minimum 125% of motor power and capable of transmitting the full starting torque without slip. Belts: Wedge belts consisting of matched sets of at least 2 belts. Belt tensioning: Provide adjustment of belt drive tension by either movement of motors on slide rails or by pivoting support. Do not use the weight of motors to provide belt tension. Restrain motors with locknuts on bolts, clamping motors in place. (i)

Drive shafts

Characteristics: Provide the following: - Designed so that the first critical resonant speed of the shaft is =130% of design maximum operating speed. - Filleted, stepped type to permit easy impeller removal for shaft diameter > 60 mm, for double width fans. - Keyed with taper-lock fixing devices for fixing of pulleys. - Countersunk ends for tachometer application or, where the end of the shaft is not accessible, make provision for use of stroboscope or optical tachometer. - Material: Mild steel or high tensile steel, as appropriate for the duty. Provide corrosion protection.

(j)

Drive guards

Characteristics: Provide the following: - Rigid, removable and totally enclosing the drive and exposed shafts. - Weatherproof, ventilated and drained where exposed to weather. - Material: Open mesh or perforated zinc-coated sheet steel.

(k) Finishes External surfaces: Equipment paint system, with primer. Internal surfaces: Prime with zinc phosphate primer. (l)

High temperature exhaust fans

Provide heat slingers and guards on shafts between the in board bearings and fan casings. Locate in board bearings clear of fire-rated insulation applied to fan casings.

Page 29 of 110

SAIGON M&C TOWER CENTRIFUGAL SHEETMETAL (a) Casing construction

MVAC SPECIFICATIONS

General: Zinc-coated steel sheet, riveted or spot welded with joints sealed. - Scroll: 1.2 mm minimum thickness. - Side plates: 2 mm minimum thickness. Bases: Formed from pressed zinc-coated steel sheets, bolted to casings. Provide at least 4 brackets for mounting. (b) Impellers - Type: Backward or Forward inclined curved section, laminar or aerofoil type. - Construction: Aluminium or zinc-coated steel blades secured between reinforced galvanized steel plates. Bearings: Self-aligning sealed for life ball or roller type. Finish: Brush and prime spot welds with zinc-rich organic primer. (c)

Motors

General: Provide electric motors compatible with requirements to give efficient fan units. Power rating: At least the power required by the fan when the air flow is increased by 10% above the specified design air flow against the corresponding increased system resistance. Maximum degree of protection: IP51. Drive: Belt drive with adjustable drive pulleys.

CENTRIFUGAL - IN-LINE (a) General Provide fans with non-overloading power characteristics. (b) Construction Casings: Rectangular or circular with spigot or flanges for duct mounting, with construction as follows: - Steel: Zinc-coated steel sheet, spot welded. Paint spot welds. Provide access panels for fan and motor removal.

Page 30 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

- Fibreglass or plastic: Moulded fibreglass or impact resistant plastic with integral support foot. Impellers: Backward or forward curved blades, constructed from zinccoated steel, aluminium or polypropylene. Balance impellers, statically and dynamically. Motors: Direct mounted to impellers with minimum class F insulation. Provide sealed for life bearings with a minimum rating fatigue life of 8750 hours. Electrical connection: Provide terminal boxes external to fan casings and wired to fan motors. AXIAL FLOW (a) General Provide fans with non-overloading power characteristics. (b) Casings Tubular, flanged at each end, constructed from mild steel, fully welded, hot dip galvanized after fabrication. Provide access panels, securely bolted to casings and sealed with neoprene gaskets, for maintenance. (c)

Impellers

General: Provide aerofoil section blades constructed from cast aluminium alloy with adjustable pitch. Select from the following: - Fans < 300 mm: Fixed pitch polypropylene impellers. - Fans < 350 mm: Fixed pitch pressed zinc-coated steel impellers. - Fans < 1000 mm: Glass-fibre reinforced polyester or Aluminium cast impellers. Balancing: Balance impellers, statically and dynamically, as appropriate.

(d) Unducted

inlets/outlets

Inlet cones: Provide aerodynamically shaped cones to inlets of fans. Guards: Provide galvanized steel or bronze mesh guards. (e)

Motors

General: Direct mount to impellers.

Page 31 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Bearings: Provide sealed for life bearings or grease packed bearings fitted with lubrication lines extending through the casing. Provide bearings with a minimum rating fatigue life of 17,500 hours, suitable for horizontal or vertical mounting as appropriate. (f)

Electrical connection

Provide terminal boxes external to fan casings and wired to fan motors.

ROOF MOUNTED (a) Types Centrifugal, mixed flow, aerofoil axial or propeller. (b) Housing General: House fans in compact bases fitted with weathering skirts. Material: UV stabilised ABS, polypropylene, polyethylene, glass-fibre reinforced polyester or zinc-coated steel. (c)

Vertical discharge

General: Provide weatherproof galvanized steel, plastic or aluminium backdraft dampers where the weather may enter when units are stopped. Birdmesh: Where backdraft dampers are not fitted, provide birdmesh guards.

(d) Motors Bearings: Provide bearings sealed for life or grease packed fitted with lubrication lines extending through roof cowls. Provide bearings with a minimum rating fatigue life of 8750 hours. Provide access to grease relief ports. Minimum degree of protection: IP55. Drive: Belt or direct as appropriate. Belt drive: Comply with Centrifugal - general purpose. (e)

Electrical connection

Provide terminal boxes external to fan casings and wired to fan motors.

Page 32 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

WINDOW/WALL

(a) Standard To AS 2681.or British Standard equivalent. (b) Impeller Propeller type. (c)

Housing

Characteristics: - Isolating mountings. - Discharge cowls with birdmesh guards. - Backdraft shutters constructed from lightweight nylon or aluminium blades, arranged to gravity close when fans are not operating.

MARKING

(d) Labels Show the following: - Manufacturers name. - Model.. - Serial number. - Size. - Direction of rotation, marked on casing. INSTALLATION

Installation

(a) Access Arrange fans and accessories to allow service access for maintenance and removal and for replacement of assemblies and component parts, without disturbance of other items of plant. (b) Duct

connections

Page 33 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Provide flexible connections to prevent transmission of vibration to ductwork. If under negative pressure, ensure that fan inlet areas are not reduced. If necessary, provide expansion pieces between fans and flexible connections. Provide vibration isolators for all fans between the fans and fan supports. Rubber isolators are permissible if the contractor can demonstrates that no noticeable vibration or noise will be transmitted, othwerwise vibration isolators with at least 25mm static deflection will be required.

END OF SECTION

Page 34 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

SECTION B05

AIR COILS GENERAL

Functional Description The air coils scope of work covers the cooling coils which are a subcomponent of the air conditioning equipment. Standard (a) Rating To ARI 410. Design (a) Maximum face velocity Cooling coils: 2.5 m/s. Heating coils: 3.5 m/s. (b) Maximum 480 fins/m. (c)

fin pitch

Maximum water pressure drop

35 kPa.

(d) Maximum 120 Pa.

air pressure drop

QUALITY

1 Pre-Completion Tests (a) Production tests

Page 35 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Pneumatic leak test: Pneumatically test coils for leakage by submerging in warm water and applying the test pressure, or by static water pressure for at least 1 hour. - Minimum test pressure: 2 MPa. Refrigerant coils: After testing, dehydrate, charge with dry nitrogen to 7 kPa (minimum), and seal.

COILS

FABRICATION (a) Arrangement Arrange pipes with uniform spacing in a staggered pattern. (b) Fins General: Provide plate fins to pipes. Spacing: Space equally, perpendicular to the pipes. Fin collars: Provide adequate control of fin spacing and provide a permanent mechanical bond between the pipes and the plate fins, by expanding pipes into fin collars, so that fin collars completely cover the pipes. Material: - Condenser coils and non-sprayed cooling coils: Aluminium alloy. Minimum thickness - Aluminium alloy: 0.12 mm. - Copper: 0.15 mm. (c)

Frames

General: Form rigid frames, from channel-type pipe sheets and top and bottom channels and intermediate pipe sheets as necessary. Minimum flange height (to provide for duct connections): 25 mm. Drain holes: Provide drain holes in cooling coil frames where water may collect. Material: - For aluminium fins: Aluminium alloy - For copper fins: Heavy gauge brass, designation 260.

Page 36 of 110

SAIGON M&C TOWER (d) Air

MVAC SPECIFICATIONS

leakage

General: Minimise air leakage through gaps between the fin ends and frames. Deemed-to-satisfy: Recess fin ends into the top and bottom channels, close gaps with sealing strips, or gaps to a maximum clearance of 1.5 mm. (e)

Coil protection

Coils with aluminium fins: Provide a proprietary corrosion protection coating for coils. Coils with copper fins: Electro-tin the coil assemblies after manufacture.

Water Coils

(a) Chilled coils Pipe material: Copper Header material: Copper (b) Headers Fluid flow: Construct headers to ensure even cooling and heating fluid flow to pipe circuits. Header/pipe joints: Braze. - Pipe holes: Provide intruded or extruded pipe holes in headers. Vents: Provide vent plugs to top of headers. Drains: Provide drain plugs to bottom of headers, arranged to fully drain coils. Piping connections: Provide inlet connections at the bottom of supply headers at the air-off face of coils and outlet connections at the top of return headers at the air-on face of coils.

Refrigerant Coils

(a) Direct expansion coils Piping connections: Provide pressure type liquid distributors and suction headers, with brazed joints. Pipe arrangement: For multiple circuits, provide interleaving. Pipe material: Copper to AS/NZS 1571 or AS 1572 designation C12200. Header material: Copper to AS 1432 or AS/NZS 1571.

Page 37 of 110

SAIGON M&C TOWER (b) Condensing

MVAC SPECIFICATIONS

coils

Piping connections: Factory fit copper pipe connection stubs to refrigerant hot gas inlet and liquid outlet headers using brazing or braze welding. Pressurise with dry nitrogen, then seal. Pipe arrangement: So that liquid refrigerant can gravitate to the outlet header without being trapped in the coil. Pipe material: Copper to AS/NZS 1571 or AS 1572 designation C12200. Header material: Copper to AS 1432 or AS/NZS 1571.

Marking

(a) Labels Provide labels showing the following: - Manufacturers name. - Model. - Serial number.

INSTALLATION

1 Protection (a) General General: Prevent ingress of foreign matter and moisture during transport and storage. Deemed-to-satisfy: Temporary sealing of end connections as follows: - Water coils: Plastic end caps. Coils (a) Configuration Install coils so that fluid and air flow directions are counter flow. (b) Supports General: Support coils by means of either - the internal support frame of conditioners; - blank-off panels around the coils; or - prefabricated, predrilled, hot dipped galvanized steel frames. Coil banks: Provide coil banks if coil sizes exceed maximum limits.

Page 38 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Dissimilar metals: Provide neoprene gaskets to separate the mating surfaces of dissimilar metals. (c)

Air leakage

Baffle plates: Close the space between the coil frame and the surrounding structure or equipment, with baffle plates. Sealing: Seal gaps between coils and surrounding structure or equipment with non-hardening mastic.

(d) Access

and removal

Keep adjacent equipment and ductwork clear of coils and provide flanges to adjacent equipment and ductwork. For duct-mounted coils, provide an access panel in the duct on the air inlet side. (e)

Fin damage

Comb straight damaged fins.

Piping

Access and removal: Install piping to coils to allow access to equipment, and to minimise disturbance to piping when coils are removed. Support: Prevent stress on coils by supporting piping to coils independently. Drain system: Extend a DN 40 drain pipe from the lowest drip tray or drip pan to a drain point outside the conditioner. Incorporate the following: - Air break. - Sealing: Seal drain pipes to the casing with rubber grommets. - Water seal: Provide a trapped water seal against double the static pressure of the air handling unit. Note, trap required also when the discharge is into a floor gulley with a trap following. END OF SECTION

SECTION B06

AIR CONDITIONING EQUIPMENT

Page 39 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

GENERAL

Functional Description The air conditioning equipment scope of works covers the primary air handling unit (PAU) and fan coil units (FCUs). These are to be TRANE or YORK.

QUALITY

1 Tests (a) Production Tests Required for all coils (ARI) & fans (BS or EN). 2 Submssions (a)

General

Submit product & selection data for the following; - Primary Air Handling Unit - Fan Coil Units (Type CRB-York or HFCA-Trane) Include - Product data - Dimensional drawings - Coil selection data - Fan selection data - Acoustic performance from fan (induct). - Acoustic performance of unit (breakout)

AIRCONDITIONING EQUIPMENT

1 General (a) Operating conditions Provide equipment which operates within an ambient temperature range of 00 to 450 C, without excessive head pressure, or unstable operation. (b) Equipment

enclosures

Page 40 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Construction: Assembled and reinforced to prevent flexing and drumming. Provide for removal of major components. Access: Provide access for inspection and maintenance. - Access panels: Readily removable with positive re-useable fasteners and soft gaskets which provide an airtight seal. Insulation: Insulate enclosures to prevent external surface condensation under operational conditions. (c)

Condensate trays

General: Provide a primary tray under each cooling coil section, extending downstream to collect water carry over, and under components on which condensation can occur. Material: Corrosion-resistant. Insulation: Insulate trays to prevent condensation internally and on external surfaces of the unit enclosure, under operational conditions. Condensate drains: Connect condensate trays to nearest drain points by means of trapped minimum DN 25 drain lines for FCUs and minimum DN 40 drain lines for PAU. Allow for suitably sized condensate drains whether shown on the drawings or not.

Primary Air Handling Units (a) General General: Provide units consisting of coils, piping, supply air fan, filters, accessories and electrical connections, mounted within an insulated enclosure. Configuration: draw through coil, single zone. (b) Enclosures Outdoor location: Provide enclosures, materials and finishes which are corrosion-resistant, and weatherproof if necessary. General: sectional or modular construction. Outer material: Galvanised sheet steel, powder coated. Inner material: Galvanised sheet steel, powder coated. Insulation: Polyurethane 50mm thickness, or the supplier to guarantee no condensation problems at the design wet bulb plus 1 deg C. Frame: Extruded aluminium frame, insulated and designed to avoid cold bridging, with composite plastic corner pieces. The supplier is to guarantee no condensation problems at the design wet bulb plus 1 deg C.

Page 41 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Access: Removable panels to provide access to all components. Access panels shall be secured with sash catches or hexagonal socket bolts. Access to commonly accessed items such as filters shall be via metallic door handles Duct connections: Provide spigots or flanged connections. (c)

Fans

Construction: as per worksection Fans. Delivery: Scheduled capacity plus 5% at scheduled static pressure. Type: Double width, double inlet, multi-blade, forward curved centrifugal aerofoil blade type. Motors: Fan motors shall be selected at 120% of the fan mechanical power. Belt drive: Fans shall be driven by a minimum of 2 belts. A belt guard shall be fitted. Motor slide rails to allow belt adjustment. Isolation: Fan and motors to be mounted on spring isolators of at least 40mm static deflection. Fan discharge to be connected to the enclosure discharge via a flexible connector.

(d) Cooling

coils

Construction: as per worksection Air Coils. Performance: Scheduled capacity. Maximum 480 fins/m. Minimum 4 rows 2.5 m/s maximum face velocity. (e)

Filter Section Box

To be provided by the AHU manufacturer. For filter details refer to the worksection Filters.

(f)

Mixing Section Box

Where mixing boxes are required, to be by the AHU manufacturer. Note dampers to be opposed blade type as per ductwork specification.

(g)

Sound power levels

Sound power levels shall not exceed the scheduled values

Fan Coils

Page 42 of 110

SAIGON M&C TOWER (a) General

MVAC SPECIFICATIONS

General: Provide units consisting of coils, piping, supply air fan, filters, accessories and electrical connections, mounted within an insulated enclosure. Configuration: draw through coil, single zone. (b) Enclosures General: sectional or modular construction. Outer material: Galvanised sheet steel, powder coated. Inner material: Galvanised sheet steel, powder coated. Insulation: Polyurethane 25mm thickness, or the supplier to guarantee no condensation problems at wet bulb 25 deg C. Frame: Insulated and designed to avoid cold bridging The supplier to guarantee no condensation problems at the design wet bulb plus 1 deg C. Access: Removable panels to provide access to all components. Access to commonly accessed items such as filters shall be via metallic door handles. Duct connections: Provide spigots or flanged connections. (c)

Fans

Construction: as per worksection Fans. Delivery: Scheduled capacity plus 5% at scheduled static pressure. Type: Double width, double inlet, multi-blade, forward curved centrifugal type. Motors: Fan motors shall be selected at 120% of the fan mechanical power. Belt drive: Fans shall be direct driven. Isolation: Fan and motors to be mounted on rubber isolators of at least 5mm static deflection. Enclosure discharge to be connected to ductwork via a flexible connector. (d) Cooling

coils

Construction: as per worksection Air Coils. Performance: Scheduled capacity. Maximum 480 fins/m. Minimum 3 rows 2.5 m/s maximum face velocity. (e) Filter Section Box

Page 43 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

To be provided on all FCUs by the FCU manufacturer. For filter details refer to the worksection Filters. (f)

Exposed fan coil units

Exposed fan coil units (under ceiling and floor standing) shall be complete with supply grille and furred in powder coated panels. END OF SECTION

Page 44 of 110

SAIGON M&C TOWER SECTION B07

MVAC SPECIFICATIONS

AIR FILTERS

GENERAL

Functional Description The air filters scope of work covers the air filters for all air handling units and fan coil units. Standard (a) Air filters Performance and construction: To EN 779, EN 1822, AS 1324.

QUALITY

1 Pre-Completion Tests (a) Production tests Standard: To EN 779. Filter size: 610 x 610 mm face dimension.

MATERIALS AND COMPONENTS

1 Materials (a)

General

Sealant performance: Resistant to air, entrained water and oil. Adhesive performance: - Characteristics under environmental conditions: Odourless and non toxic. Non-migrating, non-evaporating and non-hardening. - Environmental conditions: Normal temperature, sustained temperatures up to 600 C, and operating air velocities.

Components (a) Component sizes

Page 45 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

General: Standardised throughout the installation as far as practicable. (b) Filters Filters of the same type: From the same manufacturer. (c)

Filter performance

Minimum performance: To EN779

(d) Cell

frames

Material: Stainless steel or galvanized steel with powder coat finish. Design: Capable of withstanding distortion arising from the final pressure drop across the filter. Air by-pass: Frames must stop air by-passing the filter media. (e)

Holding frames

General: True and square. Provide gaskets and clamping systems which maintain a proper seal between the frame and the filter. Corrosion minimisation: Stainless steel or galvanized steel with powder coat finish.

Panel Filters

(a)

Filter media

Vermin resistant synthetic fibre. Washable and exchangeable media in frame with supporting mesh. Manufacturer: EMW, or equivalent with good washability. Average arrestance: mimimum 75% Rating: G2/ G3 as applicable.

Extended Surface Filters (a) Filter media Vermin resistant synthetic fibre. Washable and exchangeable media in frame with supporting mesh. Manufacturer: EMW or equivalent.

Page 46 of 110

SAIGON M&C TOWER Average arrestance: mimimum 80-85% Rating: EU5 (b) Pressure

MVAC SPECIFICATIONS

drop manometers

Provide pressure drop manometers suitable for measuring filter life. 5 Marking (a) Filter General: Permanently and legibly mark, on a suitable section of the filter, the following: - Filter type and class. - Direction of airflow. - Proprietary type, model and serial number. - Statement of compliance with AS 1324.1 (b) Replaceable

element

General: On the clean air side, fix the name of the supplier, proprietary type, type of media and filter performance rating. (c)

Plant room

General: Provide a permanent notice fixed to the wall identifying each filter and giving their design filter performance rating.

INSTALLATION

1 Installation Generally (a) Attachment General: Rigidly attach filter frames to the air handling plant casing (such as duct, or return air plenum) with a system of bolting or blind pop riveting. Locate bolts or rivets clear of the filter element. Do not fix to the casing insulation. Ensure that the installation of the filter does not reduce its rated performance. Access: Ensure that individual filter inspection and maintenance can be readily carried out without disturbing the filter bank.

Page 47 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Sealing: Ensure that there are no leaks between the filter holding frame and the casing. Seal individual filter units to each other. Seal filter connections to adjoining equipment, paneling or supporting framing. Do not use adhesive tapes for sealing. Plinth: Where possible, provide a 50 mm high plinth below the filter bank. (b) Cell

frames

Install filters so that they are accessible for maintenance and do not accumulate moisture. (c)

Blanking plates

General: Close gaps where the dimensions of the filter plenum do not match those of the framing. Seal air tight to ensure no air bypasses the filters. Plates material: 0.8mm (minimum) galvanized steel or grade 304 stainless steel sheet.

(d) Additional

bracing

General: Provide stiffeners between or behind the joint of every second column along the narrowest dimension of the plenum. Stiffeners: Fabricate from 1.6 mm (minimum) gauge galvanized steel or grade 304 stainless steel. Maximum deflection of filter bank under operating conditions (ratio of deflection: height or width): 1:500 under maximum system final resistance. (e)

Manometers

Function: Indicate differential pressure across each filter bank (EU5 and higher). Differential pressure gauge unit: Include pipework, termination and fittings necessary for correct operation and maintenance. Indicator scale: Mark in 10 Pa divisions with full scale deflection no more than twice the maximum dirty filter condition. Location: Outside unit casing in a readily readable location. Marking: Mark clean and maximum dirty pressure drops on manometer scale.

(f)

Temporary pre-filters

Provide sheets of filter media to protect filter banks at installation. Page 48 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

(g)

Filter banks

General: Provide holding frames.

(h) Filter

access platforms

General: Ensure that platforms and ladders do not obstruct filter access.

COMPLETION

1 Maintenance (a) Cleaning General: Before start-up, ensure that the installation is free from debris and dirt, and inspect filter banks and plenums to ensure integrity of the installation. (b) Temporary

pre-filters

Remove at completion of commissioning. (c)

Operation and maintenance manual

General: Submit an operation and maintenance manual describing procedures for operation, maintenance, repair and replacement of filters. END OF SECTION

SECTION B08

DUCTWORK GENERAL

Functional Description The ductwork scope of works covers all ductwork necessary to meet the air conditioning and mechanical ventilation requirements of the project.

Page 49 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Ductwork has been sized on velocities to ensure a reasonable acoustic level in the spaces as well as a reasonable pressure drop. Generally, metal ducting shall be manufactured by equal to ASLI or TROX. STANDARD (a) General Ductwork: DW 142, 143.

QUALITY

1 Samples (a) Air grilles Submit a sample of each type of air grille (equal to ASLI or TROX). (b) Flexible

duct

Submit sample 2 metre length of 300 mm diameter flexible duct with sheet metal spigot attached. (c)

Access doors, volume dampers, fire dampers etc

Submit samples of all access doors, volume dampers, fire dampers etc. (equal to ASLI or TROX). 2 Submissions (a) Shop drawings Submit shop drawings showing ductwork and grilles, co-ordinated with other services, and showing duct flanges, segment lengths and tag numbers, hangers and hanger locations. Prepare details of elevations and zoning in celing voids. Prepare detailed drawings of plantooms based upon actual air handling unit equipment to be provided, showing full details of duct segments, elevations, segments, clearances etc. Demonstrate that air handling units can be maintained in the future including

Page 50 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

removal of coils if necessary, and allowance for blockwork knockouts in walls to facilitate removal if necessary. (b) Product

data

Submit product data as follows: - Air diffusion equipment: Acoustic performance. - Duct attenuators: Broad band insertion loss and generated noise level. - Acoustic louvres: Sound transmission loss. (c) Fire and smoke dampers Manufacture: equal to ASLI or TROX. (d) Access

panels

Manufacture: equal to ASLI or TROX. (e)

Sheet metal plenums

If providing proprietary ribbed interlocking panel systems, submit details of construction.

(f)

System resistances

Contractor submit caluculations on system resistance, including a contingency factor. Calculations to be based on dirty filter conditions. Submit fan curves showing system curve and fan discharge performance under dirty and clean filter conditions.

DUCTWORK

1 Sheet Metal (a) Material Zinc-coated steel sheet, coating class G2. (b) Fasteners

Page 51 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Rivets: Expanding solid end type, aluminium base alloy, minimum size as follows: - For sheet metal to sheet metal: 3 mm. - For sheet metal to supports, brackets and rolled steel angles: 4.8 mm. Self tapping screws: Bright zinc-plated. Self drilling and tapping screws: Bright zinc-plated. Provide only if base material into which they screw is thicker than 1.5 mm, and they are unlikely to be removed or replaced. Bolts, nuts, washers and drop rods: Zinc-plated steel, service condition number 2. Provide washers under nuts and bolt heads. 2 Flexible Duct (a) Material Uninsulated flexible duct: Alumidised fabric clamped on formed metal helix. Do not use adhesives. Insulated flexible duct: As for uninsulated flexible duct with 25 or 40 mm thick glasswool blanket insulation wrapped around duct and covered with an outer vapour barrier. (b) Installation Install flexible duct as straight as possible with minimum number of bends. Maximise bend radius. Joints: Join lengths of flexible duct only for the purpose of providing an air tight or acoustic sleeve at a partition. Maximum length of flexible duct sections: 6 metres including any rigid duct or sleeves used to join lengths of flexible duct. Flexible ducts used for air containing free moisture: Locate supporting helix outside airstream. 3 Flexible Connections (a) General General: Isolate fans and conditioner casings from ductwork, by means of airtight flexible connections. Materials: Heavy duty, waterproof. Length: Provide sufficient slack to ensure free movement and vibration isolation under operating and static conditions. Alignment: Align openings of connected equipment.

Page 52 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Fixing: Fix to attachments with zinc-coated steel strip. Seal joints. Do not paint flexible material. Maintenance: Arrange to permit easy removal and replacement without disturbing ductwork or plant. Restriction: Do not protrude connections or frames into the airstream where this would be detrimental to the air flow. 4 Installation (a) Arrangement Arrange ductwork neatly. Provide access to ductwork components which require inspection, entry, maintenance and repairs. Where possible arrange duct runs adjacent and parallel to each other and to building elements. (b) Spacing Provide minimum clear spacing, additional to duct insulation, as follows: - 25 mm between adjacent ducts. - 25 mm between duct flanges or upper surfaces of ducts, and undersides of beams and slabs. - 50 mm between ducts and electric cables. - 150 mm between ducts and ground, below suspended floors. (c)

Cleaning

During installation progressively remove construction debris and foreign material from inside ducts.

DAMPERS

1 General (a) Location Provide balancing dampers at each branch duct or tee: - Splitter type: Use only for supply branches up to 600 mm wide and with velocity in main < 10 m/s. Do not use on return or exhaust ducts. - Opposed blade dampers: Use for larger size supply and for all return and exhaust ducts. Locate in each branch.

Page 53 of 110

SAIGON M&C TOWER (b) Dampers

MVAC SPECIFICATIONS

duct

on diffusers and grilles attached to flexible

In tiled ceilings: Provide a balancing damper at the spigot take-off from the rigid duct. Where spigot at rigid duct is not accessible through ceiling: Provide damper behind the grille or diffuser. 2 Volume Control (a) General General: Provide dampers which are free of rattles, fluttering or slack movement, and capable of adjustment over the necessary range without excessive self-generated noise or the need for special tools. Face dimensions: Duct size. Connections: Mating angle flanged cross joints. Frames: 1.6 mm minimum thickness zinc-coated steel or 2 mm minimum thickness aluminium folded to form channel sections at least 150 mm wide and welded at corners. Manufacture: equal to ASLI or TROX. (b) Blades Material: Zinc-coated steel, aluminium or stainless steel. Form: No sharp edges. Sufficiently rigid to eliminate movement when locked. Minimum thickness: - Steel: . Single thickness blades: 1.6 mm. . Double thickness blades: 1.2 mm. - Aluminium: . Single thickness blades: 2.4 mm. . Double thickness blades: 1.8 mm. Maximum length: 1200 mm. If necessary provide intermediate mullions. Single blade dampers: - For single thickness blades: 600 mm maximum length, 600 mm maximum width or 600 mm maximum diameter. - For single thickness blades with 6 mm minimum edge breaks: 1.2 m maximum length x 175 mm minimum width. - For double thickness blades: 1.2 m maximum length x 300 mm minimum width. Multi-blade dampers:

Page 54 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

- For single thickness blades with 6 mm minimum edge breaks: 1.2 m maximum length 175 mm minimum width. (c)

Bearings

Type: Oil impregnated sintered bronze bearings, sealed-for-life ball bearings or engineering plastic sleeve bearings. If the operating temperature is > 50 o C, do not provide nylon. Lubrication: Provide access for lubrication. Housings: Rivet to damper frames.

(d) Spindles Material: Zinc-plated steel. Construction: Securely fix to damper blades. Minimum diameter: - Blade lengths 600 mm: 10 mm. - Blade lengths > 600, =1200 mm: 12 mm. (e)

Linkages

Fix securely to blades so that the blades rotate equally and close tightly without slip.

(f)

Damper adjustment

Provide for adjusting the damper and locking it in position. Locate in an accessible position. Label the open and closed positions clearly and permanently.

Splitter Dampers (a) Construction Splitter length: 1.25 times width of branch. Push rods: 5 mm diameter with screw locking bushes to fix position. Number of push rods: - Splitter height < 600 mm: One push rod. - Splitter height 600 mm: Push rods at 600 maximum spacing.

Non-Return (a) Construction Page 55 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Comply with Volume control dampers, counterweight the assembly so that it - offers minimum resistance to air flow; and - closes by gravity. 5 Fire And Smoke (a) General Provide free cross section area at least 85% of the face area. Enlarge duct both sides of damper if necessary to achieve this. Manufacture: equal to ASLI or TROX. (b) Links Fire dampers: Frangible bulb or fusible links. Smoke dampers: Spring return close motorised dampers (note must close within 60 seconds). Fire & smoke combination dampers: Frangible bulb or fusible link, or spring return close motorised dampers (note must close within 60 seconds). Installation: Mount for easy replacement. (c)

Access panels

Provide for maintenance of dampers and replacement of links Control Provide test control from the respective mechanical electrical distribution boards.

ACCESS OPENINGS

1 Location (a) Access doors Provide an access door in each section of air handling units where access is required for maintenance, inspection or removal of components. Removable panels may be used instead of doors where access is required only for removal of coils.

Page 56 of 110

SAIGON M&C TOWER (b) Access

MVAC SPECIFICATIONS

panels

Provide access panels in the following locations: - Adjacent to each component located inside the duct requiring regular inspection and maintenance including, but not limited to: . Fire and smoke dampers. . Smoke detectors. . Motorised dampers. . Filters. . In air handling units where unit size is insufficient to fit an access door. - In other locations specified and/or shown on the drawings. 2 Access Panels (a) Sizes Access panels: Minimum clear opening: - Personnel access: 450 x 600 mm. - Hand access: 200 x 300 mm. (b) Construction Type: Double panel, deep formed, zinc-coated steel construction, insulated to match the duct, or filled with at least 25 mm mineral wool insulation. Cold bridging: Minimise. Frames: Provide rigid matching galvanized steel frames securely attached to the duct. Do not protrude any part of the panel or frame into the airstream. Seals: Silicone rubber or soft neoprene gaskets mechanically fixed to either the panel or the frame to ensure an airtight seal against the operating pressure when latched in the closed position. For fire rated seals, provide woven ceramic fibre material. Latches: Wedge type sash latches. Number of latches: - For personnel access: 4. - For hand access: 2. Handles: Provide a "D" handle on access panels for personnel access. 3 Access Doors (a) Construction General: Provide access doors reinforced to minimise distortion, and hinged so that internal air pressure holds doors closed. Page 57 of 110

SAIGON M&C TOWER

MVAC SPECIFICATIONS

Minimum clear opening: 1.35 m high x 600 mm or larger to permit safe removal of equipment inside the section. Door swing: Against air pressure. Cold bridging: Minimise. Frames: Rigid matching galvanized steel frames securely mounted. Door hardware: Provide proprietary clamping-type latches and handles which can be operated from both the inside and the outside of the door. Seals: Silicone rubber or soft neoprene gaskets mechanically fixed to the door to ensure an airtight seal when latched closed. For fire rated seals, provide woven ceramic fibre material. Insulation: To match surrounding ductwork/plenum.

AIR GRILLES 1 General

(a) Manufacture General: Provide proprietary grilles - free from distortion, bends, surface defects, irregular joints, exposed fastenings and operation vibration; - mounted with secure and concealed fixings; and - with flanges lining corners neatly mitred and buffed, with no joint gaps. Material: Steel or aluminium. Finish: Powdercoated. Made: equal to ASLI or TROX. (b) Volume

control dampers

Provide dampers adjustable through the grille faces. Paint dampers matt black if visible through grilles. 2 Types (a) Luminaire air diffusers Type: Single sided or double sided (equal to ASLI or TROX). Air flow deflection: Provide an adjusting device which can be operated through the slot in the luminaire to allow 90 0 deflection of air pattern. Air volume control: By a damper located at the flexible duct connection to the main ductwork.

Page 58 of 110

SAIGON M&C TOWER (b) Slot

MVAC SPECIFICATIONS

diffusers

Finished appearance: Continuous and unbroken irrespective of the purpose of the slot. Blank off slots not used for supply or return air. For long lengths, provide aligning devices where necessary. Material: Extruded aluminium. Air flow deflection: Provide an adjusting device which can be operated through the slot to allow 180 0 deflection of air pattern. Air volume control: By a damper located at the flexible duct connection to the main ductwork. (c)

Louvre ceiling diffusers

Type: Multi-bladed, removable core 4-way blow configuration, fitted with a blanking plate for 1-, 2-, or 3-way blow, as appropriate. Reducer necks: If the outlet neck is smaller than the outlet necessary to suit the louvre face size, provide a reducer neck. Dampers: For equalising air flow, provide an opposed blade damper to each diffuser.

(d) Circular

diffusers

Circular adjustable multi-core diffuser allowing variation of discharge pattern from horizontal to vertical by rotation of the centre core. (e)

Curved blade diffusers

Blades: Individually adjustable.

(f)

Perforated plate diffusers

Construction: Perforated plate with minimum free area of 50%. Fold plate edges so that perimeter gaps do not exceed 0.5 mm.

(g)

Side wall registers