Beruflich Dokumente

Kultur Dokumente

Heat Transfer

Hochgeladen von

acotazchotOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Transfer

Hochgeladen von

acotazchotCopyright:

Verfügbare Formate

Effect of viscous dissipation on mixed convection heat transfer

in a vertical tube with uniform wall heat flux

A. Barletta, E. Rossi di Schio

Abstract The laminar and parallel owof a Newtonian uid

in a vertical cylindrical duct with circular cross section has

been analysed. Both the viscous dissipation effect and the

buoyancy effect have been taken into account. The mo-

mentum balance equation and the energy balance equation

have been solved by means of a perturbation method, in

the case of a uniform heat ux prescribed at the wall of the

duct. The velocity distribution, the temperature distribu-

tion, the Nusselt number and the Fanning friction factor

have been evaluated analytically. Moreover, the velocity and

temperature of the uid have been compared with those

obtained in two special cases: forced convection with vis-

cous dissipation (i.e. negligible buoyancy effect); mixed

convection with negligible effects of viscous dissipation.

List of symbols

A [Gr

+

=(4Re)[

1=4

, dimensionless parameter

Br lU

2

0

=(2R

0

q

0

), Brinkman number

c

p

specic heat at constant pressure, J/kgK

f Fanning friction factor, dened by Eq. (22)

Gr 8R

3

0

gbDT=m

2

, Grashof number

h q

0

=(T

w

T

0

), convection coefcient, W/m

2

K

I

a

modied Bessel function of rst kind and order a

J

a

Bessel function of rst kind and order a

k thermal conductivity, W/mK

n non negative integer

Nu 2 R

0

q

0

=[k(T

w

T

b

)[, Nusselt number

Nu

m

2R

0

q

0

=[k(T

w

T

0

)[, modied Nusselt number

p pressure, Pa

P p q

0

gX, difference between pressure and hydro-

static pressure, Pa

q

0

prescribed wall heat ux, W/m

2

r R=R

0

, dimensionless radius

r

/

; r

//

dummy integration variables

r

c

Gr/Re[

max

, radius of convergence of the perturba-

tion series

r

+

c

Gr

+

=Re[

max

, modied radius of convergence of the

perturbation series

R radial coordinate, m

R

0

radius of the pipe, m

Re 2R

0

U

0

=m, Reynolds number

T temperature, K

T

0

mean temperature dened by Eq. (2), K

U velocity component in the axial direction, m/s

U

0

mean value of U, m/s

u U=U

0

, dimensionless axial velocity

u

n

(r) dimensionless functions dened by Eq. (33)

X axial coordinate, m

Greek symbols

a integer

b thermal expansion coefcient, K

1

DT lU

2

0

=k reference temperature difference, K

g dimensionless parameter dened by Eq. (12)

g

n

dimensionless coefcients dened by Eq. (33)

0 (T T

0

)=DT, dimensionless temperature

0

b

dimensionless bulk temperature, dened by

Eq. (19)

0

n

(r) dimensionless functions dened by Eq. (33)

k (R

2

0

=lU

0

)dP=dX. dimensionless pressure-drop

parameter

k

n

dimensionless coefcients dened by Eq. (33)

l dynamic viscosity, Pa s

m l=q

0

, kinematic viscosity, m

2

/s

N Gr/Re, dimensionless parameter

q mass density, kg/m

3

q

0

reference mass density, evaluated at T = T

0

, kg/m

3

s

w

wall shear stress, Pa

Superscripts and subscripts

+ alternative dimensionless quantities

w quantity evaluated at the wall

1

Introduction

In the literature on convection heat transfer in ducts,

combined forced and free ows have been investigated by

many authors for different geometries and boundary

conditions, with reference to vertical or inclined ducts.

The interest deserved to the argument is due to its im-

portance in many technological applications, such as the

design of heat exchangers, of nuclear reactors or of the

cooling systems for electronic devices. Most of the litera-

ture on the argument has been summarised in the review

paper by Aung [1].

In recent years, many novel investigations in the eld

of combined forced and free convection in circular

ducts have been presented. An experimental study has

Heat and Mass Transfer 38 (2001) 129140 Springer-Verlag 2001

129

Received on 26 June 2000

A. Barletta (&), E. Rossi di Schio

Dipartimento di Ingegneria Energetica

Nucleare e del Controllo Ambientale (DIENCA)

Universita di Bologna

Viale Risorgimento 2. I-40136 Bologna, Italy

been performed by Lavine et al. [2]. In this paper, the

authors consider an inclined heated pipe and study a case

of opposing mixed convection. Temperature proles in

the uid have been measured and the existence of ow

reversal regions has been observed. An extension of the

analytical methods employed by Morton [3] has been

performed by Van Dyke [4], in order to investigate the

laminar and fully developed ow in circular ducts. In

Ref. [3], buoyancy induced ow in a vertical circular

duct is studied in the case of a uniformly heated or

cooled wall. The momentum and energy balance equa-

tions have been analytically solved and expressed in

terms of Bessel functions. Van Dyke [4] provides an

extension of the analysis presented by Morton, by util-

ising a perturbation method to solve the momentum

and energy balance equations for a uniformly heated

horizontal circular duct.

In the last years, most of the literature on mixed con-

vection in circular ducts deals with computational meth-

ods [510]. For instance, Choudhury and Patankar [5]

analyse the simultaneously developing laminar ow and

heat transfer in an inclined pipe, with a boundary condi-

tion given by a uniform wall temperature. The governing

equations are solved numerically by means of a modied

nite difference method. Plots of the axial evolution of the

velocity proles as well as of the Nusselt number and

friction factor are reported. Many papers consider hori-

zontal pipes, with boundary conditions either of uniform

wall temperature [6, 7] or of uniform wall heat ux [8, 9].

In Ref. [6], the tube is kept at a uniform and constant wall

temperature. The governing equations are solved numer-

ically in the entrance region, by means of a control volume

method. Shome and Jensen [7] consider a simultaneously

developing laminar ow and heat transfer, with variable

viscosity. The method utilised is a general purpose com-

mercial program, based on the nite volume method. Plots

of the Fanning friction factor and of the mean values of the

Nusselt number are reported versus the axial coordinate.

In Refs. [8, 9], Choi and Choi investigate heat transfer in a

pipe whose upper half is insulated and whose lower half is

subjected to a boundary condition of constant and uni-

form wall heat ux. The governing equations are solved by

means of a control volume method. In Ref. [8], the fully

developed region is considered, and plots of the Nusselt

number and of the Fanning friction factor have been re-

ported versus the Grashof number. In Ref. [9], the devel-

oping region is analysed, and both the axial momentum

transport and the axial heat conduction in the uid have

been taken into account. Plots of the friction factor and of

the average Nusselt number are reported versus the axial

coordinate.

When the pipe is vertical, two different ow cases arise:

buoyancy assisted ow and buoyancy opposed ow. In

Ref. [10], both cases are considered, for the entrance re-

gion of a circular pipe with a boundary condition given

either by uniform wall temperature or by uniform wall

heat ux. The effect of viscous dissipation in the uid is

neglected, and the numerical method employed is a con-

trol volume method. The authors point out how buoyancy

affects the local and average friction factors and Nusselt

numbers.

In the literature, the effect of viscous dissipation in

laminar convection is often neglected. Indeed, this hy-

pothesis is reasonable depending on the uid properties

and on the ow characteristics. In fact, it is well known

that, in the case of forced convection, both in the ther-

mal entry region and in the fully developed region the

viscous dissipation effect becomes relevant for uids

with a high viscosity coefcient and a small thermal

conductivity and for ow regimes with small values of

the wall heat ux. For instance, in Ref. [11] the laminar

and fully developed forced convection is considered. In

this paper, the role of the Brinkman number is em-

phasised in the analysis of empirical correlations between

convective heat transfer parameters in microchannels

[11]. There is no reason why the effect of viscous dis-

sipation should be a priori neglected, in cases of com-

bined forced and free convection. In fact, the importance

of the coupled effects of buoyancy and viscous dissipa-

tion is outlined in several papers [1216]. For instance,

in Ref. [12], the authors study the fully developed mixed

convection with viscous dissipation in a vertical circular

tube, whose wall temperature undergoes a linear axial

change. Three different methods are employed: a power

series method, the Galerkin's method and a numerical

integration method (RungeKutta). Rokerya and Iqbal

[13] extend the analysis performed in Ref. [12] to the

case of laminar ow in a vertical concentric annulus. The

solution is obtained by utilising the RungeKutta inte-

gration method. In Refs. [1416] a perturbation method

solution is employed. In Ref. [14], the author investigates

the fully developed mixed convection in a vertical cir-

cular duct with uniform wall temperature. In this paper,

forced convection with viscous dissipation is regarded as

the base heat transfer process, and the velocity and

temperature distributions in the uid are expressed in

terms of a perturbation series, with respect to a pa-

rameter which accounts for the effect of buoyancy. While

in this paper the bulk temperature of the uid is chosen

as the reference temperature in the Boussinesq approxi-

mation, further analyses [17] have shown that the mean

temperature in a duct section is the best choice for the

reference temperature. This improved model is employed

in Ref. [15], where the effect of viscous dissipation in

combined forced and free convection is investigated in a

vertical channel with a uniform temperature on one wall

and a uniform heat ux on the other wall. In Ref. [16],

the analysis presented in Ref. [15] is extended to the case

of uniform heat uxes on both walls of the vertical

channel.

The aim of this paper is to investigate the effects of

buoyancy and of viscous dissipation on fully developed

laminar ow in a uniformly heated vertical pipe. The

momentum and energy balance equations will be solved by

means of a perturbation method, in which the regime of

forced convection with viscous dissipation is assumed as

the base heat transfer process. Then, the effect of buoyancy

will be taken into account through the expansion in a

power series with respect to the ratio between the Grashof

number and the Reynolds number. This solution method

will allow also the evaluation of the Fanning friction factor

and of the Nusselt number.

130

2

Governing equations

In this section, the momentum balance equation and the

energy balance equation are written in a dimensionless

form. Then, the velocity eld and the temperature eld are

determined analytically in the special case of negligible

viscous dissipation.

Let us consider a Newtonian uid which steadily ows

in a vertical cylindrical tube with circular cross section and

radius R

0

. The ow is assumed to be laminar and parallel.

The latter condition implies that the only non vanishing

component of the velocity eld U is the vertical compo-

nent U, i.e. the component along the X axis. The X axis is

parallel to the gravitational acceleration g, but with op-

posite direction. A uniform wall heat ux is prescribed, so

that both U and T depend only on R and X. The continuity

equation implies that the velocity eld is solenoidal, i.e.

oU=oX = 0.

According to the Boussinesq approximation, for the

evaluation of the gravitational body force the mass

density is assumed to depend linearly on temperature,

namely

q = q

0

1 b(T T

0

) [ [ ; (1)

where the reference temperature is chosen as the mean

temperature in a tube cross section,

T

0

=

2

R

2

0

R

0

0

T(X; R)RdR : (2)

Moreover, Morton's approximation [3] is employed. Ac-

cording to this approximation, even if the reference tem-

perature T

0

depends on the X coordinate, the

thermophysical properties q

0

, b, c

p

and l involved in the

momentum and energy balance equations are treated as

constants.

The R-momentum balance equation allows one to

conclude that P depends only on X, where P = p q

0

gX is

the difference between the pressure and the hydrostatic

pressure. On the other hand, the X-momentum balance

equation is:

m

R

d

dR

R

dU

dR

1

q

0

dP

dX

gb(T T

0

) = 0 : (3)

The velocity distribution can be determined by solving Eq.

(3) together with the no-slip boundary condition and the

symmetry condition at the axis of the cylinder, namely

U(R

0

) = 0;

dU

dR

R=0

= 0 : (4)

By calculating the derivative with respect to X of both

sides of Eq. (3), one obtains

oT

oX

=

dT

0

dX

1

q

0

g b

d

2

P

dX

2

: (5)

On account of Eq. (2), if both sides of Eq. (5) are multi-

plied by R and integrated with respect to R in the interval

(0, R

0

), one can conclude that d

2

P=dX

2

= 0, so that Eq. (5)

yields

oT

oX

=

dT

0

dX

= constant : (6)

As a consequence of Eq. (6) one can conclude that the

dimensionless temperature # = (T T

0

)=DT is indepen-

dent of the axial coordinate.

The energy balance equation can be expressed as

q

0

c

p

U

dT

0

dX

=

k

R

o

oR

R

oT

oR

l

dU

dR

2

: (7)

If the wall heat ux is uniform, the thermal boundary

condition is given by

k

oT

oR

R=R

0

= q

0

: (8)

Moreover, a symmetry condition holds at the axis of the

cylinder, i.e.

oT

oR

R=0

= 0 : (9)

If both sides of Eq. (7) are multiplied by R and integrated

with respect to R in the interval (0, R

0

), one obtains

q

0

c

p

U

0

R

0

2

dT

0

dX

= q

0

l

R

0

R

0

0

dU

dR

2

RdR ; (10)

where U

0

is the mean axial velocity in a duct cross section,

namely

U

0

=

2

R

2

0

R

0

0

U(R)RdR : (11)

By introducing the dimensionless parameter

g =

2R

0

lU

2

0

q

0

l

R

0

R

0

0

dU

dR

2

RdR

; (12)

Eq. (10) can be rewritten as

dT

0

dX

= g

lU

0

q

0

c

p

R

2

0

: (13)

Moreover, by substituting Eq. (13) into Eq. (7), the energy

balance equation can be rewritten as

k

R

o

oR

R

oT

oR

=

lU

0

R

2

0

gU l

dU

dR

2

: (14)

It must be pointed out that, in the case of negligible vis-

cous dissipation, if the uniform wall heat ux q

0

is known,

also the axial gradient dT

0

=dX can be obtained through

the integral balance expressed by Eq. (10). On the con-

trary, Eq. (10) shows that, if the effect of viscous dissipa-

tion is non-negligible, the relation between the quantities

q

0

and dT

0

=dX is not trivial. In particular, if one prescribes

the value of q

0

, Eq. (7) does not allow one to obtain the

temperature gradient dT

0

=dX, unless the velocity prole

U(R) has been determined by solving the set of Eqs. (3),

(4) and (6)(9). Therefore, if q

0

is prescribed, one cannot

consider also dT

0

=dX as prescribed. For this reason, it is

131

not possible to compare the results obtained in the present

paper to those presented in Iqbal et al. [12], where a

prescribed value of dT

0

=dX is assumed.

Equations (3), (4), (6)(9) and (13) can be rewritten in

terms of dimensionless quantities as follows:

1

r

d

dr

r

du

dr

= k

Gr

4Re

#;

u(1) = 0;

du

dr

r=0

= 0 ;

(15)

1

r

d

dr

r

d#

dr

= gu

du

dr

2

;

d#

dr

r=1

=

1

2Br

;

d#

dr

r=0

= 0 :

(16)

Equations (2) and (11) imply that two additional con-

straints have to be satised, namely

1

0

u(r)r dr =

1

2

; (17)

1

0

#(r)r dr = 0 : (18)

For prescribed values of Br and Gr/Re, the solution of the

boundary value problems (15) and (16), together with the

relations (17) and (18) yields the dimensionless velocity

eld u(r), the dimensionless temperature eld #(r) and the

values of the parameters g and k.

By employing the denition of bulk temperature of the

uid, which can be written in a dimensionless form as

#

b

= 2

1

0

#(r) u(r)r dr ; (19)

one can express the Nusselt number in terms of dimen-

sionless quantities as follows:

Nu =

2R

0

T(R

0

; X) T

b

(X)

oT

oR

R=R

0

=

1

Br[#(1) #

b

[

:

(20)

Moreover, according to Refs. [3, 16, 17], one can introduce

also a modied Nusselt number, by employing, in the

denition of the reference temperature difference, the

mean temperature in a pipe cross section. This modied

Nusselt number is written, in terms of dimensionless

quantities, as

Nu

m

=

2R

0

T(R

0

; X) T

0

(X)

oT

oR

R=R

0

=

1

Br#(1)

: (21)

The Fanning friction factor is dened as follows:

f =

s

w

1

2

q

0

U

2

0

=

4

Re

du

dr

r=1

: (22)

On account of Eq. (15), an integration with respect to r in

the interval 0 _ r _ 1 yields du=dr[

r=1

= k=2, so that the

Fanning friction factor can be rewritten as

f =

2k

Re

: (23)

Equation (23) shows that the relation between the friction

factor f and the dimensionless pressure-drop parameter is

not affected by the Grashof number, i.e. the ratio f Re=k in

the case of mixed convection is the same as in the case of

forced convection.

Let us now evaluate the velocity eld and the tem-

perature distribution in the uid, with reference to the

special case of negligible viscous dissipation (Br = 0).

Since the dimensionless quantities g and Gr are ill-

dened in the case of vanishing Brinkman number, one

can introduce the following alternative dimensionless

quantities:

#

+

= Br # =

k(T T

0

)

2q

0

R

0

;

g

+

= Br g = 1 2Br

1

0

du

dr

2

r dr;

Gr

+

=

Gr

Br

=

16R

4

0

gbq

0

k m

2

:

(24)

By employing these quantities, one obtains the following

boundary value problem:

1

r

d

dr

r

du

dr

= k

Gr

+

4Re

#

+

;

u(1) = 0;

du

dr

r=0

= 0;

1

0

u(r)r dr =

1

2

;

(25)

1

r

d

dr

r

d#

+

dr

= g

+

u(r) Br

du

dr

2

;

d#

+

dr

r=1

=

1

2

;

d#

+

dr

r=0

= 0;

1

0

#

+

(r)r dr = 0 :

(26)

Moreover, in the limit Br 0, one can notice that g

+

1.

Equations (25)(26) yield

1

r

d

dr

r

d

dr

1

r

d

dr

r

du

dr

Gr

+

4Re

u(r) = 0;

u(1) = 0;

du

dr

r=0

= 0;

d

dr

1

r

d

dr

r

du

dr

r=1

=

Gr

+

8Re

;

d

dr

1

r

d

dr

r

du

dr

r=0

= 0;

1

0

u(r)r dr =

1

2

; (27)

#

+

=

4Re

Gr

+

1

r

d

dr

r

du

dr

k

; k = 2

du

dr

r=1

:

(28)

The solution of the boundary value problem described by

Eq. (27) can be expressed as

132

u(r) =

A

2

J

0

(A)I

0

(Ar) I

0

(A)J

0

(Ar)

J

0

(A)I

1

(A) I

0

(A)J

1

(A)

; (29)

where A

4

= Gr

+

=(4Re).

Moreover, by employing Eq. (29), Eq. (28) yields

#

+

(r)

=

J

0

(A) A I

0

(Ar) 2I

1

(A) [ [ I

0

(A) A J

0

(Ar) 2J

1

(A) [ [

2A

2

J

0

(A) I

1

(A) I

0

(A) J

1

(A) [ [

;

k =

A

2

I

1

(A) J

0

(A) I

0

(A) J

1

(A)

J

0

(A) I

1

(A) I

0

(A) J

1

(A)

:

(30)

Equations (29)(30) can be employed both for Gr

+

=Re > 0

(buoyancy assisted ow) and for Gr

+

=Re < 0 (buoyancy

opposed ow). In the former case A is a real parameter,

while in the latter case A is a complex parameter.

The solution expressed by Eqs. (29)(30) is singular if A

is a positive real root of the equation

J

0

(A) I

1

(A) I

0

(A) J

1

(A) = 0 : (31)

Since reference is made to positive real roots, the case of

buoyancy opposed ow is considered. One can easily

verify that the smallest root of Eq. (31) corresponds to

Gr

+

=Re = 1808:02. According to the discussion pre-

sented in Ref. [17], one can conclude that the velocity and

temperature elds can be expressed in terms of a power

series with respect to the parameter Gr

+

=Re and that the

radius of convergence of this series is 1808.02.

On account of Eq. (30), in the case Br = 0, the modied

Nusselt number can be evaluated as

Nu

m

=

1

#

+

(1)

=

2A

2

J

0

(A) I

1

(A) I

0

(A) J

1

(A) [ [

J

0

(A) A I

0

(A) 2I

1

(A) [ [ I

0

(A) A J

0

(A) 2J

1

(A) [ [

:

(32)

3

Perturbation method solution

In this section, Eqs. (15)(18) are solved by utilising a

perturbation method. The special case of forced convec-

tion with viscous dissipation is considered as the base heat

transfer process and the effect of buoyancy is taken into

account by means of perturbation expansions with respect

to Gr=Re.

For a xed value of Br, the functions u(r), #(r), k and g

are expressed as power series with respect to the param-

eter N = Gr=Re, namely

u(r) = u

0

(r) u

1

(r) N u

2

(r) N

2

=

n=0

u

n

(r) N

n

;

#(r) = #

0

(r) #

1

(r) N #

2

(r) N

2

=

n=0

#

n

(r) N

n

;

k = k

0

k

1

N k

2

N

2

=

n=0

k

n

N

n

;

g = g

0

g

1

N g

2

N

2

=

n=0

g

n

N

n

: (33)

An exhaustive description of the perturbation method is

given in Refs. [15, 16]. To determine the value of the co-

efcients of the series which appear in Eq. (33), one sub-

stitutes Eq. (33) into Eqs. (15)(18) and collects terms

having the same power of the parameter N = Gr=Re. Then,

by equating to zero the coefcients of each power of N, one

obtains a series of boundary value problems which can be

recursively solved.

The boundary value problem of order zero yields the

solution in the special case of forced convection with

viscous dissipation, neglecting the buoyancy, and is writ-

ten as

1

r

d

dr

r

du

0

dr

= k

0

;

u

0

(1) = 0;

du

0

dr

r=0

= 0;

1

0

u

0

(r)r dr =

1

2

;

(34)

1

r

d

dr

r

d#

0

dr

= g

0

u

0

du

0

dr

2

;

d#

0

dr

r=1

=

1

2Br

;

d#

0

dr

r=0

= 0;

1

0

#

0

(r)r dr = 0 :

(35)

The solution of the boundary value problem (34)(35)

yields

u

0

(r) = 2(1 r

2

); k

0

= 8 ;

#

0

(r) = 4

1

2Br

r

2

2

1

8Br

r

4

4

3

5

24Br

; g

0

= 8

1

Br

:

(36)

In particular, Eq. (36) yields the well-known Hagen

Poiseuille expression of the velocity distribution. By em-

ploying Eq. (22), one obtains the usual expression of the

Fanning friction factor for isothermal ow in circular

tubes, f = 16=Re.

On account of Eqs. (20) and (36), one obtains

Nu =

1

11

48

Br

: (37)

Equation (37) yields the usual expression for the Nusselt

number in the case of forced convection with viscous

dissipation [18].

The boundary value problem, which corresponds to an

arbitrary n > 0, is

1

r

d

dr

r

du

n

dr

= k

n

#

n1

4

;

u

n

(1) = 0;

du

n

dr

r=0

= 0;

1

0

u

n

(r)r dr = 0 ;

(38)

133

1

r

d

dr

r

d#

n

dr

=

n

j=0

g

j

u

nj

du

j

dr

du

nj

dr

;

d#

n

dr

r=1

= 0;

d#

n

dr

r=0

= 0;

1

0

#

n

(r)r dr = 0 :

(39)

If #

n1

is known, one can determine u

n

(r) and k

n

by

solving Eq. (38), namely

u

n

(r) =

k

n

4

(1 r

2

)

1

4

1

r

dr

//

r

//

r

//

0

dr

/

#

n1

(r

/

)r

/

;

k

n

= 4

1

0

dr r

1

r

dr

//

r

//

r

//

0

dr

/

#

n1

(r

/

) r

/

:

(40)

On account of Eq. (40), by solving Eq. (39) one obtains for

#

n

(r) and g

n

the following expressions:

#

n

(r) =

r

0

dr

//

r

//

r

//

0

dr

/

n

j=0

g

j

u

nj

(r

/

)

du

j

(r

/

)

dr

/

du

nj

(r

/

)

dr

/

r

/

2

1

0

dr r

r

0

dr

//

r

//

r

//

0

dr

/

n

j=0

g

j

u

nj

(r

/

)

du

j

(r

/

)

dr

/

du

nj

(r

/

)

dr

/

r

/

;

g

n

=2

1

0

dr

/

n

j=0

du

j

(r

/

)

dr

/

du

nj

(r

/

)

dr

/

r

/

:

(41)

4

Discussion of the results

In this section, a 36 terms perturbation series has been

employed in order to determine the dimensionless velocity

and temperature distribution in the uid, for different

values of Br. The number of terms was enough to reach an

accuracy of four decimal points.

To evaluate the radius of convergence r

c

of each of the

series described by Eq. (33), the method described in

Ref. [16] has been employed. For a xed value of Br, all the

perturbation series dened in Eq. (33) have the same ra-

dius of convergence. Since the radius of convergence

cannot be dened for Br = 0, a modied radius of con-

vergence r

+

c

, given by the ratio between the radius of

convergence of the perturbation series and the modulus of

the Brinkman number, is introduced. In Fig. 1, the mod-

ied radius of convergence of the power series is plotted

versus the modulus of the Brinkman number, in both cases

Br > 0 and Br < 0. For Br = 0, as already discussed in the

previous section, the modied radius of convergence

corresponds to the smallest root of Eq. (31), i.e.

r

+

c

= 1808:02. The gure shows that, the cases Br > 0 and

Br < 0 are almost coincident. Of course, the cases Br =

and Br = are exactly coincident, since they corre-

spond to the boundary condition given by an adiabatic

wall. Moreover, for Br [ [ < 1 the modied radius of

Fig. 1. Plot of the ratio between the radius of convergence of the

perturbation series and the Brinkman number, versus [Br[

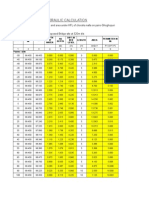

Table 1. Values of Nu

m

and f Re (in italic) for Br = 0, )0.001 and

0.001 and for Gr

+

/Re in the range )800 < Gr

+

/Re < 800

Gr

+

Re

Nu

m

f Re

Br = 0:001 Br = 0 Br = 0:001

)800 4.477 4.394 4.299

)22.84 )23.89 )25.14

)700 4.693 4.645 4.593

)15.77 )16.26 )16.80

)600 4.907 4.878 4.848

)9.519 )9.759 )10.01

)500 5.114 5.095 5.076

)4.001 )4.126 )4.253

)400 5.314 5.299 5.283

0.8933 0.8203 0.7470

)300 5.505 5.490 5.475

5.263 5.216 5.169

)200 5.687 5.670 5.653

9.192 9.162 9.131

)100 5.860 5.839 5.819

12.75 12.74 12.72

0 6.024 6.000 5.976

16.00 16.00 16.00

100 6.181 6.152 6.124

18.98 19.00 19.02

200 6.330 6.297 6.264

21.74 21.78 21.81

300 6.472 6.434 6.397

24.30 24.36 24.42

400 6.607 6.566 6.524

26.69 26.77 26.85

500 6.737 6.691 6.645

28.94 29.04 29.15

600 6.862 6.811 6.761

31.05 31.18 31.31

700 6.981 6.926 6.871

33.05 33.20 33.36

800 7.096 7.037 6.977

34.95 35.13 35.30

134

convergence of the perturbation series is larger if the

parameter Br is negative.

Let us rst compare the solution obtained analytically

for Br = 0 by means of Eqs. (29) and (30) with the solution

which has been obtained, by means of the perturbation

method, for small values of the Brinkman number, namely

Br = 0:001 and Br = 0:001. Values of the modied

Nusselt number and of the product f Re are reported in

Table 1, for Gr

+

=Re in the range 800 < Gr

+

=Re < 800.

This table shows that both the value of the modied

Nusselt number and that of f Re evaluated for Br = 0 lie

between the corresponding values assumed in the cases

Br = 0:001 and Br = 0:001. Moreover, the difference

between the case Br = 0 and the cases Br = 0:001 be-

comes more important as Gr

+

=Re [ [ increases. Both Nu

m

and f Re are increasing functions of the parameter Gr

+

=Re,

for the values of Br considered in Table 1.

In Table 2, values of Nu

m

and of the product f Re are

reported for Br = 0, Br = 1=2, Br = 1=5 and

Br = 1=10 and for Gr

+

=Re in the range

120 < Gr

+

=Re < 120. This table shows that f Re is a

strictly decreasing function of the ratio Gr

+

=Re if

Br _ 1=5 while it is a strictly increasing function of

Gr

+

=Re for higher values assumed by the parameter Br. It

can be easily checked that, if Br lies in a narrow neigh-

borhood of 0:19, the product f Re, is a function of Gr

+

=Re

which rst decreases and then increases. For instance, for

Br = 0:19 the minimum is reached for Gr

+

=Re 27:54.

The values of the modied Nusselt number for Br = 1=2

are negative because the wall heat ux is negative, but the

viscous heating is such that the wall temperature is higher

than the mean temperature in the uid. The behaviour of

the modied Nusselt number, if regarded as a function of

the ratio Gr

+

=Re, depends strongly on the values assumed

by the Brinkman number. In particular this function, for

increasing values of Gr

+

=Re, decreases if Br = 1=2 and

Br = 1=5. In analogy to the behaviour of the product

f Re, in a narrow neighborhood of 0:16, the modied

Nusselt number, if regarded as a function of Gr

+

=Re, rst

decreases and then increases; for instance, for Br = 0:16

the minimum is reached for Gr

+

=Re 371. Then, it in-

creases if Br = 1=10 and in the special case of forced

convection. Finally, for the positive values of Br consid-

ered in this table, Nu is a strictly decreasing function of the

parameter Gr

+

=Re.

Table 3 refers to Br = 1, Br = 10 and Br = , for

Gr=Re in the range 60 < Gr=Re < 60. Obviously, on

account of its denition, the modied Nusselt number for

Br is identically zero. This table shows that the

values of f Re obtained for Br = lie between those ob-

tained in the case Br = 10 and in the case Br = 10. The

difference between this three cases increases for increasing

values of [Gr=Re[. The values of Nu

m

for Br = 10 and

Br = 1 are negative because the wall heat ux is negative,

but the viscous dissipation effect in the uid is so intense

that the wall temperature exceeds the mean temperature.

The parameter f Re is an increasing function of Gr=Re for

all the values of Br considered in this table, while the

Table 2. Values of Nu

m

and f Re (in italic) for Gr

+

/Re in the range )120 < Gr

+

/Re < 120 and for different values assumed by the

parameter Br

Gr

+

Re

Nu

m

f Re

Br =

1

2

Br =

1

5

Br =

1

10

Br = 0 Br =

1

10

Br =

1

5

Br =

1

2

)120 )2.396 38.86 9.294 5.806 4.456 3.742 2.787

27.55 16.45 14.07 12.05 10.29 8.721 4.730

)100 )2.847 36.69 9.411 5.839 4.435 3.687 2.686

24.52 16.34 14.42 12.74 11.25 9.901 6.485

)80 )3.357 34.90 9.528 5.872 4.411 3.626 2.567

22.08 16.25 14.75 13.41 12.20 11.08 8.211

)60 )3.921 33.38 9.648 5.905 4.383 3.559 2.436

20.10 16.17 15.08 14.08 13.14 12.28 9.977

)40 )4.543 32.09 9.764 5.937 4.353 3.488 2.297

18.48 16.10 15.40 14.73 14.09 13.49 11.83

)20 )5.232 30.97 9.882 5.969 4.320 3.412 2.151

17.13 16.05 15.70 15.37 15.04 14.73 13.82

0 )6.000 30.00 10.00 6.000 4.286 3.333 2.000

16.00 16.00 16.00 16.00 16.00 16.00 16.00

20 )6.864 29.15 10.12 6.031 4.249 3.251 1.846

15.04 15.96 16.29 16.62 16.96 17.31 18.43

40 )7.844 28.40 10.24 6.062 4.211 3.167 1.690

14.22 15.93 16.56 17.23 17.93 18.67 21.18

60 )8.971 27.74 10.35 6.092 4.171 3.080 1.536

13.51 15.91 16.83 17.83 18.91 20.08 24.33

80 )10.28 27.14 10.47 6.122 4.130 2.992 1.388

12.91 15.90 17.09 18.42 19.90 21.55 27.93

100 )11.82 26.61 10.59 6.152 4.088 2.904 1.252

12.40 15.89 17.35 19.00 20.90 23.09 32.00

120 )13.65 26.14 10.70 6.182 4.045 2.815 1.133

11.97 15.89 17.59 19.57 21.91 29.36 36.46

135

Nusselt number is an increasing function of Gr=Re for

Br = 10 and Br = 1 and a decreasing function for

Br = 10 and Br = 1.

In Figs. 2 and 3, plots of the velocity and the temper-

ature eld in the uid are reported versus the dimen-

sionless radial coordinate for Br = 0, Br = 1=5 and

Br = 1=10. The plots in Fig. 2 have been drawn for

Gr

+

=Re = 120, which may correspond either to uid

cooling (q

0

< 0) and downward ow (U

0

< 0) or to uid

heating (q

0

> 0) and upward ow (U

0

> 0). On the con-

trary, the plots in Fig. 3 have been drawn for

Gr

+

=Re = 120. Figure 2 shows that an increase of Br

induces an increase of the dimensionless velocity in the

region next to the wall of the duct. On the contrary, Fig. 3

shows that the dimensionless uid velocity at the wall

decreases for increasing values of the Brinkman number.

Moreover, both gures show that the dimensionless tem-

perature at the wall is an increasing function of the pa-

rameter Br. In the case Br = 1=5, both for Gr

+

=Re = 120

and for Gr

+

=Re = 120 the temperature distribution

reaches a relative maximum at r = 0. Since Eq. (26) holds,

the condition d

2

#

+

=dr

2

< 0 at r = 0 implies that

g

+

u(0) < 0. Figures 2 and 3 show that the velocity dis-

tribution is not negative. This means that, when a relative

maximum of the dimensionless temperature distribution

occurs, the parameter g

+

is negative. Since a relative

maximum of #

+

occurs for a negative value of Br, the

condition g

+

< 0 implies that the viscous heating in the

uid exceeds the heat ux subtracted at the wall. This

circumstance is emphasized in Figs. 4 and 5, where the

Table 3. Values of Nu

m

and f Re (in italic) for Gr/Re in the range )120 < Gr/Re < 120 and for Br = 1, 10 and

Gr

Re

Nu

m

f Re

Br = )1 Br = )10 Br = Br = 10 Br = 1

)60 )3.626 )0.2512 0 0.2347 1.793

10.42 8.918 8.743 8.566 6.877

)50 )3.297 )0.2334 0 0.2188 1.697

11.08 9.815 9.669 9.523 8.150

)40 )2.997 )0.2162 0 0.2034 1.600

11.83 10.80 10.69 10.57 9.485

)30 )2.720 )0.1998 0 0.1886 1.501

12.67 11.89 11.81 11.72 10.91

)20 )2.463 )0.1840 0 0.1741 1.401

13.64 13.11 13.05 12.99 12.45

)10 )2.224 )0.1687 0 0.1601 1.301

14.74 14.47 14.44 14.41 14.13

0 )2.000 )0.1538 0 0.1463 1.200

16.00 16.00 16.00 16.00 16.00

10 )1.789 )0.1395 0 0.1330 1.099

17.46 17.75 17.79 17.82 18.11

20 )1.590 )0.1255 0 0.1199 1.000

19.17 19.78 19.85 19.91 20.52

30 )1.403 )0.1120 0 0.1072 0.9016

21.20 22.16 22.27 22.38 23.31

40 )1.226 )0.09917 0 0.09518 0.8076

23.64 24.98 25.13 25.28 26.56

50 )1.064 )0.08726 0 0.08399 0.7208

26.58 28.32 28.53 28.69 30.31

60 )0.9185 )0.07668 0 0.07405 0.6442

30.09 32.18 32.40 32.62 34.52

Fig. 2. Plots of u and #

+

versus r for Gr

+

=Re = 120 and

(a) Br = 1=5; (b) Br = 1=10; (c) Br = 0; (d) Br = 1=10;

(e) Br = 1=5

136

dimensionless velocity and temperature distributions in

the uid are plotted versus r for Br = 0, Br = 1=2 and

Br = 1. The plots in Fig. 4 have been drawn for

Gr

+

=Re = 60, while the plots in Fig. 5 refer to

Gr

+

=Re = 60. In both gures d

2

#

+

=dr

2

< 0 at r = 0 for

Br = 1 and for Br = 1=2. Figure 4 shows that an in-

crease of the viscous dissipation effect induces an increase

of the dimensionless velocity in a region next to the wall of

the duct. On the other hand, Fig. 5 reveals that, if the value

of Br is increased, the dimensionless uid velocity next to

the axis of the tube is enhanced. A comparison between

the dimensionless velocity distributions reported in the

upper frame of Figs. 4 and 5 shows that the case

Gr

+

=Re = 60 and Br = 1 yields a velocity distribution in

the uid which is similar to that found in the case

Gr

+

=Re = 60 and Br = 1. Moreover, both gures reveal

that the dimensionless uid temperature at the wall of the

duct is an increasing function of the Brinkman number.

In Figs. 6 and 7, plots of the dimensionless velocity and

of the dimensionless temperature distribution in the uid

are reported versus r for Br = , Br = 1=2 and

Br = 1. The plots in Fig. 6 have been drawn for

Gr=Re = 60, while the plots in Fig. 7 have been drawn for

Gr=Re = 60. Both gures show that the dimensionless

temperature at the wall of the duct is a decreasing function

of the Brinkman number. Moreover, these gures show

that the dimensionless velocity and temperature distribu-

tions in the cases Br = 1 and Br = 1 are similar to the

dimensionless velocity and temperature distribution in the

special case of adiabatic wall (Br = ).

Fig. 3. Plots of u and #

+

versus r for Gr

+

=Re = 120 and (a)

Br = 1=5; (b) Br = 1=10; (c) Br = 0; (d) Br = 1=10; (e)

Br = 1=5

Fig. 4. Plots of u and #

+

versus r for Gr

+

=Re = 60 and (a)

Br = 1; (b) Br = 1=2; (c) Br = 0; (d) Br = 1=2; (e) Br = 1

Fig. 5. Plots of u and #

+

versus r for Gr

+

=Re = 60 and (a)

Br = 1; (b) Br = 1=2; (c) Br = 0; (d) Br = 1=2; (e) Br = 1

137

Figure 8 refers to the special case of a pipe with an

adiabatic wall (Br = ). In this gure, plots of the velocity

and the temperature distribution in the uid are reported

versus r for Gr=Re = 70, Gr=Re = 0, Gr=Re = 40,

Gr=Re = 70. In particular, this gure shows that, for a

negative value of the ratio Gr=Re, there exists a region next

to the wall where both u and # are smaller than in the case

of forced convection. On the contrary, for a positive value

of the ratio Gr=Re, both u and # are greater than in the

case of forced convection in a region next to the wall of the

duct.

5

Coupled effects of viscous dissipation and buoyancy:

an example

In this paragraph, the convection coefcient and the

pressure-drop parameter will be determined in a special

case of practical interest, i.e. in the case of an engine oil at

290 K.

The thermophysical properties of this uid, as reported

in Ref. [19], are as follows: dynamic viscosity coefcient,

l = 0:999 Pa s; kinematic viscosity coefcient,

m = 1:12 10

6

m

2

/s; thermal conductivity, k = 0:145 W/

(m K); thermal expansion coefcient, b = 7 10

4

K

1

.

In Fig. 9, the convection coefcient h (upper frame) and

the pressure-drop dP=dX (lower frame) are reported ver-

sus the prescribed wall heat ux q

0

. Reference has been

made to a vertical duct with radius R

0

= 0:05 m, and to a

ow regime whose mean velocity is U

0

= 0:023 m/s. It can

Fig. 6. Plots of u and # versus r for Gr=Re = 60 and (a)

Br = 1=2; (b) Br = 1; (c) Br = ; (d) Br = 1; (e) Br = 1=2

Fig. 7. Plots of u and # versus r for Gr=Re = 60 and (a)

Br = 1=2; (b) Br = 1; (c) Br = ; (d) Br = 1; (e) Br = 1=2

Fig. 8. Plots of u and # versus r for Br = and (a)

Gr=Re = 70; (b) Gr=Re = 0; (c) Gr=Re = 40; (d) Gr=Re = 70

138

be easily veried that those values imply Re = 2054. In

both frames, line (a) has been obtained by modelling the

ow as mixed convection with no viscous dissipation; line

(b) has been obtained by modelling the ow as forced

convection with viscous dissipation; line (c) has been

obtained by modelling the ow as mixed convection with

viscous dissipation.

Since small values of q

0

have been considered, the effect

of the viscous dissipation, in this case, is denitely not

negligible. Figure 9 shows that the model of mixed con-

vection with viscous dissipation yields values of h very

similar to those obtained by neglecting the buoyancy ef-

fect, but quite different from those obtained by neglecting

the viscous dissipation effect. However, the behaviour of

dP=dX is strongly different in the three cases, thus

showing that neither the buoyancy effect nor the viscous

dissipation effect can be neglected. Moreover, as expected,

in Fig. 9 is evident that in the special case of forced con-

vection the pressure-drop dP=dX does not depend on the

prescribed wall heat ux.

6

Conclusions

The combined forced and free convection of a Newtonian

uid which ows in a cylindrical duct with circular cross

section has been analysed. The ow has been considered

laminar and parallel, and the effects of viscous dissipation

in the uid have been taken into account. A boundary

condition of prescribed and uniform wall heat ux has

been assumed. The Boussinesq approximation has been

employed and the reference temperature has been chosen

as the mean temperature in a cross section of the pipe.

Moreover, in order to neglect the dependence of the uid

properties on the streamwise coordinate, Morton's ap-

proximation has been utilised. The momentum balance

equation and the energy balance equation have been

written in a dimensionless form and solved by means of a

perturbation method. In particular, the dimensionless

velocity and temperature, as well as the dimensionless

parameters k and g, have been written as power series with

respect to the ratio between the Grashof number and the

Reynolds number. In fact, in the perturbation method,

forced convection with viscous dissipation has been re-

garded as the base heat transfer process. The radius of

convergence of the perturbation series has been estimated

and it has been shown to depend on the Brinkman num-

ber. Truncated perturbation series with 36 terms have

been employed to obtain values of the Nusselt number and

of the Fanning friction factor, as well as plots of the ve-

locity and temperature elds, for different values of the

ratio Gr=Re.

The presence of viscous dissipation in the uid has led

one to notice the following features:

(a) In the case of a heated duct, the effect of viscous

dissipation, for positive xed values of the parameter

Gr

+

=Re, reduces the value of the Nusselt number and

increases the value of the Fanning friction factor.

(b) If one considers the friction factor as a function of

Gr=Re for a xed value of Br, the cases Br = 10

almost coincide with the special case of adiabatic wall

(Br = ).

(c) As it has been already observed in previous papers,

if the ow is buoyancy assisted (Gr

+

=Re > 0), the

dimensionless velocity close to the wall of the duct

increases when the value assumed by Br increases.

On the contrary, when the ow is buoyancy

opposed (Gr

+

=Re < 0), the dimensionless uid

velocity close to the wall decreases for increasing

values of Br.

References

1. Aung W (1987) Mixed convection in internal ow. In: Kacac

S; Shah RK; Aung W (eds.) Handbook of Single-Phase Con-

vective Heat Transfer, Chapter 15, Wiley, New York

2. Lavine AS; Kim MY; Shores CN (1989) Flow reversal in op-

posing mixed convection ow in inclined pipes. ASME J Heat

Transfer 111: 114120

3. Morton BR (1960) Laminar convection in uniformly heated

vertical pipes. J Fluid Mech 8: 227240

4. Van Dyke M (1990) Extended Stokes series: laminar ow

through a heated horizontal pipe. J Fluid Mech 212: 289308

5. Choudhury D; Patankar SV (1988) Combined forced and free

laminar convection in the entrance region of an inclined

isothermal tube. ASME J Heat Transfer 110: 901909

6. Hwang GJ; Lai HC (1994) Laminar convective heat transfer in

a horizontal isothermal tube for high Rayleigh numbers. Int J

Heat Mass Transfer 37: 16311640

7. Shome B; Jensen MK (1995) Mixed convection laminar ow

and heat transfer of liquids in isothermal horizontal circular

ducts. Int J Heat Mass Transfer 38: 19451956

Fig. 9. Plots of the convection coefcient h and the pressure-drop

parameter dP=dX versus the wall heat ux in the following three

cases: (a) negligible effect of viscous dissipation; (b) negligible

effect of the buoyancy; (c) coupled effect of buoyancy and viscous

dissipation

139

8. Choi DK; Choi DH (1992) Dual solution for mixed convection

in a horizontal tube under circumferentially non-uniform

heating. Int J Heat Mass Transfer 35: 20532056

9. Choi DK; Choi DH (1994) Developing mixed convection ow

in a horizontal tube under circumferentially non-uniform

heating. Int J Heat Mass Transfer 37: 18991913

10. Moutsoglou A; Kwon YD (1993) Laminar mixed convec-

tion ow in a vertical tube. J Thermophysics Heat Transfer 7:

361368

11. Tso CP; Mahulikar SP (1998) The use of the Brinkman

number for single phase forced convective heat transfer in

microchannels. Int J Heat Mass Transfer 41: 17591769

12. Iqbal M; Aggarwala BD; Rokerya MS (1970) Viscous dissi-

pation effects on combined free and forced convection

through vertical circular tubes. ASME J Appl Mech 37: 931935

13. Rokerya MS; Iqbal M (1971) Effects of viscous dissipation on

combined free and forced convection through vertical con-

centric annuli. Int J Heat Mass Transfer 14: 491495

14. Barletta A (1999) Combined forced and free convection with

viscous dissipation in a vertical circular duct. Int J Heat Mass

Transfer 42: 22432253

15. Barletta A (1999) Analysis of combined forced and free ow in

a vertical channel with viscous dissipation and isothermal-

isoux boundary conditions. ASME J Heat Transfer 121:

349356

16. Barletta A (1999) Heat transfer by fully developed ow and

viscous heating in a vertical channel with prescribed wall heat

uxes. Int J Heat Mass Transfer 42: 38733885

17. Barletta A; Zanchini E (1999) On the choice of the reference

temperature for fully-developed mixed convection in a ver-

tical channel. Int J Heat Mass Transfer 42: 31693181

18. Ou JW; Cheng KC (1973) Viscous dissipation effects on

thermal entrance region heat transfer in pipes with uniform

wall heat ux. Applied Scientic Research 28: 289301

19. Incropera FP; De Witt DP (1985) Fundamentals of heat and

mass transfer. 2nd edn., Appendix A, 772, Wiley, New York

140

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Mineline MSP Sell SheetDokument2 SeitenMineline MSP Sell SheetMary Huaylla ANoch keine Bewertungen

- Unit Weight or Density of Different Construction MaterialsDokument2 SeitenUnit Weight or Density of Different Construction MaterialsHari RNoch keine Bewertungen

- Annex 2.1: Contingency Plan Template For SchoolDokument21 SeitenAnnex 2.1: Contingency Plan Template For SchoolJapeth PurisimaNoch keine Bewertungen

- CNNs: Convolutional Neural Networks for Image ClassificationDokument13 SeitenCNNs: Convolutional Neural Networks for Image ClassificationRahul VasanthNoch keine Bewertungen

- Classified2020 1 16770965Dokument2 SeitenClassified2020 1 16770965Mohamed MaharNoch keine Bewertungen

- Happy, Secure and Convenient Living With Nobrokerhood: Visitor, Society and Accounting Management SystemDokument10 SeitenHappy, Secure and Convenient Living With Nobrokerhood: Visitor, Society and Accounting Management SystemVIKAS PAIDIPEDDIGARI100% (1)

- Sample Integration Test PlanDokument16 SeitenSample Integration Test PlanAnkita WalkeNoch keine Bewertungen

- JH Tests Sky High WB Test U3a 6Dokument5 SeitenJH Tests Sky High WB Test U3a 66yftz9d529Noch keine Bewertungen

- Software House C CURE 9000 v2.90: - Security and Event Management SystemDokument5 SeitenSoftware House C CURE 9000 v2.90: - Security and Event Management SystemANDRES MORANoch keine Bewertungen

- Spray Dryer ExperimentDokument17 SeitenSpray Dryer Experimentdrami94100% (7)

- Surfer 8 GuideDokument664 SeitenSurfer 8 GuideYuliana DomínguezNoch keine Bewertungen

- A10 Thunder Series and AX Series: ACOS 2.7.2-P7-SP3 22 December 2015Dokument360 SeitenA10 Thunder Series and AX Series: ACOS 2.7.2-P7-SP3 22 December 2015huonz mrNoch keine Bewertungen

- SetuplogDokument307 SeitenSetuplogJuan Daniel Sustach AcostaNoch keine Bewertungen

- Characterization of uPVC Pipes Using Thermal AnalysisDokument7 SeitenCharacterization of uPVC Pipes Using Thermal AnalysisFaiz SabianNoch keine Bewertungen

- Hydraulic CaculationDokument66 SeitenHydraulic CaculationgagajainNoch keine Bewertungen

- Cinnamomum Cassia - Twig: 1. ScopeDokument3 SeitenCinnamomum Cassia - Twig: 1. ScopeTaufik HidayatullohNoch keine Bewertungen

- Process Maps and Turtle DiagramsDokument1 SeiteProcess Maps and Turtle Diagramskyle1991100% (1)

- Historic Costume: (Early 15 Century) 1400-1500 European FashionDokument33 SeitenHistoric Costume: (Early 15 Century) 1400-1500 European FashionRaina varshneyNoch keine Bewertungen

- Wiring 87T E01Dokument4 SeitenWiring 87T E01Hau NguyenNoch keine Bewertungen

- Software Customisation Reference ManualDokument269 SeitenSoftware Customisation Reference ManualTonthat QuangNoch keine Bewertungen

- Process Control Lecture 9 (M2)Dokument53 SeitenProcess Control Lecture 9 (M2)lalusebanNoch keine Bewertungen

- Articol Indicatori de PerformantaDokument12 SeitenArticol Indicatori de PerformantaAdrianaMihaiNoch keine Bewertungen

- The Impact of Air Cooled Condensers On Plant Design and OperationsDokument12 SeitenThe Impact of Air Cooled Condensers On Plant Design and Operationsandi_babyNoch keine Bewertungen

- 3D MapsDokument1.128 Seiten3D MapsjoangopanNoch keine Bewertungen

- MODULE 7-11 Notes PrefiDokument7 SeitenMODULE 7-11 Notes PrefiPASCUAL, ALJON R.Noch keine Bewertungen

- Total Chrom TutorialDokument94 SeitenTotal Chrom TutorialRachelHechanovaNoch keine Bewertungen

- CopdDokument74 SeitenCopdSardor AnorboevNoch keine Bewertungen

- Acestream Channels List 1Dokument64 SeitenAcestream Channels List 1loo juu33% (3)

- Japanese Aircraft Recognition (1941)Dokument76 SeitenJapanese Aircraft Recognition (1941)CAP History LibraryNoch keine Bewertungen

- TerraPower Case PDFDokument7 SeitenTerraPower Case PDFKaustav DeyNoch keine Bewertungen