Beruflich Dokumente

Kultur Dokumente

Got Milk - Chemistry World Science Communication Competition

Hochgeladen von

RazzNakOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Got Milk - Chemistry World Science Communication Competition

Hochgeladen von

RazzNakCopyright:

Verfügbare Formate

Got milk?

Razzan Nakhlawi Sunday 15 July 2012 20.00 BST

The future of fashion? Photograph: Placbo/Flickr

At present, the textile industry relies heavily upon oil byproducts, or withering natural resources to meet a demand that is bubbling over currently an immense 1800 litres of water is needed to manufacture a single cotton t-shirt. Now Qmilch (aptly named after Q for quality and the German word for milk, milch) presents itself as a novel answer to the industrys dilemmas. It is a fabric created from milk which is allowed to ferment, reducing a milk protein called casein into a powder. It is then heated and mixed with a few natural additives like beeswax into strands that can be woven into a fabric. Now if there were any qualms about how ecological the manufacture of a new textile would be, the biochemist/fashiondesigner/mastermind behind Qmilch, Anke Domaske affirms that, Water consumption during the process is minimized to a maximum of 2 litres. There is no waste in the whole process; all ingredients are used in the fibre.

Qmilch even provides a useful output for the abundance of expired dairy we chuck out on a daily basis, We also take a waste product from the dairy industry, as we use the 20% of -Anke Domaske, creator of Qmilch. cows milk unfit for human consumption. But although she told Reuters, "it feels like silk and it doesn't smell, whether we would jump at the chance to buy a plush, designer jacket made from Bill-down-the-roads rancid butter, is a different matter completely. Qmilch is the offshoot of milk fibre production that has been looming around since the 1930s, albeit abandoning the chemicals previously used in the 60-hour manufacture process.

There is no waste in the whole process.

So it may be a rehash of an older concept, but Domaskes search for such a versatile fabric was inspired by her cancer-stricken father who suffered skin problems from irritating and non-organic fabrics whilst going through treatment. "There are so many people who really suffer just by wearing normal clothing," Domaske told The Associated Press. "I wanted to find a way to help them."

Under the scanning electron microscope.

On top of its non-allergenic qualities, it is even claimed that the proteins that make up the textile retain antibacterial and anti-aging amino acids. Caseins biochemistry is substantial to the claims, as it appears to assemble into naturally-occurring fibrous proteins, called amyloid fibrils, when in the blood vessels. It is said Domaskes use of body-indigenous design dips its toes in the waters of biomimicry. By examining the makeup of matter found in nature and how those structures relate to the functions they carry out, the purpose of biomimicry is to utilise these principles for the improvement of man-made items, like Qmilch.

At the moment, the clothes are biodegradable; reducing landfill space, but it is thought the fibres can be used again, depending on the finishing. The casein fibres are considered thermoplastic, meaning when heated the fibres turn to a homogenized liquid but they can also harden when cooled. Frozen thermoplastics become brittle and fracture typically to glass. These qualities are reversible, so they can be heated, reshaped and frozen forevermore- which makes thermoplastics recyclable. The head of the Textile Research Association, Klaus Jansen says, "We know that everything that is based on oil has a limit, that materials like cotton that take up a lot of land, water and chemicals are limited, so we need to think about how we in produce fabrics and textiles in the future."

Anke and the Qmilch.

If alternative textiles such as Qmilch are an indication of where an industry plagued by antifur activism, rampant globalisation and a carbon footprint the size of Wales, is going- should we have to concern ourselves with the imminent? Fashion feeds a growing industry and ranks textile and clothing as the worlds secondbiggest economic activity for intensity of trade. Stiff competition forces down costs while working conditions, more often than not in developing countries, are far from ideal, Lakshmi Challa, head of Apparel Technology at Bangalore University tells us, But the environment

pays a heavy price too. To improve conditions for workers and stem pollution, textile manufacturers are launching the first initiatives built around sustainable development. It may just be that green is the new black.

Das könnte Ihnen auch gefallen

- Earn USD $ 200+ by Making A Designer Dress From 6 Liters of MilkDokument2 SeitenEarn USD $ 200+ by Making A Designer Dress From 6 Liters of MilkRonitsinghthakur SinghNoch keine Bewertungen

- Biopolymers Casein Its Preparation And Use A Practical HandbookVon EverandBiopolymers Casein Its Preparation And Use A Practical HandbookNoch keine Bewertungen

- Is 'Vegan Leather' A Sustainable Alternative To Animal Leather?Dokument7 SeitenIs 'Vegan Leather' A Sustainable Alternative To Animal Leather?Aquib MaksudNoch keine Bewertungen

- If Your Clothes Aren't Already Made Out of Plastic, They Will Be - QuartzDokument6 SeitenIf Your Clothes Aren't Already Made Out of Plastic, They Will Be - QuartzKhristiam AlvarezNoch keine Bewertungen

- PSE - Notes and CountersDokument8 SeitenPSE - Notes and CountersKristina Pauline ObraNoch keine Bewertungen

- The Story of Microfibers: Annotated ScriptDokument4 SeitenThe Story of Microfibers: Annotated Scriptreza dnNoch keine Bewertungen

- Corn Plastic To The RescueDokument4 SeitenCorn Plastic To The RescueEliud NogueraNoch keine Bewertungen

- Modal FabricDokument30 SeitenModal FabricGillian Faye LechocoNoch keine Bewertungen

- USE OF MILK AS RAW MATERIAL IN CASEIN PLASTIC PRODUCTION FinalDokument12 SeitenUSE OF MILK AS RAW MATERIAL IN CASEIN PLASTIC PRODUCTION Finalameriemendoza100% (1)

- Hack 11 - Krisha ShahDokument7 SeitenHack 11 - Krisha ShahkrishaNoch keine Bewertungen

- Wycombe Medical and Asnwer 1st QuestionDokument3 SeitenWycombe Medical and Asnwer 1st QuestionGabriel RusuNoch keine Bewertungen

- Milk FabricDokument2 SeitenMilk FabricatanqueNoch keine Bewertungen

- Fashion and The EnvironmentDokument5 SeitenFashion and The EnvironmentThu UyenNoch keine Bewertungen

- Chapter 01Dokument34 SeitenChapter 01Ashutosh RaiNoch keine Bewertungen

- Sustainable FashionDokument6 SeitenSustainable FashionbreakbeatdocNoch keine Bewertungen

- Sustainable FashionDokument4 SeitenSustainable FashionMichael SmithNoch keine Bewertungen

- Making Plastic From MilkDokument5 SeitenMaking Plastic From MilkJosh Aldrin SarioNoch keine Bewertungen

- Special Problem: TopicDokument7 SeitenSpecial Problem: TopicALI SHER HaidriNoch keine Bewertungen

- Region 4 Grade 10 12 Shiitake Diapers Capturing CO Poo One Diaper at A Time William Lyon Mackenzie C.I.Dokument26 SeitenRegion 4 Grade 10 12 Shiitake Diapers Capturing CO Poo One Diaper at A Time William Lyon Mackenzie C.I.deez96954Noch keine Bewertungen

- Sustainable Processing in Garment IndustryDokument12 SeitenSustainable Processing in Garment IndustryAmrita MitraNoch keine Bewertungen

- Sustainable Fashion: By: Vieru CristinaDokument11 SeitenSustainable Fashion: By: Vieru CristinaKristinaVieru100% (1)

- Marketing Myopia Div CDokument13 SeitenMarketing Myopia Div CSAI SHRIYA NYASAVAJHULANoch keine Bewertungen

- Impact of Textiles and Clothing Industry On EnvironmentDokument15 SeitenImpact of Textiles and Clothing Industry On Environmentranjann349Noch keine Bewertungen

- Headers To Find ClipartDokument6 SeitenHeaders To Find ClipartShiwangi NagoriNoch keine Bewertungen

- BioplasticsDokument12 SeitenBioplasticsAlejandro De la GarzaNoch keine Bewertungen

- RRLDokument12 SeitenRRLAlejandro De la GarzaNoch keine Bewertungen

- Lyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpDokument3 SeitenLyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpMiraz HossainNoch keine Bewertungen

- WA 107 - Plastic PollutionDokument3 SeitenWA 107 - Plastic PollutiondyyoungblqsNoch keine Bewertungen

- Reading 1Dokument2 SeitenReading 1Marcelo BorsiniNoch keine Bewertungen

- Leather IndustryDokument3 SeitenLeather IndustryDouglas Martins GonçalvesNoch keine Bewertungen

- Hides and Skins and the Manufacture of Leather - A Layman's View of the IndustryVon EverandHides and Skins and the Manufacture of Leather - A Layman's View of the IndustryNoch keine Bewertungen

- Rethinking Fashion: Fashion As If People and The Planet Actually MatterDokument10 SeitenRethinking Fashion: Fashion As If People and The Planet Actually Matterapi-25924519100% (2)

- Textile RecyclingDokument22 SeitenTextile RecyclingSunil JaglanNoch keine Bewertungen

- Better Cotton InitativeDokument17 SeitenBetter Cotton InitativeokyougotmeNoch keine Bewertungen

- Environmental Protection and Sustainability in The Textile IndustryDokument3 SeitenEnvironmental Protection and Sustainability in The Textile IndustryCarlos Ernesto Aguilar LópezNoch keine Bewertungen

- The AnthropoceneDokument44 SeitenThe Anthropocenezaidiamna9Noch keine Bewertungen

- An Eco-Friendly Alternate Method of Stone-Washing of Indigo-Dyed Denim Jeans-GarmentsDokument12 SeitenAn Eco-Friendly Alternate Method of Stone-Washing of Indigo-Dyed Denim Jeans-GarmentsSamuel VanoostenNoch keine Bewertungen

- Circular EconomyDokument4 SeitenCircular EconomyAnna Samchuk100% (1)

- The University of Trinidad and Tobago: Master of Science inDokument99 SeitenThe University of Trinidad and Tobago: Master of Science inAlvin FormalesNoch keine Bewertungen

- Cradle To Cradle Manufacturing - Moving Beyond The Industrial RevolutionDokument11 SeitenCradle To Cradle Manufacturing - Moving Beyond The Industrial RevolutionEdern Le BrisNoch keine Bewertungen

- 3 - 4 - The Milkman Model - 1Dokument2 Seiten3 - 4 - The Milkman Model - 1FatimaNoch keine Bewertungen

- Thesis - Vegan LeatherDokument32 SeitenThesis - Vegan LeatherDr Waseem CNoch keine Bewertungen

- EcoFriendly Humans Benefit From Recycled Polyester Fabric in Globally Diverse WaysDokument5 SeitenEcoFriendly Humans Benefit From Recycled Polyester Fabric in Globally Diverse WaysJing-YunNoch keine Bewertungen

- A Study of the Changes in Skins During Their Conversion into LeatherVon EverandA Study of the Changes in Skins During Their Conversion into LeatherNoch keine Bewertungen

- Plastic Eaters and Turbo Trees: How to Save the Climate, Remove all the Trash from the Sea, and Master the Rest with BrillianceVon EverandPlastic Eaters and Turbo Trees: How to Save the Climate, Remove all the Trash from the Sea, and Master the Rest with BrillianceNoch keine Bewertungen

- A Brief History of BioplasticsDokument8 SeitenA Brief History of BioplasticsSHANKAR PRINTINGNoch keine Bewertungen

- Denim Finishing With EnzymesDokument3 SeitenDenim Finishing With Enzymesapi-26494555Noch keine Bewertungen

- Report On Garment Appreciation by Reversing The Manufacturing ProcessesDokument16 SeitenReport On Garment Appreciation by Reversing The Manufacturing ProcessesADYA MANISHINoch keine Bewertungen

- Mini Research PaperDokument4 SeitenMini Research Paperapi-280731067100% (1)

- Critical Thinking PaperDokument10 SeitenCritical Thinking PaperCharlotte FosterNoch keine Bewertungen

- Floating Seabin: (Review of Related Study)Dokument4 SeitenFloating Seabin: (Review of Related Study)Romar MirandaNoch keine Bewertungen

- A Brief History of PlasticsDokument10 SeitenA Brief History of PlasticsHaries GarciaNoch keine Bewertungen

- (Citation Han18 /L 1033) : Hul Techtonic Case SubmissionDokument2 Seiten(Citation Han18 /L 1033) : Hul Techtonic Case SubmissionAshi JainNoch keine Bewertungen

- Fashion Orientation Jury ReportDokument14 SeitenFashion Orientation Jury ReportSaloni YadavNoch keine Bewertungen

- Clothing & Pollution: ReferenceDokument6 SeitenClothing & Pollution: Referenceranjann349Noch keine Bewertungen

- History of Smart Textiles: A Comprehensive Guide To E-TextilesVon EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNoch keine Bewertungen

- Innovations and Research Ideas For Recycling Textile WastesDokument7 SeitenInnovations and Research Ideas For Recycling Textile WastesInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Biology ResearchDokument5 SeitenBiology ResearchEireen Nicole EreñetaNoch keine Bewertungen

- Chapter 1Dokument7 SeitenChapter 1john philip s garcia100% (1)

- Nonwoven Bags Project Report DubaiDokument54 SeitenNonwoven Bags Project Report Dubaisugaimpax80% (10)

- 2.1 Polyester & Viscose Rayon FibreDokument5 Seiten2.1 Polyester & Viscose Rayon FibreKAWSER RAFI100% (1)

- Eco Innovation Manual Textiles SupplementDokument170 SeitenEco Innovation Manual Textiles SupplementYisi LrNoch keine Bewertungen

- Design of Composite MaterialsDokument174 SeitenDesign of Composite MaterialsyigitilgazNoch keine Bewertungen

- My ProjectDokument56 SeitenMy ProjectAnusuiya ThankapazhamNoch keine Bewertungen

- A Review Study On The Behaviour of Black Cotton Soil With Bamboo Fibre PDFDokument3 SeitenA Review Study On The Behaviour of Black Cotton Soil With Bamboo Fibre PDFVikram NikhilNoch keine Bewertungen

- Dynamic Analysis of Fibre Reinforced Composite Dome Roof StructuresDokument21 SeitenDynamic Analysis of Fibre Reinforced Composite Dome Roof StructuresAbhishek JaiswalNoch keine Bewertungen

- Chemical Engineering Journal-2024Dokument13 SeitenChemical Engineering Journal-2024Suman NandyNoch keine Bewertungen

- Theory of Fiber Reinforced MaterialsDokument702 SeitenTheory of Fiber Reinforced MaterialsPonsyo PonsiNoch keine Bewertungen

- Experimental and Finite Element Analysis On Thermal Conductivity of Fiber Reinforced Building MaterialsDokument10 SeitenExperimental and Finite Element Analysis On Thermal Conductivity of Fiber Reinforced Building MaterialsNazish MunirNoch keine Bewertungen

- Essential Requirements ER No.: TEC70012008: Optical Fibres (Single Mode)Dokument27 SeitenEssential Requirements ER No.: TEC70012008: Optical Fibres (Single Mode)prakash barikNoch keine Bewertungen

- Bionanocomposites As Industrial Materials, Current and Future Perspectives A ReviewDokument16 SeitenBionanocomposites As Industrial Materials, Current and Future Perspectives A ReviewMartin MagangNoch keine Bewertungen

- Basic and Reactivedyeable Polyester Fabrics Using Lipase Enzymes 2157 7048 1000271Dokument5 SeitenBasic and Reactivedyeable Polyester Fabrics Using Lipase Enzymes 2157 7048 1000271Nurul Apsari AjiNoch keine Bewertungen

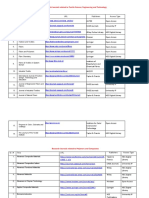

- 1 - Data For Website - LibraryDokument6 Seiten1 - Data For Website - LibrarySajid Zeb AwanNoch keine Bewertungen

- Thermal Degradation of Nicalon SiC FibersDokument13 SeitenThermal Degradation of Nicalon SiC FibersbbeeNoch keine Bewertungen

- A Review of The Design and Analysis of Reinforced Thermoplastic Pipes For Offshore ApplicationsDokument18 SeitenA Review of The Design and Analysis of Reinforced Thermoplastic Pipes For Offshore Applicationsshimaa magdyNoch keine Bewertungen

- Design of Storage TanksDokument176 SeitenDesign of Storage TanksSaravanan Silamban100% (3)

- Arbocel-Prospekt PetfoodDokument8 SeitenArbocel-Prospekt PetfoodАндрей Педченко100% (1)

- 12th Chemistry Project PDFDokument16 Seiten12th Chemistry Project PDFTashan RazaNoch keine Bewertungen

- ESPRJOURNALDokument26 SeitenESPRJOURNALM. AZIZINoch keine Bewertungen

- Properties of Wool and SilkDokument8 SeitenProperties of Wool and SilkPriyalNoch keine Bewertungen

- Carbon FibreDokument16 SeitenCarbon FibreRakshit Mitra83% (6)

- Noc19 Te01 Assignment4Dokument3 SeitenNoc19 Te01 Assignment4Tanishq AwasthiNoch keine Bewertungen

- Bioresources.: Analysis of The Tensile Modulus of Polypropylene Composites Reinforced With Stone Groundwood FibersDokument14 SeitenBioresources.: Analysis of The Tensile Modulus of Polypropylene Composites Reinforced With Stone Groundwood FibersAbdul jeleelNoch keine Bewertungen

- FRC - (BS en 14889-2 - 2006) - Fibres For Concrete. Polymer Fibres. Definitions, Specifications and ConformityDokument30 SeitenFRC - (BS en 14889-2 - 2006) - Fibres For Concrete. Polymer Fibres. Definitions, Specifications and ConformityE Hammam El MissiryNoch keine Bewertungen

- Rosa Et Al. (2010) PDFDokument9 SeitenRosa Et Al. (2010) PDFمحمود بن ماجد نصارNoch keine Bewertungen

- 8.STITCHES & ClassificationDokument56 Seiten8.STITCHES & ClassificationUmer MushtaqNoch keine Bewertungen

- Free Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDokument5 SeitenFree Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDr Engr Md Zillur RahmanNoch keine Bewertungen

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDokument5 SeitenSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNoch keine Bewertungen