Beruflich Dokumente

Kultur Dokumente

Esm Manual

Hochgeladen von

Akhil BhadouriaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Esm Manual

Hochgeladen von

Akhil BhadouriaCopyright:

Verfügbare Formate

INSTRUCTION MANUAL

For

ELECTRONIC SPEED MONITOR

PROTOCONTROL INSTRUMENTS (I) PVT. LTD.

EL-31/1, ELECTRONIC ZONE, M.I.D.C., BHOSARI, PUNE, MAHARASHTRA INDIA. PIN: 411 026 PH : 0091-020-27130197, 0091-020-27130398 FAX: 0091-020-27130918

Email : protocontrol@ eth.net

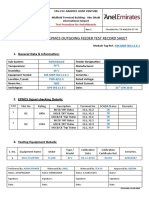

INSTRUCTION MANUAL FOR ELECTRONIC SPEED MONITOR TECHNICAL DETAILS : TYPE CONTRO L SUPPLY : ESM -1-W-3-S-1-S-1-P : 230 V AC, 50 Hz

CONTACT ACTUATION SPEED RANGE : 10 - 100 RPM ENCLOSURE NO. OF IMPULSES / ROTATION : IP 65 CAST AL : 4

INITIAL TIME DELAY : 3 30 Secs. (Time setting knob is marked as 0 10 means Min is 3 Secs & Max is 30 Secs.) DUTY INDICATION : UNDER SPEED MONITORING : GREEN LED FOR SIGNAL RED LED FOR RELAY. : POTENTIOMETRIC : 2 C/O POTENTIAL FREE : IPS D3 OS NO M30 N : 10 to 30 V DC : 2 Mtr. : 10 to 12 mm.

SETTING OUTPUT SPEED SENSOR TYPE SUPPLY CABLE LENGTH SENSING DISTANCE

PROTECTION GRADE FOR CONTROL UNIT IP 65 & FOR SENSOR : IP 67 THE SENSOR PROBE USED IS SUITABLE FOR SENSING 4 M.S.BOLTS OF SIZE M30 FITTED ON SHAFT.

APPLICATION & GENERAL DETAILS

This Zero Speed switch (Electronic Speed Monitor) is used to protect rotating machinery like crushers, conveyors in mines, or for use in AC motors to sense the UNDER SPEED of motor shaft for the purpose of locked rotor protection. Red LED to indicate Relay ON" condition. Special green LED is also provided for signal status. Speed setting is done with a separate potentiometer. Sensor probe is epoxy potted & is totally enclosed. Protection grade for sensor probe is IP67. Control Unit is having protection grade of IP 65. TESTING: Wire control unit & sensor properly. Give specified control supply voltage to control unit terminal 1 & 2. Whenever supply to the unit is ON, Supply 'ON' as well as 'Relay ON' LED will glow. The relay ON indicates that supply to motor is ON & it starts rotating. This is the healthy condition. Now bring any metallic object in front of sensor probe. Red LED at the back of the sensor probe will be ON & at the same time signal LED on controller will be also ON. When object is taken away from the sensor probe, LED will OFF.Thus we can check that speed monitor & sensor probe is working properly so we can install the system as per our requirements. INSTALLATION : Install sensor probe such that it can sense the 2 M.S.bolts of size M20 or M30 fitted on shaft diametrically opposite. The gap between sensor probe and M.S bolts should be 6 to 8 mm. Wire control-unit & sensor probe by any ordinary three core cable. The maximum distance between control unit and sensor probe can be upto 500 meters. CABLING : Cable entries are provided at the bottom of enclosure as shown in drawing enclosed. First cable entry is for mains cable, second is for Sensor & third is for Relay contacts. Wire external connections through these cable entries only to avoid electrical interference (noise) problem.

OPERATION :

When supply is given to the unit the relay gets energised. Since relay is energised the P - NO contacts can be used to give supply to MOTOR. Now motor starts rotating but it will achieve normal speed slowly. Due to arrangement of sensor probe starts sensing M.S.bolts fitted on shaft of motor.These pulses are received by speed monitor unit At this stage if speed setting knob is at more RPM than motor speed then control unit will turn OFF the relay means motor will stop unnecessarily. To avoide this condition Initial time delay knob is provided so that relay will remain energized till set time & it will make sure that MOTOR is running at its normal speed . It keeps on comparing the speed with set speed. The relay will remain in energised condition when motor is rotating at more than set speed. And if the motor speed drops below set speed, relay gets de-energised & remains latched condition until the motor speed achieves its normal condition. Thus motor is prevented from under speed running or zero speed condition. FAULT FINDING : CHECK 1) Whether ESM is getting proper control supply. 2) Whether sensor probe LED is sensing M.S.bolts fixed on the shaft. The LED should get ON & OFF in presence & absence of metal. 3) Check the setting of the speed setting knob. 4) Check contacts of the output relay. 5) If the set speed is above the normal speed of the equipment, output relay will not energize. If checking above points, fault is not traced send unit back to our works.

********************************

Das könnte Ihnen auch gefallen

- Calibration Procedure For BFP-T Turbine Rotor Expansion SensorDokument9 SeitenCalibration Procedure For BFP-T Turbine Rotor Expansion Sensornaresh977977Noch keine Bewertungen

- Axial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoDokument3 SeitenAxial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoShiva KotamrajuNoch keine Bewertungen

- Technical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)Dokument12 SeitenTechnical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)SeresdfrtNoch keine Bewertungen

- Pressure Transmitter Information & Installation Manual (M374)Dokument10 SeitenPressure Transmitter Information & Installation Manual (M374)gusmilexaNoch keine Bewertungen

- FB 1200Dokument52 SeitenFB 1200Eduardo AlvarezNoch keine Bewertungen

- TND 063191 135912Dokument180 SeitenTND 063191 135912Kanupriya AgarwalNoch keine Bewertungen

- P-I Transducer - P200-P290 PDFDokument4 SeitenP-I Transducer - P200-P290 PDFman_y2kNoch keine Bewertungen

- Forbes AWA Phenol - Oil in WaterDokument6 SeitenForbes AWA Phenol - Oil in WaterpspsuparingNoch keine Bewertungen

- Ip Pressure Transmitter Data SheetDokument2 SeitenIp Pressure Transmitter Data Sheetneurolepsia3790Noch keine Bewertungen

- 878 CpiDokument4 Seiten878 Cpijust_hamma100% (1)

- Saes J 002Dokument25 SeitenSaes J 002Dinesh BoopalanNoch keine Bewertungen

- Fftmu 2ch@aDokument3 SeitenFftmu 2ch@asteam100deg8229Noch keine Bewertungen

- Sop-35 Calibration of Vacuum Pressure TransmitterDokument3 SeitenSop-35 Calibration of Vacuum Pressure TransmitterOSAMANoch keine Bewertungen

- AhmadJavaid (TZIDC ABB Positioner)Dokument17 SeitenAhmadJavaid (TZIDC ABB Positioner)ahmedNoch keine Bewertungen

- GJX 3 ManualDokument13 SeitenGJX 3 Manualعبدالحميد عبدالغفار الدرديريNoch keine Bewertungen

- Sa Sar ActuatorDokument56 SeitenSa Sar ActuatorJoel CatubayNoch keine Bewertungen

- Flame ScannerDokument4 SeitenFlame ScannerAlok Kumar NayakNoch keine Bewertungen

- Electromagnetic FLOW METERDokument13 SeitenElectromagnetic FLOW METERpabloasotoNoch keine Bewertungen

- Sensepoint XCD TechMan MAN0873 Iss8 0913 EMEAIDokument84 SeitenSensepoint XCD TechMan MAN0873 Iss8 0913 EMEAImusajcNoch keine Bewertungen

- General Specification For Electric Actuators - Integral Motor ControlDokument4 SeitenGeneral Specification For Electric Actuators - Integral Motor ControlschgirlNoch keine Bewertungen

- Leak Detection in Pipeline-JijoDokument17 SeitenLeak Detection in Pipeline-Jijoamulbaby31Noch keine Bewertungen

- Price List MSRP For WEB PDFDokument3 SeitenPrice List MSRP For WEB PDFnavneetNoch keine Bewertungen

- Anubar SpecDokument8 SeitenAnubar SpecSHIVAJI CHOUDHURYNoch keine Bewertungen

- Actuator Data SheetsDokument4 SeitenActuator Data SheetsCibi SubramaniamNoch keine Bewertungen

- Model S214 Hydrogen Sulfide ManualDokument28 SeitenModel S214 Hydrogen Sulfide ManualPeter Malone0% (1)

- FS 3210 - FS-Gas Flow ComputerDokument6 SeitenFS 3210 - FS-Gas Flow ComputerBinu ManiNoch keine Bewertungen

- Basics of Instrumentation TheoryDokument63 SeitenBasics of Instrumentation TheorysanthoshramrNoch keine Bewertungen

- Procon LDS Maintenance Manual-R5Dokument18 SeitenProcon LDS Maintenance Manual-R5Watchara ThepjanNoch keine Bewertungen

- Max DnaDokument17 SeitenMax DnaAdil ButtNoch keine Bewertungen

- Product List: Pressure MeasurementDokument6 SeitenProduct List: Pressure MeasurementSr FarezNoch keine Bewertungen

- HJDokument4 SeitenHJShajil VazhakkalilNoch keine Bewertungen

- 57-606.9 Eclipse Model 706 Hart Io 1 PDFDokument108 Seiten57-606.9 Eclipse Model 706 Hart Io 1 PDFAbdul Shaharlal ENoch keine Bewertungen

- Pid Controls PLC EnvironDokument22 SeitenPid Controls PLC EnvironAbhinav GuptaNoch keine Bewertungen

- How To Select A Variable Frequency DriveDokument2 SeitenHow To Select A Variable Frequency Drivehasbi fadli100% (1)

- Calibration of Temperature Transmitter Anil Kumar KallaDokument5 SeitenCalibration of Temperature Transmitter Anil Kumar KallaRamanathanNoch keine Bewertungen

- Motion Controller BES-516-604, Typical Applications: Balluff Zero Speed Controller On A Grinding MachineDokument8 SeitenMotion Controller BES-516-604, Typical Applications: Balluff Zero Speed Controller On A Grinding MachinenorbertoNoch keine Bewertungen

- 15 - Test Format For SCADA Test (OUTGOING)Dokument1 Seite15 - Test Format For SCADA Test (OUTGOING)Gajendran SriramNoch keine Bewertungen

- MC-J0-03 Tubing - TemplateDokument4 SeitenMC-J0-03 Tubing - TemplatePipin AripinNoch keine Bewertungen

- Presentation On Presentation On Plant Controls & Inst. Overview OF GGSR - Bathinda (CPP) GGS (C) Owner: M/S Hmel PMC: M/S EILDokument34 SeitenPresentation On Presentation On Plant Controls & Inst. Overview OF GGSR - Bathinda (CPP) GGS (C) Owner: M/S Hmel PMC: M/S EILGunadevan ChandrasekaranNoch keine Bewertungen

- SN74LVC07Dokument23 SeitenSN74LVC07abcdNoch keine Bewertungen

- DPT Smart Pressure TransmitterDokument15 SeitenDPT Smart Pressure Transmitterprasanta_bbsrNoch keine Bewertungen

- 01 Installation of Ratio Flow ControllersDokument1 Seite01 Installation of Ratio Flow ControllersBrandon TrocNoch keine Bewertungen

- Functional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualDokument24 SeitenFunctional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualPaul Ramos CarcaustoNoch keine Bewertungen

- # 6 - 1 Attachment ABB DCSDokument4 Seiten# 6 - 1 Attachment ABB DCSKevin NgoNoch keine Bewertungen

- Chapter-8 (Part-I) : (Programmable Peripheral Interface)Dokument12 SeitenChapter-8 (Part-I) : (Programmable Peripheral Interface)belihuNoch keine Bewertungen

- Control Valve OcrDokument14 SeitenControl Valve OcrpathakshashankNoch keine Bewertungen

- En ACS580 Standard Control Program FW C A5Dokument440 SeitenEn ACS580 Standard Control Program FW C A5joseNoch keine Bewertungen

- Literature Pressure GaugesDokument5 SeitenLiterature Pressure GaugesHardik AcharyaNoch keine Bewertungen

- Orifice FlowMeterDokument12 SeitenOrifice FlowMetersanggul elli noraNoch keine Bewertungen

- SPPA-T1000 System OverviewDokument14 SeitenSPPA-T1000 System OverviewNAYEEMNoch keine Bewertungen

- Instruction Manual WHL Rupture DiskDokument26 SeitenInstruction Manual WHL Rupture DiskRinda_RaynaNoch keine Bewertungen

- Vortex FMDokument14 SeitenVortex FMtirutkkNoch keine Bewertungen

- Data SheetDokument2 SeitenData SheetyiuhimluiNoch keine Bewertungen

- Process Control (Level)Dokument12 SeitenProcess Control (Level)Gino GalanoNoch keine Bewertungen

- Velocity Transducers 141626Dokument14 SeitenVelocity Transducers 141626Vladimir KojicNoch keine Bewertungen

- Zero Speed SensingDokument3 SeitenZero Speed SensinggsnptiNoch keine Bewertungen

- 140M D4N BD LiftDokument6 Seiten140M D4N BD LiftsuelifashNoch keine Bewertungen

- Hly 5011Dokument4 SeitenHly 5011Mike WallaceNoch keine Bewertungen

- Tea Sensor de Velocidade 2Dokument7 SeitenTea Sensor de Velocidade 2Valmaq Prestação Serviço LdaNoch keine Bewertungen

- Use of Series and Shunt Capacitors in Transmission LinesDokument7 SeitenUse of Series and Shunt Capacitors in Transmission LinesMilinda Prabhath100% (1)

- Experiment No. 2: Aim: A) D Flip-Flop: Synchronous VHDL CodeDokument6 SeitenExperiment No. 2: Aim: A) D Flip-Flop: Synchronous VHDL CodeRahul MishraNoch keine Bewertungen

- ExportDokument271 SeitenExportSpartacus CaesarNoch keine Bewertungen

- Kaiweets ManualDokument29 SeitenKaiweets ManualpittawaygrahameNoch keine Bewertungen

- Computer Motherboard I. Computer Motherboard: Property of STIDokument4 SeitenComputer Motherboard I. Computer Motherboard: Property of STIRachelle GandaNoch keine Bewertungen

- Usb Implementation Using Utmi MacrocellDokument71 SeitenUsb Implementation Using Utmi Macrocellrockfloyd100% (6)

- 86 924N Iss.2 SART S4 Service ManualDokument27 Seiten86 924N Iss.2 SART S4 Service ManualMike Olumide JohnsonNoch keine Bewertungen

- Copley Absolute Encoder GuideDokument54 SeitenCopley Absolute Encoder GuideAlecsandruNeacsuNoch keine Bewertungen

- Beken BK3633Dokument26 SeitenBeken BK3633AlexandrNoch keine Bewertungen

- EE321L Lab 6 MOSFET Differential AmplifierDokument3 SeitenEE321L Lab 6 MOSFET Differential Amplifierdevpritam100% (1)

- Superserver 1028R-Wc1R: Key FeaturesDokument5 SeitenSuperserver 1028R-Wc1R: Key Featuresegghead2point0Noch keine Bewertungen

- AN010 Bias Web PubDokument7 SeitenAN010 Bias Web PubGs SrikanthNoch keine Bewertungen

- Felcom 16 Service Part 1Dokument75 SeitenFelcom 16 Service Part 1emilio gustavo saez duroNoch keine Bewertungen

- 1-PGNiG Kickoff MOM Rev1.0Dokument4 Seiten1-PGNiG Kickoff MOM Rev1.0zeeshansuboorNoch keine Bewertungen

- Lic Syllabus 4th SemDokument4 SeitenLic Syllabus 4th SemYo Yo AnandNoch keine Bewertungen

- Lect05 LIBDokument14 SeitenLect05 LIBalokNoch keine Bewertungen

- Lec48 PDFDokument17 SeitenLec48 PDFabm999100% (1)

- SAD Unit 4 Real Time Systems1Dokument20 SeitenSAD Unit 4 Real Time Systems1onesnoneNoch keine Bewertungen

- Fpio Design GuidelineDokument59 SeitenFpio Design GuidelinedahofibinezdiroorgNoch keine Bewertungen

- Shelby Cherms - Senior Project Research PaperDokument4 SeitenShelby Cherms - Senior Project Research Paperapi-664531732Noch keine Bewertungen

- 929midterm Exam Routine SP 23 and Au 2022Dokument1 Seite929midterm Exam Routine SP 23 and Au 2022ET201004 Md Imam HossainNoch keine Bewertungen

- DEBIX Model A DatasheetDokument5 SeitenDEBIX Model A DatasheethxNoch keine Bewertungen

- Chapter 9. Controller Design: 9.2. Effect of Negative Feedback On The Network Transfer FunctionsDokument74 SeitenChapter 9. Controller Design: 9.2. Effect of Negative Feedback On The Network Transfer FunctionsHoang ManhNoch keine Bewertungen

- AD630 Balanced Modulator-DemodulatorDokument20 SeitenAD630 Balanced Modulator-DemodulatorSergeyNoch keine Bewertungen

- Timer Controller PDFDokument182 SeitenTimer Controller PDFBrandom Rodriguez100% (1)

- O-OEM-SSD DDR HDD Quotation 6.7Dokument6 SeitenO-OEM-SSD DDR HDD Quotation 6.7Farhad Anwar SiddiquiNoch keine Bewertungen

- NSN 3g Radio PlanningDokument152 SeitenNSN 3g Radio Planninglezrac_09100% (1)

- Ig Mint Mint+iom 6.2Dokument135 SeitenIg Mint Mint+iom 6.2100003Noch keine Bewertungen

- Quectel MC60 at Commands Manual V1.0Dokument256 SeitenQuectel MC60 at Commands Manual V1.0Adimaro100% (1)

- CH 2 PC 3Dokument1 SeiteCH 2 PC 3Danny Q.Noch keine Bewertungen

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsVon EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsBewertung: 5 von 5 Sternen5/5 (3)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Von EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Bewertung: 5 von 5 Sternen5/5 (3)

- Chip War: The Fight for the World's Most Critical TechnologyVon EverandChip War: The Fight for the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (82)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (229)

- CISSP All-in-One Exam Guide, Ninth EditionVon EverandCISSP All-in-One Exam Guide, Ninth EditionBewertung: 5 von 5 Sternen5/5 (1)

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Von EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Bewertung: 5 von 5 Sternen5/5 (2)

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Von EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Bewertung: 5 von 5 Sternen5/5 (2)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsVon EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNoch keine Bewertungen

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Von EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Bewertung: 5 von 5 Sternen5/5 (1)

- Computer Science: A Concise IntroductionVon EverandComputer Science: A Concise IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Raspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideVon EverandRaspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideNoch keine Bewertungen

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XVon EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XBewertung: 3 von 5 Sternen3/5 (2)

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneVon EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNoch keine Bewertungen

- Cancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionVon EverandCancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionBewertung: 5 von 5 Sternen5/5 (2)

- Essential iPhone X iOS 12 Edition: The Illustrated Guide to Using iPhone XVon EverandEssential iPhone X iOS 12 Edition: The Illustrated Guide to Using iPhone XBewertung: 5 von 5 Sternen5/5 (1)

- Hacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxVon EverandHacking With Linux 2020:A Complete Beginners Guide to the World of Hacking Using Linux - Explore the Methods and Tools of Ethical Hacking with LinuxNoch keine Bewertungen

- The comprehensive guide to build Raspberry Pi 5 RoboticsVon EverandThe comprehensive guide to build Raspberry Pi 5 RoboticsNoch keine Bewertungen

- Arduino and Raspberry Pi Sensor Projects for the Evil GeniusVon EverandArduino and Raspberry Pi Sensor Projects for the Evil GeniusNoch keine Bewertungen

- The User's Directory of Computer NetworksVon EverandThe User's Directory of Computer NetworksTracy LaqueyNoch keine Bewertungen

- Raspberry Pi Retro Gaming: Build Consoles and Arcade Cabinets to Play Your Favorite Classic GamesVon EverandRaspberry Pi Retro Gaming: Build Consoles and Arcade Cabinets to Play Your Favorite Classic GamesNoch keine Bewertungen

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1715193157?v=1)