Beruflich Dokumente

Kultur Dokumente

Pre-Feasibility Report For The Production of Herbal Drink

Hochgeladen von

barmarwanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pre-Feasibility Report For The Production of Herbal Drink

Hochgeladen von

barmarwanCopyright:

Verfügbare Formate

PRE-FEASIBILITY REPORT FOR THE PRODUCTION OF HERBAL DRINK

Name of the R&D Organization: Name of contact person: Designation: Address: Phone: Fax: Mobile: Email: PCSIR Laboratories, Complex Peshawar Mr. Saeed Akhtar Principal Scientific Officer PCSIR Laboratories, Complex Jamrud Road, Peshawar 091-9216240-42 091-9216232 03469038497 Saeedpcsir1@yahoo.com

1. Introduction of Technology/Process/Product Name of Technology/Process/Product: Production of Herbal Red Syrup Summary:

Due to location in the temperate region Pakistan is one of those countries where the demand for beverage are very high. The ingredients of the extract on which the drink is based are obtained from local herbal sources which are commonly used in Tibb for their pro-health characteristics. These herbs have carminative, cooling and stimulating effects some are even used as tonics. The drink has an appealing flavor, good taste and color, incorporating the original characteristics of the herbs used. This product is economical as compared to the similar drinks available in the market. It has a great potential for export to Afghanistan and Central Asian Countries.

Project brief (Local/International Perspective)

Distillation of herbs Preparation of sugar syrup Mixing of ingredients Filtration Cooling of the material Monitoring of the process control parameters Production of Herbal Red Syrup in hygienic conditions to ensure the quality control of the final product.

2 Main Parameters of Technology/Process/Product Main Feature: Prepared from natural herbal extract Pro-health characteristics Carminative, cooling and stimulating effects Use as a Tonic Appealing flavour, good taste and attractive colour

Input (Raw materials with specifications) Sugar Herbal Distillate Food colour Flavour Water

Output (Products, byproducts with specification) Red Herbal Syrup Brix pH Application/Uses This product can be used as a refreshing drink when diluted with water or milk, having carminative, cooling and stimulating effects, appealing flavour, good taste and attractive colour. One standard bottle(750 ml ) would yield about 30 glasses of drink , making it more economical than the other similar products available in the market. Good 75 6.2

Trail Results: Technical data

Proposed capacity: 500 bottles / day/batch Production time per batch: 8 hr Packing size:750 ml each

Production process/Flow diagram

Flow sheet for Red Herbal Syrup Preparation

Herbs Weighing Grinding Distillation Preparation of sugar syrup

Mixing of herbal distillate with sugar syrup + color

Filtration

Cooling + addition of flavour

Mixing

Labeling

Capping

Filling of bottles

Equipment layout diagram

Weighing Balance Distillation Apparatus Syrup Preparation Tank Syrup Mixing Tank Syrup Cooling Tank Syrup Filling Machine Labeling

Machinery required with specification S. No 1 2 3 4 5 6 7 8 9 10 11 10 Items Syrup Preparation Tank with Agitator(Steam Jacketed) Syrup Filtration Unit Housing complete Mixing Tank with Agitator and Cooling facilities Herbs Distillation Unit Bottle filling Machine with capping and labeling facilities Herbs Distillate Storage vessels (glass or plastic ) Weighing Balance Weighing Balance Grinding Machine pH meter Refractometer Miscellaneous Description 500 liter capacity 100 Liter/hr.500 Liters capacity 10 liters / hour 100 bottles/hr. 50 liters 50 Kg capacity 01 Kg capacity 10 Kg capacity Qty One One One One One Four One One One One One Cost (Million Rs.) 0.5 0.4 0.5 0.1 0.6 0.02 0.05 0.01 0.1 0.15 0.1 0.02 Total 2.55

Standard specifications & test methods Standard specifications Total Soluble Solids pH Acidity Preservative Test methods AOAC 2000 AOAC 2000 AOAC 2000 AOAC 2000

Quality control equipment with specifications

S. No 1 2 3 Items Digital Balance Digital Refractometer pH meter

Quantity One One One Friendly Available Brochure will be prepared Not Patented

xii. Environmental Impact: xiii. Availability of technical support: xiv. Available of Brochures/Pamphlets: xv. Status of registration/Patent/Trade Mark:

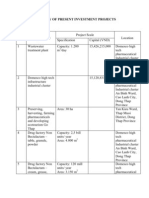

3. Estimation of Fixed Capital Investment (PKR) Fixed Capital Investment

Land 02 Kanal

Building (covered area) 8000 Sq. feet Furniture & Fixture (Office /Factory) Plant & Machinery Technology Transfer fee Total Fixed cost of the project Add: working capital Total project cost 4 Marketing Aspects

8.0 million 12.0 million 1.0 million 2.55 million 1.0 million 24.55 million 5.0 million 29.55 million

Total industry and annual growth Current demand Local production facilities Imports Major users Marketing strategy

Data not available Data not available Data not available Nil Public

Hold regional exhibition & seminars i) ii) iii) Supplied samples to SAMEDA for marketing Displayed samples at various chamber of commerce & industries. Exhibited in various exhibitions held in capital cities. Nil

Publicity through electronic & print media

5 Detail of Cost:: Direct Production Cost Raw materials cost per Unit Direct wages cost per unit Production overhead cost per unit Admin. & Selling Expenses, Salaries & benefits per month Utilities charges per month Communication expanses per month Other expanses per month Publicity, advertisement expenses per month Rs.50000/month Rs.2000/batch Rs.5000/month Rs.10000/month Rs.29000/batch 26500/batch 500/batch

Das könnte Ihnen auch gefallen

- Guava Nectar PDFDokument10 SeitenGuava Nectar PDFErica LindseyNoch keine Bewertungen

- D2-7 Antoine Charbonneau - AISC 2016 NOVASEPDokument26 SeitenD2-7 Antoine Charbonneau - AISC 2016 NOVASEPhendrajobNoch keine Bewertungen

- Ed ProjectDokument15 SeitenEd ProjectCrown Gamers and EntertainmentNoch keine Bewertungen

- Hawassa MoHA Millennium Pepsi-Cola Factory SDokument98 SeitenHawassa MoHA Millennium Pepsi-Cola Factory SBereket Getnet100% (4)

- Fruit Juice Concentrate PlantDokument25 SeitenFruit Juice Concentrate Plantbonker508100% (15)

- As 2012711Dokument37 SeitenAs 2012711Sukitha KothalawalaNoch keine Bewertungen

- Carbonated Soft Drinks Powder 1Dokument44 SeitenCarbonated Soft Drinks Powder 1fms162100% (2)

- Nurag JHA: Mobile: (+91) 9016365802 EmailDokument5 SeitenNurag JHA: Mobile: (+91) 9016365802 EmailTarendra ChourasiyaNoch keine Bewertungen

- Food Colours: Profile No.: 41 NIC Code: 47219Dokument7 SeitenFood Colours: Profile No.: 41 NIC Code: 47219SOMNATH KHAMARUNoch keine Bewertungen

- Beverage Processing and Packaging PlantsDokument20 SeitenBeverage Processing and Packaging Plantscor jansenNoch keine Bewertungen

- Business Plan On Energy DrinkDokument48 SeitenBusiness Plan On Energy DrinkSaneetGuravNoch keine Bewertungen

- CDH Product Catalogue 2018 19Dokument340 SeitenCDH Product Catalogue 2018 19Matriya NitinNoch keine Bewertungen

- Innovative Technologies in Beverage ProcessingVon EverandInnovative Technologies in Beverage ProcessingIngrid Aguilo-AguayoNoch keine Bewertungen

- 54 - Non Carbonated Water Based Beverages (Non Alcoholic)Dokument40 Seiten54 - Non Carbonated Water Based Beverages (Non Alcoholic)shubham vatsNoch keine Bewertungen

- A Project Profile On: HAND SANITIZER (Alcohol Based)Dokument10 SeitenA Project Profile On: HAND SANITIZER (Alcohol Based)Himansu Sekhar SahuNoch keine Bewertungen

- Moin&jigsDokument7 SeitenMoin&jigsMoin VahoraNoch keine Bewertungen

- Project Profiles For MUDRADokument183 SeitenProject Profiles For MUDRAManishGuptaNoch keine Bewertungen

- Project Profiles For Various ProjectsDokument1.085 SeitenProject Profiles For Various Projectsheman.shethNoch keine Bewertungen

- Banana JuiceDokument33 SeitenBanana JuiceDeepak Ola50% (2)

- Invert Sugar LetterDokument1 SeiteInvert Sugar LetterHarpreet SinghNoch keine Bewertungen

- ONEWATER PackagedDrinkingWater V0.1Dokument22 SeitenONEWATER PackagedDrinkingWater V0.1prasanthdusiNoch keine Bewertungen

- A Experimental Study of Vinegar Production From Different Fruit Products-IJAERDV04I0460188Dokument6 SeitenA Experimental Study of Vinegar Production From Different Fruit Products-IJAERDV04I0460188Madel DalindingNoch keine Bewertungen

- Hand Sanitizer Project ReportDokument7 SeitenHand Sanitizer Project ReportMisraNoch keine Bewertungen

- OPM ProjectDokument65 SeitenOPM ProjectMohammad FaheemNoch keine Bewertungen

- Halal Product Registration ProcedureDokument7 SeitenHalal Product Registration ProcedureIvan ZhongNoch keine Bewertungen

- Asli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Dokument16 SeitenAsli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Nilesh HiremathNoch keine Bewertungen

- Eyhorn-2004-Organic Agriculture in IndiaDokument30 SeitenEyhorn-2004-Organic Agriculture in IndiaZoran H. VukchichNoch keine Bewertungen

- Bottled Coconut Water TrishnaDokument25 SeitenBottled Coconut Water TrishnaRolando MurilloNoch keine Bewertungen

- Feasibility StudyDokument37 SeitenFeasibility StudyPraveen PuthuparambilNoch keine Bewertungen

- Investment ProjectsDokument3 SeitenInvestment ProjectsAnnie PhamNoch keine Bewertungen

- Herbella: An Ayurvedic Health Drink 'Dokument12 SeitenHerbella: An Ayurvedic Health Drink 'Raja PenawarNoch keine Bewertungen

- EMP Industrial Waste Management and ControlDokument29 SeitenEMP Industrial Waste Management and Controlhue2000Noch keine Bewertungen

- Cacttus WaterDokument25 SeitenCacttus WaterSelva KumarNoch keine Bewertungen

- Formulations: Local Production ofDokument9 SeitenFormulations: Local Production ofNkengafac Armstrong menjuaNoch keine Bewertungen

- Process Technology:: For The Perfect MixDokument8 SeitenProcess Technology:: For The Perfect Mixkaax1ys2b7Noch keine Bewertungen

- PILONT PLANT Design Liquid Semisolid InjDokument101 SeitenPILONT PLANT Design Liquid Semisolid InjRamesh RajNoch keine Bewertungen

- Apri Sip - OPM - Final Report PDFDokument22 SeitenApri Sip - OPM - Final Report PDFsaadNoch keine Bewertungen

- Product Catalogue 2011 12Dokument184 SeitenProduct Catalogue 2011 12Jagesh RanjanNoch keine Bewertungen

- Application of Industrial Ingineering TechniqueDokument14 SeitenApplication of Industrial Ingineering TechniquebunskygirlNoch keine Bewertungen

- Design and Development of A Multi - Bottling Machine For Adlai DrinksDokument4 SeitenDesign and Development of A Multi - Bottling Machine For Adlai Drinksjsph021603Noch keine Bewertungen

- Intercambiador de CalorDokument20 SeitenIntercambiador de CalorLina Gonzalez HNoch keine Bewertungen

- Imploader - Business OverviewDokument7 SeitenImploader - Business OverviewElwa SzaboNoch keine Bewertungen

- Internship Report On Dashen BreweryDokument27 SeitenInternship Report On Dashen Brewerydesalegn abera70% (10)

- Technology of Food Processing IndustriesDokument10 SeitenTechnology of Food Processing Industrieseiribooks0% (2)

- Ground and Processed SpicesDokument11 SeitenGround and Processed SpicesAnas MKNoch keine Bewertungen

- Pptwaterpurifier 161008124026Dokument26 SeitenPptwaterpurifier 161008124026Harshit KoshtaNoch keine Bewertungen

- Procedures For Analysis of Citrus ProductsDokument193 SeitenProcedures For Analysis of Citrus ProductsHenik SukoriniNoch keine Bewertungen

- Project Profile On Liquid SoapDokument9 SeitenProject Profile On Liquid SoapMostafa Sarowar100% (1)

- Industry ReportDokument26 SeitenIndustry ReportRudra PangeniNoch keine Bewertungen

- United Beverage Factory D1Dokument7 SeitenUnited Beverage Factory D1stan leeNoch keine Bewertungen

- Venkteshwar Institute of Pharmacy RajeshDokument17 SeitenVenkteshwar Institute of Pharmacy RajeshShahrukh SindhiNoch keine Bewertungen

- The Technology of Wafers and Waffles II: Recipes, Product Development and Know-HowVon EverandThe Technology of Wafers and Waffles II: Recipes, Product Development and Know-HowBewertung: 5 von 5 Sternen5/5 (1)

- Toilet Preparations World Summary: Market Values & Financials by CountryVon EverandToilet Preparations World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Integrated Processing Technologies for Food and Agricultural By-ProductsVon EverandIntegrated Processing Technologies for Food and Agricultural By-ProductsZhongli PanNoch keine Bewertungen

- Biomethane Production from Vegetable and Water Hyacinth WasteVon EverandBiomethane Production from Vegetable and Water Hyacinth WasteNoch keine Bewertungen

- Soaps & Detergents World Summary: Market Values & Financials by CountryVon EverandSoaps & Detergents World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Engineering Applications in Livestock ProductionVon EverandEngineering Applications in Livestock ProductionAyon TarafdarNoch keine Bewertungen

- R354Dokument3 SeitenR354barmarwanNoch keine Bewertungen

- 14699Dokument4 Seiten14699barmarwanNoch keine Bewertungen

- Liquid Ring Vacuum Pump Specification: Process Conditions - Select Steady State And/or Evacuation Steady StateDokument4 SeitenLiquid Ring Vacuum Pump Specification: Process Conditions - Select Steady State And/or Evacuation Steady StatebarmarwanNoch keine Bewertungen

- Unilever 'S Detergent Powder Plant: Dryer Control and Optimization Project Increases Production, Reduces Product GiveawayDokument2 SeitenUnilever 'S Detergent Powder Plant: Dryer Control and Optimization Project Increases Production, Reduces Product GiveawaybarmarwanNoch keine Bewertungen

- 1I InfoDokument2 Seiten1I InfobarmarwanNoch keine Bewertungen

- Manganese EngDokument6 SeitenManganese EngbarmarwanNoch keine Bewertungen

- Pallet ClassificationDokument8 SeitenPallet ClassificationbarmarwanNoch keine Bewertungen

- Combined Heat & Power (CHP) Evaluation GuidelinesDokument8 SeitenCombined Heat & Power (CHP) Evaluation GuidelinesbarmarwanNoch keine Bewertungen

- Dissertation StructureDokument7 SeitenDissertation StructurebarmarwanNoch keine Bewertungen

- Appendix 5A: Natural Gas Use in Industrial BoilersDokument7 SeitenAppendix 5A: Natural Gas Use in Industrial BoilersbarmarwanNoch keine Bewertungen

- Sample Cost-Benefit Analysis For Manufacturing Business OperationsDokument1 SeiteSample Cost-Benefit Analysis For Manufacturing Business OperationsbarmarwanNoch keine Bewertungen

- Worksheet 4 1Dokument2 SeitenWorksheet 4 1barmarwanNoch keine Bewertungen

- GlossaryDokument6 SeitenGlossarybarmarwanNoch keine Bewertungen

- Boiler Sizing GuideDokument1 SeiteBoiler Sizing GuideSuyog123123Noch keine Bewertungen

- Cost-Benefit Analysis WorksheetDokument5 SeitenCost-Benefit Analysis WorksheetbarmarwanNoch keine Bewertungen

- RRO Adequacy Assessment Practices-Survey Responses 08-14-08 2Dokument144 SeitenRRO Adequacy Assessment Practices-Survey Responses 08-14-08 2barmarwanNoch keine Bewertungen

- ERRATA5EDokument1 SeiteERRATA5EbarmarwanNoch keine Bewertungen

- C 4: P F P C: Hapter Olicy Ramework For Romoting OgenerationDokument10 SeitenC 4: P F P C: Hapter Olicy Ramework For Romoting OgenerationbarmarwanNoch keine Bewertungen

- Regulatory Handbook For Cogeneration Projects in Minnesota: Public Review Draft July 31, 2001Dokument5 SeitenRegulatory Handbook For Cogeneration Projects in Minnesota: Public Review Draft July 31, 2001barmarwanNoch keine Bewertungen

- TheHub Master BrochureDokument30 SeitenTheHub Master BrochureOliver GiamNoch keine Bewertungen

- The Strategic Position and Action Evaluation (SPACE) MatrixDokument5 SeitenThe Strategic Position and Action Evaluation (SPACE) MatrixMahmoud OmranNoch keine Bewertungen

- Internship Report AsifaliDokument71 SeitenInternship Report AsifaliRajaHaillianNoch keine Bewertungen

- Porter's Generic Strategies AnalysisDokument9 SeitenPorter's Generic Strategies AnalysisSaadiShahwanNoch keine Bewertungen

- NestleDokument4 SeitenNestleAsrafuzzaman RobinNoch keine Bewertungen

- Consumer Behavior & Marketing StrategyDokument34 SeitenConsumer Behavior & Marketing StrategyAnant JainNoch keine Bewertungen

- Pepsi CaseDokument36 SeitenPepsi CaseErman DemirNoch keine Bewertungen

- PWC Hugo Pintos ResumeDokument1 SeitePWC Hugo Pintos Resumeapi-391866160Noch keine Bewertungen

- Crafting The Brand Positioning 11Dokument18 SeitenCrafting The Brand Positioning 11ratnakar_3785Noch keine Bewertungen

- Business Plan Guideline-Service Providers-FinalDokument19 SeitenBusiness Plan Guideline-Service Providers-FinalCarlsson_Lim_4772Noch keine Bewertungen

- White Paper FORCECOINDokument23 SeitenWhite Paper FORCECOINSurya HaleluyaNoch keine Bewertungen

- Flight Ticket - Mumbai To Coimbatore, Coimbatore To Mumbai: Information - IndigoDokument3 SeitenFlight Ticket - Mumbai To Coimbatore, Coimbatore To Mumbai: Information - IndigovijaynairNoch keine Bewertungen

- Nebula - Presn Ad ResearchDokument90 SeitenNebula - Presn Ad Researchmuthum44499335Noch keine Bewertungen

- Project PPT Dominos Pizza 1207157685277483 9Dokument22 SeitenProject PPT Dominos Pizza 1207157685277483 9Pinky Utwani100% (1)

- Individual Presentation Assignment Brief and Guide (Assignemnt 1)Dokument5 SeitenIndividual Presentation Assignment Brief and Guide (Assignemnt 1)zigova1997Noch keine Bewertungen

- Cassie Marshall Resume - FinalDokument2 SeitenCassie Marshall Resume - Finalapi-271732549Noch keine Bewertungen

- OperationsDokument11 SeitenOperationsMark Justin LicuanNoch keine Bewertungen

- AlishaDokument2 SeitenAlishamohammadjewelNoch keine Bewertungen

- Shan Foods 1Dokument32 SeitenShan Foods 1Muhammad Kamran Javed50% (4)

- EAC Question BankDokument4 SeitenEAC Question BanksaravmbaNoch keine Bewertungen

- Process CostingDokument16 SeitenProcess CostingPiyush Gupta100% (2)

- RESUME Lydia KellamDokument2 SeitenRESUME Lydia Kellamcontact7930Noch keine Bewertungen

- MCI 11 Purchasing and Vendor Control ProcedureDokument5 SeitenMCI 11 Purchasing and Vendor Control ProcedureThương VũNoch keine Bewertungen

- Montenegro WaterDokument5 SeitenMontenegro Waternatali_popescuNoch keine Bewertungen

- Group 6 - 23250ENTI1012Dokument29 SeitenGroup 6 - 23250ENTI1012Ngo Huong Giang QP2045Noch keine Bewertungen

- Questionnaire For Company ProfileDokument2 SeitenQuestionnaire For Company ProfileShubham KumarNoch keine Bewertungen

- Fdocuments - in Chapter 11 Pricing Issues in Channel Management 2 Major Topics For CH 11Dokument26 SeitenFdocuments - in Chapter 11 Pricing Issues in Channel Management 2 Major Topics For CH 11Don DollanoNoch keine Bewertungen

- Green Washing Reading PlanDokument8 SeitenGreen Washing Reading PlanGustavo ArdilaNoch keine Bewertungen

- Contract Management Guide (Texas)Dokument155 SeitenContract Management Guide (Texas)Roland NicolasNoch keine Bewertungen

- Social Media For AuthorsDokument17 SeitenSocial Media For AuthorsJosh Peters100% (35)