Beruflich Dokumente

Kultur Dokumente

Hot Chamber Die Casting Machine

Hochgeladen von

Anand BossOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hot Chamber Die Casting Machine

Hochgeladen von

Anand BossCopyright:

Verfügbare Formate

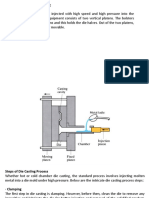

Hot Chamber Die Casting Machine:

It is also called a gooseneck machine because of the shape of the metal passage way. In this machine the melting pot, usually made of cast iron, is a part of the machine. The gooseneck containing a cylinder and metal passage way is kept immersed in the metal pot. The plunger in the gooseneck cylinder is actuated either hydraulically or pneumatically. In operation the plunger is withdrawn letting the liquid metal into the gooseneck cylinder through the port provided. When the die halves are closed and ready for casting the plunger forces the liquid metal entrapped in the cylinder into the die through the gooseneck passage and a nozzle. After a predetermined time interval the plunger is retracted allowing the liquid metal in the gooseneck channel and nozzle to fall back into cylinder. The die halves are opened and the solidified casting is ejected from the die. Hot chamber machines are designed to operate almost automatically and fast. A press button operation will make the machine go through a complete cycle of activities including closing the die halves, forcing the metal into the die, holding the pressure for a predetermined time, withdrawing the plunger, opening the die, ejecting the casting and stop ready for the next cycle. The operator then removes the casting, inspects the dies, gives spray lubrication to the dies and starts the next cycle. Metal injection speeds and pressures can be controlled to suit different metals and castings.

Since the melting pot plunger and cylinder of a hot chamber die casting machine are made of cast iron and cast iron reacts with metals like aluminium at elevated temperatures, only low melting-point metals can be cast by this method. There is also a limit on the maximum pressure which can be applied. Hot chamber machines are mostly operated below 14 kPa. Alloys of lead, tin and zinc are the most common metals cast by this process

Cold chamber die casting machine:

The metal in this case is melted in a separate furnace and the required quantity of metal is ladled to the machine. A plunger operated hydraulically forces the metal into the die. Injection pressures of 28 kPa to 250 kPa are possible in cold chamber machines. The machine is semiautomatic in that after the metal is ladled into the cold chamber the rest of the operation is automatic. Hot chamber machines are made in capacities varying from 0.25 to 7.5 MN and cold chamber ones from 1 to 10 MN. Advantages of Die Casting Process: Advantages of die casting include excellent die life, high production rates, close dimensional tolerances, good details, and excellent surface finish of the castings. Die casting dies retain their accuracies for long production runs Production rates vary- from 5 to 6 castings per minute with hot chamber machines to 2 to 3 castings per minute when cold chamber machine are used. Dimensional tolerances can be held to 0.075 mm. Very thin sections can be cast and good surface finish obtained with excellent details.

Disadvantages of Die Casting Process:

(1) High cost of dies and machines. (2) Restriction on the size of the casting to about 100 kg for zinc alloys and 30 kg for aluminium alloys: (3) Only certain non-ferrous metals can be economically die cast. (4) Die casting products also are mechanically weaker because of the air entrapped during casting. (5) The entrapped air makes die casting unsuitable for heat treatment. When these castings are heated for heat treatment the entrapped air expands causing blisters to be formed on the surface of the castings.

Das könnte Ihnen auch gefallen

- Starbucks Delivering Customer Service Case Solution PDFDokument2 SeitenStarbucks Delivering Customer Service Case Solution PDFRavia SharmaNoch keine Bewertungen

- Cover LetterDokument2 SeitenCover LetterSasi Gangadhar BNoch keine Bewertungen

- Special Casting ProcessesDokument31 SeitenSpecial Casting Processesdarshan_rudraNoch keine Bewertungen

- Helicopter MaintenanceDokument347 SeitenHelicopter MaintenanceJai Deep88% (24)

- How To Post Bail For Your Temporary Liberty?Dokument5 SeitenHow To Post Bail For Your Temporary Liberty?Ruel Benjamin Bernaldez100% (1)

- Pressure Die CastingDokument62 SeitenPressure Die CastingChetan Nehete100% (2)

- Pressure Die CastingDokument62 SeitenPressure Die CastingARUNSFRH83% (6)

- Die Casting Theory: DTDM Final YearDokument31 SeitenDie Casting Theory: DTDM Final YearpratibhaNoch keine Bewertungen

- DM-1 CO-1 Special Castings MaterialDokument9 SeitenDM-1 CO-1 Special Castings MaterialSree vishnu Sai chandan guntupalliNoch keine Bewertungen

- Interview QuestionDokument22 SeitenInterview QuestionsugeshNoch keine Bewertungen

- Special CastingDokument46 SeitenSpecial CastingJith Viswa100% (1)

- Working of Online Trading in Indian Stock MarketDokument81 SeitenWorking of Online Trading in Indian Stock MarketVarad Mhatre100% (1)

- Lab Report Die CastingDokument12 SeitenLab Report Die CastingaaqibaminNoch keine Bewertungen

- Equipment Design and Drawing: Project ReportDokument40 SeitenEquipment Design and Drawing: Project Reportsurajagtap01Noch keine Bewertungen

- Casting 1Dokument26 SeitenCasting 1Lal KishanNoch keine Bewertungen

- 15ae307j - Aees - Unit 3Dokument41 Seiten15ae307j - Aees - Unit 3Aahana KhannaNoch keine Bewertungen

- Die Casting DieDokument156 SeitenDie Casting DieHeetNoch keine Bewertungen

- Top Notch 1, 3° Edicion Workbook Answer KeyDokument14 SeitenTop Notch 1, 3° Edicion Workbook Answer KeyLuis Lopez90% (61)

- Dr. Babasaheb Ambedkar Technological University, LonereDokument36 SeitenDr. Babasaheb Ambedkar Technological University, LonereNikhil PawarNoch keine Bewertungen

- Sess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Dokument7 SeitenSess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Prakash RagupathyNoch keine Bewertungen

- Continuous Casting: Equipment and ProcessDokument8 SeitenContinuous Casting: Equipment and ProcessErickman Simorangkir100% (1)

- Die CastingDokument6 SeitenDie Castingkutik3bugerNoch keine Bewertungen

- Iwcf Section OneDokument20 SeitenIwcf Section OnesuifengniliuNoch keine Bewertungen

- Die CastingDokument29 SeitenDie CastingUmair MirzaNoch keine Bewertungen

- Revision Questions For Cswip ExamsDokument65 SeitenRevision Questions For Cswip Examshandsomeforever91% (11)

- Die Casting Theory: DTDM Final YearDokument31 SeitenDie Casting Theory: DTDM Final Yearpratibha100% (1)

- 1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IDokument8 Seiten1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IChinmay Das100% (2)

- Unit3 Part C RevisedDokument72 SeitenUnit3 Part C Revisedraymon sharmaNoch keine Bewertungen

- Lecture 26Dokument22 SeitenLecture 26phankhoa83100% (1)

- Al Die CastingDokument11 SeitenAl Die CastingMallesh Munje100% (1)

- Pressure Die-CastingDokument12 SeitenPressure Die-CastingAyush PandeyNoch keine Bewertungen

- Die CastingDokument11 SeitenDie CastingJimmy Clavel100% (1)

- Az 203 PDFDokument337 SeitenAz 203 PDFViktors PetrinaksNoch keine Bewertungen

- Die Casting Is A Manufacturing Process That Can Produce Geometrically Complex Metal Parts Through The Use of Reusable MoldsDokument13 SeitenDie Casting Is A Manufacturing Process That Can Produce Geometrically Complex Metal Parts Through The Use of Reusable MoldsSanjay MukalaNoch keine Bewertungen

- 2.14. Multiple-Use-Mould Casting ProcessesDokument3 Seiten2.14. Multiple-Use-Mould Casting Processesaman chaudharyNoch keine Bewertungen

- Unit-3 - Special Moulding Processes PART-2Dokument25 SeitenUnit-3 - Special Moulding Processes PART-2mahammad kamaluddeenNoch keine Bewertungen

- Zinc High Pressure Die CastingDokument1 SeiteZinc High Pressure Die CastingGutierrezOmar5Noch keine Bewertungen

- Report On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Dokument21 SeitenReport On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Maroof Alam100% (2)

- Casting ProcessDokument6 SeitenCasting ProcessniteshNoch keine Bewertungen

- Nitin 123Dokument18 SeitenNitin 123shayarigurunitinNoch keine Bewertungen

- Casting Its Types 1 (29-40) - 2Dokument12 SeitenCasting Its Types 1 (29-40) - 2VDNoch keine Bewertungen

- Metal Mould-Casting Processes: Unit Iv Moulding ProcessesDokument26 SeitenMetal Mould-Casting Processes: Unit Iv Moulding ProcessesMr. T. Anjaneyulu Mr. T. AnjaneyuluNoch keine Bewertungen

- Die Casting With TypesDokument4 SeitenDie Casting With TypesAdarsh TiwariNoch keine Bewertungen

- Manuf ProcessDokument15 SeitenManuf ProcessKaruppiah ArunachalamNoch keine Bewertungen

- ME - 32021 Chapter (3) Hard Mold Casting ProcessesDokument26 SeitenME - 32021 Chapter (3) Hard Mold Casting ProcessesWILYNoch keine Bewertungen

- Die Casting: Mechanical Manufacturing - IIDokument39 SeitenDie Casting: Mechanical Manufacturing - IIAdnan Javed100% (1)

- DV03PUB23 Study GuideDokument4 SeitenDV03PUB23 Study GuidesobheysaidNoch keine Bewertungen

- Lecture 2 Manufacturing ProcessDokument31 SeitenLecture 2 Manufacturing Processكل ما يريده القلبNoch keine Bewertungen

- Permanent Mold Casting Processes: Usually Made From Metal Gas Pressure or A Vacuum UsedDokument57 SeitenPermanent Mold Casting Processes: Usually Made From Metal Gas Pressure or A Vacuum UsedJacob KussiaNoch keine Bewertungen

- BME B Project Armaan SinghDokument16 SeitenBME B Project Armaan Singharmaansingh 2K20B1220Noch keine Bewertungen

- 8 Die CastingDokument6 Seiten8 Die CastingAkshayNoch keine Bewertungen

- Die-Casting Process: Types, Applications & LimitationsDokument24 SeitenDie-Casting Process: Types, Applications & LimitationssoorajNoch keine Bewertungen

- Die CastingDokument9 SeitenDie CastingBhushan SalunkeNoch keine Bewertungen

- Die Casting ReportDokument11 SeitenDie Casting ReportFaria KhanNoch keine Bewertungen

- 1die CastingDokument71 Seiten1die CastingmaitinNoch keine Bewertungen

- Die CastingDokument8 SeitenDie CastingVishwath RamNoch keine Bewertungen

- Die CastingDokument3 SeitenDie CastingEngr Arfan Ali DhamrahoNoch keine Bewertungen

- RohitDokument19 SeitenRohitshayarigurunitinNoch keine Bewertungen

- Die CastingDokument4 SeitenDie Castingthasarathanr1993_939Noch keine Bewertungen

- Special Casting MethodsDokument73 SeitenSpecial Casting Methods359 Srinivasa RamanNoch keine Bewertungen

- Metal Castings Quality Is Determined by The Casting Properties of The Metal: FluidityDokument28 SeitenMetal Castings Quality Is Determined by The Casting Properties of The Metal: FluidityBharichaloNoch keine Bewertungen

- Topic 4 Contemporary Casting ProcessesDokument47 SeitenTopic 4 Contemporary Casting ProcesseslucasNoch keine Bewertungen

- Department of Technical Education Andhra PradeshDokument27 SeitenDepartment of Technical Education Andhra PradeshRavi RanjanNoch keine Bewertungen

- Estelar: Asting Process Can Be Divided Into Two Basic CategoriesDokument15 SeitenEstelar: Asting Process Can Be Divided Into Two Basic CategoriesVDNoch keine Bewertungen

- 05 CastingDokument19 Seiten05 CastingSports GloballyNoch keine Bewertungen

- Sp. Casting ProcessesDokument71 SeitenSp. Casting Processesakshatkumargarg 2K20PE09Noch keine Bewertungen

- Mechanical Working of MetalsDokument53 SeitenMechanical Working of Metalsmurari100% (3)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeVon EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNoch keine Bewertungen

- Constuction ManagementDokument12 SeitenConstuction ManagementAnand BossNoch keine Bewertungen

- Important Points in SurveyingDokument4 SeitenImportant Points in SurveyingAnand BossNoch keine Bewertungen

- Pavement Skidding, Pavement Uneveness, Pavement InstrumentationDokument32 SeitenPavement Skidding, Pavement Uneveness, Pavement InstrumentationAnand BossNoch keine Bewertungen

- ErtyerDokument3 SeitenErtyerAnand BossNoch keine Bewertungen

- ErtyerDokument3 SeitenErtyerAnand BossNoch keine Bewertungen

- Licencias AVAST 5 Hasta 2038Dokument1 SeiteLicencias AVAST 5 Hasta 2038yersyniNoch keine Bewertungen

- Licencias AVAST 5 Hasta 2038Dokument1 SeiteLicencias AVAST 5 Hasta 2038yersyniNoch keine Bewertungen

- Application For Type Aircraft Training: Farsco Training Center IR.147.12Dokument1 SeiteApplication For Type Aircraft Training: Farsco Training Center IR.147.12benyamin karimiNoch keine Bewertungen

- Google Translate - Google SearchDokument1 SeiteGoogle Translate - Google SearchNicole Alex Bustamante CamposNoch keine Bewertungen

- SIFI-131 Fire Protection in Electrical Equipment RoomsDokument8 SeitenSIFI-131 Fire Protection in Electrical Equipment RoomsemiljanlazeNoch keine Bewertungen

- SLA707xM Series: 2-Phase Unipolar Stepper Motor DriverDokument20 SeitenSLA707xM Series: 2-Phase Unipolar Stepper Motor DriverKatherine EsperillaNoch keine Bewertungen

- Piston EffectDokument11 SeitenPiston EffectBK180Noch keine Bewertungen

- Kamaka Company Catalogue 2016 PDFDokument13 SeitenKamaka Company Catalogue 2016 PDFWendy0% (3)

- NISE3600EDokument2 SeitenNISE3600ENgo CuongNoch keine Bewertungen

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectDokument10 SeitenMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiNoch keine Bewertungen

- Sikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetDokument3 SeitenSikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetKhin Sandi KoNoch keine Bewertungen

- Nil Queries Sheet: S. No. ProcessDokument24 SeitenNil Queries Sheet: S. No. ProcessTarun BhardwajNoch keine Bewertungen

- Nigeria Country Profile - 0Dokument4 SeitenNigeria Country Profile - 0Nden SohbutNoch keine Bewertungen

- Sinteza Engleza TradusaDokument6 SeitenSinteza Engleza TradusaRobert TintaNoch keine Bewertungen

- Pmwasabi EB3Dokument4 SeitenPmwasabi EB3AlleleBiotechNoch keine Bewertungen

- Device Protocol - v2.2.4Dokument81 SeitenDevice Protocol - v2.2.4Aston MartinNoch keine Bewertungen

- The Effect of Cross-Cultural Management On The Performance of Multinational Companies in NigeriaDokument13 SeitenThe Effect of Cross-Cultural Management On The Performance of Multinational Companies in NigeriaPreethu GowdaNoch keine Bewertungen

- " My Heart Will Go On ": Vocal: Celine DionDokument8 Seiten" My Heart Will Go On ": Vocal: Celine DionLail Nugraha PratamaNoch keine Bewertungen

- Tia-Eia-Is 801-1 - 2001Dokument148 SeitenTia-Eia-Is 801-1 - 2001John UrdanetaNoch keine Bewertungen

- Micro Link Information Technology Business College: Department of Software EngineeringDokument34 SeitenMicro Link Information Technology Business College: Department of Software Engineeringbeki4Noch keine Bewertungen

- Social Studies 2014 Qu and AnsDokument18 SeitenSocial Studies 2014 Qu and AnsSaidu H SwarayNoch keine Bewertungen

- Bodie8ce FormulaSheet PDFDokument24 SeitenBodie8ce FormulaSheet PDFSandini Dharmasena PereraNoch keine Bewertungen

- GNDDokument16 SeitenGNDDEAN TENDEKAI CHIKOWONoch keine Bewertungen

- 1.doosan D1146Dokument1 Seite1.doosan D1146Md. ShohelNoch keine Bewertungen