Beruflich Dokumente

Kultur Dokumente

Heat Transfer To Liquid Nitrogen Droplets During

Hochgeladen von

Leonid PastukhovOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Transfer To Liquid Nitrogen Droplets During

Hochgeladen von

Leonid PastukhovCopyright:

Verfügbare Formate

Pertanika 8(1), 79 - 88 (1985)

Heat transfer to Liquid Nitrogen Droplets during

Cyrogenic Freezing of Foods

MOHD. ALI HASSAN, DZULKIFLY MAT HASHIM and RUSSLY ABDUL RAHMAN

Department of Food Technology,

Faculty of Food Science and Technology,

Universiti Pertanian Malaysia,

Serdang, Selangor, Malaysia.

Key words: Heat transfer; liquid nitrogen droplets; cyrogenic freezing of foods.

ABSTRAK

Kajian ini dilakukan untuk menyelidiki fenomena pemindahan haba yang terjadi apabila

titik-titik cecair nitrogen jatuh ke atas permukaanmakanan. Kepingan gelatin digunakan sebagai

bahan makanan. Nitrogen cair dijatuhkan ke atasnya daripada sistem penjatuh/ bakungan. Suhu ke-

pingan serta masa penyejatan titik tersebut dzukur bagi suatu jangkamasa tertentu. Danpada nz"lai-

nz"lai inz; koefisien pemindahan haba dzkira. Ia dibandingkan dengan nlai ramalan teori dan

didapati nilai yf!-ng dzperolehz" adalah tiga hingga empat kalz" "lebih tinggi. Walau bagaimanapun

dengan mengambz"lkra bahawa titk tersebut menjadi semakin ke.c[ semasa penyejatan, nilai purata

kofilisien pemindahan haba di dalam julat tersebut menjadi lebz"h hampir kepada nilai teon; iatu

kuiang danpada dua kali ganda lebz"h tinggi.

ABSTRACT

This work investigates the heat transfer phenomena that occurs when lz"quid nitrogen droplets

fall onto afood surface. A gelatin slab was used as the food material. Liquid nitrogen was dropped on

it from a dropper/reservoir system. The temperature of the slab and the droplet evaporation time

were measured over a period of time. The heat transfer coeffcents were calculatedfrom these values.

These are compared with the theoretical predicted values. It is seen that the experimental values are

three to four times hz"gher than the predicted values. However, if the average value of heat transfer

coeffcent is taken over the whole size range as the droplet evaporates, a closer agreement is obtained

- the experimental values being less than twice hz"gher.

INTRODUCTION

Industrially, liquid nitrogen is used to

cyrogenically freeze foods at it gives very high

freezing rates due to its low boiling point of

. -195.8C at atmospheric pressure. An added

advantage is that it gives individually quick

frozen items. Liquid nitrogen is 0lle of the few

refrigerants which can come into intimate con-

tact with foodstuffs without causing adverse

effects - it is tasteless, chemically inert, sterile

and has a very low liquid viscosity.

Liquid nitrogen is sprayed onto the foods to

provide the cooling effect. Freezing by immer-

sion of foodstuffs in liquid nitrogen is generally

regarded as an inefficient method despite a high

heat transfer coefficient in the nucleate boiling

region. This is due to the fact that the spheroidal

heat transfer coefficient is a hundred fold lower,

i.e. the coefficient of heat transfer when a solid

sphere or food material -is in contact with the

liquid refrigerant causing vigorous boiling as a

result of the large temperature difference (Anon,

1969).

MOHD AHLI HASSAN

It is a normal practice to have an initial pre-

cooling section in a cryogenic freezer where the

product is cooled by an air/nitrogen mixture at a

temperature of around -100C. In this section,

the product is brought down to a temperature of

around OC. This chilled product is then sub-

jected to a spray of liquid nitrogen droplets.

When the liquid nitrogen hits the food surface, it

immediately enters into the film boiling regime,

due to the large temperature difference between

the product and the liquid nitrogen. Film boil-

ing of discrete masses of liquid is commonly

referred to as the Leidenfrost phenomena

(Keshock <j.nd Bell, 1970); this is in constrast with

pool film boiling where the liquid is of essentially

infinite extent. A well known manifestation of

the phenomenon is the action of water droplets

splashed on a frying pan whose surface is so hot

that nucleate boiling cannot occur.

log..9:..

A

(Heat flux)

A B

log

A Natural Convection

B Nucleate Boiling

C Metastable Film Boiling

D Fihn Boiling (Stable)

X Leidenfrost Temperature

C D

6 T (surface temp. - bulk temp,)

In the Leidenfrost region, since there is con-

siderable vapour formation, the droplets are

surrounded by a vapour blanket. When they

meet the food surface, the liquid evaporating

from the bottom part of the drop produces a

"vapour cushion" with a slight positive pressure

(Wachters and Bonne, 1966) enough to keep

the drop suspended above the food surface (See

Fig. 1). Hence the drops do not actually touch

the food surfaces, and this has the effect of

reducing the overall heat transfer, since heat

transfer then occurs by conduction through a

vapour phase (Keshock and Bell, 1970).

vapour flow

'>... food surface

Fig. 1. Liquid nitrogen drop on afood surface.

From the boiling heat transfer curve shown

(Flynn et al., 1962) (Hg. 2), the region of

nucleate boiling (region B) gives high heat flux,

i.e. high heat transfer coefficients. Unfortu-

nately, due to the Leidenfrost boiling (film boil-

ing of liquid nitrogen drops) which involves a

blanketting vapour film, the heat transfer coeffi-

cient is reduced. Hence a much higher tempera-

ture difference is required for the same heat flux

(region D).

Fig. 2. Bo#ing heat transfer curve.

In the freezing process, we aim to achieve

high heat rates. Since high heat tramfer

rates are possible with lower values of 6 T

(region B), it is therefore evident that the freez-

ing process needs to be closely controlled. If the

foodstuffs are immersed in liquid nitrogen, the

temperature is high enough to push the point of

boiling towards region D. In the spray system

however, the process can be controlled by spray-

ing liquid nitrogen droplets onto the food su.r-

face and using the cold gaseous mixture of air

and nitrogen at around -100C to provide the

precooling. This also has the advantage of mini-

mising bio-physical stresses in the food and

reducing damage to the cells.

Heat Transfer Coeffident

Baumeister, Hamill and Schoessow (1966)

used dimensionless parameters for volume, area,

latent heat and vapourisation time to predict the

Leidenfrost heat transfer coefficients. Different

correlations are given for different drop sizes.

The size range is' classified by using the dimen-

sionless volume v* given by:

80 PERTANIKA VOL. 8 NO.1. 1985

HEAT TRANSFER DURING CYRO.GENIC FREEZING OF FOODS

The classification is given in Table 1.

In the present work, the drop diameter used

is 2.37 mm. When the values of 0.0827 N/m and

804 kg/m 3 are substituted for the surface tension

and density of liquid nitrogen at atmospheric

pressure respectively (Weast, 1973), a value of

6.9 for v* is obtained. Hence we are in the large

drop domain.

Keshoc;:k and Bell (1970) pointed out that

the parameters are 30% below the theoretical

curve. for liquid nitrogen Leidenfrost pheno-

menon although the experimental data con-

forms with the general trend of the theory. They

also suggested that the actual heat transfer

coefficient in the Leidenfrost boiling region was

30% higher than the prediction made by

Baumeister et al. (1966).

Baumeister's analyses were based upon a

drop model in the shape of a cylindrical disk,

separated from the solid surface by a constant

gap thickness. In his model, drop vapourisation

occurs because of energy addition to the lower

drop surface by conduction across the constant

vapour-fIlm thickness; mass diffusion from the

top and sides is assumed negligible and radiation

is neglected.

The research work carried out in this pro-

ject involves measuring the evaporation time

associated with single drops dropped onto a

gelatin slab and the temperature drop expe-

rienced by the gelatin s l ~ b . These enable .us to

calculate the heat transfer rates and the heat

transfer coefficient. The results obtained are

then compared with the theoretical predictions

of heattransfer coefficients due to fIlmboiling of

nitrogen drops on horizontal surfaces. These

results on single droplet be"haviour should give

an insight into the problems associated with the

spray system in the liquid nitrogen freezing

plant.

MATERIALS AND METHODS

In order to produce single drops of nit-

rogen, a dropper system was designed. It consist-

ed of a copper c)'linder; 2.5 cm internal

diameter and 20 cm long. A piece of 2.5 cm

diameter brass with a small spout was welded to

the base of the cylinder. The brass had a 3 mm

hole drilled at the centre. A small 26 gauge

hypodermic needle was attached to the spout.

The whole unit was insulated with 7 cm thickness

expanded polystyrene, to reduce the rate of heat

flow into the reservoir when it was filled with

liquid nitrogen. In order to obtain single drops

of liquid nitrogen, a very fine wire was inserted

through the hypoaermic needle and bent to form

a very small loop. Single drops of consistent size

was formed.

A gelatin slab about 1.5 cm thick in a petri

dish was used as the food material. The gelatin

was prepared by dissolving 10 grams of gelatin

into 100 ml of hot water to obtain the right

texture and hardness. The ratio of 1 : 10 was

found to be satisfactory.

When the nitrogen droplets fall on the

surface, it moves about from side to side, effec-

tively floating on the vapour cushion. In order to

keep it stationary, a small indentation was made

TABLE 1

Classification of drop domain

Volume Range

Drop Domain Representation

~ . 0.8

Small spheroid

V*

~ ~ ~ ~ ~

0.8

<

V* ~ 155 Large drop

...

~ ~ ~ ~

V*

>

155

Extended drop

(constant thickness)

" ' ~ ~ ~ ~ ~

PERTANlKA VOL. 8 NO. I, 1985 81

MOHD ALI HASSAN

on the surface and liquid nitrogen was dropped

into it.

heat transfer rates to the higher temperature

range (from OC to - 30C).

Temperature Measurement

Measurement of temperature was done by

placing a thermocouple just underneath the

indentation and another at a point 3 cm away.

The temperature measurement was recorded.on

a chart recorder. Hence a comparison could be

made between the cooling due to the nitrogen

drops and that due to the cold medium.

,(the insulation is not shown here)

Fig. 3. The modified dropperlreservoir system.

Hem

1"'"1

, I

I I

I I

f I

I I

fl

I I

I I

I I

: i

, I

f I

, I

I I

I I

I

I

I

I

I

I

I I

' ~ [ ~ ~ . l II

1..

s

u

o

CN

A dewar vessel with a small window was

tried. Temperatures of -lOOC could be easily

achieved inside the dewar when it was filled with

liquid nitrogen. However, when the gelatin slab

was placed in the cold environment at -100C,

there was considerable 'haze', Le. a foggy

environment was produced. It was impossible to

see whether the nitrogen drops had fallen exactiy

into the surface indentation on the slab. A diffe-

rent apparatus which consisted of a reservoir

with provision for liquid nitrogen to be circulat-

ed around its base (see Fig. 3) to provide the

cooling effect was tried. This was done in order

to reduce the temperature of the surrounding air

around the bottom of the reservoir. The reser-

voir consisted of a copper cylinder of 14 cm

internal diameter and 20 cm in height. A similar

hypodermic needle was attached to its base to

reduce the nitrogen drops. The reservoir was

insulated with 5 cm of polystyrene, but this time

the base was left uninsulated to produce the cold

environment.

As mentioned earlier, industrially the freez-

ing of foods using liquid nitrogen is done in a

medium consiSting of nitrogen and air at about

-lOOC. However in the present study, with

liquid nitrogen droplets falling over a distance of

about 3 cm onto the gelatin slab in open labo-

ratory conditions, the air/nitrogen cloud

surrounding the slab surface was at - lOoC to

- 20C. Hence to obtain results at medium tem-

peratures around -lOOC, a separate cooling

apparatus was required.

When this apparatus was tried out, there

was a lot of 'drip' and wetting on the outside at

the base of the copper vessel due to condensation

of atmospheric oxygen which provided addi-

tional cooling on the gelatin slab. An attempt to

eliminate the drops by placing a very thin layer

of glass fibre for insulation at the base of the

reservoir resulted in the temperature of the air

around the base of the cylinder being only

- 30C. Due to the difficulties involved in

achieving the -100C working environment, it

was decided to restrict the experiments on the

Evaporation Time ofthe Droplet

The evaporation time of the drops is diffi-

cult to measure visually, for evaporation occurs

at a rapid rate and moreover it is difficult to

determine when exactly the drop has totally

evaporated. However, from the chart recorder

measurements of the temperature against time,

it was observed that when the droplet fell into

the hole, the temperature there started to drop

sharply. When the droplet had evaporated,

there was again a sharp increase in the tempera-

82 PERTANlKA VOL. 8 NO.1, 1985

HEAT TRANSFER DURING CYROGENIC FREEZING OF FOODS

. Fig. 4. Temperature ofslab surface against medium

temperature.

A temperature drop caused by the

rutrogen drops.

B Temperature drop caused by the cold medium.

....

10

4

2

o

-2

-4

-6

-8

.-10

-12

-14

-16

-18

-20

-22

Medium. temperature

ture. Hence, the evaporation time of the droplet

on the gelatin surface can be taken as the time

from which the temperature measurement on

the recorder statts to fall sharply until it starts to

rise sharply again.

Droplet Size

The droplet size was measured by an impact

technique. The droplets were allowed to fall

onto fine nickel powder, placed in a petri dish

at a distance of 3 cm from the droplet formation

site i.e. of equal distance between the droplet

formation site and the gelatin slab. The droplets

evaporated on this powder-and left a crater. The

crater size diameter was measured for several

drops. It was observed that by using the same 26

gauge needle and the fine wire through it, the

diameter of the crater was quite consistent.

From the diameter of the crater, the' actual

size of the drpps is given by the formula quoted

by May (1950) as

d =! xC

C t

where d is the actual diameter of the drop; I )sa

coefficient which depends on the droplet size

range, and C t is the crater diameter. For drop

sizes from 200 to 2000 microns, May suggested a

value of 0.86 for C .

t

RESULTS

The instantaneous temperature drop of the

gelatin slab due to the heat transfer by the liquid

nitrogen droplets were measured at medium

temperature of OC to - 30C to determine the

effect of medium temperature on the heat

transfer rate. The other parametres (the droplet

size, the initial temperature of the gelatin slab,

the frequency of the droplets) were kept

constant. The results are shown in Fig. 4. The

droplet evaporation time at a medium tempera-

ture of - 20C is given in Fig. 5.

Heat Transfer Rates

Neglecting heat transfer by radiation and

convection to the surrounding medium, the rate

of heat transfer due to the nitrogen droplets on

the gelatin surface is given by:

Q= h.A. !::,T (1)

where h is the overall heat transfer coefficient,

A is the effective heat transfer area of the

drop on the gelatin surface, and

!::,T is the temperature difference between the

droplet and the surface of the gelatin.

The effective area of the droplet, is given by

Baumeister et al. (1966) as the average of the

projected area of the sphere (i.e. 1Tr

Z

) and the

surface area of the lower half of the sphere (i.e.

2 1Tr

Z

). So, the effective area is

A == 1.5 7Tr

z

This is for a small liquid droplet on. a flat

surface. In the present work, since the droplets

actually fall into an indentation on the surface

whose diameter is of the same order of magni-

tude as the drop, it is deemed more reasonable to

assume that a larger part of the droplet surface

area is involved in the heat transfer to the gelatin

slab. The surface area chosen is half the surface

PERTANIKA VOL. 8 NO. I, 1985

83

MOHO ALI HASSAN

t

Slab surface temperature

when d is the initial drop diameter. The final

drop volume is zero since all the drop evaporates.

If we let the time for the droplets to evapo-

rate be t, then the heat transfer rate

Q = Ax 1r x PLX d 5/6 x t (2)

area of a sphere. i.e. the surface area of the

lower half of the drop. So, the heat transfer area 1200

A is given by:

A = 2 1rr

2

-4

-5

(3)

Heat transfer

coefficient

0N/m

2

K)

Table 2 gives the evaporation time of the

droplet at various temperatures of the slab and

the average temperature difference 6. T. Values

of 191500 j/kg and 804 kg/m 5 are used for the

latent heat anc!- density of liquid nitrogen at

atmospheric boiling point. The initial droplet

diameter is 2.37 mm. The average temperature

difference !:I T is taken as the difference between

the atmospheric boiling point of liquid nitrogen

and the average temperature of the gelatin slab

due to the liquid nitrogen droplets at the inden-

tation. The droplet evaporation time is obtained

from Fig. 5.

The heat transfer coefficient between the

nitrogen drops and the gelatin surface calculated

from equation (3) is plotted against the freezing

time in Fig. 6.

Heat Transfer Coefficient

Equating equation (1) and (2) and re-

arranging, we get

1r

h = 6" A . P

L

. d

3

fA . !:IT.t

e

0.6 0.7 0.8 0.9 1.0

Droplet Evaporation Time (sees)

Fig. 5. Graph ofslab surface temperature against

droplet evaporation time.

o

2

-6

0.5

-3

-2

-1

1050

900:

18 24 30 36 42 48 54 60 66

Time (mins)

6

Fig. 6. Experimental heat transfer coefficient against

time.

750 L

o

If we assume that the droplets are spherical

Gustifiable for small drops with v* = 6.9), then

the initial drop volume is V = d 5

6

If we assume that the rate of evaporation of

the drops is constant. then the heat transfer rate

Qis also given by:

Q = Ax (rate of evaporation of drops in

kg/s)

Ax (volumetric rate-of evaporation of

dropx P

L

)

84 PERTANlKA VOL. 8 NO.1. 1985

HEAT TRANSFER DURING CYROGENIC FREEZING OF FOODS

TABLE 2

Droplet evaporation time at Mean Slab Temperatures

(Medium temperature: - 20C)

Average temp. of slab surface

Temp. of slab surface due to nitrogen drops Average Temp. Diff. Droplet Evaporation

(0C) (0C) 6 T (0C) Time (sees)

3.5

-23.5 172.3 0.600

3.0

-25.0 170.8 0.650

2.0 -25.0 170.8 0.725

1.0

-24.5 171.3 0.780

0

-23.5 172.3 0.825

-1.0 -32.5 163.3 0.865

-2.0 -20.0 175.8 0.900

-3.0

-26.0 169.8 0.935

-4.0 - 32.0 163.8 0.965

-5.0 -35.0 160.8 0.85

-5.5 - 35.5 160.3 1.000

DISCUSSION

The theoretical value for the heat transfer'

coefficient is calculated for comparison with the

experimental values. In the large drop domain,

Baumeister et at. (1966) suggested that

h = 1.075 [k

3

. gY> cry, . PL Y, ". Pv . 'A ] y., (4)

6T . /-Lv . V

2

/

3

The temperature of the vapour in-between

the drop and the slab is assumed to be between

-195.8C and - 30C (slab temperature). The

values of the vapour properties used are at

-173C. The modified latent heat of vapourisa-

tion of liquid nitrogen (Baumeister et at. 1966) is

given by:

'A* = 'A [ 1 +.l X ~ p . 6T 1- 3

20 'A

The droplet diameter that is involved is only

2.37 mm. Due to the low surface tension of nitro-

gen, the dimensionless drop volume v gives a

value of 6.9. Hence it is in the large drop

domain. Since the value of 6.9 for V is at the

low end of the range for the large drop, and

since the drop actually sits around the identation

on the slab, it is deemed reasonable to assume

that the droplets acquire a greater degree of

sphericity than on a flat surface. Hence it is

possible to assume that the droplets are in fact

spherical and in the small spheroid drop

domain, where the heat transfer coefficient

(Baumeister et at., 1966) is given by:

h= 1.1 [k

3

. 'A*. g. PL' Pv ]'1. (5)

6T . /-Lv . Vl/3

Table 3 gives the value of the heat transfer

coefficient for different 6 T for both the large

drop and the small drop domain, calculated

using equations (4) and (5) respectively.

Hence it is seen that by assuming a large

drop domain, the heat transfer coefficient is be-

tween 275 W1m 2K and 284 W1m2K; whereas by

assuming the drop to be in the small drop

domain, the value of the heat transfer coefficient

is between 329 W1m2K and 339 W1m2K.

However the experimental value is from 1174

W/m

2

K to758 W/m 2K.

The theoretical value of the heat transfer

coefficient assuming a small drop domain gives a

PERTANlKA VOL. 8 NO. I, 1985 85

MOHD ALI HA.SSAN

TABLE 3

Theoritical heat transfer coefficient at different t:.T

Heat transfer coefficient (W1mi\.) h; assuming

Time Average t:.T A* Large drop Small drop

(mins)

(0C)

Qlkg)

6 172.3 "82231 275 329

8.5 170.8 82760 276 330

9.5 170.8 82760 276 330

13 17l.3 82583 276 330

15 172.3 82231 275 329

21.5 163.3 85478 282 337

32 175.8 81012 273 326

42 169.8 83116 277 331

53 163.8 85293 281 336

62 160.8 86410 284 339

65 160.3 86598 284 339

better agreement to the experimental value com-

pared with the heat transfer coefficient calculat-

ed by assuming the large drop domain. This

suggests that the drop may actually be more

spherical than it appears to be by just consider-

ing the v* range.

However the experimental values are higher

by a factor of three to four than the theoretical

ones. Keshock and Bell (1970) also reported this

where they showed that for the larger drops, the

difference between experimental and theoretical

values is large, but for small droplets the agree-

ment was quite good. In this present work how-

ever, the difference is quite large although we

are dealing with small drop sizes.

If we consider that the droplets actually

decrease in size as they evaporate, we can cal-

cuIate the theoretical heat transfer coefficient

for varying drop sizes (see Table 4).

The values of the heat transfer coefficient in

Table 4 is calculated at 168 K, Le. the arith-

metic mean of the temperature difference t:. T

given in Table 2.

It is evident from Table 4 that the heat

transfer coefficient increases with decreasing

drop sizes. In the experimental value, the heat

transfer coefficient is calculated using the largest

drop size and the evaporation rate was assumed

constant. If we compare the experimental value

with the average value of the heat transfer coeffi-

cient at varying drop sizes, we get a better agree-

ment with the theory.

86

TABLE 4

Theoretical heat transfer coefficient at different drop sizes

Drop diameter Drop volume V dimensionless drop Heat transfer coefficient h

(m) (ml Volume V* (W/m i\.)

0.00237 6.970175 X

10 -9

6.5 (large drop) 278

0.001 5.235988 X

10 -10

0.49 (small drop) 413

0.0005 6.544985 X

10 -10

0.06 (small drop) 491

0.00005 6;544985 X

10 -14

0.000061 (small drop) 873

PER'I'ANIKA VOL. 8 NO.1. 1985

HEAT TRANSFER DURING CYROGENIC FREEZING OF FOODS

The other factor that is noticeable is that

from the theory, the heat transfer coefficient

rises slightly with time, i.e. it rises with decreas-

ing !:J. T. This is not so in the experimental

values which decrease with decreasing !:J. T. In

the theoretical expressions the only variable is !:J.

T (since A* also varies with !:J. T). A* increases

with decreasing !:J. T and the total effect is to

increase the heat transfer coefficient. In the

experimental expression, the heat transfer co-

efficient is inversely proportional to the product

of !:J. T and the evaporation time t. Although

!:J. T decreases with time, t increases from 0.6

seconds to 1.0 second. The sum effect is to

reduce the heat transfer coefficient with decreas-

ing !:J. T. This difference in behaviour between

the theoretical and the experimental values' is

believed to have been due to the fact that the

evaporation time included in the calculation of

the experimental value varies with !:J. T, whereas

in the theoretical expressions, no evaporation

time is included.

The droplet evaporation time increases with

decreasing !:J. T. This is expected since the de-

creasing !:J. T, the driving force for evaporation

to occur is less and hence it takes longer to

evaporate.

CONCLUSION

The experimental heat transfer coefficient

obtained is about three 'to four times higher than

the theoretical predictions. Keshock and Bell

(1970) also found that the theoretical values are

lower than the experimental ones, but they

reported that for small droplets (less than 0.1 ml)

the difference is not excessive. The droplet size

that we are working with is much less than this,

but still the difference is quite substantial. If

however, we taken an average value of the theo-

retical heat transfer coefficient over varying drop

sizes as the droplet evaporates, we get quite a

good approximation to the theory - the experi-

mental values being higher by a factor of one

and a half to two.

From the v* of 6.9, the droplets fall into

the large drop domain. It is helieved that since

the drops were made to fall into a hole, it takes a

more spherical shape. By calculating the theore-

tical values of t.he heat transfer coefficients, the

values in the smalldrop domain gives a better

approximation to the experimental ones. This

suggests that the droplets may in fact be'sphe-

rical.

Another difference between the theoretical

and experimental values is that whilst the experi-

mental values of the heat transfer coefficient

decrease with decreasing !:J. T, the theoretical

values show a slight increase. In the expression to

calculate the experimental value the vapourisa-

tion time is present and has the effect of decreas-

ing the heat transfer coefficient. In the theore-

tical expression however, the only variable is

!:J.T.

It is thought essential that for future work in

this area, some thought be given to designing a

dropper system which would produce consistent

drop frequency throughout the entire experi-

ment. Ice deposition can be reduced if the work

is done in a more enclosed environment. Also, in

order to achieve realistic values of the heat

transfer coefficient as in the cryogenic freezers,

the medium temperature needs to be around

- 100C. More accurate values for the droplet

evaporation time can be obtained by using

photographic techniques.

It is suggested that future work should in-

clude photographic and microscopic studies of

the droplet on the food surface. From these we

can ascertain what the drop domain is. I ~ might

provide further insight into the Leidenfrost boil-

ing phenomena.

The effect of droplet velocity is not included

here. Further research could include this

variable. It is believed that the droplet velocity in

the spray system can have a marked effect on the

heat traIll'fer coefficient.

Evaporative cooling effect is also not dealt

with here. If the temperature of the droplets can

be measured as it evaporates, then this effect can

be taken into account. If it is significant, then

the temperature'difference between the droplet

and the slab can be corrected. This would have

an effect of reducing the experimental heat

transfer coefficient.

PERTANlKA VOL. 8 NO. I. 1985

87

MOHD ALI HASSAN

NOMENCLATURE

A surface area of droplet

A* dimensionless surface area of droplet

C p specific heat of vapour at constant pressure

f radiation correction factor

g gravitational acceleration

h heat transfer coefficient to the drop

. h* dimensionless heat transfer coefficient to the drop

k thermal conductivity of vapour underneath drop

t evaporation time of droplet

t* dimensionless evaporation time to droplet

T temperature of food su.rface

p

T temperature difference between food surface and the drop

y volume of drop

y* dimensionless volume of drop

a surface tension of liquid droplet

A latent heat of vapourisation

A* modified latent heat of vapourisation

P

L

liquid density

P

v

vapour density

J1 dynamic viscosity of vapour

REFERENCES

ANON. (1969): Food freezing with liquid nitro-

gen. Food Technology in New Zealand. 4: 1.

BAUMEISTER, K.J., HAMILL, T.D. and SCHORS-

SOW, G.J. (1966): A generalised correlation

in vapourisation times of drops in film boil-

ing on a flat plat. Proceedings of the Third

International Heat Transfer Conference.

American Instz"tute of Chemical Engineers.

4: 66.

BAUMEISTER, K.J., KESHOCK, E.G. and PUCCI,

D.A. (1971): Anomalous behaviour of liquid

nitrogen drops in film boilding. Advances in

Cryogenic Engineering. 16: 445.

BELL, K.J. (1967): The Leidenfrost phenomena:

A survey, Chemical Engineering Progress

Symposium Series. 63: 73 -79.

FLYNN, T.M., DRAPER, J.W. and Ross, J.J.

(1962): The nucleate and film boiling curve

of liquid nitrogen at one atmosphere.

Advances in Cryogenic Freezing. 7: 539.

Hsu, Y.Y. (1971): A review in film boiling at

cryogenic temperatures. Advances in .Cryo-

genic Engineering. 17: 361.

KESHOCK, E.G. and BELL, K.J. (1970): Heat

transfer coefficient measurement of liquid

nitrogen drops undergoing film boiling.

Advances in Cryogenic Engineering. 15:

271.

WATCHERS, L.H.J. and BONNE, H. (1966): The

heat transfer from a hot horizontal plate to

sensile water drops in the spheroidal state.

Chemical Engineering Science. 21: 923-

936.

WEAST, R.C. (1973): Handbook of Chemistry

and Physics. 54th. Edition.

(Received 7 April, 1984)

88

PERTANlKA VOL. 8 NO.1. 1985

Das könnte Ihnen auch gefallen

- Filmwise and Dropwise ExperimentDokument16 SeitenFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- Filmwise and Dropwise ExperimentDokument33 SeitenFilmwise and Dropwise ExperimentValentinoDullSatin100% (2)

- 7000 Technical Ebooks Free Download (Links)Dokument572 Seiten7000 Technical Ebooks Free Download (Links)Javed Mohammed50% (2)

- Direct To TOEFL iBT Answer KeyDokument44 SeitenDirect To TOEFL iBT Answer KeyLeonid Pastukhov50% (12)

- Standard Practice For Conditioning Plastics For TestingDokument4 SeitenStandard Practice For Conditioning Plastics For TestingJORGE ARMANDO CASTRO ESCUDERONoch keine Bewertungen

- Measuremen: in ADGE - 104 (General Chemistry)Dokument22 SeitenMeasuremen: in ADGE - 104 (General Chemistry)Narag KrizzaNoch keine Bewertungen

- Pressure Cooker PDFDokument6 SeitenPressure Cooker PDFTooba GhouriNoch keine Bewertungen

- Research TopicDokument2 SeitenResearch TopicAbhijit PalNoch keine Bewertungen

- Spray Cooling in A Closed System With Different Fractions of Non-Condensibles in The EnvironmentDokument16 SeitenSpray Cooling in A Closed System With Different Fractions of Non-Condensibles in The Environmentbruce1312Noch keine Bewertungen

- Analysis of The Pressure Rise in A Partially Filled Liquid Tank in Microgravity With Low Wall Heat Flux and Simultaneous Boiling and CondensationDokument12 SeitenAnalysis of The Pressure Rise in A Partially Filled Liquid Tank in Microgravity With Low Wall Heat Flux and Simultaneous Boiling and Condensationedgardiaz5519Noch keine Bewertungen

- Heat Transfer in Freeze-Drying ApparatusDokument25 SeitenHeat Transfer in Freeze-Drying ApparatusErickMartinS100% (1)

- Film Boiling Heat Transfer of Droplet Streams and SpraysDokument15 SeitenFilm Boiling Heat Transfer of Droplet Streams and SprayseidelsayedNoch keine Bewertungen

- 1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfDokument15 Seiten1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfMutant_DNANoch keine Bewertungen

- Heat Mass TransferDokument5 SeitenHeat Mass Transferlampshade17Noch keine Bewertungen

- The Rice InstituteDokument52 SeitenThe Rice InstituteAyush SinghNoch keine Bewertungen

- Primary Drying: The Sublimation of Ice: 8.1 Principles of Coupled Heat and Mass TransferDokument16 SeitenPrimary Drying: The Sublimation of Ice: 8.1 Principles of Coupled Heat and Mass TransferLIZETH YULIANA FAJARDO CENDALESNoch keine Bewertungen

- Condensation On Inclined SurfacesDokument8 SeitenCondensation On Inclined SurfacesSutanwi LahiriNoch keine Bewertungen

- Experiment No. 7: Objective: Apparatus: ComponentsDokument5 SeitenExperiment No. 7: Objective: Apparatus: ComponentsHannanNoch keine Bewertungen

- Filmwise and Dropwise ExperimentDokument16 SeitenFilmwise and Dropwise ExperimentHafizszul FeyzulNoch keine Bewertungen

- Lab Manual Exp 2-Boiling Heat TransferDokument7 SeitenLab Manual Exp 2-Boiling Heat TransferChong EkNoch keine Bewertungen

- Boiling and Condensation Heat TransferDokument30 SeitenBoiling and Condensation Heat TransferzetseatNoch keine Bewertungen

- Heat Transfer TheoryDokument6 SeitenHeat Transfer TheoryKTINE08Noch keine Bewertungen

- Heat Transfer in Freeze-Drying ApparatusDokument25 SeitenHeat Transfer in Freeze-Drying Apparatustwintwin91Noch keine Bewertungen

- International Journal of Heat and Mass Transfer: Robert A. Taylor, Patrick E. PhelanDokument9 SeitenInternational Journal of Heat and Mass Transfer: Robert A. Taylor, Patrick E. PhelanSaad Ayub JajjaNoch keine Bewertungen

- Natural Convection Heat Transfer in Vertical Internally Finned TubeDokument10 SeitenNatural Convection Heat Transfer in Vertical Internally Finned TubeAdarsh Kumar AngNoch keine Bewertungen

- Numerical Simulations of The Dynamics and Heat Transfer Associated With A Single Bubble in Subcooled Pool BoilingDokument15 SeitenNumerical Simulations of The Dynamics and Heat Transfer Associated With A Single Bubble in Subcooled Pool Boiling9thwonder10Noch keine Bewertungen

- RAC Experiment 01Dokument24 SeitenRAC Experiment 01Sudhir AdsulNoch keine Bewertungen

- Doble Tubo 2016 01Dokument9 SeitenDoble Tubo 2016 01Francisco Meneses FajardoNoch keine Bewertungen

- International Journal of Heat and Fluid Flow: J. Cui, W.Z. Li, Y. Liu, Y.S. ZhaoDokument12 SeitenInternational Journal of Heat and Fluid Flow: J. Cui, W.Z. Li, Y. Liu, Y.S. ZhaoFahmi KhaerulNoch keine Bewertungen

- 2006 Experimental Investigation of Oxide Nanofluids Laminar Flow Convective Heat TransferDokument7 Seiten2006 Experimental Investigation of Oxide Nanofluids Laminar Flow Convective Heat TransferAnonymous 7BQxlt8cNoch keine Bewertungen

- Boiling Modes - Types of BoilingDokument3 SeitenBoiling Modes - Types of BoilingParmar BhaveshNoch keine Bewertungen

- The SolidDokument4 SeitenThe SolidQumisoft 78Noch keine Bewertungen

- Thermodynamics of The Swelling of WoodDokument12 SeitenThermodynamics of The Swelling of Woodhalel111Noch keine Bewertungen

- Jjmie: Modeling and Verification of Double Slope Single Basin Solar Still Using Laboratory and Actual Solar ConditionsDokument8 SeitenJjmie: Modeling and Verification of Double Slope Single Basin Solar Still Using Laboratory and Actual Solar ConditionsSindhuvkreddyNoch keine Bewertungen

- Fouling of Heat Transfer SurfacesDokument20 SeitenFouling of Heat Transfer Surfacessakshi_devi_mec14Noch keine Bewertungen

- 2016 Ribatski and Da Silva Highlight PDFDokument38 Seiten2016 Ribatski and Da Silva Highlight PDFhemanthNoch keine Bewertungen

- Blunier EPSL 04Dokument10 SeitenBlunier EPSL 04Rita KirkbyNoch keine Bewertungen

- 6-Heat Transfer in Boiling and CondensationDokument17 Seiten6-Heat Transfer in Boiling and CondensationPratiksha GoreNoch keine Bewertungen

- Ogst 200053Dokument10 SeitenOgst 200053Carmel UyumbuNoch keine Bewertungen

- Influencia Del Agua en La SinterizacionDokument7 SeitenInfluencia Del Agua en La SinterizacionRuselkis FloresNoch keine Bewertungen

- Three Phase Interfacial Heat Transfer During The Dissociation of Propane HydratesDokument8 SeitenThree Phase Interfacial Heat Transfer During The Dissociation of Propane HydratesAnonymous kejOID9QsNoch keine Bewertungen

- Rapid Depressurization of Pressure VesselsDokument4 SeitenRapid Depressurization of Pressure VesselsChristian CândidoNoch keine Bewertungen

- Group-2 ChE-135 Post Lab Experiment-1Dokument18 SeitenGroup-2 ChE-135 Post Lab Experiment-1Rievelyn MartusNoch keine Bewertungen

- Numerical Simulations of The Thermal Impact of Supercritical CO2 Injection On Chemical Reactivity in A Carbonate Saline Reservoir - Andre - AzaroualDokument45 SeitenNumerical Simulations of The Thermal Impact of Supercritical CO2 Injection On Chemical Reactivity in A Carbonate Saline Reservoir - Andre - AzaroualwordindustriesNoch keine Bewertungen

- BoilingDokument6 SeitenBoilingpps companyNoch keine Bewertungen

- Boiling PDFDokument6 SeitenBoiling PDFpps companyNoch keine Bewertungen

- Thermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleDokument23 SeitenThermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleHéctor ParrAlNoch keine Bewertungen

- Lab Report 5 - Group 7 - Eh2203cDokument21 SeitenLab Report 5 - Group 7 - Eh2203cAriff HaiqalNoch keine Bewertungen

- Cooling of BottleDokument5 SeitenCooling of BottleMikkelsNoch keine Bewertungen

- Mechanism of Calcium Carbonate Scale Deposition UnderDokument7 SeitenMechanism of Calcium Carbonate Scale Deposition UnderDiman Aditya KardiNoch keine Bewertungen

- 01 Principles of Refrigeration & Reversed Carnot CycleDokument13 Seiten01 Principles of Refrigeration & Reversed Carnot CycleVinNoch keine Bewertungen

- Final Boiling AssignmentDokument47 SeitenFinal Boiling AssignmentBrianRungenNoch keine Bewertungen

- Second: Heat Transfer Correlations For Flow Boiling Heat TransferDokument9 SeitenSecond: Heat Transfer Correlations For Flow Boiling Heat Transfermalek mustafaNoch keine Bewertungen

- Thermal Physics PartDokument17 SeitenThermal Physics PartSammyJayNoch keine Bewertungen

- Experimental Thermal and Fluid Science: SciencedirectDokument6 SeitenExperimental Thermal and Fluid Science: SciencedirectRoger David Melendez GuevaraNoch keine Bewertungen

- Unsteady Natural Convection Heat Transfer in A Nanofluid-Filled Square Cavity With Various Heat Source ConditionsDokument18 SeitenUnsteady Natural Convection Heat Transfer in A Nanofluid-Filled Square Cavity With Various Heat Source Conditionskada hanafiNoch keine Bewertungen

- Condensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationDokument6 SeitenCondensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationyamakunNoch keine Bewertungen

- Transition Boiling DropletsDokument5 SeitenTransition Boiling DropletsthahirNoch keine Bewertungen

- Spe 176089 MS PDFDokument11 SeitenSpe 176089 MS PDFatilio martinezNoch keine Bewertungen

- Chapter 7 Science of CryobiologyDokument27 SeitenChapter 7 Science of CryobiologyAmir IqbalNoch keine Bewertungen

- SOAwonorin 2Dokument1 SeiteSOAwonorin 2jrcorreacNoch keine Bewertungen

- Global Warming Temperatures and Projections: As Related to CO2 and H2O Absorptions, H2O Evaporation, and Post-Condensation ConvectionVon EverandGlobal Warming Temperatures and Projections: As Related to CO2 and H2O Absorptions, H2O Evaporation, and Post-Condensation ConvectionNoch keine Bewertungen

- Beyond Global Warming: How Numerical Models Revealed the Secrets of Climate ChangeVon EverandBeyond Global Warming: How Numerical Models Revealed the Secrets of Climate ChangeNoch keine Bewertungen

- Vanishing Peaks: Unveiling the Impact of Climate Change on Global SnowpacksVon EverandVanishing Peaks: Unveiling the Impact of Climate Change on Global SnowpacksNoch keine Bewertungen

- Karger Kocsis 1990Dokument12 SeitenKarger Kocsis 1990Leonid PastukhovNoch keine Bewertungen

- POLYMERS Brochure Web PDFDokument29 SeitenPOLYMERS Brochure Web PDFLeonid PastukhovNoch keine Bewertungen

- Sadanand A 2015Dokument15 SeitenSadanand A 2015Leonid PastukhovNoch keine Bewertungen

- TGD-KetaSpire® KT-820-EN-v3.0Dokument126 SeitenTGD-KetaSpire® KT-820-EN-v3.0Leonid PastukhovNoch keine Bewertungen

- Thesis Goutianos 2004 PDFDokument214 SeitenThesis Goutianos 2004 PDFLeonid PastukhovNoch keine Bewertungen

- ElectroPuls Controller Console and Software PDFDokument2 SeitenElectroPuls Controller Console and Software PDFLeonid PastukhovNoch keine Bewertungen

- 1 s2.0 S0142941809001044 Main PDFDokument9 Seiten1 s2.0 S0142941809001044 Main PDFLeonid PastukhovNoch keine Bewertungen

- Predicting The Long-Term Mechanical Performance of Polycarbonate From Thermal History During Injection MoldingDokument10 SeitenPredicting The Long-Term Mechanical Performance of Polycarbonate From Thermal History During Injection MoldingLeonid PastukhovNoch keine Bewertungen

- Bulletin April 2012 TocDokument2 SeitenBulletin April 2012 TocLeonid PastukhovNoch keine Bewertungen

- Strandman ED-ROP Review PolymChem2011 PDFDokument9 SeitenStrandman ED-ROP Review PolymChem2011 PDFLeonid PastukhovNoch keine Bewertungen

- Evaluating Chalcogen Heteroatoms in Conjugated Polymers For Organ PDFDokument257 SeitenEvaluating Chalcogen Heteroatoms in Conjugated Polymers For Organ PDFLeonid PastukhovNoch keine Bewertungen

- 1 s2.0 S0749641911000209 Main PDFDokument13 Seiten1 s2.0 S0749641911000209 Main PDFLeonid PastukhovNoch keine Bewertungen

- 1 s2.0 S0142941809001044 Main PDFDokument9 Seiten1 s2.0 S0142941809001044 Main PDFLeonid PastukhovNoch keine Bewertungen

- P 325Dokument23 SeitenP 325Leonid PastukhovNoch keine Bewertungen

- Midterm 20210405 SolutionDokument12 SeitenMidterm 20210405 SolutionSelf SevNoch keine Bewertungen

- Every Life Is On Fire How Thermodynamics Explains The Origins of Living Things by Jeremy England.Dokument225 SeitenEvery Life Is On Fire How Thermodynamics Explains The Origins of Living Things by Jeremy England.ARGHA MANNANoch keine Bewertungen

- NDE Procedure - Flare KOD - Structure Rev ADokument90 SeitenNDE Procedure - Flare KOD - Structure Rev ARajesh K PillaiNoch keine Bewertungen

- Parcial Examen Final Quiz Validación Otro XDokument2 SeitenParcial Examen Final Quiz Validación Otro XJuan De DiosNoch keine Bewertungen

- REPORT-MT 21.10.2022 (Test)Dokument2 SeitenREPORT-MT 21.10.2022 (Test)Nhien ManNoch keine Bewertungen

- Saptarshi CV PDFDokument20 SeitenSaptarshi CV PDFParamita HaldarNoch keine Bewertungen

- Vaisala RH Sensor HMT120 (Quick Guide Multilingual - 2018) PDFDokument103 SeitenVaisala RH Sensor HMT120 (Quick Guide Multilingual - 2018) PDFIvan BriscoeNoch keine Bewertungen

- Unit 5 - Shear Strength of SoilDokument66 SeitenUnit 5 - Shear Strength of SoilMr.Bhaskar Wabhitkar100% (1)

- Fluid Machinery Module 4 - Continuation of Centrifugal PumpsDokument3 SeitenFluid Machinery Module 4 - Continuation of Centrifugal PumpsMark Renbel ParanNoch keine Bewertungen

- Physics HL IA - ViscosityDokument5 SeitenPhysics HL IA - ViscosityDavid Sendín LloredaNoch keine Bewertungen

- Binocular Balancing: Presented By: Hina Hafeez TOD (1 Semester)Dokument14 SeitenBinocular Balancing: Presented By: Hina Hafeez TOD (1 Semester)Xid KhanNoch keine Bewertungen

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDokument5 SeitenIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesEduardoNoch keine Bewertungen

- Wavin Katalog System Ekoplastik Vel Prum en NahledDokument20 SeitenWavin Katalog System Ekoplastik Vel Prum en NahledIoan CovaliovNoch keine Bewertungen

- DPP No. 41: PhysicsDokument6 SeitenDPP No. 41: PhysicsGajanan PurudNoch keine Bewertungen

- Vector Differential CalculusDokument12 SeitenVector Differential CalculusBattle SagaNoch keine Bewertungen

- MECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesDokument18 SeitenMECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesFirst name Last nameNoch keine Bewertungen

- ACI 207.2 (R2002) EffectofRestraint VolumeChange &reinf Cracking MassConcreteDokument26 SeitenACI 207.2 (R2002) EffectofRestraint VolumeChange &reinf Cracking MassConcretephilipyapNoch keine Bewertungen

- Lecture Notes On Distributions: Hasse CarlssonDokument83 SeitenLecture Notes On Distributions: Hasse CarlssonRajesh MondalNoch keine Bewertungen

- Student-5.1 PHET LAB - Friction LabDokument3 SeitenStudent-5.1 PHET LAB - Friction Labisaacrose876Noch keine Bewertungen

- Applications of Differential EquationsDokument5 SeitenApplications of Differential EquationsSowjanyaNoch keine Bewertungen

- Indoor&Outdoor Duct Cable (GJYXFDH03) Datasheet 01Dokument5 SeitenIndoor&Outdoor Duct Cable (GJYXFDH03) Datasheet 01Amine InpticNoch keine Bewertungen

- OIML R 61-1: Nternational EcommendationDokument48 SeitenOIML R 61-1: Nternational Ecommendationdavid dcNoch keine Bewertungen

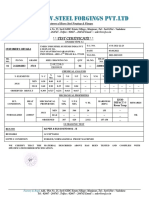

- A.V.Steel Forgings PVT - LTD: Test CertificateDokument1 SeiteA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiNoch keine Bewertungen

- Review Module - Algebra: Complex NumbersDokument3 SeitenReview Module - Algebra: Complex NumbersJames Darwin SorianoNoch keine Bewertungen

- MAT1106-Formula Sheet For ExamDokument3 SeitenMAT1106-Formula Sheet For ExamQueh Chen HongNoch keine Bewertungen

- AME 21241 Laboratory 3: Beam Bending and Strain TransformationDokument7 SeitenAME 21241 Laboratory 3: Beam Bending and Strain TransformationChangZianLiNoch keine Bewertungen

- Theorem of Physics 2Dokument15 SeitenTheorem of Physics 2duong.ph210238Noch keine Bewertungen

- Successive Differentiation: (For B.Sc./B.A. Part-I, Hons. and Subsidiary Courses of Mathematics)Dokument23 SeitenSuccessive Differentiation: (For B.Sc./B.A. Part-I, Hons. and Subsidiary Courses of Mathematics)Aadil khan89% (9)