Beruflich Dokumente

Kultur Dokumente

Quality

Hochgeladen von

pavankumar001Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quality

Hochgeladen von

pavankumar001Copyright:

Verfügbare Formate

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.

5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 1 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

QUALITY ASSURANCE

1.0 GENERAL

1.1

Term Owner and Project Manager, in this Chapter and elsewhere also shall include Owners Consultant, Project Managers Consultant or Consultant who is duly nominated and such intimation formally given to Contractor. Immediately after Award of Work along with the Master Control Work Chart, Contractor shall submit Detailed Quality plans spelling out various tests / inspections to be carried out and finalize manufacturing plans for all works, major components and equipment, which should meet requirement of specifications, standards, quality practices and procedures specified. He shall also submit his organization, reference documents, standards and acceptance norms etc. during all stages of material procurement, manufacture, assembly and final testing / performance testing. In the above document, one requirement shall be the brands, makes and names of important supply / manufactured items. While Owner is providing at his own level, a list of established and preferred brand names fro few items, Contractor shall provide this detail in more depth. This shall be taken as guidance in all subsequent activities. This figures in both the Documents to be submitted before and after Award of Work. In second instance, the updated version shall be provided. Copies of reference documents / plants standards / acceptance norms / test and inspection procedure etc., referred in Quality / reference documents / standards etc., will be subject to Owners approval without which manufacturer shall not proceed with Works. Owner reserves right to add any inspection or test, which are felt necessary for completion of work. These approved documents shall form part of Contract. In these approved Quality Plans, Owner shall identify customer Hold points (CHPs) i.e., testing checks etc which need to be carried out in his presence. All deviations to these specifications, approved quality plans and applicable standards must be documented and referred along with technical justification for approval and dispositioning. Contractor shall also submit and finalise field quality plans, which will detail out for all the equipment, the quality practices and procedures etc., to be followed by Contractors site Quality Control Organisatoin during various stages activities from receipt of material / equipment at site. These shall also be approved by Owner.

1.2

1.3

1.4

1.5

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 2 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

1.6

No material shall be dispatched from manufacturers works unless same is accepted after pre-dispatch / final inspection including verification of records of all previous tests / inspection by Owners representative and duly authorized for dispatch. All Vendors / Sub Contractors engaged by Contractor for services and supplies of major bought out items including casting, forging, semi-finished and finished components / equipment list of which shall be drawn up shall be subject to Owners approval. Contractors proposal in this regard shall contain Sub Contractors / Vendors facilities established at respective works, process capability and stabilization, Quality Control System followed, experience list etc., along with his own technical evaluation. The approval of these shall not relieve Contractor from any obligation, duty or responsibility under Contract. This action would also, not involve Owner in any complications arising between Contractor and his Sub Contractors / Vendors or any other liabilities. Contractor shall also obtain Quality Plans from such Sub Contractors / Vendors and submit these for Owners approval.

1.7

1.8

Normally, no request for change of Sub Contractor / Vendor shall be entertained by Owner. But in the peculiar circumstances if request for change is found reasonable and justified, then this may be entertained and decision of Owner in this respect shall be final and binding. Time consumed for this change shall not be excluded from the time of completion of contract. This change shall not relieve him from responsibility of completing the work within the stipulated time. Owner reserves right to carry out quality audit and quality surveillance of the system and procedures of his Contractor / Sub Contractors / Vendors. Latter shall provide all necessary assistance to enable him to carry out such details and surveillance including Quality Manuals. For all spares and replacement items, the quality requirements as agreed for main equipment supply shall be applicable. Repair / rectification procedures to be adopted to make the job acceptable shall be subjected to approval of Owner. Before sub-contracting any portion of work, Contractor will take prior approval of Owner. This work shall be carried out as per specification only. All materials used or supplied shall be accompanied by valid, approved material certificates with tests, inspection reports. These certificates and reports shall indicate the heat numbers or other such acceptable identification numbers of the material. The material certified should also have the identification details stamped on it.

1.9

1.10 1.11 1.12 1.13

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 3 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

1.14

All materials, components and equipment covered under this specification shall be procured manufactured, erected, commissioned and tested at all the stages, as per a comprehensive Quality Assurance Programme. An indicative programme of inspection / tests to be carried out for some of the major items is given in the respective technical specification, even though it is not intended to form a comprehensive programme. Contractor shall draw up, get approved and implement such programmes.. Detailed Quality Plans for manufacturing and field activities also should be drawn up separately for each activity in format (to be given at a later date) and will be got approved. Contractor shall submit field-welding schedule for field welding activities along with all supporting procedures, like welding procedures, heat treatment procedures. NDT procedures etc., at east ninety days before schedule start of erection work at site. All materials used for, equipment manufacturer indicating castings and forging etc., shall be tested quality as per relevant codes / standards. Details of results of tests conducted to determine mechanical properties, chemical analysis and details of heat treatment procedure recommended and actually conducted shall be recorded on certificates and time temperature chart. Tests shall be carried out as per applicable material standards and / or agreed details. Test results of qualification and specimen testing shall be furnished for approval. However, where so directed, such tests shall be conducted in presence of Owner. Any statutory requirements for the equipments / system shall also be complied with All the heat treatment results shall be recorded on time temperature charts and verified with recommended regimes. No welding shall be carried out on cast iron components for repair. Unless otherwise proven and specifically agreed with Owner, welding of dissimilar materials and high alloy materials shall be carried out at shop only. All non-destrcutive examination shall be performed in accordance with written procedure as per relevant IS codes or other equivalent International standards. NDT operator shall be qualified as per relevant IS code or equivalent International Standards. NDT shall be recorded in a report which includes details of methods and equipment used, result evaluation, job data and identification of personnel employed and details of correlation of the test report with the job.

1.15

1.16

1.17

1.18 1.19 1.20 1.21 1.22

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 4 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

1.23

For components / equipment procured for Project work shall have the written approval of Owner regarding purchase specifications. Contractor shall call for quality plans to be submitted by suppliers shall set out during the various stages of manufacture and installation, quality control organization, the relevant reference documents / standards used, acceptance level, inspection of documentation raised etc., Such quality plans of successful vendors shall be finalized with Owner. Such approved plans will form a part of each purchase order / contract between Contractor and Vendor. Within three weeks of the release of purchase order / contracts for such bought out components, copy of these with out price details but together with the detailed purchase specifications, quality plans and delivery conditions shall be furnished.

1.24

Quality Audit / Surveillance / approval of the results of the tests and inspection will not however, prejudice right of Owner to reject the equipment if it does not comply with specification when erected or does not give complete satisfaction in service and the above shall in no way limit liabilities and responsibilities of Contractor in ensuring complete conformance of the materials / equipment supplied to relevant specification, standard data sheets drawings etc., QUALITY ASSURANCE PROGRAM 2.1 To ensure that the equipments and services under the scope of this Contract whether manufactured or performed within Contractors Works or at his Sub Contractors premises or at Owners site or at any other place of Work are in accordance with the specifications, Contractor shall adopt suitable quality assurance programme to control such activities at all points, necessary. Such programmes shall be outlined and finally accepted by Owner. A quality assurance programme of Contractor, generally covering the following points, shall be submitted to owner. a. His organization structure for the management and implementation of the proposed quality assurance programme b. Documentation control system c. Qualification data for Contractors key personnel d. Procedures for purchase of materials, parts, components and selection of Sub-Contractors services including vendor analysis, source inspection, incoming raw-material inspection, verification of materials purchased, etc., e. System for shop manufacturing and site erection controls including process controls and fabrication and assembly controls; f. Control of non-confirming items and system for corrective actions; g. Inspection and test procedure both for manufacture and field activities; h. Control of calibration and testing of measuring and testing equipments;

2.0

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 5 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

i. j. k. l. m. n.

System for quality audits System for indication and appraisal of inspection status; System for authorizing release of manufactured product to the OWNER. System for handling storage and delivery; System for maintenance of records; and A quality plan detailing out the specific quality control procedure adopted for controlling the quality characteristics relevant to each item of works / equipment / component furnished. o. System for authorizing release of engineering date, documents draw to OWNER. QUALITY ASSURANCE DOCUMENTS

3.0 3.1

Contractor shall be required to submit in requisite copies the following Quality Assurance documents and get them approved by Owner prior to start of fabrication work a. All Non-destructive Examination procedures like stress relief and weld repair procedure actually used during fabrication b. Welding procedures, welders, welding operators qualification certificates c. Welder identification list, listing Welders and Welding operators qualification procedure and welding identification symbols. d. Material mill test reports on components as specified by the specification e. The inspection plan with verification, inspection plan check points, verification sketches, if used and methods used to verify that the inspection and testing points, in the inspection plan were performed satisfactorily. f. Sketches and drawings used for indicating the method of traceability of the radio-graphics to the location on the equipment or location of materials used in works. g. Non-Destructive Examination result reports with radiography interpretation reports h. Stress relief time temperature charts i. Factory test results for testing required as per applicable codes and standards referred in the specifications j. Inspection reports duly signed by Quality Assurance Personnel of Owner and Contractor for the agreed inspection hold points. Same shall be recorded during course of inspection. Also the copy of repair / upgrading process and procedures, requiring Owners approval shall be provided in documentation package. k. Record of disposition of deviations duly authorized by Owner Accepted deviation shall be indicated in complete technical details. l. Notification of conformity certifying that the equipment is in compliance with finalized specification requirements.

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 6 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

4.0 QUALITY ASSURANCE IN EXECUTION OF WORKS 4.1 Contractor shall establish staff, equip and operate a comprehensive quality assurance set-up at the site during the full period of the Works. Principal responsibility and duty of this set-up shall be to ensure that all work carried out and materials produced or supplied by the Contractor comply fully with Specifications. With his tender, Contractor, shall submit detailed proposal (in terms of experienced supervisory staff, trained workmen, procedures of work, equipments, (support he shall be getting from outside agencies) for achieving quality. Under Civil works, main areas are cited below: Underground excavation particularly quality control in blasting and minimisation of overbreaks and damage to surrounding rock. Maintaining clean working environment inside underground work with particular reference to lighting, ventilation and dewatering. Rock support installations particularly the grouting of rock bolts / rock anchors / tendons in surface and underground works. Workmanship in shotcrete placement. Workmanship in concrete placement in surface and underground works. Grouting activities particularly the mix designs and selection of mixes for particular application. Final clean up. The proposal shall be specific enough to assure that all works are executed in a professional manner and he has included in his bid provision of employment of best international practices of construction in executing Work. 4.3 At time of award of work, Quality & Inspection Plan now provided with Tender shall be considered. This shall be improved upon and re confirmed for implementation.. Immediately after the award of work, during mobilization phase, Contractor shall take systematic steps to implement all Quality commitments made by him for achieving the desired quality in construction. During course of execution, quality matters of on going works shall be regularly reviewed at least once in 3 months in the Quality Assurance meeting specifically called by Project Manager along with the Contractors. In case former is not satisfied with the amounts of resources employed vis-vis commitments made in proposal, contractor shall take additional steps to supplement his efforts.

4.2

4.4

4.5

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 7 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

5.0 5.1

CONTROL OF THE PROGRESS OF WORK Close progress control, and preparation of corresponding progress reports, shall be an important part of Contractors quality control responsibilities. Contractor must at all times apprise Project Manager of latest progress of work and the hindrances that could lead to additional costs. Contractor shall submit detailed monthly progress reports, in which contractual programme for works is updated and information given on quantitative completion of civil works (in the form of tables indicating the quantities of completed work). Monthly progress reports shall give full details of any delays to work in progress or planned, delays in transport to/from the site, together with detailed proposals for overcoming or preventing delays, and for regaining any lost time. Contractor shall at any time, on request of Project Manager , submit detailed reports on particular matters relating to execution and progress of works, if such reports are required in order to assess the quality or progress of specific activities or works. CONTRACTORS QUALITY CONTROL STAFF Contractor shall assign one experienced Engineer at site as full-time Quality Control Manager and he shall be responsible for getting implements on ground all requirement of Technical Specifications. Experience and qualifications of this Engineer shall be given in Contractors tender and this shall be subject to the approval of Owner. Positions, qualifications and duties, of Contractors quality control staff shall be indicated in the Quality Control Organisation plan, and shall likewise be subject to approval by Project Manager. As a minimum, the contractor shall appoint one qualified and experienced tunnelling engineer / geologist to be responsible for Quality control of each of the underground works. CONTRACTORS LABORATORIES Contractor shall establish, equip and operate on site laboratories for the testing of following principal construction materials: a) Concrete, including also testing of sand, aggregates, cement, water & admixtures. b) Any site testing and/or calibration of monitoring instrument. Numbers of samples to be tested, and the timing of testing, shall be as may be given elsewhere in these specifications, or as may be instructed by Owner.

5.2

5.3

5.4

6.0 6.1

6.2 6.2

7.0 7.1

7.2

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 8 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

7.3 7.4 7.5 .

Staff of Quality laboratory shall have proven experience in similar previous work and their qualifications shall be subject to approval by Project Manager Complete records shall be kept of all laboratory tests carried out and shall be available at any time to Project Manager for inspection. Owner shall be empowered at any time and without notice to visit without prior notice, observe tests being carried out, inspect equipment and study results in any of the Contractors laboratories.

9 .0 9.1

MATERIAL DELIVERED TO SITE Contractors quality control staff shall keep records of all materials delivered to site for use in Works and of all tests made on such materials either prior to or following delivery to site. These records shall be available always to Project Manager , together with any factory testing certification. Contractors quality control staff shall keep records of all materials delivered to site for use in Works and of all tests made on such materials either prior to or following delivery to site. These records shall be available always to Project Manager, together with any factory testing certification.

9.2

9.3

10.0

10.1

SHOP INSPECTION AND TESTS

Plant and Equipment covered by this Contract shall be subjected to inspection and testing. Contractor shall provide all services to establish and maintain quality of workmanship in his Works and that of his Sub Contractors to ensure the performance criteria, the mechanical accuracy of components, compliance with drawings, identification and acceptability of all materials, parts and Equipment. For supply of systems, at the start of Contract, he shall furnish a total list of items in their scope of work. This list, living a brief description of the item, quantity, names of probable Sub Contractors, and a blank column for agency for final approval of drawing / data sheets, shall be submitted for approval. The list shall be submitted within two weeks from the date of LOI. For systems and major items such as hydro mechanical works, pressure / load bearing items, machineries etc., he shall furnish quality plan giving details of checks / tests to be conducted by them on material, process, subassembly and assembly. These shall include requirements as prescribed in the applicable specifications, codes and statutory requirements. Quality plan shall be reviewed by Owner and the stages to be witnessed and verified shall be indicated by him and approved.

10.2

10.3

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 9 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

10.3.1 Contractor shall give Owner written notice of any material being ready for testing as per format enclosed. The clear notice period shall be seven (7) days for local inspection and fifteen (15) days for outstation inspection. Such tests shall be to Contractors account except for the expenses of Owner. Latter, unless the inspection of the tests is virtually waived, shall fix a date for inspection with Contractor and attend such tests within fifteen (15) days of the date on which such equipment is notified as being ready for test / inspection. If Contractor fails to offer this for inspection as per the agreed date, he is liable to pay for time and expenses for the anfractuous visit of Owner. 10.4 In all cases where inspection and tests are required whether at the premises or Works of Contractor or his Sub Contractor or at laboratory, he except where otherwise specified, shall provide free of charge all facilities such as labour, materials, electricity, fuel, water, stores, test bed, apparatus and instruments, laboratory tests etc., as may be required by Owner to carry out effectively such tests of Equipment in accordance with Contract and shall give facilities to Owner or to his authorized representative to accomplish testing. In case of stage inspection hold points, Contractor shall proceed from one stage to another only after the component is inspected by Owner and written permission given to proceed further. Same procedure shall be adopted for any rectifications / repairs suggested by Owner. Owner shall have the right to inspect any machinery, material, structures, equipment or workmanship furnished or used by Contractor and may reject any which is defective or unsuitable for the use and purpose intended, or which is not in accordance with the intent of Contract. Contractor shall remedy or replace such equipment at his own cost. All principal mill test reports, Contractor inspection / tests reports, test certificates and test curves shall be supplied for all inspection / tests carried out including other records such as stress relieving charts, radiographic charts and other non-destructive testing records in accordance with the provisions of Contract, duly certified by Contractor. Owner shall reserve the right to call for certificates of origin and test certificates for all raw material and Equipment at any stage of manufacture. Owner shall within fifteen (15) days from the date of inspection as defined herein give notice in writing to Contractor of any non-conformance pertaining to all or any Equipment and workmanship, which in his opinion is not in accordance with Contract. Contractor shall give due consideration to such objections and shall either make the modifications that may be necessary to meet the said objections or shall confirm in writing to Owner giving reasons therein that no modifications are necessary to comply with Contract

10.5

10.6

10.7

10.8

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 10 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

10.9

When the factory tests and documentation have been satisfactorily completed at Contractors or Sub Contractors works, Owner shall issue acceptance note / certificate to this effect within fifteen (15) days after completion. Failure of Owner to take such an action shall not prevent Contractor from proceeding with Work. Completion of these tests, or the issue of the certificates shall not bind Owner to accept the equipment should it, on further tests after erection, be found not to comply with the Contract

10.10 None of Plant and equipment to be furnished or used in connection with Contract shall be dispatched until shop inspection has been completed. However, such shop inspection and / or certification shall not relieve Contractor of his responsibility for furnishing Plant and the Equipment performing to requirements of Contract. Nor shall it prejudice any claim, right or privilege which Owner may have because of use of defective or unsatisfactory items. Should latter waive right to inspect any item, such waiver shall not relive Contractor from his obligation under Contract. In case of Owners inspection revealing poor quality of goods, Owner shall be at liberty to specify additional inspection procedures, if required, to ascertain Contractors compliance with Equipment specifications. 11.0 11.1 SUB-ORDERS In order to facilitate the inspection of bought-out materials and Plant, Contractor shall submit for approval, three (3) copies of all sub-orders placed by him as soon as they are issued. Copies of any drawing referred to in the sub-order shall also be submitted unless otherwise agreed by Owner. Sub-orders and drawing referred to above shall include all components which are subjected to electrical and mechanical pressure or stress when the Plant is in operation, and also auxiliaries and spares which are to be directly dispatched to Site from Sub Contractors Works. All sub-orders of main Contractor and Sub Contractors shall clearly be marked with Main Contractors name and Owners name and Contract reference. They shall include the following statement: The Plant or the Equipment which is the subject of this order shall comply in every respect with the requirements of Owners technical specifications and shall be subject to inspection and tests to his satisfaction and ourselves For the purpose of this clause, interworks orders shall also be treated as sub-orders. It is obligatory on Contractor that he advises his Sub Contractor of the pertinent clauses in this specification when ordering bought out Plant, Equipment or materials. In particular, Contractor shall

11.2

11.3

11.4

11.5

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 11 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

advise every Sub Contractor that he is required to supply design calculations, drawings, inspection reports and test certificates strictly in accordance with Specifications and technical information for inclusion in the Instruction manual. The Sub Contractors should also be reminded that they should include with their offer all tools and appliances necessary for proper maintenance and all spare parts in accordance with Specifications. Itemized prices of the recommended spare parts shall be submitted together with the appropriate part numbers and drawings. 11.6 12.0 12.1 Sub-ordering / sub-contracting for major items can be done only with approval of Owner.. MATERIAL TESTS In case of Owner being supplied with certified particulars of tests, which have been carried out for Contractor by supplier of material, Owner may, at his own discretion, accept the same as proper evidence of compliance with the requirements of appropriate specifications for the materials. Contractor is to provide test pieces required by Owner to enable him to determine quality of material supplied under the Contract. If any test piece fails to comply with requirements, Owner may reject the entire lot of material represented by the test piece. Critical materials used in manufacture of the Equipment and construction of the Plant covered by the Contract may also be subjected to one or more of the non-destructive tests (NDT) as called for in the specification or as mutually agreed. Salvaging of material due to unacceptable defect is to be attempted by Contractor only after getting specific concurrence from Owner and according to the approved procedure. WELDING All welding involved in construction and fabrication of the Plant and items covered under Contract shall be carried out in accordance with specifications and applicable codes. Welding procedures and welders qualifications shall be approved by Owner. Where applicable, welders shall be tested as detailed in codes specified for pipe welding, vessel welding and structural welding and appropriate to the corresponding weld position using test pieces of appropriate parent metal to be used on the job. Owner shall have right to have any welder retested at any time during Contract.

12.2

12.3

13.0 13.1

13.2

13.3 Recommendations of applicable codes shall be followed for non-destructive tests, wherever applicable.

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 12 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

13.3

Copies of all welding procedures, procedure qualification records, welders performance qualification certificates, post-heating / stress relieving records, NDT records and other test results shall be made available upon request of Owner. FABRICATION / INSPECTION Fabrication / Inspection procedures for vessels, pipes, tubes, valves, etc., shall be in accordance with procurement specifications, applicable codes or any other approved equal.

14.0

15.0 15.1

TESTS AT MANUFACTURERS WORKS GENERAL Tests at Works shall include electrical, mechanical and hydraulic test in accordance with the appropriate clauses of Statutory Regulation, relevant codes and standards and approved drawings / specifications and in addition any test called for by Owner to ensure that Plant being supplied fulfils the requirements of the Specifications. Contractor shall carry out all the shop tests and inspections as per specifications, in addition to those normally required as per codes / standards. For items not covered by any code or specifically mentioned in the Specifications, the tests are to be agreed with by Owner. If considered necessary by latter, multipart assemblies shall be fully erected and tested in Works prior to packing and dispatch to the Site.

16.0.

TEST CERTIFICATES Test certificates including test records, performance curves and balancing certificates shall be supplied according to the Distribution Schedule. All the tests shall be carried out in accordance with the provisions of the Contract All test certificates must be endorsed with sufficient information to identify the material or the equipment to which the certificates refer, and must carry at the top right hand corner the identification of Owner and Contract No.

17.0.

CALIBRATION All instruments used for critical measurement such as pressure gauges for leak tests, instruments for measuring performance parameters, instruments for precision dimension measurements shall have valid calibration certificates traceable to national standards. This means that the calibrating agency engaged by Contractor shall use instruments which are in turn calibrated by

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 13 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE

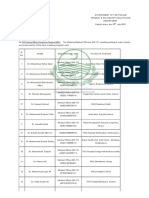

Government approved agencies and such an information shall be recorded in the calibration certificate issued by the calibrating agency by giving the certificate number, date and date of validity of the certificate given by the Government approved agency. A copy of calibration certificate shall be kept at site office of Contractor. Copies of the certificates shall be made available to Owner as per specifications. 18.0 FORMAT FOR INSPECTION REQUEST FROM CONTRACTOR To Project Director M/s. The Tata Power Company Limited. Attn.: Mr. Dear Sirs, Items detailed below are ready for inspection. Please arrange inspection and confirm the date. 1. Project 2. Location of Equipment 3. Clients Order Ref. 4. Consultants Ref. 5. Sub-Order Ref. 6. Sub-Contractors name and full address: 7. Place of Inspection (full address) 8. Contact person, phone, fax & telex nos. 9. Description of item and Qty. 10. Billing Schedule No. 11. Nature of inspection required 12. Proposed date (s) : : : : : : : : : : :

THE TATA POWER COMPANY LIMITED BHIRA 100MW-AUGMENTATION SCHEME INCLUDING MULSHI LAKE SUB-STORAGE UTILIZATION Doc. No TCE.5270A-H-112-601

VOLUME: IV PART: 4 SECTION: A 5 SHEET 14 OF 14

CIVIL & HYDRO-MECHANICAL WORKS TECHNICAL SPECIFICATIOS ACTIVITIES

QUALITY ASSURANCE :

13. Weekly holiday

We confirm that the items have been fully inspected / tested by us, all stages of inspection as per quality plan have been done by you and us and all material test certificates, Q.C. records and test reports and valid calibration reports of measuring / testing instruments with traceability to national level are ready with us. Thanking you and awaiting your confirmation. Yours faithfully,

Note: 1. Following clear notice periods (date of receipt at TPC to date of inspection) a. Local Inspection 7 days b. Outstation Inspection 15 days Cc: Consultant

Cc: Sub Contractor

Das könnte Ihnen auch gefallen

- Reply by Customer Pre-Bid Query Held On 2225092009 PDFDokument140 SeitenReply by Customer Pre-Bid Query Held On 2225092009 PDFpavankumar001Noch keine Bewertungen

- Technical Data Sheets - TurbineDokument19 SeitenTechnical Data Sheets - Turbinepavankumar001Noch keine Bewertungen

- 4 MivDokument19 Seiten4 Mivpavankumar001Noch keine Bewertungen

- Laplace Transform TableDokument3 SeitenLaplace Transform TableNasir NaeemNoch keine Bewertungen

- NAFR-TFV00-0000-TR Technical Description MIV Spherical ValveDokument10 SeitenNAFR-TFV00-0000-TR Technical Description MIV Spherical Valvepavankumar001100% (1)

- DIBN HC BR SR TransportationDokument4 SeitenDIBN HC BR SR Transportationpavankumar001Noch keine Bewertungen

- Alak Description Pelton TurbineDokument12 SeitenAlak Description Pelton Turbinepavankumar001Noch keine Bewertungen

- Alak - MIV 1500 WeightDokument1 SeiteAlak - MIV 1500 Weightpavankumar001Noch keine Bewertungen

- MIV Technical Data SheetDokument3 SeitenMIV Technical Data Sheetpavankumar001Noch keine Bewertungen

- Spiral VolumeDokument1 SeiteSpiral Volumepavankumar001Noch keine Bewertungen

- Colli Dibbin Turbine RevDokument6 SeitenColli Dibbin Turbine Revpavankumar001Noch keine Bewertungen

- NAFRA Guaranteed Technical Perticulars Spherical ValveDokument8 SeitenNAFRA Guaranteed Technical Perticulars Spherical Valvepavankumar001Noch keine Bewertungen

- DIBN TFV00 0000 PRS Technical Description TurbineDokument21 SeitenDIBN TFV00 0000 PRS Technical Description Turbinepavankumar001Noch keine Bewertungen

- Dibn Tfv00 0000 Bom Turbine RevDokument15 SeitenDibn Tfv00 0000 Bom Turbine Revpavankumar001Noch keine Bewertungen

- Draft Tube VolumeDokument1 SeiteDraft Tube Volumepavankumar001Noch keine Bewertungen

- Dibn Tfv10 0000 Bom Air AdmissionDokument8 SeitenDibn Tfv10 0000 Bom Air Admissionpavankumar001Noch keine Bewertungen

- MIV Seal Area For CoatingDokument2 SeitenMIV Seal Area For Coatingpavankumar001Noch keine Bewertungen

- BJHL TFV00 0000 PRS Turbine Technical DescriptionDokument23 SeitenBJHL TFV00 0000 PRS Turbine Technical Descriptionpavankumar001Noch keine Bewertungen

- 8 Penstock BFV and AccessoriesDokument6 Seiten8 Penstock BFV and Accessoriespavankumar001Noch keine Bewertungen

- 3-Digital Governor GTP SainjDokument5 Seiten3-Digital Governor GTP Sainjpavankumar001Noch keine Bewertungen

- Spherical Valve Technical DescriptionDokument12 SeitenSpherical Valve Technical Descriptionpavankumar001100% (6)

- NAFR-TFV00-0000-TR Turbine and Valve Allowable StressesDokument6 SeitenNAFR-TFV00-0000-TR Turbine and Valve Allowable Stressespavankumar001Noch keine Bewertungen

- Turbine and AccessoriesDokument21 SeitenTurbine and Accessoriespavankumar001Noch keine Bewertungen

- 4 Main Inlet ValveDokument6 Seiten4 Main Inlet Valvepavankumar001Noch keine Bewertungen

- 26.control Building SectionsDokument1 Seite26.control Building Sectionspavankumar001Noch keine Bewertungen

- 2 Turbine and AccessoriesDokument18 Seiten2 Turbine and Accessoriespavankumar001Noch keine Bewertungen

- Potyard Area Gis PlanDokument1 SeitePotyard Area Gis Planpavankumar001Noch keine Bewertungen

- Oil Handling SystemDokument1 SeiteOil Handling Systempavankumar001Noch keine Bewertungen

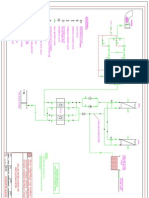

- Fire Fighting System Without InstrumentDokument1 SeiteFire Fighting System Without Instrumentpavankumar001Noch keine Bewertungen

- Chilled Water Scheme For Vent SysDokument1 SeiteChilled Water Scheme For Vent Syspavankumar001Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Goes 300 S Service ManualDokument188 SeitenGoes 300 S Service ManualШурик КамушкинNoch keine Bewertungen

- What Is Inventory Management?Dokument31 SeitenWhat Is Inventory Management?Naina SobtiNoch keine Bewertungen

- 3240-B0 Programmable Logic Controller (SIEMENS ET200S IM151-8)Dokument7 Seiten3240-B0 Programmable Logic Controller (SIEMENS ET200S IM151-8)alexandre jose dos santosNoch keine Bewertungen

- Gamma World Character SheetDokument1 SeiteGamma World Character SheetDr8chNoch keine Bewertungen

- John PFTDokument231 SeitenJohn PFTAlexander Santiago ParelNoch keine Bewertungen

- Amniotic Membrane in Oral and Maxillofacial SurgeryDokument13 SeitenAmniotic Membrane in Oral and Maxillofacial SurgerySooraj SNoch keine Bewertungen

- Funny Physics QuestionsDokument3 SeitenFunny Physics Questionsnek tsilNoch keine Bewertungen

- DJDokument907 SeitenDJDeepak BhawsarNoch keine Bewertungen

- Developmen of Chick EmbryoDokument20 SeitenDevelopmen of Chick Embryoabd6486733Noch keine Bewertungen

- Amo Plan 2014Dokument4 SeitenAmo Plan 2014kaps2385Noch keine Bewertungen

- North American Countries ListDokument4 SeitenNorth American Countries ListApril WoodsNoch keine Bewertungen

- TESTIS PHYSIOLOGY Spermatogenic Cell Syncytium Makela and Toppari 2018Dokument10 SeitenTESTIS PHYSIOLOGY Spermatogenic Cell Syncytium Makela and Toppari 2018LudimilaNoch keine Bewertungen

- Galley cleaning hazards and controlsDokument9 SeitenGalley cleaning hazards and controlsRosalie RosalesNoch keine Bewertungen

- Maturity Mode Agile BookDokument110 SeitenMaturity Mode Agile BookSai VenkatNoch keine Bewertungen

- Research PaperDokument15 SeitenResearch PapershrirangNoch keine Bewertungen

- Ds 3805Dokument4 SeitenDs 3805sparky2017Noch keine Bewertungen

- Ceccato Original Parts CatalogDokument68 SeitenCeccato Original Parts CatalogRamon Sanhueza67% (3)

- Data Validation and Verification - BBC BitsizeDokument56 SeitenData Validation and Verification - BBC BitsizeluciferothegoatNoch keine Bewertungen

- Afrah Summer ProjectDokument11 SeitenAfrah Summer Projectاشفاق احمدNoch keine Bewertungen

- Fuather, That Smid Govern-: Such Time As It May Deem Proper: TeDokument18 SeitenFuather, That Smid Govern-: Such Time As It May Deem Proper: Tencwazzy100% (1)

- Trabajo de Investigación FormativaDokument75 SeitenTrabajo de Investigación Formativalucio RNoch keine Bewertungen

- Lay Out New PL Press QltyDokument68 SeitenLay Out New PL Press QltyDadan Hendra KurniawanNoch keine Bewertungen

- Government of The Punjab Primary & Secondary Healthcare DepartmentDokument3 SeitenGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorNoch keine Bewertungen

- BE 510 Business Economics 1 Problem Set 5 SolutionsDokument5 SeitenBE 510 Business Economics 1 Problem Set 5 SolutionsCreative Work21stNoch keine Bewertungen

- Guiffre V MaxwellDokument40 SeitenGuiffre V MaxwellTechno Fog91% (32)

- O - 6 Series Mill Operation Manual-ENDokument119 SeitenO - 6 Series Mill Operation Manual-ENLeonardo OlivaresNoch keine Bewertungen

- Pathways-Childrens Ministry LeaderDokument16 SeitenPathways-Childrens Ministry LeaderNeil AtwoodNoch keine Bewertungen

- 8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamDokument129 Seiten8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamAnonymous J32rzNf6ONoch keine Bewertungen

- ĐỀ CƯƠNG ANH 9 - CK2 (23-24)Dokument7 SeitenĐỀ CƯƠNG ANH 9 - CK2 (23-24)thuyhagl2710Noch keine Bewertungen

- Arcelor Mittal - Bridges PDFDokument52 SeitenArcelor Mittal - Bridges PDFShamaNoch keine Bewertungen