Beruflich Dokumente

Kultur Dokumente

Mechanical Seal Replacement Instructions

Hochgeladen von

Giorgio FerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechanical Seal Replacement Instructions

Hochgeladen von

Giorgio FerCopyright:

Verfügbare Formate

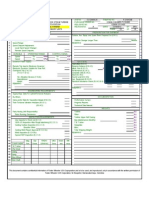

FILE NO: DATE: SUPERSEDES: DATE:

43.84 Mar.18, 2009 43.84 May 15, 1997

MECHANICAL SEAL REPLACEMENT INSTRUCTIONS SERIES 4300 & 4302

OUTSIDE MECHANICAL SEALWITH P-BASE & TCZ MOTOR FRAME

SEAL REPLACEMENT Handle mechanical seal carefully to protect seal faces from damage. Do not contaminate seal faces with finger prints.

2 4 5 6 8

E. Replace the stationary seat (11) with gaskets (13 & 14). Ensure the large diameter gasket (14) is on the bottom. Replace seal plate (10) and tighten the seal plate bolts (9) evenly and diagonally. (DO NOT OVERTIGHTEN) TIP: For best seal flush, align seat flush hole with seal plate flush line connection (10 A) F. When installing the mechanical seal (8), make sure that all parts are perfectly clean. G. Apply a sparse amount of silicone lubricant (provided) to the seal O ring (15).Carefully slide the mechanical seal rotating assembly (8) down the shaft onto the stationary seat (11). Care must be taken not to cut the seal O ring on the keyways. Do not tighten the set screws (1) on the side of the mechanical seal yet. Do not remove holding clips (12). H. Coupling halves (3) are machined together and identified by match marks, (a letter or numeral stamped on each coupling half). Make sure that the match marks correspond with each other before installing the coupling. I. Fit the motor shaft key and collar (4 & 5) and the pump shaft key and collar (6 & 7) and install the keyed coupling halves (3). Tighten the coupling bolts (2) evenly and firmly. For easier coupling installation, motor and pump shaft keys (4 & 6) should be 180 degrees from the working area. To automatically locate the impeller in the pump, lift the pump shaft until the pump shaft collar is positioned in the coupling groove, then rotate coupling to locate the pump shaft key (6) into the (Sometimes blind) keyway in the coupling. A wooden 2x4 piece may be firmly positioned to allow a pry-bar to be placed securely under the pump shaft collar; the rotating assembly may be levered and raised-up in this manner until the pump shaft collar is positioned in the coupling groove. For the 20x20x19 size pump refer to File 43.803 for rotating assembly lifting instructions and File 43.806 for seal service instructions. Push mechanical seal (8) firmly onto the stationary seat (11) and tighten the setscrews (1). Remove the holding clips (12) for operation.

12 15 13 14

9 10 11

SEAL REMOVAL An important feature of the Series 4300 and 4302 pump is that the design permits removal of the mechanical seal without disturbing the pump, motor or electrical wiring. A. Disconnect the power supply at the main switch and close the isolating valves on the suction and discharge. Empty casing by removing drain plug(s) located at the bottom. B. Loosen off the seal collar set screws (1) Remove the coupling bolts (2) and separate the coupling halves (3). C. Remove the motor shaft key (4) and the pump shaft key and collar (4 & 5) and the pump shaft key and collar (6 & 7). D. Remove the mechanical seal rotating assembly (8) through the gap between the pump and motor shafts. J.

NOTE 1) 2) The mechanical seal is preset at the correct working length. Installation of the coupling automatically locates the impeller in the pump.

K. Replace the seal flush piping (10A) and drain plug(s). Series 4302: Equalize pump pressure within dualArm pump by temporarily opening valve on connecting tubing. L. Open all isolating valves prior to operating pump(s). Reconnect power supply.

S. A. Armstrong Limited 23 Bertrand Avenue Toronto, Ontario Canada, M1L 2P3 T: (416) 755-2291 F (Main): (416) 759-9101

Armstrong Pumps Inc. 93 East Avenue North Tonawanda, New York U.S.A. 14120-6594 T: (716) 693-8813 F: (716) 693-8970

Armstrong Holden Brooke Pullen Wenlock Way Manchester United Kingdom, M12 5JL T: +44 (0) 161 223 2223 F: +44 (0) 161 220 9660

S.A. Armstrong Limited 2009

For Armstrong locations worldwide, please visit www.armstrongpumps.com

Das könnte Ihnen auch gefallen

- 416E, 422E, and 428E Backhoe Loader Hydraulic System (Interactive) 225-6836-04 05102011 PDFDokument13 Seiten416E, 422E, and 428E Backhoe Loader Hydraulic System (Interactive) 225-6836-04 05102011 PDFChagas Oliveira50% (2)

- Grua GROVE Hydraulic SchematicDokument6 SeitenGrua GROVE Hydraulic SchematicGiorgio Fer100% (3)

- DW13294103Dokument72 SeitenDW13294103p_jankoNoch keine Bewertungen

- Service Manual: (From Serial Number 100 To 1186)Dokument275 SeitenService Manual: (From Serial Number 100 To 1186)Giorgio FerNoch keine Bewertungen

- METROLOGY JNTUK Mech III - IIDokument103 SeitenMETROLOGY JNTUK Mech III - IIRajesh Shah0% (3)

- Aerodynamic and Aerothermodynamic Analysis of Space Mission Vehicles (Viviani-Pezzella) PDFDokument918 SeitenAerodynamic and Aerothermodynamic Analysis of Space Mission Vehicles (Viviani-Pezzella) PDFJesusDavidDeantonioPelaezNoch keine Bewertungen

- Schematic Diagram of Basic Elements of Centrifugal PumpDokument17 SeitenSchematic Diagram of Basic Elements of Centrifugal Pumpahsanul haqueNoch keine Bewertungen

- Installation & Troubleshooting Guidelines For API Seal Flush PlansDokument132 SeitenInstallation & Troubleshooting Guidelines For API Seal Flush PlansP_I_P_HNoch keine Bewertungen

- Unparalleled Solutions in Clean Water PumpingDokument20 SeitenUnparalleled Solutions in Clean Water PumpingkaranNoch keine Bewertungen

- Services Product CatalogueDokument132 SeitenServices Product CatalogueAhmed Ben OthmanNoch keine Bewertungen

- Disassembly & Reassembly: RequiredDokument19 SeitenDisassembly & Reassembly: RequiredChriscarl De Lima100% (1)

- Cat Ground Engaging ToolsDokument484 SeitenCat Ground Engaging ToolsDennis Farquhar100% (2)

- Foundation Design Philosophy For Rotating EquipmentDokument5 SeitenFoundation Design Philosophy For Rotating EquipmentjiokoijikoNoch keine Bewertungen

- Reeving Information v2Dokument19 SeitenReeving Information v2Giorgio Fer100% (2)

- Maxiforce 2013 CatalogDokument314 SeitenMaxiforce 2013 CatalogAdolfo MoscosoNoch keine Bewertungen

- Operation and Maintenance DamperDokument4 SeitenOperation and Maintenance DamperBharatsinh ChauhanNoch keine Bewertungen

- PIXMA Ip4200: Parts CatalogDokument6 SeitenPIXMA Ip4200: Parts Catalogpl3ym0b1l100% (1)

- Persatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)Dokument19 SeitenPersatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)HaryadiNoch keine Bewertungen

- Operation and Maintenance of Centrifugal PumpDokument10 SeitenOperation and Maintenance of Centrifugal PumpLutfil HakimNoch keine Bewertungen

- 8 Relevant Provisions of IS456Dokument14 Seiten8 Relevant Provisions of IS456kiran sreekumarNoch keine Bewertungen

- pmp1000 Pump InstallationDokument7 Seitenpmp1000 Pump InstallationPitipong SunkhongNoch keine Bewertungen

- Englisch Allgemein Hetronic InfoDokument32 SeitenEnglisch Allgemein Hetronic InfoGiorgio Fer75% (4)

- Fluke 77 Series III Service ManualDokument59 SeitenFluke 77 Series III Service ManualGiorgio FerNoch keine Bewertungen

- Using Variable Speed Drives VSDs in Pump Applications 1700774456Dokument36 SeitenUsing Variable Speed Drives VSDs in Pump Applications 1700774456hamedNoch keine Bewertungen

- Gas Turbine - Compressor AlignmentDokument2 SeitenGas Turbine - Compressor AlignmentNazmiNoch keine Bewertungen

- Profile of the International Pump Industry: Market Prospects to 2010Von EverandProfile of the International Pump Industry: Market Prospects to 2010Bewertung: 1 von 5 Sternen1/5 (1)

- AQA AS Physics A Chapter 11 Textbook AnswersDokument3 SeitenAQA AS Physics A Chapter 11 Textbook AnswerscathylisterNoch keine Bewertungen

- 2009-2010 APRILIA RSV4 FactoryDokument81 Seiten2009-2010 APRILIA RSV4 FactoryMade ChristianNoch keine Bewertungen

- Presentation On - : Horizontal Centrifugal PumpDokument78 SeitenPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Selecting A Centrifugal Pumps by System Analysis PDFDokument27 SeitenSelecting A Centrifugal Pumps by System Analysis PDFmishraenggNoch keine Bewertungen

- Centrifugal Pump Axial ThrustDokument4 SeitenCentrifugal Pump Axial Thrustfawmer61100% (1)

- Impellers Information: Show All Impellers ManufacturersDokument6 SeitenImpellers Information: Show All Impellers ManufacturersAbdul RahmanNoch keine Bewertungen

- GT24/GT26 Operation Training Module: Jacking Oil SystemDokument15 SeitenGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNoch keine Bewertungen

- Centrifugal CompressorDokument5 SeitenCentrifugal CompressorDeliaChiaNoch keine Bewertungen

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDokument4 SeitenStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanNoch keine Bewertungen

- Ice Qube ManualDokument16 SeitenIce Qube ManualGiorgio FerNoch keine Bewertungen

- Case Study Failure of Boiler Feed Water Pump-ADokument13 SeitenCase Study Failure of Boiler Feed Water Pump-Akirany58Noch keine Bewertungen

- Packing MachineDokument9 SeitenPacking Machinemiha3la33Noch keine Bewertungen

- Strainer YoshitakeDokument25 SeitenStrainer YoshitakeMuhammad ImranNoch keine Bewertungen

- ChecklistDokument3 SeitenChecklistAndy Noven KrisdiantoNoch keine Bewertungen

- Bomba CPKDokument20 SeitenBomba CPKPatricio Andres Silva SanzanaNoch keine Bewertungen

- Pumping Control Methods and Their Impact On System EfficiencyDokument16 SeitenPumping Control Methods and Their Impact On System EfficiencyWahidHamedNoch keine Bewertungen

- MasoneilanDokument20 SeitenMasoneilanJohn MarshalNoch keine Bewertungen

- AgitatorsDokument9 SeitenAgitatorsB Santosh Kumar DoddalaNoch keine Bewertungen

- T20 Retractable SootblowerDokument4 SeitenT20 Retractable SootblowerBadukwangNoch keine Bewertungen

- ChecklistDokument2 SeitenChecklistdassayevNoch keine Bewertungen

- Thermowell Insertion and Immersion+LengthDokument4 SeitenThermowell Insertion and Immersion+LengthinstrengNoch keine Bewertungen

- Compressor Turbo-Air API a4-IRDokument12 SeitenCompressor Turbo-Air API a4-IRMachineryengNoch keine Bewertungen

- The Basics of Pneumatic Control ValvesDokument3 SeitenThe Basics of Pneumatic Control ValvesAshutosh KhareNoch keine Bewertungen

- Water and Oil Free Screw Compressor Evaluation ReportDokument4 SeitenWater and Oil Free Screw Compressor Evaluation ReportdaritiNoch keine Bewertungen

- Positive Displacement PumpsDokument6 SeitenPositive Displacement PumpsVignesh DuraiNoch keine Bewertungen

- DGT W 16700 ETP 1140 IM 004 - A - Anexo - 4Dokument25 SeitenDGT W 16700 ETP 1140 IM 004 - A - Anexo - 4Ivan Maltsev100% (1)

- JHON CRANE 2152037 Barrier FluidsDokument19 SeitenJHON CRANE 2152037 Barrier Fluidstotalquality100% (2)

- Teikoku Rotary Guardian: Principle of OperationDokument2 SeitenTeikoku Rotary Guardian: Principle of OperationMón Quà Vô Giá100% (1)

- Hermetic Canned PumpDokument16 SeitenHermetic Canned PumpYlm PtanaNoch keine Bewertungen

- ACHE Windmill DraftguardDokument5 SeitenACHE Windmill DraftguardTIKSHALANoch keine Bewertungen

- Winston Engineering CompanyDokument10 SeitenWinston Engineering Companylimcsiang99Noch keine Bewertungen

- Ebara Horizontal Multistage PumpDokument27 SeitenEbara Horizontal Multistage PumpYohanes KrisNoch keine Bewertungen

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDokument1 SeiteApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNoch keine Bewertungen

- EBARA TEM Brochure - March 02Dokument6 SeitenEBARA TEM Brochure - March 02xsi666Noch keine Bewertungen

- Gear Drive Manual No. 702Dokument38 SeitenGear Drive Manual No. 702MaintenanceNoch keine Bewertungen

- OHH OHHL E00697 (Pump Zulzer)Dokument6 SeitenOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNoch keine Bewertungen

- S. No. Problem Potential Causes SolutionsDokument6 SeitenS. No. Problem Potential Causes SolutionsSyed Abdullah FaizNoch keine Bewertungen

- Manual B4601Dokument159 SeitenManual B4601FER-ARTNoch keine Bewertungen

- SIHI Thermal Fluid Circulating PumpDokument11 SeitenSIHI Thermal Fluid Circulating Pumpwilmer fernando lopez galeanoNoch keine Bewertungen

- Preservation of Fans For Long Shut DownDokument1 SeitePreservation of Fans For Long Shut DownKapil_1983Noch keine Bewertungen

- 0001152572Dokument14 Seiten0001152572AhmadNoch keine Bewertungen

- The Axial Flow Compressor CompromiseDokument8 SeitenThe Axial Flow Compressor Compromisekincandia100% (4)

- Pipe Strain Check ProcedureDokument1 SeitePipe Strain Check Procedurekamal arabNoch keine Bewertungen

- Vacuumpump SihiDokument9 SeitenVacuumpump SihikzwinnenNoch keine Bewertungen

- Flygt Vertical Column FAS VersionDokument8 SeitenFlygt Vertical Column FAS VersioncomedyboNoch keine Bewertungen

- Gas Turbine in Cairo North Power StationDokument38 SeitenGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- Dokumen - Tips Dv200 Manual Master1Dokument45 SeitenDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezNoch keine Bewertungen

- SIHI Multistage Brochure NA - RGBDokument7 SeitenSIHI Multistage Brochure NA - RGBMaria Gabriela BusteloNoch keine Bewertungen

- 10 Ways To Murder A PUMPDokument10 Seiten10 Ways To Murder A PUMPBaqirMuhammadNoch keine Bewertungen

- 43 88 - Mechanical - Seal - Replacement - Instructions - TCDokument4 Seiten43 88 - Mechanical - Seal - Replacement - Instructions - TCAlan MercesNoch keine Bewertungen

- 43.88UK Mechanical Seal Replacement Instructions TCDokument4 Seiten43.88UK Mechanical Seal Replacement Instructions TCMohammed Mostafa El HaddadNoch keine Bewertungen

- rt600 Tier3amptier4i Parts Manual For Reference Only April2013 PDFDokument370 Seitenrt600 Tier3amptier4i Parts Manual For Reference Only April2013 PDFGiorgio Fer100% (1)

- Bandas CartekDokument26 SeitenBandas CartekGiorgio FerNoch keine Bewertungen

- Spare Part List: Diamond Coring Tool DD 80 115V USDokument6 SeitenSpare Part List: Diamond Coring Tool DD 80 115V USGiorgio FerNoch keine Bewertungen

- Serial Number Range: To SN 780Dokument110 SeitenSerial Number Range: To SN 780Giorgio FerNoch keine Bewertungen

- KMK6190Dokument12 SeitenKMK6190Giorgio FerNoch keine Bewertungen

- Armstrong Kit Sello MecanicoDokument2 SeitenArmstrong Kit Sello MecanicoGiorgio FerNoch keine Bewertungen

- v1 Quiz 3 PDFDokument2 Seitenv1 Quiz 3 PDFParam Veer ChoudharyNoch keine Bewertungen

- Stirling Engine ApplicationsDokument20 SeitenStirling Engine ApplicationsChaitanya Raghav SharmaNoch keine Bewertungen

- KE52 Jurnal SNTTM2019Dokument8 SeitenKE52 Jurnal SNTTM2019yadiNoch keine Bewertungen

- Module 4: Deflection of Structures Lecture 7: Tutorial ProblemsDokument9 SeitenModule 4: Deflection of Structures Lecture 7: Tutorial ProblemsSaurav ChoudhuryNoch keine Bewertungen

- ERIKS - Techniki UszczelnienDokument28 SeitenERIKS - Techniki UszczelnienAdrian BożykNoch keine Bewertungen

- Laterally Loaded Pile With Plaxis 3dDokument5 SeitenLaterally Loaded Pile With Plaxis 3dteomalancuNoch keine Bewertungen

- SN/SD Bearings: Key Benefits of The Split Plummer Block AreDokument7 SeitenSN/SD Bearings: Key Benefits of The Split Plummer Block AreLymeParkNoch keine Bewertungen

- CHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Dokument68 SeitenCHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Anonymous 7MdZQn167% (3)

- Geas Iecep PDFDokument26 SeitenGeas Iecep PDFMichael Cabrera RabinoNoch keine Bewertungen

- 3D Stress and Strain Tutorial SheetDokument2 Seiten3D Stress and Strain Tutorial SheetTasmin Chandran0% (1)

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNoch keine Bewertungen

- Module 2 - Flywheels Part 2Dokument5 SeitenModule 2 - Flywheels Part 2Johnlloyd BarretoNoch keine Bewertungen

- Absolute CEDokument2 SeitenAbsolute CEhaan luuNoch keine Bewertungen

- Turbines and ExpandersDokument8 SeitenTurbines and ExpandersMusa KaleemNoch keine Bewertungen

- 3118F 3318F 3618F-SeriesDokument6 Seiten3118F 3318F 3618F-SeriesDavid CandoNoch keine Bewertungen

- Advanced Aerodynamics: Lecture 2: Turbulence Models Applied To AerodynamicsDokument66 SeitenAdvanced Aerodynamics: Lecture 2: Turbulence Models Applied To AerodynamicsCarlos Aparisi CanteroNoch keine Bewertungen

- Mech 32-Strength of Materials: Fundamental Concepts 1Dokument34 SeitenMech 32-Strength of Materials: Fundamental Concepts 1Alyssa MadelNoch keine Bewertungen

- DXS Mobile Tower Brochure - 1.1Dokument2 SeitenDXS Mobile Tower Brochure - 1.1Sabri JamilNoch keine Bewertungen

- Homework For FDGDokument5 SeitenHomework For FDGgrace9pengNoch keine Bewertungen

- Large Roofs and Sports Stadiums: Wind Loading and Structural Response Lecture 20 Dr. J.D. HolmesDokument22 SeitenLarge Roofs and Sports Stadiums: Wind Loading and Structural Response Lecture 20 Dr. J.D. HolmesFreddy Aparicio QuispeNoch keine Bewertungen

- Hydraulic Circuit (PKD/Finned/1 & 2 Floating Rollers)Dokument5 SeitenHydraulic Circuit (PKD/Finned/1 & 2 Floating Rollers)Oscar ItzolNoch keine Bewertungen