Beruflich Dokumente

Kultur Dokumente

57 07-05-21 Isaif8 0021-Chen

Hochgeladen von

Weins GemerlapOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

57 07-05-21 Isaif8 0021-Chen

Hochgeladen von

Weins GemerlapCopyright:

Verfügbare Formate

Proceedings of the 8th International Symposium On Experimental and Computational Aerothermodynamics of Internal Flows Lyon, July 2007 Paper

reference: ISAIF8-0021

Blade Parameterization and Aerodynamic Design Optimization For a 3D Transonic Compressor Rotor

Naixing Chen Hongwu Zhang Yanji Xu Weiguang Huang

Institute of Engineering Thermophysics, Chinese Academy of Sciences, P.O. Box 2706, Beijing 100080, CHINA. E-mail: nxc@mail.etp.ac.cn; Fax: +8610-8257-3335 Keywords: Aerodynamic optimization, blade optimization, compressor bladings

The present paper describes an optimization methodology for aerodynamic design of turbomachinery combined with a rapid 3D blade and grid generator (RAPID3DGRID), a N.S. solver, a blade parameterization method (BPM), a gradient-based parameterization-analyzing method (GPAM), a response surface method (RSM) with zooming algorithm and a simple gradient method. By the use of blade parameterization method a transonic compressor rotor can be expressed by a set of polynomials, and then it enables us to transform coordinate-expressed blade data to parameter-expressed and then to reduce the number of parameters. With changing any one of the parameters and by applying grid generator and N.S. solver, we can obtain several groups of samples. Here only ten parameters were considered to search an optimized compressor rotor. As a result of optimization, the adiabatic efficiency was increased by 1.73%.

Introduction

It is well known that the compressor is one of the most important components of a gas turbine unit. Uncountable experimental investigations have been carried on to understand 3D flow phenomena happened in a compressor and the effects of the different geometric parameters on its aerodynamic performance. In recent two decades due to that aerodynamics design of compressor blades has progressed by the development of 3D N.S. equation computation methodologies and the computer technology there has been availability to allow these methods to be used extensively in the design process. At the same time using the computational fluid dynamics enables us to obtain the internal flow physics in details and to save investment for experimental facilities construction, manpower and time. Optimization methodology has become an important tool to increase turbomachinery efficiency. Hence the studies [1-27] on aerodynamic optimization methods became important tasks in turbomachinery community in order to achieve higher blade efficiency without carrying out high cost experimental tests. Turbomachinery design is a complex task that involves many different objectives and constraints coming from different disciplines. Many optimization algorithms have been reported to date with varying

degree of success. It is well known that up to now the 3D design process has been mainly iterative and sequential. Any slight change of turbomachinery geometry to improve the flow pattern and shock structure always leads to re-meshing and parameterization analyses, N.S. computations and further optimizations. Therefore, we need to have to know how the influence of each design parameter on aerodynamic performance is, and some of them can be neglected, otherwise the manpower and time for computations will be increased rapidly. Therefore, to reduce the number of design parameters is one of very important tasks for reducing the computational time and manpower in optimization technologies. In the present study, a rapid 3D blade and grid generation method (BPM), a blade parameterization procedure method, a N.S. computation method and a set of aerodynamic optimization methods were used for designing a 3D single compressor rotor blading. In our case the optimization methodologies used herein are gradient-based parameterization-analyzing method (GPAM), response surface method (RSM) with zooming algorithm (ZA) and simple gradient method, etc. The N.S. solver, applied in the paper, is a 3D finite volume algorithm coupled with the Baldwin-Lomax eddy viscosity turbulence model. A wall function that

Naixing CHEN: Professor http://www.lmfa.ec-lyon.fr/ISAIF8/

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

accounts for the boundary effect is used for reducing the grid number. The computations are performed with a second-order centered scheme and with an artificial dissipation term as suggested by Jameson. The discrete algebraic equations are solved by means of a multi-stage Runge-Kutta time-marching procedure. The authors with this code joined the NASA Single Rotor 37 Blind Test Case organized by the ASME Turbomachinery Committee in 1994 [28-31]. To avoid heavy and troublesome work to build a 3D blading and its meshes we applied a rapid 3D blade and grid generator (RAPID3DGRID). Giving the parameterized geometrical data, a 3D blade and its computational meshes can be obtained within a few minutes. A parameterization method, suggested in the papers [22, 23, 25], was applied to construct a compressor blading with a set of polynomials. The calculation example shown in this paper is a single rotor compressor that was modified from NASA Rotor 37 by the use of parameterization method and then optimized by the present methodologies.

once, the 3D blade geometry can be obtained. The advantages of blade parameterization are as follows: (1) it enables us to transform the blade geometry from coordinate-expression to parameterized expression, and vice versa; (2) it easily can be accepted by the designers, since their experiences can be used in the blade optimization stage. If we use polynomials instead of previous two expressions, we could transform the blade data from discrete to parameterized data. This is a reconstruction procedure. Using a computer code that was developed by the authors, for rebuilding a compressor blade profile only a few minutes are required. By choosing appropriate complex of different parameter values and using an optimization methodology we can obtain an optimal compressor blading. In this study the section profile geometry at any span height can be discribed by using only two groups of polynomials. They are able to replace the camber line and the thickness distribution approximately. One of the following three curves, (1) blade camber line, (2) thickness distribution and (3) radial stacking line of any blading, can be approximated by a polynomial, i.e.:

Blade Parameterization and Reconstruction Methods

Blade parameterization is an important tool in the blade optimization process. Designers can obtain the effects of different geometrical parameters on blade performance using a N.S. solver. Any blade geometery can be expressed by the following two expressions, one is by the conventioal coordinates and another is by the design parameters, ie:

yi = Ci 0 + j1 Cij x j , =

n j

(3)

where C i 0 , C i1 , C i 2 ,...C ij ,...C in are the coefficients of the polynomial of order j . Each curve can be represented by one or two polynomials. This depends on the number of parameters and the order of the polynomial to be used.

f ( x, y, z ) = 0

or

(1)

f ( X 1 , X 2 , X 3 ,..., X n ) = 0

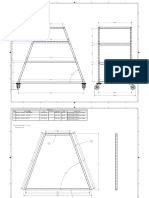

(2) In the latter expression, X 1 , X 2 , X 3 ,... X i ... X n are the design parameters. All parameters can be seen in Fig. 1 and Fig. 2. For a compressor blade profile the parameters are as follows: maximum camber and its location, maximum thickness and its location, stagger angle, leading and trailing edge circle radii, thickness gradient angles of leading and trailing edges, inlet and outlet blade angles, etc. Please see Figs 1 and 2. Some of them are decided by the structure requirement. We could use the following groups of polynomials instead of (1) camber line and (2) thickness distribution of each section profile; (3) radial distribution of each design parameter; (4) stacking bowing line; (5) sweeping line. The latter two are not considered in the present paper. Here we adopted that the stacking line is a straight line. Since each polynomial can be expressed by the design parameters, as the design parameters are given

BX mc

SX mth

Fig.1 Camber line and thickness distribution

The polynomial coefficients are obtained from the given design parameters. As shown in Fig.1 they are: blade meridian width B , length of camber line S , maximum camber

H max and its relative location

X mc = x mc / B , maximum thickness circle radius Rmax and its relative location X mth = x mth / S , leading and

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

trailing edge thickness radii R1 , R2 , thickness gradient angles of leading and trailing edges 1 , 2 , blade inlet and outlet geometrical angles (blade angles) g 1 , g 2 , and stagger angle st , etc. Therefore, we have 14 design parameters. Similarly as the reference [25] all coefficients of the polynomials can be estimated as the functions of above-mensioned design parameters. So, the camber line is a function of the parameters:

showing some of them. In Figs.4-6 the radial variations of maximum camble and its location, maximum thickness and its location and stagger angle are demonstrated. In these figures the red solid circles and the dotted lines denote the profile results of different span heights rebuilt by the blade parameterization algorithm and their polynomial approximation, respectively.

y camber = f camber ( g1 , g 2 , st , B, H max , xmc , y mc ) (4)

By the same way we can also obtain the thickness distribution as a function of the parameters:

y thick = f thick ( 1 , 2 , R1 , R2 , Rmax , S , x mth ) (5)

We can transform the blade profile from the coordinate expression to parameterized expressions, by comparing two functions, Eqs. (1) and (2) expressed by conventional coordinates and parameterized, respectively.

Fig.3 Blade profile reconstruction (tip section of NASA Rotor37)

1.2

0.8

0.4

0.2

Fig.2 Radial stacking line

0.0

Fig.2 shows a bowing stacking line that can be also expressed by a polynomial with 3 design parameters. If we consider blade sweeping, there are three design parameters increased. In the present paper we did not consider blade bowing and sweeping. In Fig.3 we are demonstrating the tip section profile of NASA Rotor 37. As shown in the figure the reconstructed tip section profile (expressed by design parameters) are closed well with the original NASA Rotor 37 transonic single rotor compressor (expressed by conventional coordinates). There are twelve groups of section profile coordinates at different radial span heights were given by NASA. Using the blade parameterization method all the section profiles were reconstructed by the design parameters. And then, the radial distributions of all design parameters can be obtained. Here we are only

160

180 200 220 240 radial direction (mm)

260

Fig.4 Radial distributions of maximum camber and its location

The radial variation of any design parameter along span height of the compressor rotor, R37, to be optimized was assumed as a second order polynomial approximition. Then, we could obtain approximitety all the radial distribution of this parameter by interpolation. Here we assume that any three of the parameters along the span height, for example at hub, mid-span and tip, are given. By this way the number of design parameters used for creating samples will be much reduced. It is known that the number of unknown

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

coefficients for creating a second order response surface can be determined as: (6) ncoef = (n des nsec + 1) ( n des nsec + 2) / 2 where ndes and nsec denote the number of design parameters for each section profile and the section number along whole span height, respectively. Therefore, the number of coefficients for a response surface is increased with increasing the total design parameter number. In this study the number of design parameters for generation of a blade profile, we use, is 14. In our case the number of sections profile along radial direction is three. Then, the total number joined the parameterization process for rebuilding a blading is 42. Here we have not yet considered blade sweeping and compound leaning.

2.5

2.0

1.5

1.0

0.5

usually are given from structure requirement and some can be neglected due to their slight effect on the blade performance. Therefore, reducing the number of design parameters is one of important tasks. In our case there are ten parameters that we used, i.e. stagger angle, maximum camber location and maximum thickness location for three section profiles (hub, midand tip span heights) and blade solidify (or blade number), are used in the optimization process. In the later paragraph we will discuss the maximum thickness location effect. This problem is partially decided by the structure requirement. The optimization methodology in this paper is an iteration process including blade reconstruction (parameterization), parameter selection and grid generation, N.S. equation solution and sample creation, optimization steps. The above steps are repeated again until the solution is converged. These procedures are in general lengthy and computer-power hungry. Especially, N.S. computations are much computer time consumed. Fig.7 and Fig.8 show the grid system (85x30x30) of the modified (parameterized) rotor and its performance calculated by using the N.S. solver proposed by the authors, respectively. The performance of the original Rotor 37 is also plotted in the figure. We got these experimental results [28, 29] during the period of NASA Single Rotor Blind Test Case in 1994.

0.0 160

180 200 220 240 radial direction (mm)

260

Fig.5 Maximum thickness radius and its location

70

Stagger angle (deg.)

60

50

40

Fig.7 Grid system of rebuilt compressor rotor

30 160

180 200 220 240 Radial direction (mm)

260

Fig.6 Radial distributions of stagger angle

From the above expression we know that the number of unknown coefficients to be determined is increasing rapidly with increasing the number of design parameters to be joined the optimization process. For such a great number of the design parameters we could not use all of them in the optimization stage since some of them

As shown in Fig.8 the calculated pressure ratio of the modified (or reconstructed) rotor is lower than that of the experimental results, and the calculated chock flow rate is also smaller than that of the experiment. The red circle is the design point at which back static pressure we would like to optimize. The computer code developed by the authors and validated by CFD Code Assessment Exercise of ASME Turbomachinery Committee. As a whole, using this code the predicted results are reasonably acceptable, and it can be applied and integrated into the present optimization

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

system. In Fig.9-11 are plotted the thermal loss coefficients vs. the design parameter for different groups.

Adiabatic efficiencyTotal pressure ratio

3.0 2.5 2.0 1.5 1.0 90 80 70 19.2 19.6 20.0 20.4 Flow rate (kg/sec) 20.8

Adiabatic efficiency (%)

Calculated

the minimal thermal loss coefficient. It is clearly seen that the optimal points for these three design parameters are equal to 0.73, 0.74 and 0.75 for the hub, mid- and tip sections, respectively.

13.5

Total pressure ratio

Thermal loss coefficient (%)

Calculated

13.0

12.5

12.0

30.0, 50.0, 65.0 (deg.) 37.5, 48.5, 57.5 Optimum

11.5

38.533, 50.267, 60.467 40.0, 50.0, 60.0 42.5, 52.5, 62.5

11.0 0.64

0.68

0.72

0.76

Fig.8 Performances of the original rotor R37 (experiment) and of the modified (or parameterized) rotor (calculated)

Fig.9 Relationship between thermal loss coefficient and maximum camber location for different groups of stagger angles (at hub-span height)

OPTIMIZATION BY GRADIENT-BASED PARAMETERIZATION ANALYZING METOD GPAM

Thermal loss coefficient (%)

13.5

In our case the optimization methodologies used herein are gradient-based parameterization analyzing method, response surface method with zooming algorithm and simple gradient method, etc. In this section we will show the results of optimization for searching the optimal stagger angle along the span height and optimal maximum camber location of the single compressor blading. In the present paper the objective is to optimize the adiabatic efficiency, ad , or to minimize the thermal loss coefficient,

13.0

12.5

12.0

30.0, 50.0, 65.0 (deg.) 37.5, 48.5, 57.5 Optimum

11.5

38.533, 50.267, 60.467 40.0, 50.0, 60.0 42.5, 52.5, 62.5

11.0 0.64

0.68

0.72

0.76

= 1 ad .

Fig.10 Relationship between thermal loss coefficient and maximum camber location for different groups of stagger angles (at mid-span height)

We randomly elected a few groups of blades with different radial distributions of stagger angle and maximum camber location along span height. These blades were well parameterized with only changing the above-mentioned two parameters and keeping other parameters to be constant. The thermal loss coefficient was calculated using the N.S. solver. As shown in the figures we could see: (1) the third group, shown by red solid circles (or red symbol of plus for fig.12), has the minimal loss coefficients for all design parameters of the maximum camber location at different sections along span height; (2) the front of the minimal thermal loss coefficient, shown by the black dash lines approximately; is a curve, that can not be simply expressed by the second order polynomial. But, we could observe it easily from these figures and the optima of the design parameters along span height can be obtained with the gradient method from the front line of

13.5

Thermal loss coefficient (%)

13.0

12.5

12.0

30.0, 50.0, 65.0 (deg.) 37.5, 48.5, 57.5 Optimum

11.5

38.533, 50.267, 60.467 40.0, 50.0, 60.0 42.5, 52.5, 62.5

11.0 0.64

0.68

0.72

0.76

Fig.11 Relationship between thermal loss coefficient and maximum camber location for the third group of stagger angles (at tip-span height)

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

13.6

Thermal loss coefficient (%)

was obtained by second order polynomial interpolation. In the figures (Figs.13-15) the samples, the response surfaces and the optimal point obtained are plotted. The

Samples Optomal point

13.2

symbols,

st , hub , st, mid , st ,tip denote relative

12.8

stagger angle at near hub-, mid- and near tip-sections, respectively, i.e.:

12.4

st ,i = [( st ,i )up st ,i ] /[( st ,i )up ( st ,i ) down ] ,

(7)

12.0

11.6 0.64 0.66 0.68 0.70 0.72 0.74 0.76 0.78

Fig.12 Relationship between thermal loss coefficient and maximum camber location for the third group of stagger angles (at mid-span height)

where the subscripts up and down denote upper and lower boundaries of creating response surfaces; Subscript, i, represents hub-, mid- and tip-sections. Here in the present case the upper and lower boundaries were adopted as 28 and 44 deg., 46 and 54 and 56 and 66 deg. for near hub-, mid- and near tip-sections, respectively. This measure to create response surface usually we call Zooming algorithm.

20

Samples

The further computations and creations of greater number of samples for the third group of samples with the same stagger angle distribution proved this observation again. We would like to show the relationship between loss coefficient and maximum camber location again. It is plotted here only for the hub section (Fig.12). As shown in the figure, the optimal point of maximum camber location for the mid-span blade section is just equal to 0.74, where it is indicated by the red symbol of plus. Therefore, the present parameterization method can be applied for multi-parameter blade optimizations.

20

Samples

Thermal loss coefficient (%)

RSM approximation

18

Optimal point

16

14

12

10 0.0

0.2

0.4

0.6

0.8

1.0

Thermal loss coefficient (%)

RSM approximation

18

Optimum point

Fig.14 Relationship between thermal loss coefficient and relative stagger angle for given radial distribution of maximum camber location (at mid-span height)

20

16

Samples

Thermal loss coefficient (%)

RSM approximation

18

Optimal point

14

16

12

14

10 0.0

0.2

0.4

0.6

0.8

1.0

Fig.13 Relationship between thermal loss coefficient and relative stagger angle for given radial distribution of maximum camber location (at near hub- span height)

12

10 0.0

0.2

0.4

0.6

0.8

1.0

OPTIMIZATION WITH RESPONSE SURFACE METHOD RSM Response surface method was applied to estimate the optimal stagger angles at near hub, mid- and near tip sections, and then at any blade section the stagger angle

Fig.15 Relationship between thermal loss coefficient and relative stagger angle for given radial distribution of maximum camber location (at near tip-span height)

We use response surface method with such a zooming algorithm to reduce the sample number and the order of the response surface approximation, then to

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

reduce working time and manpower. In the multi-optima case this is a very effective measure to be taken. For this objective we should know the approximate place where is the optimum point located firstly, and then, to zoom in this zone and to looking for the local optimal point.

Thermal loss coefficient (%)

15 12 9 0.5 6 3 0 12 16 20 24 Sample number 28 0.0 1.0

Rel. design parameter

stagger angles for near hub-, mid- and near tip-sections are 38.2, 52.0 and 61.4 degrees, respectively. The convergence history of the optimization using RSM method is demonstrated in Fig.16. The thermal loss coefficient and three relative design parameters are converged to be constant with increasing the sample number to be joined the process. MAXIMUM THICKNESS LOCATION EFFECT STUDY From basic aerodynamics theory we know that in the transonic flow case usually appears strong shock in the blade channel. The shock loss is decreased with enlarging the front flat portion of the blade profile. Many researchers have proved it. Fig.17 shows that the thermal loss coefficient is decreased with increasing the maximum thickness location for all the sections from hub to tip along span height. Therefore, it is beneficial to have larger maximum thickness location for us at the viewpoint of aerodynamics. But it also depends on the structure requirements. So, for this problem would to have a deliberate decision by both sides of designer SEARCHING OF OPTIMAL BLADE CASCADE SOLIDITY In the present paragraph we will discuss how to search the optimal blade cascade solidity on the compressor blading performance. It is known that the blade cascade solidity is increased with increasing the blade number. There are 36 blades installed in the single rotor compressor 37. On the base of optimized results, changing the number of blades only, generating the grid system again, then we obtained the performance of the blading with different blade numbers calculated by using N.S. solver. Fig.18 shows the blade solidity (or blade number) effect on the performance, i.e. adiabatic efficiency, total pressure ratio and flow rate. CALCULATED RESULTS

Fig.16 Convergence history of RSM approximation

15.0

Thermal loss coefficient (%)

14.0

Polynomial

Polynomial

13.0

Polynomial

12.0

11.0

10.0 0.4

0.5 0.6 0.7 Rel. max.thickness location

0.8

Fig.17 Relationship between thermal loss coefficient and rel. maximum thickness location for the stagger angle radial distribution of 38.5, 50.2 and 60.5 degrees

2.00 1.99 1.98 89.0 88.0 87.0 20.6

Flow rate (kg/sec) Total pressure ratio

Adiabatic efficient (%)

20.4 20.2 34 35 36 Blade number 37 38

Fig.18 Performance of the blading with different number installed

In the foregoing optimization process we used the parameterization analyzing method, response surface method with zooming algorithm and gradient method to optimize a single rotor compressor blading. The object was to optimize the adiabatic efficiency (minimize the thermal loss coefficient). The final results are given in the tables 1-4. TABLE 1 Performances of original and optimized bladings

Blading Original Optimized Flow rate (kg/sec) 20.40 20.43 Total pressure ratio 1.939 1.987 Adiabatic efficiency (%) 86.85 88.58 Loss coefficient (%) 13.15 11.42

From Figs.13-15 it is clearly seen that the optimal relative stagger angle is located at 0.64, 0.8 and 0.54 for the near hub-, mid- and near tip-sections, respectively. The thermal loss coefficient is about 11.74 %. With corresponding to these relative values we have the

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

Table 2 Hub, mid- and tip span stagger angles of original and optimized bladings

Blading Original

edge. It makes the shocks weaker and their locations are pushed forwards to the direction of trailing edges.

st ,hub

(deg.) 38.53

st ,mid

(deg.) 50.25

st ,tip

(deg.) 60.47

Optimized

38.24

52.0

61.40

Table3 Relative maximum camber locations at hub, mid- and tip span for original and optimized bladings

Blading Original Optimized

Original

Hub

Mid-span

Original

Tip

Original rotor

X mc,hub

0.623 0.730

X mc , mid

0.546 0.740

X mc ,tip

0.740 0.750

Table 4 Relative maximum thickness locations at hub, mid- and tip span for original and optimized bladings Blading Original Optimized

Optimized

Optimize

Hub

Mid-span

Tip

Optimized rotor

X mth ,hub

0.525 0.525

X mth ,mid

0.546 0.546

X mth ,tip

0.660 0.660

Fig.19 Relative Mach number contours at 5%, 50% and 95% span heights

In above tables the aero-thermodynamic and design geometric parameters of the original and optimized single rotor compressor bladings are compared for the designated point are given. The original one is that blading we had rebuilt from the original rotor 37 by the parameterization method. Based on the parameterized blading we obtained the optimized rotor by the methods presented in this paper. The optimized data given in these tables are for the blade number of 35 only. Increasing of the adiabatic efficiency for the optimized blading is 1.73% comparing with that of the original one. The flow rate is almost the same, and the total pressure ratio is increased a little bit. We took the maximum thickness distribution along the span height to be the same as the original blading. As shown in the previous paragraph the adiabatic efficiency is increased with the longer maximum thickness location from the leading edge. Since this problem is also interested for the structure designers it is better to decide it by the negotiation with them. Therefore, we are still keeping the maximum thickness distribution along the span height as the same as the original rotor. Fig.19 shows the Mach number contours at three different span heights, i.e. near hub- (5%), mid- (50%) and near tip- (95%) span heights. Both groups of Mach number contours are at the same designated working point (signed with red circle in Fig.8). As shown in the figure it is evident that the shock structure of the optimized blading is weaker than that of the original one. This is due to that the maximum camber location of the optimized blading is closer to the trailing

In Fig.20 the pressure contours on suction and pressure surfaces of optimized and original compressor blades. The same shock structures can be obviously seen. The shock wave strength of the optimized rotor is weaker than that of the original one. So, the shock loss of the first blading is lower. We can see that from these two figures the supersonic flow causes a shock wave attached the leading edge in the inlet region. There is a bow wave appeared. This shock wave extends to the space of the upstream in one direction and in the opposite direction to the suction surface of the neighbor blade. After the shock wave the flow continuously goes forward. If the flow is still supersonic, entering the blade channel a new shock wave is still formed in the blade channel. Sometimes, these two shock waves coincide with each other. In this case the shock wave becomes much stronger than the single shock. Then the very strong shock wave sharply hits the suction surface, and in the result of shock-boundary layer interaction that easily to causes a strong separation, and then the shock loss becomes greater. If there is no superposition of two shock waves, and they are separately located at the regions of leading and trailing edges, the shock wave loss is smaller. This case can be found in the Mach number contours at the tip span height of the optimized blading (please see Fig.19). Due to this reason the shock wave loss of the blading is less than of the original blading. From the above-mentioned analyzes we can see that for the supersonic zone the shock wave loss is dominated, and to improve the blade channel design, that enables us to have a reasonable supersonic flow pattern and shock system, is an important measure to reduce the shock wave loss.

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

multi-objective and multi-optima problems.

Pressure surfaces

Pressure surfaces Fig.20 Pressure contours on suction and pressure surfaces of optimized and original compressor rotor blades

CONCLUSIONS From previous paragraphs of the present paper we could obtain the following conclusions: (1) The blade parameterization method, proposed by the authors, can be used for blade reconstruction from discrete to parameterized data. A single rotor compressor of NASA Rotor 37, as an example, was reconstructed and parameterized using a set of polynomials. The significances of the blade parameterization are as follows: (a) It enables us to transform the blade from coordinate-expressed data to parameter-expressed ones; (b) Let us to have a possibility to study the effect of any one of the parameters on the blade geometry and the blade aerodynamic performance that can be numerically calculated by a N.S. solver. (2) The present parameterization method can be used to search the optima in multi-parameter optimization problems. (3) In the present paper the optimization methodologies used herein for aerodynamic design of turbomachinery were combined with a rapid 3D blade and grid generator (RAPID3DGRID), a N.S. solver, a blade parameterization method (BPM), a gradient-based parameterization analyzing method (GPAM), a response surface method (RSM) with zooming algorithm and a simple gradient method. (4) The response surface method with zooming algorithm is a direction for the solution of (5) We used also a simple gradient method to obtain an optimal blade number. (6) We used also a simple gradient method to obtain an optimal blade number. (7) The flow pattern and the shock structure of the optimized compressor rotor are reasonable. The increasing of adiabatic efficiency of the rotor by the optimization is about 1.73%. The total pressure ratio and the flow rate are also increased a little bit. The present optimization methodologies are successful. REFERENCES [1] Lee, S.Y. and Kim, K.Y., 2000, Design Optimization of Axial Flow Compressor Blades with Three-Dimensional Navier Stokes Solver, ASME Paper 2000-0488, 2000. [2] Shahpar, S., 2001, Three-Dimensional Design and Optimization of Turbomachinery Blades Using the Navier-Stokes Equations, Proceeding of 2001 ISAIF, Paper No. ISABE 2001-1053. [3] Nagel, Marc G., Fottner, L., 2001, Optimization of Three Dimensionally Designed Turbine Blades and Side Walls, Proceeding of 2001 ISAIF, Paper No. ISABE 2001-1058. [4] Oyama, A., Liou, M.S. and Obayashi, S., 2002, Transonic Axial Flow Blade Shape Optimization Using

10

Proceeding of the 8th International Symposium 0n Experimental and Computational Aerothermodynamics of Internal flows

Evolutionary Algorithm and Three-Dimensional Navier Stokes Solver, ASME Paper 2002-5642, 2002. [5] Ahn, C.S. and Kim, K.Y., 2002, Aerodynamic Design Optimization of an Axial Flow Compressor Rotor, ASME Paper 2002-30445, 2002. [6] Ernesto B., 2004, Three-Dimensional Multi-Objective Design Optimization of a Transonic Compressor Rotor, J. Propulsion and Power, Vol.20, No.3, May-June 2004. [7] Moroz, L., Govoruschenko, Y., Romenenko, L. and Pagur, P., 2004, Methods and Tools for Multidisciplinary Optimization of Axial Turbine Stages with Relatively Long Blades, ASME Paper GT2004-53000. [8] Demeulenaere, A., Ligout, A. and Hirsch, Ch., 2004, Application of Multipoint Optimization to the Design of Turbomachinery Blades, ASME Paper GT2004-53110. [9] Ashihara, K., Guo, S.J., Goto, and A. Okamoto, H., 2004, Optimization of Micro-turbine Aerodynamics Using CFD, Inverse Design and FEM Structural Analysis (1st Report: Compressor Design), ASME Paper GT2004-53431. [10] Watanabe, H., Okamoto, H., Guo, S.J., Goto, A. and Zangeneh, M., 2004, Optimization of Micro-turbine Aerodynamics Using CFD, Inverse Design and FEM Structural Analysis (2nd Report: Turbine Design), ASME Paper GT2004-53583. [11] Wingelhofer, F. and Haselbacher, H., 2004, New Optimization Criteria for the Design of Three-Dimensional Bladings Applied to Compound Lean Nozzles of an Axial Turbine, ASME Paper GT2004-53830. [12] Arnone, A. Bonaiuti, D., Focacci, A., Pacciani, R., Greco, A.S.D. and Spanco, E., 2004, Parametric Optimization of a High-Lift Turbine Vane, ASME Paper GT2004-54308. [13] Dawes, W.N., 2004, Rapid Prototyping Design Optimisation Using Flow Sculpting, ASME Paper GT2004-53830. [14] Hasenjager, M., Sendhoff, B., Sonoda, T. and Arima, T., 2005, Three Dimensional Aerodynamic Optimization for an Ultra-Low Aspect Ratio Transonic Turbine Stator Blade, ASME Paper GT2005-68680. [15] Oksuz, O. and Akmandor, I.S., 2005, Turbine Blade Shape Aerodynamic Design Using Artificial Intelligence, ASME Paper GT2005-68094. [16] Kuzmenko, M.L., Egorov, I.N., Shmotin, Yu. N., 2005, Axial Fan Optimization Using 3D Codes, ASME Paper GT2005-68290. [17] Lian, Y.S. and Liou, M.S., 2005, Multi-Objective Optimization Using Coupled Response Surface Model and Evolutionary Algorithm, AIAA Journal, Vol.43, No.6, June 2005, pp.1316-1325, 2005. [18] Wang, Z.H. and Xi Guang, 2006, Aerodynamic Optimization Design for Vaned Diffuser of a High Pressure Ratio Centrifugal Compressor, No. 062048, Proceeding of Chinese Society of Engineering

Thermophysics, 2006, (in Chinese). [19] Kawagishi, H. and Kudo, K., 2005, Development of Global Optimization Method For Design of Turbine Stages, ASME Paper GT2005-68290. [20] Li, J., Li, G.J., Feng, Z.P. and Liu, L.J., 2005, Multiobjective Optimization Approach to Turbomachinery Blades Design, ASME Paper GT2005-68303. [21] Song, L.M., Feng, Z.P., Li, J., 2005, Shape Optimization of Turbine Stage Using Adaptive Range Differential Evolution and Three-Dimensional Navier-Stokes Solver, ASME Paper GT2005-68280. [22] Chen, N.X., Zhang, H.W., Xu, Y.J. and Huang, W.G., 2005, Geometry Effects on Aerodynamics Performance of a Low Aspect Ratio Turbine Nozzle, Journal of Thermal Science, No.1, March, or Proceeding of 7th ISAIF Conference, September 11-15, 2005, Tokyo Japan. [23] Chen, N.X., Zhang, H.W., Huang, W.G. and Yu, S., 2005, Study on Aerodynamic Design Optimization of Turbomachinery Blades, Invited Presentation, 7th ISAIF Conference, September 11-15, 2005, Tokyo Japan. [24] Chen, N.X., Zhang, H.W., Xu, Y.J. and Huang, W.G., 2005, Effect of Maximum Camber Location on Aerodynamics Performance of Transonic Compressor Blades, Proceedings of GT2005-68541, ASME Turbo Expo 2005, June 6-9, 2005, Reno-Tahoe, Nevada, USA. [25] Chen, N.X., Zhang, H.W., Ning, F.F, Xu, Y.J. and Huang, W.G., 2006, An Effective Turbine Parameterization and Aerodynamic Optimization Procedure Using an Improved Response Surface Method, Proceedings of GT2006, ASME Turbo Expo 2006, May 8-11, 2006, Barcelona, Spain. [26] Song, L.M., Li, J., Feng, Z.P. and Lou, C., 2006, Multi Objective Aerodynamic Optimization Design of a Transonic Compressor Blading, No. 062051, Proceeding of Chinese Society of Engineering Thermophysics, 2006, (in Chinese). [27] Chen, Z., Yuan X., Three-Dimensional Aerodynamics Optimum Design of Compressor Blade Based on Numerical Simulation of Fan/Compressor, No. 062115, Proceeding of Chinese Society of Engineering Thermophysics, 2006, (in Chinese). [28] Denton, J.D., Private communications1993. [29] Strazisar, A., Private communications, 1993. [30] Strazisar, A.L. and Denton, J.D., CFD Code Assessment in Turbomachinery a Progress Report, IGTE Global Gas Turbine News, May/June, pp.12-14, 1995. [31] Denton, J.D., Lessons from Rotor 37, Proceedings of the Third International Symposium on Experimental and Computational Aero-thermodynamics of Internal Flows, pp. 3-14Beijing, 1996.

Das könnte Ihnen auch gefallen

- Axial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationDokument10 SeitenAxial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationAditya SawantNoch keine Bewertungen

- Design Sensitivity Analysis of Air-Lubricated Slider BearingsDokument3 SeitenDesign Sensitivity Analysis of Air-Lubricated Slider BearingsDeepak SharmaNoch keine Bewertungen

- Multi-Objective Optimization of An Axial Compressor Blade: Abdus Samad and Kwang-Yong KimDokument9 SeitenMulti-Objective Optimization of An Axial Compressor Blade: Abdus Samad and Kwang-Yong KimEslam NagyNoch keine Bewertungen

- Three-Dimensional Design of Axial Flow Compressor Blades Using The Ball-Spine AlgorithmDokument9 SeitenThree-Dimensional Design of Axial Flow Compressor Blades Using The Ball-Spine Algorithmluisgonzalezf95Noch keine Bewertungen

- Optimization of The LS89 Axial Turbine Profile Using A CAD and Adjoint Based ApproachDokument13 SeitenOptimization of The LS89 Axial Turbine Profile Using A CAD and Adjoint Based ApproachLas UkcuNoch keine Bewertungen

- Numerical Simulation of The Francis Turbine and CAD Used To Optimized The Runner Design (2nd)Dokument11 SeitenNumerical Simulation of The Francis Turbine and CAD Used To Optimized The Runner Design (2nd)Dadi DahalNoch keine Bewertungen

- Optimisation of Double Box Girder Overhead Crane in Function of Cross Section Parameter of Main GirdersDokument4 SeitenOptimisation of Double Box Girder Overhead Crane in Function of Cross Section Parameter of Main GirdersAjla BećirovićNoch keine Bewertungen

- 2 Okui - 3D OptDokument11 Seiten2 Okui - 3D OptAhmed FaridNoch keine Bewertungen

- Mathematical Programming Methods For The Optimal Design of Turbine Blade ShapesDokument14 SeitenMathematical Programming Methods For The Optimal Design of Turbine Blade ShapesTarun ChoudharyNoch keine Bewertungen

- Axial Compressor Optimization Method: IOP Conference Series: Materials Science and EngineeringDokument10 SeitenAxial Compressor Optimization Method: IOP Conference Series: Materials Science and EngineeringSami AhmadNoch keine Bewertungen

- The Design and Analysis of Gas Turbine BladeDokument3 SeitenThe Design and Analysis of Gas Turbine Bladeaerobrother100% (3)

- 2010 MIT Wind Turbine Blade Design OptimizationDokument12 Seiten2010 MIT Wind Turbine Blade Design Optimizationsohaib31Noch keine Bewertungen

- Optimization of Partial Admission Stages for Improved Turbine PerformanceDokument6 SeitenOptimization of Partial Admission Stages for Improved Turbine PerformancePratik Joshi100% (1)

- Parametric Study and Design Optimization of A Radial Flow Pump ImpellerDokument9 SeitenParametric Study and Design Optimization of A Radial Flow Pump ImpellerErnad BešlagićNoch keine Bewertungen

- Griffith UniversityDokument8 SeitenGriffith UniversityAshokNoch keine Bewertungen

- Aerodynamics of Solar CarsDokument4 SeitenAerodynamics of Solar CarsNeil WuNoch keine Bewertungen

- J55ODokument15 SeitenJ55OUmair MunirNoch keine Bewertungen

- Numerical Analysis of Convergent-Divergent Nozzle Using Finite Element MethodDokument10 SeitenNumerical Analysis of Convergent-Divergent Nozzle Using Finite Element MethodTJPRC PublicationsNoch keine Bewertungen

- Optimization of Axial Compressor Stage Using Nsga-Ii TechniqueDokument5 SeitenOptimization of Axial Compressor Stage Using Nsga-Ii TechniqueDanielNoch keine Bewertungen

- Small Wind Turbine DesignDokument19 SeitenSmall Wind Turbine DesignIqbal MeskinzadaNoch keine Bewertungen

- Please Dont Delete1Dokument4 SeitenPlease Dont Delete1Sayee ChandrasekaramouliNoch keine Bewertungen

- B16 Grapsas Epsmo05Dokument9 SeitenB16 Grapsas Epsmo05Surjit DuttaNoch keine Bewertungen

- A Design Method For Turbine Blades Using Genetic Algorithms On Parallel ComputersDokument6 SeitenA Design Method For Turbine Blades Using Genetic Algorithms On Parallel ComputersWeins GemerlapNoch keine Bewertungen

- Aerodynamic Shape Optimization of Tall BDokument8 SeitenAerodynamic Shape Optimization of Tall BSiti Rohani IsdrisNoch keine Bewertungen

- New Analytical Approach To Calculate The Melt Flow Within The Co-Rotating Twin Screw Extruder by Using The Performance Mapping MethodDokument6 SeitenNew Analytical Approach To Calculate The Melt Flow Within The Co-Rotating Twin Screw Extruder by Using The Performance Mapping MethodGabriel PóvoaNoch keine Bewertungen

- CFD analysis improves radial pump impeller designDokument8 SeitenCFD analysis improves radial pump impeller designFarooqNoch keine Bewertungen

- Optimization of Machining Parameters in PDFDokument6 SeitenOptimization of Machining Parameters in PDF임학진Noch keine Bewertungen

- An Improved 3d Adaptive EFG Method For Forging and Extrusion Analysis With Thermal Coupling in Ls-DynaDokument8 SeitenAn Improved 3d Adaptive EFG Method For Forging and Extrusion Analysis With Thermal Coupling in Ls-DynausamaumerNoch keine Bewertungen

- An experimental investigation on surface quality and dimensional accuracy of FDM componentsDokument7 SeitenAn experimental investigation on surface quality and dimensional accuracy of FDM componentsnewkid2202Noch keine Bewertungen

- Mi 180114Dokument18 SeitenMi 180114Thomas DalatiNoch keine Bewertungen

- Numerical ModeizationDokument13 SeitenNumerical ModeizationJay KrishnaNoch keine Bewertungen

- Optimization Technique For The Geometry of Twin Screw Cryogenic ExtruderDokument5 SeitenOptimization Technique For The Geometry of Twin Screw Cryogenic ExtruderIJSTENoch keine Bewertungen

- Vaneless DiffuserDokument8 SeitenVaneless Diffuseramir_karimiNoch keine Bewertungen

- Axial Flow Compressor PDFDokument7 SeitenAxial Flow Compressor PDFkamal arabNoch keine Bewertungen

- Design and testing of underwater thruster for SHRIMP ROVDokument8 SeitenDesign and testing of underwater thruster for SHRIMP ROVHollanda CocobearNoch keine Bewertungen

- 3D Gear Measurement by CMM: W. Otze' F. AertiDokument12 Seiten3D Gear Measurement by CMM: W. Otze' F. Aertikalvino314Noch keine Bewertungen

- A Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerDokument5 SeitenA Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerVignesh KumaranNoch keine Bewertungen

- Applied Sciences: Axial Turbine Cascade CorrelationDokument12 SeitenApplied Sciences: Axial Turbine Cascade CorrelationPIYUSH PORWALNoch keine Bewertungen

- Hashemian 2020Dokument12 SeitenHashemian 2020lzq8306Noch keine Bewertungen

- 0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorDokument5 Seiten0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorAnonymous hWj4HKIDOF100% (1)

- Rotary Vanes To Increase Turbulence in A Can TypeDokument10 SeitenRotary Vanes To Increase Turbulence in A Can TypeAaryaa KNoch keine Bewertungen

- Design and Optimization of Multi Stage Manufacturing Process of Stirling Engine CrankshaftDokument14 SeitenDesign and Optimization of Multi Stage Manufacturing Process of Stirling Engine CrankshaftAnkit SahuNoch keine Bewertungen

- Model Based Strategies For An Optimised Ribbing Design of Large Forming ToolsDokument6 SeitenModel Based Strategies For An Optimised Ribbing Design of Large Forming ToolsPankaj ChhabraNoch keine Bewertungen

- Multicriterion Optimization of Multistage Gear Train TransmissionDokument9 SeitenMulticriterion Optimization of Multistage Gear Train TransmissionRiad RamadaniNoch keine Bewertungen

- Circle Method For Isolated AirfoilsDokument8 SeitenCircle Method For Isolated AirfoilsAkshay DeshpandeNoch keine Bewertungen

- Research ArticleDokument15 SeitenResearch Articlejunaid ikramNoch keine Bewertungen

- IJMPERDFEB20176Dokument8 SeitenIJMPERDFEB20176TJPRC PublicationsNoch keine Bewertungen

- Optimizing Supersonic Nozzle Geometry for Uniform FlowDokument14 SeitenOptimizing Supersonic Nozzle Geometry for Uniform FlowSanjay Kumar AdvaniNoch keine Bewertungen

- Enhancement of Lift-Drag Characteristics of Naca 0012: SciencedirectDokument10 SeitenEnhancement of Lift-Drag Characteristics of Naca 0012: SciencedirectasdasddasNoch keine Bewertungen

- Machining Part Program Optimization Through An Advanced Multidisciplinary ProcedureDokument14 SeitenMachining Part Program Optimization Through An Advanced Multidisciplinary ProcedureFahmiNoch keine Bewertungen

- CFD Analysis of Screw Compressor Performance: Ahmed Kovacevic, Nikola Stosic and Ian K. SmithDokument28 SeitenCFD Analysis of Screw Compressor Performance: Ahmed Kovacevic, Nikola Stosic and Ian K. Smithmahesh_1402Noch keine Bewertungen

- 4th National Conference on Multidisciplinary Design OptimizationDokument16 Seiten4th National Conference on Multidisciplinary Design Optimizationumashankar_gNoch keine Bewertungen

- Fast Numerical Method for Centrifugal Pump DesignDokument6 SeitenFast Numerical Method for Centrifugal Pump DesignCesar AudivethNoch keine Bewertungen

- The Design of Modeled Cam Systems: Part I: Dynamic Synthesis and Chart Design For The Two-Degree-of-Freedom ModelDokument6 SeitenThe Design of Modeled Cam Systems: Part I: Dynamic Synthesis and Chart Design For The Two-Degree-of-Freedom ModelVivekanandan_Sama012Noch keine Bewertungen

- Modelling of Metal Flow For Bearing DesignDokument8 SeitenModelling of Metal Flow For Bearing DesignLucian DragosNoch keine Bewertungen

- An Integrated Design and CAPP System For Cold or Hot Forging ProductsDokument8 SeitenAn Integrated Design and CAPP System For Cold or Hot Forging ProductsAmir JoonNoch keine Bewertungen

- Manual of Engineering Drawing: British and International StandardsVon EverandManual of Engineering Drawing: British and International StandardsBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsVon EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNoch keine Bewertungen

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationVon EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNoch keine Bewertungen

- Quality in Education: Shelley O'Grady, M.SDokument54 SeitenQuality in Education: Shelley O'Grady, M.SEslam NagyNoch keine Bewertungen

- BF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDDokument1 SeiteBF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDEslam NagyNoch keine Bewertungen

- Mirage ERP Presentation 2019 PDFDokument69 SeitenMirage ERP Presentation 2019 PDFEslam NagyNoch keine Bewertungen

- Archshaders Vol 1Dokument130 SeitenArchshaders Vol 1Michelle KalogerakiNoch keine Bewertungen

- Aerodynamic Optimization of a Transonic Axial Compressor Rotor ThesisDokument100 SeitenAerodynamic Optimization of a Transonic Axial Compressor Rotor ThesisEslam NagyNoch keine Bewertungen

- 1 s2.0 S100093611300071X Main PDFDokument11 Seiten1 s2.0 S100093611300071X Main PDFEslam NagyNoch keine Bewertungen

- Opp Rating Rating: Risk Rating Limit: 8.0 8.0 5.0Dokument3 SeitenOpp Rating Rating: Risk Rating Limit: 8.0 8.0 5.0Eslam NagyNoch keine Bewertungen

- International Material Grade Comparison TableDokument9 SeitenInternational Material Grade Comparison Tablenyamuk06100% (4)

- Main FrameDokument9 SeitenMain FrameEslam NagyNoch keine Bewertungen

- Transonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverDokument11 SeitenTransonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverEslam NagyNoch keine Bewertungen

- BF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDDokument1 SeiteBF6M1013 Deutz Diesel Engine Technical Data: Shijiazhuang Houfeng Trading Co. LTDEslam NagyNoch keine Bewertungen

- Effects of Alloying Elements in SteelDokument3 SeitenEffects of Alloying Elements in SteelEslam NagyNoch keine Bewertungen

- A CFD Assessment To Subsonic Flow Around NACA4412Dokument16 SeitenA CFD Assessment To Subsonic Flow Around NACA4412Eslam NagyNoch keine Bewertungen

- Asme JT Oct2004 Part2Dokument11 SeitenAsme JT Oct2004 Part2Eslam NagyNoch keine Bewertungen

- Aiaa JPP Rotor37Dokument7 SeitenAiaa JPP Rotor37Eslam NagyNoch keine Bewertungen

- Tut03 Modeling External Compressible FlowDokument30 SeitenTut03 Modeling External Compressible FlowEslam NagyNoch keine Bewertungen

- Transonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverDokument11 SeitenTransonic Axial-Flow Blade Shape Optimization Using Evolutionary Algorithm and Three-Dimensional Navier-Stokes SolverEslam NagyNoch keine Bewertungen

- Tut24 Turbo PostprocessiHFHngDokument20 SeitenTut24 Turbo PostprocessiHFHngEslam NagyNoch keine Bewertungen

- PDRDokument14 SeitenPDREslam NagyNoch keine Bewertungen

- Transonic Flow Over A RAE 2822 AirfoilDokument1 SeiteTransonic Flow Over A RAE 2822 AirfoilEslam NagyNoch keine Bewertungen

- A Basic Experimental Investigation of Passive Control Applied To A Transonic InteractionDokument13 SeitenA Basic Experimental Investigation of Passive Control Applied To A Transonic InteractionEslam NagyNoch keine Bewertungen

- AerodynamicShapeDesign FinalReport Fall2010Dokument156 SeitenAerodynamicShapeDesign FinalReport Fall2010benimmmNoch keine Bewertungen

- Fluent OverviewXZDokument48 SeitenFluent OverviewXZEslam NagyNoch keine Bewertungen

- Airfoil optimization using CFDDokument25 SeitenAirfoil optimization using CFDEslam NagyNoch keine Bewertungen

- Gas TurbinesDokument376 SeitenGas TurbinesAlan Sala50% (2)

- MSC - Eng - Steady Three-Dimensional Shock Wave Reflection Transition PhenomenaDokument69 SeitenMSC - Eng - Steady Three-Dimensional Shock Wave Reflection Transition PhenomenaEslam NagyNoch keine Bewertungen

- Blade Design Methods and IssuesDokument48 SeitenBlade Design Methods and IssuesEslam NagyNoch keine Bewertungen

- A CFD Analysis of Blade Row Interactions Within A High-Speed Axial CompressorDokument195 SeitenA CFD Analysis of Blade Row Interactions Within A High-Speed Axial CompressorEslam NagyNoch keine Bewertungen

- Wind TurbinesDokument163 SeitenWind TurbinesEslam Nagy100% (1)