Beruflich Dokumente

Kultur Dokumente

Topic 1

Hochgeladen von

Felipe Soares MaiaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Topic 1

Hochgeladen von

Felipe Soares MaiaCopyright:

Verfügbare Formate

1994 by Alexander H.

Slocum

Precision Machine Design

Topic 1 Introduction to the design process for precision machines Purpose:

This lecture provides an introduction to the machine design process, with emphasis on overall design philosophy, case studies, and concept selection methods.

Outline:

Design methodology Functional Requirements, Design Parameters, & Preliminary calculations Conceptual designs Importance of sketching designs Conceptual design: Decision making methods

Machining center design case study Coordinate measuring machine design case study

"Enthusiasm is one of the most powerful engines of success. When you do a thing, do it with all your might. Put your whole soul into it. Stamp it with your own personality. Be active, be energetic, be enthusiastic and faithful and you will accomplish your object. Nothing great was ever achieved without enthusiasm" Ralph Waldo Emerson

1-1

1994 by Alexander H. Slocum

Basic precision machine design philosophy

Designs should be made as mechanically good as is reasonably possible. Increases in performance are then obtained via measurement, mapping, and servo control:

Metrology frame based servomechanism Mapped servomechanism Simple servomechanism Mechanical system

Cost

Difficulty = Environment Load Range Speed Accuracy

Make the design hospitable to measurement: Make room for sensors. Design in alignment surfaces. Minimize Abbe errors.

Use modular elements whenever possible: Create a platform concept that is upgradeable merely by substituing new components.

Choose bearings, actuators, sensors, and controller as interdependent components. Design the machine as if you had to use it.

1-2

1994 by Alexander H. Slocum

Organize your thought process

Design is like a giant box of Legos You need to empty the box on the floor and spread the Legos out in order to find the best parts for your spaceship. While looking for a cool wing, you may discover a better engine!

So:

Organize your brain to be a collector and analyzer of information. Organize your thoughts to be a digester of information and a synthesizer of new designs. Organize your mind to be an n-dimensional holographic comparator. Provide it with systematic and random search, compare, and synthesizing capabilities.

1-3

1994 by Alexander H. Slocum

Imagine that your mind is a vast three dimensional array of cubes which are designed to hold information:

Wisdom Knowledge

Imagination

With time, the number of cubes that are filled with information grows. When you read about a new type of bearing, you file the information in a knowledge cube. New methods for using bearings may be filed in an imagination cube. Past experiences with the bearing may be filed in a wisdom cube.

Random or systematic search patterns through the array of cubes allows you to think of solutions to problems. During the search for solutions: Often you will discover that there is a collection of cubes that do not have the contents you need. Thus you may discover the need for a new invention.

1-4

1994 by Alexander H. Slocum

How to keep informed

Catalogs. One must keep things in perspective and not develop catalogitis. Catalogitis: "design is the gospel according catalogs, and thou musteth use stock parts." to

The use of standard versus nonstandard parts must be considered carefully. Before specifying a part, a designer should also check a listing of companies (e.g., in the Thomas Register) .

Trade magazines and their "Bingo cards" (used to order manufacturers' product literature). A small personal library of reference books. Societies that exists for engineers.1 Standards used that pertain to the products being designed.2 Networking: You must build a network of friends and associates who can help you to keep informed, and vice versa. You must be able to function effectively in a team.

For example, the American Society for Precision Engineering in Raleigh, NC (919) 839-8444, and the Japan Society of Precision Engineering. 2 For example, a designer of rotary tables or spindles should keep a copy of Axis of Rotation: Methods for Specifying and Testing, ANSI Standard B89.3.4M-1985, and Temperature and Humidity Environment for Dimensional Measurement, ANSI Standard B89.6.2-1973. A catalog of standards is available from the American Society of Mechanical Engineers, United Engineering Center, 345 East 47th St., New York, NY 10017. 1-5

1994 by Alexander H. Slocum

Whenever you obtain a new piece of information

Search through your mind and see if this new piece can combine with any existing pieces to make something useful. Take note during the search if the information can be useful to someone else whom you know has a problem that needs solving. Networking is one of the most powerful assets of an information-based society.

Always look for new applications and opportunities. Opportunity always knocks, but one needs to do a careful MFT (mental Fourier transform) to see where the peaks are!

1-6

1994 by Alexander H. Slocum

Resulting Overall design strategy

1 ) Carefully establish your database and networks as stated above. 2 ) Remember Maudslay's maxims: l . Get a clear notion of what you desire to accomplish, then you will probably get it. 2 . Keep a sharp look-out upon your materials: get r i d of every pound of material you can do without. Put yourself to the question, "what business has i t there?" Avoid complexities and make everything as simple as possible. 3 . Remember the get-ability of parts. Stated by Henry Maudslay in the 1700's, they are the foundation of concurrent engineering.

3 ) Know your customers. Talk to them directly, in addition to listening to marketing and maintenance and manufacturing.

1-7

1994 by Alexander H. Slocum

Recognize that there are three types of design:

Scaled design: An existing design does the job well, and just needs to be scaled for the new application. For example, a ballscrew size change for a larger machine.

Evolutionary design: An existing design is pretty good, but fundamental improvements can be made. For example, a ballscrew evolves into a planetary rollerscrew.

1-8

1994 by Alexander H. Slocum

Revolutionary design: A totally new approach is used to achieve the same function, but with better performance. For example, a linear electric motor instead of a screw-type transmission.

Rail

Carriage

Linear motor coil

Linear motor magnet assembly

1-9

1994 by Alexander H. Slocum

But be careful not to jump to quickly!

INA introduced ballscrew-like shaft with a helical gothic arch lead. Instead of small balls rolling on a large shaft (at high speed), it uses four ball bearings: The inner races are rounded to mate with the gothic arch groove, and the axes of rotation are inclined to the shaft.

The result is an order-of-magnitude lower rolling element velocity, and no need for lost contact during recirculation. This actuator is half the cost of a linear motor system and can run at nearly the same speed! It is perfect for the actuation of grinding tables at either creep-feed or reciprocal grinding speeds; However, it still has the issue of shaft rotational inertia.

1-10

1994 by Alexander H. Slocum

The Result of all the above is the Design Process

A good designer: Carefully budgets time and resources. Defines what she wants to accomplish (functional requirements). Defines the resources available (materials, parts that can be used). Creates solutions ranging from a safe solution to a neat, wild WOW solution. Evaluates the physics and feasibility of solutions that can be created within the context of the allowable time and budget! Updates the schedule and budget Embodiment and Details: Makes the design happen in a timely, orderly, well-documented manner. Implements the design (competes) and then reflects on what went right and wrong.

Functional Requirements, Design Parameters, & Preliminary calculations

Before you start designing, you have to get your box of Legos in order. You are designing a deterministic machine, so deterministically: Determine what the machine must do (Functional Requirements, Frs) Start thinking about what elements (Design Parameters, DPs) could enable you to satisfy the FRS. Identify the physics that govern the performance of the DPs.

1-11

1994 by Alexander H. Slocum

Functional Requirements (FRs) & Design Parameters (DPs)

From the overall strategy, the functional requirements can be developed (sketches of the design strategy can be helpful). Design Parameters: Physical attributes that satisfy FRs.

Physics of the problem

It is often useful to list the physics involved next to the functional requirements (simple models can help).

Example:

Basic FRs Fast travel speed Initial DPs Easy to do 0.25m/s Impressive .5 m/s WOW 1 m/s Dominant physics F=ma =Fr V=at V=r x=0.5at Front scooper Climb peak Forklift type (raise only) wheels close spaced Raise and curl Tracks Raise, curl, extend Jump! M=Fl =Mc/I Friction F=F N

2

Not flippable

Low center Outriggers of gravity, wide stance

BIG wheels, M=0 no basic protruding stability hardware, drives upside down

1-12

1994 by Alexander H. Slocum

Conceptual design

Conceptual design can affect a machine's: Accuracy. Repeatability. Resolution. Frictional qualities. Difficulty of design. Difficulty of manufacture. Operating cleanliness. Cost. Safety. Ruggedness. Availability.

Any overlooked item will come back to haunt you, so get it right the first time!

1-13

1994 by Alexander H. Slocum

There are several methods for generating conceptual designs: FIRST get the design team to identify the Functional Requirements!, Then:

Individual thought: Often the most creative.

Rohrbach's 635 method: First individual, and then group analysis and discussions, offers the best of both worlds.

Group brainstorming: Greatest breadth of resources applied collectively.

1-14

1994 by Alexander H. Slocum

Individual thought is often the most creative.

Do leisurely things (e.g., long walks) that you know inspire creative thought. Get out of traffic and take alternate routes.

Sketch ideas and the ideas principal components. Cut out the principal components and pretend they are modular elements. Like toy building blocks, try different combinations of components to make different machines. Pit one machine idea against another and imagine strategies for winning. Take the best from different ideas and evolve them into the best 2 or 3 ideas that you can think of.

1-15

1994 by Alexander H. Slocum

Rohrbach's 635 method:

Six people write down their three best ideas and circulate them to the other five for comments. The people then get together to discuss their ideas.

A written record is made of who first had the idea, so personality conflicts are more easily avoided. It tends to generate a collective mind, so everybody knows what everyone else has been thinking. The group mind then works together in a more efficient manner when brainstorming.

1-16

1994 by Alexander H. Slocum

Group brainstorming:

A means to often solve personal creativity deadlocks. A means to make sure something hasn't been overlooked. Group personality factors must be considered: Shy individuals getting run over. Aggressive individuals driving. An individual's personality often has nothing to do with creativity.

Careful to avoid conflicts over the issue of who first thought of the idea. The people in the group must be willing to take praise or scolding as a group. Formal methods exist. Psychologists have generated established rules to make the process work successfully.3

Have the meeting over the hardware! or in the shop!

G. Pahl and W. Beitz, Konstruktionslehre, Springer-Verlag, Berlin, 1977. Translated and published as Engineering Design, Design Council, London, 1984, pp. 8788. 1-17

1994 by Alexander H. Slocum

Importance of sketching designs

The ability to sketch approximate scale drawings of a concept is invaluable. Sloppy disproportionate sketches send a signal to managers that the design will also be sloppy.

Design sketches of ideas and major components allow one to build and compare models of ideas. A matrix of ideas can be laid out and "what-if" scenarios can then be performed. "Moving" components (a piece of paper) from design to design allows for rapid real-time evolution.

1-18

1994 by Alexander H. Slocum

The ability to sketch a stick figure of a design and label the error motions is invaluable. Knowing where the errors are signals that you understand the physics of the design.

The ability to tell which error motions cause critical errors at the tool point is invaluable. Knowing what the critical errors are signals that you understand the details of the design.

A stick figure helps to: Define the sensitive directions in a machine. Locate coordinate systems. Set the stage for error budgeting.

It helps to prevent the designer from locking in on a shape too early.

Spindle (rotor in bearings)

215

300

110 Z carriage

Wheel/ Workpiece

240 330 115 700 100

Y carriage

Sensitive for surface and profile grinding Sensitive for profile grinding

400

545

Table

300 450 100 1700

Column

Y Reference

Bed

1700

Z

425 315 400

1-19

1994 by Alexander H. Slocum

Sketching example: A surface grinder:

Z axis linear motion bearings Z axis Ballscrew Y axis column Y axis carriage Z axis carriage Table Bed Wheel Z Y X

Y axis motor

1-20

1994 by Alexander H. Slocum

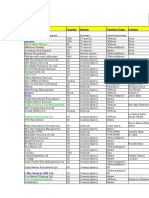

Preliminary calculations

Past the hand sketch, and before the computer sketch, to determine feasability, and to guiode initial FEA. Spreadsheets provided with this course to aid in the design of precision machines:

Spreadsheet AHP.XLS Purpose To apply the Analytic Hierarchy Process to selection of the "best" concept

BALLSCRW.XLS To determine equivalent load rating for ballscrew selection BEAMBEND.XLS To determine slope, bending, and shear deflections of a simply supported beam loaded by its own weight. BIMAT.XLS BOLTJDES.XLS To determine thermal deformations in a bi-material beam To design bolted joints

CYLNDEXP.XLS To calculate the radial displacement of a pressurized cylinder HERT.XLS To determine Hertz contact stresses between bodies in point contact.

HERTZTAN.XLS To determine tangential stiffness and contact stress between two bodies (e.g., for friction drive design) KINCOUP.XLS KINSLIDE.XLS RAILDES.XLS RAILFND.XLS To design three groove kinematic couplings To analyze of errors in a kinematically supported carriage (slide) To design bolted "boxway" bearing rails To determine characteristics of a bolted rail on elastic foundation

SCREWPOW.XLS To calculate power to turn a screw CLD.XLS To design a constrained layer damper

THERMERR.XLS To determine temperature gradient induced errors in a simply supported beam TMDDES.XLS To design tuned mass dampers

1-21

1994 by Alexander H. Slocum

Error Budget Spreadsheets provided with this course to aid in the design of precision machines:

Spreadsheet Name CShelp.XLS User Input Location (position and orientation) of coordinate systems for tool and work. none. none Output to User

CS_inp.XLS

Ideal location of tool in work.

K_inp.XLS

Compliances between coordinate systems. Forces and moments applied to coordinate systems. Thermal expansion coefficient and temperature differences between coordinate systems. Geometric errors between the coordinate systems None

None.

F&M_inp.XLS

Resultant sum forces and moments. Thermal expansion errors.

Temp_inp.XLS

Geo_err.XLS Sum_err.XLS

Sum of all the errors in each coordinate system. Ideal and actual location of tool in work, and the resulting location error between the tool and the work in the reference frame

Err_out.XLS

Error toggle switch and mapping improvement factors

1-22

1994 by Alexander H. Slocum

Conceptual design: Decision making methods

There are many systematic methods available for evaluating design alternatives. Most rely on some sort of weighting of attributes to arrive at a "desirability score".

The simplest method is a linear weighting scheme: Apply a desirability value to each parameter that affects the performance of a component in a design. Easiest to use provided user bias can be minimized. Acceptable when there are only a few design alternatives to consider. A linear weighting scheme (a series of +, -, 0 wrt a baseline design) will give equal weighting to attributes.

Design 1 Design 2 Design 3 Design 4

(Baseline)

Accuracy Ergonomics Cost Flexibility Robustness Manufacturability Serviceability Total + and -

0 0 0 0 0 0 0 0

+ 0 0 + + + 3

0 + 0 + -1

+ + + + 0 2

Use to identify positive attributes of competing designs that can be blended in with the best to make it better.

1-23

1994 by Alexander H. Slocum

Example: Select a linear bearing for a machine tool

Factors to consider in their selection include: Accuracy of motion: Straightness, Smoothness. Friction Characteristics: Static , Dynamic . Cost: Purchase, Install, Maintain

Rail Keeper Base

C, Co Mt Mto Ml Mlo S1 THREAD B E2 E3

When there are more than several variables, it is often difficult to evaluate their relative importance. It is like trying to add Newtons to meters, the dimensions cannot be added properly. A method is needed to non-dimensionalize the parameters.

Carriage (saddle)

E1

H1 N2

N1 H2 N3

S2 SCREW SIZE A3 A1 A A2 S3 SCREW SIZE T L

R R Ru

u R

V R Rl Rl R

1-24

1994 by Alexander H. Slocum

Thomas Saaty developed the Analytic Hierarchy Process (AHP) to help make complex decisions. First determine the relative importance of each characteristic at each level in the outline of design attributes. Next evaluate the relative characteristics of each component of the design with respect to the most explicit characteristic. Comparisons are done with experienced personnel from: Engineering Marketing Manufacturing Service

The relative evaluation characteristics' importances are debated in an open forum. The relative importances of the components are debated in an open forum. Egos are diffused, and only rationally justifiable positions are accepted.

This is an excellent method to start a project off on a concurrent engineering track

1-25

1994 by Alexander H. Slocum

Step 1: Setting up the AHP Model

Compare the AHP's construction to a system of water tanks

100% Le v e l 1

40%

20%

40% Le v e l 2

Le v e l 3 25% 15% 12% 8% 15% 15% 10%

The distribution of water is analogous to the distribution of priorities (or weights). The desirability (or weight) for each entry with respect to other entries on that level can be equated to: The distribution (by percent) of the initial volume of water among the reservoirs on the same level.

At any level the total percentage of water distributed among the reservoirs at that level is equal to 100%.

Select a bearing for a Diamond Turning Machine Accuracy Straightness Smoothness Dynamic Friction Static Purchase Cost Install Maintain

1-26

1994 by Alexander H. Slocum

Step 2: Importance of design choices

The evaluation of a design option is done by determining its "importance" for each Level 3 entry (the lowest level). The "importance" of an item with respect to each entry in Level 3 can be expressed in terms of actual physical values. Most often, a numerical scale should be used such as: Importance 1 3 5 7 9 Definition Equal importance One a little more important than the other (1/3) One is more important than the other (1/5) One is much more important than the other (1/7) Absolute importance (1/9)

Accuracy Accuracy Friction Cost 1 .5 .25

Friction

Cost

2

1 .5

4

2 1

The team debates the comparisons and fills out the top row. The matrix is diagonal, and determinism is applied to ensure consistency. Check lower diagonal values to make sure the team agrees with them.

This forms a "fuzzy Logic set" characterizing what the team feels are the important judgment factors for a design.

1-27

1994 by Alexander H. Slocum

Priority is approximately the geometric mean of the row. Overall priority is normalized with respect to the sum of the individual priorities. The level three normalized priorities are multiplied by the corresponding level two normalized priorities. This yields a normalized weight for the level three characteristics.

For the bearing selection, the spreadsheet output for levels 2 & 3 is:

Accuracy Friction 1.000 2 . 0 0 0 0.500 1.000 0.250 0.500 1.750 3.500 Cost 4.000 2.000 1.000 7.000 Priority N. Prior. 2.000 0.571 1.000 0.286 0.500 0.143 3.500 1.000 Level 2 =57% =29% =14% Level 3 33*57=19% 67*57=38% Level 3 80*29=23% 20*29=6% Level 3

Accuracy Friction Cost Sum

Accuracy Straight. Smooth. Straightness 1.000 0 . 5 0 0 Smoothness 2.000 1.000 Sum 3.000 1.500 Friction Static Dynamic Sum Cost Purchase Install Maintain Sum Static Dynamic 1.000 4 . 0 0 0 0.250 1.000 1.250 5.000 Purchase 1.000 2.000 2.000 5.000

Priority N. Prior. N. Wght 0.707 0.333 0.190 1.414 0.667 0.381 2.121 1.000 0.571 Priority N. Prior. N. Wght 2.000 0.800 0.229 0.500 0.200 0.057 2.500 1.000 0.286

Install Maintain 0.500 0.500 1.000 1.000 1.000 1.000 2.500 2.500

Priority N. Prior. N. Wght 0.630 0.200 0.029 1.260 0.400 0.057 1.260 0.400 0.057 3.150 1.000 0.143

Note that the total of all the normalized weights is 1.0. Each matrix is diagonal (mathematical relationships). enter numbers in bold Only

This defuzzifies the qualitative judgments so they can be applied in a deterministic manner to evaluate options.

1-28

1994 by Alexander H. Slocum

Step 3: Results

Desirability is found by combining the normalized weights with the relative evaluations of bearing characteristics: desirability = (level 3 weights) (bearing desirability values)

j=1 7

Again, a team discusses and justifies the comparisons, s o novice designers become enlightened. For the bearing selection, the spreadsheet output is:

Overall Norm Maintain Goodness Goodness 5.000 0.274 0.27 5.000 0.283 0.28 1.000 0.443 0.44

Bearing comparison: Straight. Smooth. Static mu Dyn. mu Purchase Sliding teflon 7 0 . 0 0 0 7 . 0 0 0 1.000 2.000 5.000 Rolling balls 6 0 . 0 0 0 5 . 0 0 0 3.000 5.000 3.000 Hydrostatic 90.000 9.000 9.000 5.000 1.000

Install 3.000 5.000 2.000

To prevent a person from driving the results to their favorite without rational discussion: Each product in the overall goodness column is normalized by the sum of the choices' desirability values.

1-29

1994 by Alexander H. Slocum

The AHP should be used by a group of "experts" from engineering, marketing, manufacture, maintenance, etc. The numbers you generate while practicing alone may seem arbitrary to you. However, they do get you to think about the design criteria. A group will educate members about why design decisions are made. It helps a group to rapidly converge on consensus, because it forces members to focus on one topic at a time. It then gives a deterministic means to pull all the elements together for a total decision.

1-30

1994 by Alexander H. Slocum

Case study: Cincinnati Milacron's high speed machining center (HSMC)

Designed for high speed hole drilling and near-net-shape part finishing. Speed and reliability were of prime concern. Goal was to minimize the number of parts. Machine would be used in duplex mode (two machines facing each other), so a horizontal spindle was required.

1-31

1994 by Alexander H. Slocum

Conceptual designs

Fully articulated and traveling articulated designs: Low rigidity. Large error at tool cause by angular error at joint (Abbe error). Too many degrees of freedom.

1-32

1994 by Alexander H. Slocum

Scissors jack design: Large number of joints. Non-uniform transmission ratio:

1-33

1994 by Alexander H. Slocum

Rectilinear design for a high speed machining center: Linear axes are easy to manufacture.

Configuration lends itself to the use of a single moving wall to prevent chips and coolant from getting into sensitive areas.

Spindle Moving wall

1-34

1994 by Alexander H. Slocum

1-35

1994 by Alexander H. Slocum

Effects of sealing systems on concept selection

Greater stiffness and accuracy can be obtained if the duplex requirement is dropped and the pallet is allowed to be on a moving axis. The spindle is then carried on a 2 degree of freedom stacked axis. The work holding table (pallet) has a single degree of freedom. With the pallet on a Z axis, the spindle stacked axes only needs a single seal: The Y axis can be positioned behind a moving wall.

1-36

1994 by Alexander H. Slocum

Case study: Sheffield's ring bridge coordinate measuring machine (CMM)

Structural configurations for CMMs: Fixed table cantilever arm CMM. Moving bridge CMM. Column type CMM. Moving ram horizontal arm CMM. Moving table horizontal arm CMM. Gantry type CMM. Ring bridge type CMM.

Goodness can be defined by CA factor:

CA = volume throughput accuracy price (1.6.1)

The CA factors for existing machines and the CA factor customers wanted indicated the need for a new CMM design.

Z

Ring bridge

Workpiece table

Probe

1-37

1994 by Alexander H. Slocum

Applying the AHP method to CMM design

The CA factor is not too helpful for a qualitative comparison of design concepts. Existing design types to be evaluated using the AHP include: Fixed table cantilever arm Moving bridge Column Moving ram horizontal arm Moving table horizontal arm Gantry Ring bridge

1-38

1994 by Alexander H. Slocum

AHP parameters for CMM evaluation:

Accuracy Modularity Scanning (contouring) X axis Abbe (sensors) Yaxis Abbe (actuators) Zaxis (ram) Abbe (bearings) Structure Center of stiffness/mass congruence Dynamic (stiffness) Evolvability Dynamic (mass) Automated Decoupling (part weight) Touch trigger Different sizes Cost Sale price Ergonomics Maintain Operator Labor to produce Service Components to buy Sales Manufacturability Bearings Structure Assembly

1-39

1994 by Alexander H. Slocum

The importance of the major design criteria were assumed to be:

Manufact- Modul- E v o l v - ErgonNorm. Accuracy C o s t urability arity a b i l i t y o m i c s Priority priority 1.00 1 . 0 0 3.00 5.00 5.00 5.00 2.69 0.34 1.00 1.00 3.00 5.00 5.00 5.00 2.69 0.34 0.33 0.33 1.00 1.67 1.67 1.67 0.90 0.11 0.20 0.20 0.60 1.00 1.00 1.00 0.54 0.07 0.20 0.20 0.60 1.00 1.00 1.00 0.54 0.07 0.20 0.20 0.60 1.00 1.00 1.00 0.54 0.07 2.93 2.93 8.80 14.67 14.67 14.67 7.88 1.00

Accuracy Cost Manufacturability Modularity Evolvability Ergonomics Sum

Existing design types evaluated using the AHP gave the following results: Column Moving table horizontal arm Moving bridge Fixed table cantilever arm Moving ram horizontal arm Ring bridge Gantry 0.75 0.84 0.88 1.00 1.01 1.05 1.07

1-40

1994 by Alexander H. Slocum

When one performs a sensitivity analysis by trying different priorities in the AHP spreadsheet: The accuracy requirement drives the decision towards a closed frame structure. It also implies that the part should not rest on a moving axis. The gantry design drives the main mass closer to the center of mass and stiffness. The ring bridge design drives the mass through the bottom portion of the ring. If ease of part loading and the ability to program the CMM in teach mode, the ring bridge may become an equal choice. The lighter moving structure of the bridge design would make the gantry machine easier to move by hand. Even though the access is more limited.

1-41

1994 by Alexander H. Slocum

Two designs were done, and cost and ergonomics considerations indicated the ring bridge design was best. From the sales literature Company):

(Courtesy of Sheffield Measurement, a Giddings & Lewis

1-42

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Donald McLean Automatic Flight Control SystemsDokument610 SeitenDonald McLean Automatic Flight Control SystemsAndra Radu100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- From Russia With Thanks, Major George Racey Jordan DiariesDokument28 SeitenFrom Russia With Thanks, Major George Racey Jordan DiariesklinnskuttNoch keine Bewertungen

- Pli New 22012006Dokument119 SeitenPli New 22012006Sai PraneethNoch keine Bewertungen

- Bearing Mounting Methods. Métodos de Montaje de Rodamientos SKFDokument12 SeitenBearing Mounting Methods. Métodos de Montaje de Rodamientos SKFTeckelino100% (1)

- Sharp BP30C25 - Installation ManualDokument58 SeitenSharp BP30C25 - Installation ManualSathish SukumaranNoch keine Bewertungen

- Antenna PrimerDokument14 SeitenAntenna PrimerStephen Dunifer100% (3)

- ASTM 6365 - 99 - Spark TestDokument4 SeitenASTM 6365 - 99 - Spark Testjudith_ayala_10Noch keine Bewertungen

- Linear GuidesDokument76 SeitenLinear GuidesFelipe Soares MaiaNoch keine Bewertungen

- ASHRAE - HVAC Noise and Vibration ControlDokument93 SeitenASHRAE - HVAC Noise and Vibration Controlmnt6176100% (3)

- Beeman Gs 1000 ManualDokument4 SeitenBeeman Gs 1000 Manualanbsc2100% (1)

- Windpro Directory - 04.02.11Dokument54 SeitenWindpro Directory - 04.02.11Krishnan Veeraraghavan100% (1)

- Brunch: Menu OnlineDokument1 SeiteBrunch: Menu OnlineFelipe Soares MaiaNoch keine Bewertungen

- DiffEQ Basics NotesbDokument9 SeitenDiffEQ Basics Notesbchristopher_kephart1Noch keine Bewertungen

- Snail Farming: Mortality RateDokument4 SeitenSnail Farming: Mortality RateFelipe Soares MaiaNoch keine Bewertungen

- F - Physically Based Modeling, Principles and Practice - Constrained DynamicsDokument13 SeitenF - Physically Based Modeling, Principles and Practice - Constrained DynamicsFelipe Soares MaiaNoch keine Bewertungen

- C - Physically Based Modeling, Principles and Practice - Particle System DynamicsDokument13 SeitenC - Physically Based Modeling, Principles and Practice - Particle System DynamicsFelipe Soares MaiaNoch keine Bewertungen

- E - Physically Based Modeling, Principles and Practice - Implicit Methods For Differential EquationsDokument5 SeitenE - Physically Based Modeling, Principles and Practice - Implicit Methods For Differential EquationsFelipe Soares MaiaNoch keine Bewertungen

- Precision Machine Design: Topic 19 Power Transmission System RequirementsDokument26 SeitenPrecision Machine Design: Topic 19 Power Transmission System RequirementsFelipe Soares MaiaNoch keine Bewertungen

- Topic 18aDokument24 SeitenTopic 18aFelipe Soares MaiaNoch keine Bewertungen

- Topic 18bDokument25 SeitenTopic 18bFelipe Soares MaiaNoch keine Bewertungen

- Topic 18cDokument5 SeitenTopic 18cFelipe Soares MaiaNoch keine Bewertungen

- Topic 18aDokument24 SeitenTopic 18aFelipe Soares MaiaNoch keine Bewertungen

- Topic 17Dokument20 SeitenTopic 17Felipe Soares MaiaNoch keine Bewertungen

- Topic 11Dokument41 SeitenTopic 11Felipe Soares MaiaNoch keine Bewertungen

- Precision Machine DesignDokument56 SeitenPrecision Machine DesignFelipe Soares MaiaNoch keine Bewertungen

- Precision Machine DesignDokument56 SeitenPrecision Machine DesignFelipe Soares MaiaNoch keine Bewertungen

- Topic 11Dokument41 SeitenTopic 11Felipe Soares MaiaNoch keine Bewertungen

- Topic 4Dokument35 SeitenTopic 4Felipe Soares MaiaNoch keine Bewertungen

- Precision Machine Design: Topic 3 Examples of ErrorsDokument24 SeitenPrecision Machine Design: Topic 3 Examples of ErrorsFelipe Soares MaiaNoch keine Bewertungen

- Entrelec DIN RailsDokument5 SeitenEntrelec DIN RailsFelipe Soares MaiaNoch keine Bewertungen

- Human Resource Management 7 Steps in Developing HRM StrategyDokument11 SeitenHuman Resource Management 7 Steps in Developing HRM StrategyjaysoreNoch keine Bewertungen

- Evaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanDokument33 SeitenEvaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanhoangpalestineNoch keine Bewertungen

- Project DocumentDokument50 SeitenProject DocumentVijay B VijayNoch keine Bewertungen

- Reconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsDokument5 SeitenReconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsSubhanjali MyneniNoch keine Bewertungen

- Engineering and Ginning: Dust Cyclone Technology - A Literature ReviewDokument12 SeitenEngineering and Ginning: Dust Cyclone Technology - A Literature ReviewviettiennguyenNoch keine Bewertungen

- Essay On The Traffic Conditions in Big CitiesDokument3 SeitenEssay On The Traffic Conditions in Big CitiesCeciliaNoch keine Bewertungen

- Upgrading A P - SupplyDokument7 SeitenUpgrading A P - SupplyDrift GeeNoch keine Bewertungen

- Datasheet Borne SiemensDokument3 SeitenDatasheet Borne Siemenslorentz franklinNoch keine Bewertungen

- Quality Control TechniquesDokument10 SeitenQuality Control Techniquesdevilunleashed090% (1)

- JDokument4 SeitenJapi-299173937Noch keine Bewertungen

- Chapter 7 Part B Automatic Transmission: Band AdjustmentsDokument8 SeitenChapter 7 Part B Automatic Transmission: Band AdjustmentsSandorNoch keine Bewertungen

- How McAfee Took First Step To Master Data Management SuccessDokument3 SeitenHow McAfee Took First Step To Master Data Management SuccessFirst San Francisco PartnersNoch keine Bewertungen

- OODMSDokument8 SeitenOODMSvanikkdi76Noch keine Bewertungen

- MGT 162Dokument2 SeitenMGT 162Myra Choyy100% (1)

- R1 6a Training r2Dokument95 SeitenR1 6a Training r2dot16eNoch keine Bewertungen

- Ddal Players Guide v5Dokument12 SeitenDdal Players Guide v5Jakob Cherpovsky100% (1)

- Summer Practice Report Format For CeDokument8 SeitenSummer Practice Report Format For CesohrabNoch keine Bewertungen

- Case Report Form (CRF) : Design and DevelopmentDokument26 SeitenCase Report Form (CRF) : Design and Developmentapi-3810976Noch keine Bewertungen

- Ispmach 4000V/B/C/Z Family: FeaturesDokument100 SeitenIspmach 4000V/B/C/Z Family: Featuresjose morenoNoch keine Bewertungen

- Arduino Bluetooth Ralay 4chDokument5 SeitenArduino Bluetooth Ralay 4chRaul Lara RochaNoch keine Bewertungen

- Company Name Country Service Function/Type Contact: RigzoneDokument4 SeitenCompany Name Country Service Function/Type Contact: RigzonekokabawaNoch keine Bewertungen