Beruflich Dokumente

Kultur Dokumente

Rotary Polishing Tool 2

Hochgeladen von

bcairns12Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rotary Polishing Tool 2

Hochgeladen von

bcairns12Copyright:

Verfügbare Formate

Can I Get a Shiner?

MEMS1029 Dr. Ludwick

By: Robert Leslie Cairns

I.

Introduction

Mechanically powered machinery has allowed for human beings to accomplish almost anything imaginable. Machines can be designed to a wealth of different actions including lifting heavy objects, hurling projectiles, and cutting grass. As our grasp of the mechanics involved with these machines has grown we have come to find new applications for instance polishing brass. Though polishing brass may be a seemingly simple albeit tedious task to do by hand, the complexity of a machine capable of this action is rather astounding. Although there are many different mechanical means which may accomplish the task, the following details specifically the design of a sufficient belt and gear system. II. Functional Requirements For consideration of this design, a successful rotary polishing machine tool must achieve the following goals. The device must include a belt drive and gear train. The tool should be driven by a nominal input power of 1,500 Watts on a shaft rotating at 2,000 rotations per minute. To accomplish a reasonable brassy shine the polishing fixture must attain a speed of at least 10,000 rotations per minute. The design should be capable of accomplishing one hundred million (108) cycles with a system reliability of 95%. A safety factor for the gears of at least three is desired with a minimum gear safety factor of two. The overall size of the design happens to be unimportant as it will be a stationary unit inside of a large warehouse and the cost should be preferably $250 dollars or less. Additionally, an efficiency of 8095% will be acceptable. If all of these conditions are met the design will be successful and those decrepit brass badges will be as shiny as new. III. Design Concepts There is an almost endless supply of potential belt drives coupled with gear trains. Some factors to consider at this stage are what overall torque will be required and distance from the initial power source. Three slightly different designs are depicted in Figures 1-3 below, corresponding to Design A, Design B, and Design C.

Figure 1 Design A Flat belt without twist

Figure 2 Design B V-belt

Figure 3 Design C Flat belt with twist

For a rotary polishing tool our final torque value can be relatively low, however we do want to have a high rotational velocity for polishing. Therefore flat belt drive as depicted in Figure 1 and Figure 3 can be considered while the V-belt in Figure 2 can be eliminated as V-belts transmit much higher torques but at slightly lower efficiency and also limit the distance to the power source. While Design C has better belt wear characteristics as a result of the uniform wear from the crossover, this could potentially require additional tensioning devices, or guides for the belt. Design A on the other hand might be capable of catenaryinduced tensioning to provide the initial tension and maintain operational tension after elongation of the belt. Based upon these very basic assumptions, Design A (Figure 1) will be detailed. IV. Design Analysis Using the basic conceptual configuration presented in Design A (Figure 1), a set of free body diagrams can be developed for use in the analysis of the belt drive and gear train. Figure 4 below illustrates the free body diagram for the belt drive where the larger pulley is mounted on the input power shaft.

Figure 4 Free body diagram of pulley configuration The important factors to note in Figure 4 are that the driving pulley is larger than the driven pulley, the slack side is on the top, and the pulleys will rotate in the same direction. The slack side has been configured to be on the top so that the dip will contribute to increasing the tension as a result of a larger contact angle. Since the driving pulley is larger than the driven pulley a higher rotational speed should be expected on the driven pulley, which is important towards reaching the design goal of 10,000 RPM. The gear train configuration represented in Figure 5 below illustrates the free body diagram for the gearing from Design A, the gears have been drawn with space between them for force indications when in reality they would be in contact. Note that the larger driving gear is attached to the same shaft as the driven pulley, thus it will have the same rotational speed as that pulley.

Figure 5 Free body diagram of gear train configuration Some important factors to note from Figure 5 are that the tool will be mounted on the same shaft as the pinion thus having the same rotational speed and the pinion is driven by the larger gear thus will have a higher rotational speed. Another important factor is that the tangential force of the gear will be the same as that of the pinion but in the opposite direction thus resulting in the pinion rotating in the opposite direction of the gear. V. Belt Analysis This design has many potential variables that can be manipulated to produce different results. We are going to assume that we have a 6 inch diameter pulley (D) as the driving pulley, a 2.5 inch diameter driven pulley (d), and a center to center distance (C) of 72 inches. Some additional assumptions must be made about the service factor (Ks) and the design factor (d) before we can calculate the design power of our tool (Hd), each factor will be assumed to be 1.1. To calculate the design power the equation below is used, where the nominal power (Hnom) is the given input power of 1500W or 2.0115 horsepower. Hd= Hnom/Ksd = 2.0115/(1.1*1.1) = 1.662 horsepower

Knowing that our design power will be 1.662 horsepower and the initial rotational speed of the driving pulley (nD) of 2000 RPM, we can proceed to calculate the initial torque to be transmitted () with the equation below. = 63025Hd/nD = 63025*1.662/2000 = 52.38 lbf in Based upon the previously assumed and calculated data we can calculate the wrap angle (d) of the smaller driven pulley where the highest forces will occur, and the belt speed (V) through the use of the following equations. d = -2*sin-1[(D-d)/(2C)] = -2*sin-1[(6-2.5)/(2*72)] = 3.093 rad V = nDD/12 = *2000*6/12 = 3141.6 ft/min With the belt speed known, the rotational speed of the driven pulley (nd) can easily be found with the following equation. nd = 12V/(d) = 12*3141.6/(*2.5) = 4800 RPM With these calculations and assumed constraints in mind, the belt thickness is restricted by the specification of a polyamide belt, which we will assume is an A-2c. Based upon this assumption we immediately know that the velocity correction factor (Cv) will be 1 since it is a polyamide belt. Shigleys Table 17-2 suggests that for the selected belt, the thickness (t) will be 0.11, a specific weight () of 0.037 lbf/in3, an allowable tension per unit width (Fa) of 60 lbf/in, and a coefficient of friction () of .8. To calculate the belt width (b), we must first do several calculations in terms of b. The first of which will be to find the mass per unit length (w) as shown in the following calculation in terms of belt width. w = 12bt = 12*.037*b*0.11 = 0.04884b lbf/ft The next step is to calculate the hoop tension due to centrifugal force (Fc), which incorporates the gravitational constant (g) of 32.17 ft/s2, the calculation is shown below. Fc = (w/g)(V/60)2 = (.04884b/32.17)(3141.6/60)2 = 4.16b lbf Now we need to find the largest allowable tension (F1)a which requires the pulley correction factor (Cp) from Shigleys Table 17-4 which is .73 for the selected belt material. The largest allowable tension calculation is determined below. (F1)a = bFaCpCv = b*60*.73*1 = 43.8b lbf The difference between the largest allowable tension and the slack side tension (F2) is equivalent to twice the transmitted torque divided by the driven diameter. Thus the slack side tension can be found as a function of the belt width as shown below. (F1)a-F2 = 2/d => F2 = (F1)a-(2)/d = 43.8b-(2*52.38)/6 = 43.8b-17.5 lbf Next, the initial tension (Fi) can be calculated based off of the previous tension calculations as the following depicts. 5

Fi = [(F1)a+F2]/2 -Fc = (43.8b+43.8b-17.5)/2 4.16b = 39.64b 8.75 lbf Finally, to solve for a belt width we should base it off of the friction development (f) to ensure slipping does not occur. To do this we use Shigleys equation 17-7 solved for f as shown below and plug in our previously established values and set f to be equivalent to the belt coefficient of friction. With some fancy mathematical manipulation we can determine a minimal value for the belt width to transmit the load without slippage. f= =(1/)ln{[(F1)a-Fc]/[F2-Fc]} => .8 = (1/3.093)ln{[43.8b-4.16b]/[43.8b-17.5-4.16b]} => b = .481 in Since belt width is based upon what is easily manufactured and available, a belt width of 0.5 inches has been selected. With this value we can find the mass per unit length and the actual tension values by plugging in the belt width into the equations that were derived in terms of belt width, these calculations are shown below. w = 12bt = 12*.037*0.5*0.11 = 0.0244 lb/ft Fc = 4.16b = 4.16*0.5 = 2.08 lbf (F1)a = 43.8b = 43.8*0.5 = 21.9 lbf F2 = 43.8b - 17.5 = 43.8*0.5 - 17.5 = 4.4 lbf Fi = 39.64b - 8.75 = 39.64*0.5 8.75 = 11.1 lbf To purchase a belt we would also need to know the required belt length (L) but to do that we need the wrap angle of the driving pulley (D). Both calculations are shown below. D = +2*sin-1[(D-d)/(2C)] = +2*sin-1[(6-2.5)/(2*72)] = 3.190 rad L = (4C2-(D-d)2).5 + 0.5(DD+dd) = (4*722-(6-2.5)2 + 0.5(6*3.190+2.5*3.093) = 157.4 in Flat belts are available in lengths made to order so a 157.4 inch belt should be available. The last step is to calculate the belt dip (dip) on the slack side of the belt. This final calculation is shown below. dip = (C2w)/(96*Fi) = (722*0.0244)/(96*11.1) = 0.119 in This dip should be acceptable as it is not great enough to conflict with the lower side of the belt and will allow for the belt to stretch increasing the dip slightly but preserving the tension. VI. Gear Analysis The speed of the driving gear (nG) is equivalent to the speed of the driven pulley which is 4,800 RPM. To get to the rotational speed of at least 10,000 RPM given the driven pulley speed, we can deduce that a gear ratio of at least 2.083:1, for simplicity and the fact that the desired rotational speed can be greater than 10,000 RPM, a ratio of 3:1 will be used. This means that the rotational speed of the pinion or driven gear (np) will be 14,400 RPM. Based upon gears available from Ondrivesus.com a 6

common pressure angle () is 20 and their AGMA quality standard (Qv) is 10. These gears are made from 303 Stainless steel with a Brinell hardness of 160, and have been assumed to have a Grade of 1 although not specified by the manufacturer. Through the use of the American Gear Manufacturers Association (AGMA) equations, we can calculate the bending stresses and safety factors for bending, as well as the contact stresses and safety factors relative to these stresses. Given the transmitted power based off of the previous belt calculations, we know that our input power is 1.662 Hp at a rotational speed of 4,800 RPM. Since the driving gear is mounted on the same shaft as the driven pulley, they will share the same rotational speed thus the speed of the driving gear (nG) is also 4,800 RPM. To begin the calculations we must select some value of teeth to examine, a pinion tooth count (Np) of 20 was selected based on available gear sizes. Therefore the gear tooth count (NG) based off of the desired gear ratio. The manufacturers indicate that for 16-pitch gears with 20 pressure angles, a 60 tooth gear will have a diameter (dG) of 3.75 inches or 95.25mm, and a 20 tooth pinion will have a diameter (dp) of 1.25 inches or 31.75mm. These dimensions allow for a module (m) to be calculated, which turns out to be .0625 inches or 1.59mm. All of the remaining AGMA calculations will be done with SI units and equations. The AGMA calculations are shown in Figure 6, and figure 7 shows the final results with important values drawn from data contained in the tables and figures of Shigleys chapter 14. Some of the values that are not derived directly from formulas include the Lewis form factor for the pinion (Yp) and gear (YG), the face width (F) which is available from the gear manufacturer and found to be adequate at 12.7mm. The load distribution factor (KH) required several bits of information from the manufacturer including teeth crown, pinion mounting, and assembly adjustment, each yielded a respective value of 1. Based upon the idea that the final product will have the gearing enclosed, commercial enclosed unit conditions were used in the calculations. The rim thickness factor (KB) was found to be 1 based off of the tooth height and rim thickness provided by the manufacturer. The dynamic factor (Kv) was found to be 1.27 based upon the AGMA quality of the gear and the velocity of the pinion since it is the fastest spinning gearing component. Since the overall system desires a 95% reliability, an reliability of 0.983 was used to calculate the reliability factor (Yz) which was found to be 0.845. It is assumed that the overload factor (Ko) will be 1, and the hardness ratio (CH) will also be 1 since both gears are made of the same material.

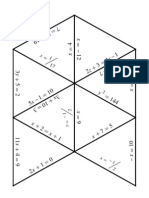

Figure 6 AGMA Calculations 8

Figure 7 AGMA Results Based upon the AGMA calculations we find that our bending stresses in the pinion (p) are 11.46 MPa with a safety factor of 17.5 and the bending stress in the gear (G) is 9.23 MPa with a safety factor of 21.7. The contact stress in the pinion (Cp) are 239.3 MPa with a safety factor of 2.6 and the contact stress in the gear (CG) is also 239.3 MPa but with a safety factor of 2.7. These contact safety factors are in between the design minimums and preferred factors of safety and thus justified. Although many assumptions were made in this selection of AGMA calculations, these fairly large factors of safety should compensate for at least mildly incorrect assumptions. VII. Efficiency The overall efficiency (e) of the machine can be calculated by taking the final output power (Hf) and dividing by the initial power provided. The final output power is determined from the speed and diameter of the pinion gear and the transmitted load (Wt) from the gear to the pinion, the transmitted load calculation is shown in Figure 6 and is 51.8N. Both calculations are shown below. Hf = dpnpWt/60000 = *31.75*14400*51.8/60000 = 1239 W e = Hf/Hnom = 1239/1500 = .826 * 100% = 82.6% The efficiency of the design turns out to be 82.6% which is fairly decent and within the range set by the functional requirements. VIII. Visualization Based upon the design and calculated dimensions and lengths, Figure 8 illustrates the overall configuration. Although not depicted on the shafts or shaft configuration, bearings would be required to support the shaft and allow free spinning or the various components.

Figure 8 Design Configuration Figure 9 illustrates the driving pulley on the power input shaft, notice the key that is used to transfer the shaft rotation into the pulley and thus through the system.

10

Figure 9 Large Pulley on Input Shaft Figure 10, below shows how the tool side of the machine will work. The small pulley has a similar key and keyway to transfer the motion to the shaft, and the driving and driven gears each have set screws that allow the motion to be transferred through the gears to and from each shaft. The final element on the tool shaft is the polishing tool to shine up that brass.

Figure 10 Tool Side Pulley and Gear Train 11

The shafts have been specially designed to allow for shoulders for positioning, along with keyways and keys to transfer the torque from the shaft to the pulley. There are snap ring grooves located to hold the pulleys in place on each shaft. For the gears, which are manufactured with set screws, additional slight holes were added for the set screws to engage in to help transfer the torque from the shaft to the gears without any slipping. Bearings are not illustrated on the shafts nor are any shaft features associated with bearings such as shoulders or additional snap ring grooves. Additionally, considerations for filleting sharp corners and shoulders should be considered as well. Figure 11 below highlights some of these key design features.

Figure 11 Shaft Features

12

The pulleys are very similar in their design; each has a keyway cut into the bore diameter to be used with a key to transfer the torque from the shaft. Each pulley has a crowned surface, sloped sides, and raised edges to assist in the tracking of the belt. Figure 12 shows the key features present on each of the pulleys.

Figure 12 Pulley Features IX. Cost The bill of materials for this project is rather extensive, especially when considering components such as shafts, keys, snap rings, bearings and mounting components. However, strictly for the belt, gears, and associated pulley, Figure 13 depicts the bill of materials for the project.

Figure 13 Bill of Selected Materials The total cost of the basic components of this design is approximately $283.21, which is slightly out of the ideal provided by the functional requirements but still reasonable. X. Conclusion Based upon the technical calculations for this design, the functional requirements seem to be appropriately accounted for. The design has been successfully powered using a shaft that is inputting 1,500 Watts at 2,000 RPM. A fairly large margin over the design requirement of 10,000 RPM was 13

achieved, with this device rotating at about 14,400 RPM, 44% faster than required and perfectly capable of a nice shiny finish. The design was based off the use of a cycle count of one hundred million cycles and a system reliability of 95%, yielding safety factors of 2.61 and 2.67 for contact stresses. These safety factors are in excess of the minimum factors and sufficient per the requirements. The cost of this design is slightly more than the functional requirements desire, but within about a 10% margin, although the cost excludes bearings, shafts, and shaft components which would likely cost well over double the predicted cost at the moment. However, the efficiency of the design has been found to be about 83% which is comfortably into the range desired by the functional requirements. Based upon these findings, this design should be reasonably successful in meeting the demands set forth and should be quite capable of providing a nice brass shiner. XI. Appendices

14

Das könnte Ihnen auch gefallen

- Machine Design Elements and AssembliesVon EverandMachine Design Elements and AssembliesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsVon EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNoch keine Bewertungen

- Lecture #10 Types of Belts and Belt Selection: Course Name: Design of Machine Elements Course Number: MET 214Dokument22 SeitenLecture #10 Types of Belts and Belt Selection: Course Name: Design of Machine Elements Course Number: MET 214Anup M UpadhyayaNoch keine Bewertungen

- Integrated Mechanical DesignJAN - 11Dokument4 SeitenIntegrated Mechanical DesignJAN - 11SasiKumar PetchiappanNoch keine Bewertungen

- Shaft Design (Mini Project 2) Machine Design ProjectDokument26 SeitenShaft Design (Mini Project 2) Machine Design ProjectMohammad Tahir100% (5)

- Selection and Adaptation of Hydraulic Cylinders For Tipper HoistingDokument7 SeitenSelection and Adaptation of Hydraulic Cylinders For Tipper HoistingManohar M Hegde100% (1)

- Lab Integrated DesignDokument2 SeitenLab Integrated DesignSpidyNoch keine Bewertungen

- Driveshaft Senior Design ReportDokument61 SeitenDriveshaft Senior Design ReportAlex BradleyNoch keine Bewertungen

- Shaft Design ProjectDokument14 SeitenShaft Design Projectjwm6085% (13)

- New Friction Mechanical TransmissionDokument5 SeitenNew Friction Mechanical TransmissionInternational Journal of Engineering Inventions (IJEI)Noch keine Bewertungen

- Chain Drives: Why Use A Chain Drive?Dokument6 SeitenChain Drives: Why Use A Chain Drive?Syed Raheel AdeelNoch keine Bewertungen

- HELLODokument9 SeitenHELLORavinder ChaudharyNoch keine Bewertungen

- Problems s2Dokument6 SeitenProblems s2zangue billy jamesNoch keine Bewertungen

- Final Form 2 373Dokument12 SeitenFinal Form 2 373Abood RainNoch keine Bewertungen

- ME450 - 06 FlexElem Ch17A HODokument28 SeitenME450 - 06 FlexElem Ch17A HOJudah Cochrane KatzNoch keine Bewertungen

- R.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenDokument6 SeitenR.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenAjay ChandranNoch keine Bewertungen

- Belt AnalysisDokument4 SeitenBelt AnalysisMaheswaran MuthaiyanNoch keine Bewertungen

- Chapter 5 - Friction Devices - Theory of Machines - Part 1Dokument17 SeitenChapter 5 - Friction Devices - Theory of Machines - Part 1Sandip GhoshNoch keine Bewertungen

- Lec4-Belt DrivesDokument37 SeitenLec4-Belt Drivesmohamed.hassan031Noch keine Bewertungen

- Static and Dynamic Analysis of Suspension System With Longitudinal Spring and Damper Assembly NEWDokument6 SeitenStatic and Dynamic Analysis of Suspension System With Longitudinal Spring and Damper Assembly NEWTrbvmNoch keine Bewertungen

- 679 02 Fenner Chain DrivesDokument32 Seiten679 02 Fenner Chain Drivesparag76760% (1)

- Design and Analysis of Multi-Angular Gearless Transmission SystemDokument9 SeitenDesign and Analysis of Multi-Angular Gearless Transmission SystemShrikkNoch keine Bewertungen

- DTS - Unit - 2 PDFDokument14 SeitenDTS - Unit - 2 PDFmani100% (1)

- AT8611 Lab QuestionsDokument9 SeitenAT8611 Lab QuestionsChirpiNoch keine Bewertungen

- Topic BeltsDokument20 SeitenTopic BeltsAstri Ngent100% (1)

- Volvo PRV Engine ManualDokument17 SeitenVolvo PRV Engine ManualjbouzaNoch keine Bewertungen

- Assignment 1 (Unit 1 and 2)Dokument5 SeitenAssignment 1 (Unit 1 and 2)Atharva ChoudhariNoch keine Bewertungen

- 5 - Machine Tool SpindleDokument23 Seiten5 - Machine Tool SpindleOkan ÖzelNoch keine Bewertungen

- Application of Belt Drive and Selection MethodDokument11 SeitenApplication of Belt Drive and Selection MethodAshutosh kumarNoch keine Bewertungen

- Lathe DesignDokument11 SeitenLathe DesignShiyas Basheer0% (1)

- Shaft Design and Flywheel DimensioningDokument13 SeitenShaft Design and Flywheel DimensioningihtishamuddNoch keine Bewertungen

- Case Study and Stress Analysis of A 3Dokument12 SeitenCase Study and Stress Analysis of A 3Talha MemonNoch keine Bewertungen

- Machine Design - LDokument2 SeitenMachine Design - LNilesh Mistry (Nilesh Sharma)Noch keine Bewertungen

- 181505-181902-MD - IiDokument2 Seiten181505-181902-MD - IiSiddharth PanchalNoch keine Bewertungen

- New Gearbox DesignDokument16 SeitenNew Gearbox DesignIAN MIGOTNoch keine Bewertungen

- Detc2002/mech 34231Dokument10 SeitenDetc2002/mech 34231kaesarNoch keine Bewertungen

- Roller Chain Drive Selection: Table 1 - Service FactorsDokument5 SeitenRoller Chain Drive Selection: Table 1 - Service FactorsPercy TorresNoch keine Bewertungen

- Bike CrankansysDokument5 SeitenBike CrankansysPranav ěýĕѕ ŠpęăқNoch keine Bewertungen

- Idler DesignDokument6 SeitenIdler DesignVaibhav GuptaNoch keine Bewertungen

- Sr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Dokument38 SeitenSr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Narendra Kumar DhayalNoch keine Bewertungen

- Tripod Joint and Drive ShaftDokument10 SeitenTripod Joint and Drive ShaftArnob DasNoch keine Bewertungen

- BELT Lecture 01Dokument56 SeitenBELT Lecture 01mahaveer dasNoch keine Bewertungen

- Fundamentals of Pulley and WinchesDokument62 SeitenFundamentals of Pulley and WinchesvikasgahlyanNoch keine Bewertungen

- 39 Design of V - Belt DrivesDokument10 Seiten39 Design of V - Belt DrivesPRASAD326100% (6)

- Gear Design 2Dokument15 SeitenGear Design 2cracking khalifNoch keine Bewertungen

- NUiCONE-2015 Design and Analysis of 100 T Capacity Bottom Pulley Hook Block For Double Girder EOT CraneDokument5 SeitenNUiCONE-2015 Design and Analysis of 100 T Capacity Bottom Pulley Hook Block For Double Girder EOT CraneGogyNoch keine Bewertungen

- 3.2 Design SystemDokument48 Seiten3.2 Design SystemMahmoud RababahNoch keine Bewertungen

- l3 Group 8 2Dokument5 Seitenl3 Group 8 2api-281193401Noch keine Bewertungen

- Finite Element Analysis of Orbital Forming Used in Spindle/Inner Ring AssemblyDokument6 SeitenFinite Element Analysis of Orbital Forming Used in Spindle/Inner Ring AssemblyEldori1988Noch keine Bewertungen

- Example of Gearbox CalculationDokument9 SeitenExample of Gearbox CalculationWassihun Amdie100% (1)

- Mech 325 Tutorials (Questions Only)Dokument54 SeitenMech 325 Tutorials (Questions Only)Shahriar Norouzi ZadehNoch keine Bewertungen

- Smoothing The Ride: A Simple ModelDokument16 SeitenSmoothing The Ride: A Simple ModelChristian QuitoNoch keine Bewertungen

- Example of Gearbox Calculation.: Input ConditionsDokument5 SeitenExample of Gearbox Calculation.: Input Conditionsoman1148100% (1)

- Planar Linkage Synthesis: A modern CAD based approachVon EverandPlanar Linkage Synthesis: A modern CAD based approachNoch keine Bewertungen

- Control of DC Motor Using Different Control StrategiesVon EverandControl of DC Motor Using Different Control StrategiesNoch keine Bewertungen

- Solution Manual for 100 Genesys Design Examples: Second EditionVon EverandSolution Manual for 100 Genesys Design Examples: Second EditionNoch keine Bewertungen

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsVon EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- Team Awesome Thermal System Report - Water SlideDokument12 SeitenTeam Awesome Thermal System Report - Water Slidebcairns12Noch keine Bewertungen

- ME2 Lab Raw Data MEMS1042Dokument2 SeitenME2 Lab Raw Data MEMS1042bcairns12Noch keine Bewertungen

- Butterfly and Poppet ValvesDokument5 SeitenButterfly and Poppet Valvesbcairns12Noch keine Bewertungen

- ProposalDokument1 SeiteProposalbcairns12Noch keine Bewertungen

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Dokument21 SeitenDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- (English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)Dokument41 Seiten(English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)YaaroNoch keine Bewertungen

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDokument86 Seiten141 ISACA NACACS Auditing IT Projects Audit Programkautaliya100% (6)

- Detailed Lesson Plan in Mathematics 10 I. ObjectivesDokument4 SeitenDetailed Lesson Plan in Mathematics 10 I. ObjectivesLouis Fetilo FabunanNoch keine Bewertungen

- 3-Storeyed 31-3-2015-Schedule PDFDokument1 Seite3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNoch keine Bewertungen

- Chapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyDokument12 SeitenChapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyEmad ManniNoch keine Bewertungen

- pm2 5 Sensor 201605Dokument6 Seitenpm2 5 Sensor 201605Vennela NandikondaNoch keine Bewertungen

- IPE SakibBhaiMagicChothaDokument55 SeitenIPE SakibBhaiMagicChothaTousif SadmanNoch keine Bewertungen

- Silenat Berhanu SimaDokument6 SeitenSilenat Berhanu SimaSilenat BerhanuNoch keine Bewertungen

- Literature Review On Parking SpaceDokument6 SeitenLiterature Review On Parking Spacefvgy6fn3100% (1)

- Century 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthDokument8 SeitenCentury 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthJohn0% (4)

- The Aerodynamics of ParachutesDokument78 SeitenThe Aerodynamics of Parachutesstevehuppert50% (2)

- Anatomy & Physiology MCQsDokument26 SeitenAnatomy & Physiology MCQsMuskan warisNoch keine Bewertungen

- Strategic Cost AnalysisDokument24 SeitenStrategic Cost AnalysisBusiness Expert Press100% (10)

- Bhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Dokument37 SeitenBhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Anu RsNoch keine Bewertungen

- Exposure: The PhotoreactionDokument16 SeitenExposure: The PhotoreactionGeetha ThiruvengadamNoch keine Bewertungen

- Staad 4Dokument37 SeitenStaad 4saisssms9116100% (2)

- Data Migration Good DocumentDokument16 SeitenData Migration Good Documentsambit76Noch keine Bewertungen

- 9A02505 Electrical Machines-IIIDokument4 Seiten9A02505 Electrical Machines-IIIsivabharathamurthyNoch keine Bewertungen

- Critique of Violence - Walter BenjaminDokument14 SeitenCritique of Violence - Walter BenjaminKazım AteşNoch keine Bewertungen

- Miracle Mills 300 Series Hammer MillsDokument2 SeitenMiracle Mills 300 Series Hammer MillsSNoch keine Bewertungen

- Python - Data EngineeringDokument34 SeitenPython - Data EngineeringChetan PatilNoch keine Bewertungen

- Fuses f150Dokument7 SeitenFuses f150ORLANDONoch keine Bewertungen

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Dokument27 SeitenChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNoch keine Bewertungen

- Si2304 (Mosfet Sot 23)Dokument6 SeitenSi2304 (Mosfet Sot 23)Alfredo Valencia RodriguezNoch keine Bewertungen

- Analytical Chemistry (CHM111) Laboratory ManualDokument73 SeitenAnalytical Chemistry (CHM111) Laboratory ManualKatrina BucudNoch keine Bewertungen

- Olympiad Problem 2Dokument3 SeitenOlympiad Problem 2Đạt Nguyễn BáNoch keine Bewertungen

- Introduction To Neutrino Physics: Paolo LipariDokument85 SeitenIntroduction To Neutrino Physics: Paolo LipariSubhankar HowladerNoch keine Bewertungen

- Algebra1 Review PuzzleDokument3 SeitenAlgebra1 Review PuzzleNicholas Yates100% (1)

- 07 Endodontic RetreatmentDokument64 Seiten07 Endodontic RetreatmentGayathriNoch keine Bewertungen