Beruflich Dokumente

Kultur Dokumente

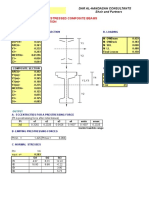

Cast Place 1 1-4 A36 - 22IN

Hochgeladen von

mjlazoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cast Place 1 1-4 A36 - 22IN

Hochgeladen von

mjlazoCopyright:

Verfügbare Formate

www.hilti.us Company: Specifier: Address: Phone I Fax: E-Mail: Specifier's comments: Page: Project: Sub-Project I Pos. No.

: Date: 1

Profis Anchor 2.3.2

17/09/2012

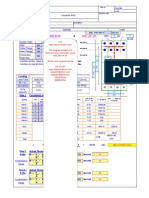

1 Input data

Anchor type and diameter: Effective embedment depth: Material: Proof: Stand-off installation: Profile: Base material: Reinforcement: Seismic loads (cat. C, D, E, or F) Geometry [in.] & Loading [lb, in.lb] Hex Head ASTM F 1554 GR. 36 1 1/4 hef = 22,000 in. ASTM F 1554 design method ACI 318 / CIP - (Recommended plate thickness: not calculated) no profile uncracked concrete, 4000, fc' = 4000 psi; h = 42,000 in. tension: condition B, shear: condition B; edge reinforcement: > No. 4 bar with stirrups no

Input data and results must be checked for agreement with the existing conditions and for plausibility! PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

www.hilti.us Company: Specifier: Address: Phone I Fax: E-Mail: Page: Project: Sub-Project I Pos. No.: Date: 2

Profis Anchor 2.3.2

17/09/2012

2 Load case/Resulting anchor forces

Load case: Design loads Anchor reactions [lb] Tension force: (+Tension, -Compression) Anchor Tension force Shear force Shear force x 1 33000 0 0 max. concrete compressive strain: - [] max. concrete compressive stress: - [psi] resulting tension force in (x/y)=(0,000/0,000): 0 [lb] resulting compression force in (x/y)=(0,000/0,000): 0 [lb] Shear force y 0

3 Tension load

Steel Strength* Pullout Strength* Concrete Breakout Strength** Concrete Side-Face Blowout, direction ** * anchor having the highest loading 3.1 Steel Strength Nsa = n Ase,N futa f Nsteel Nua Variables n 1 Calculations Nsa [lb] 56202 Results Nsa [lb] 56202 fsteel 0,750 f Nsa [lb] 42151 Nua [lb] 33000 Ase,N [in.2] 0,97 futa [psi] 58000 ACI 318-08 Eq. (D-3) ACI 318-08 Eq. (D-1) Load Nua [lb] 33000 33000 33000 N/A **anchor group (anchors in tension) Capacity fNn [lb] 42151 56981 152943 N/A Utilization bN = Nua/fNn 79 58 22 N/A Status OK OK OK N/A

Input data and results must be checked for agreement with the existing conditions and for plausibility! PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

www.hilti.us Company: Specifier: Address: Phone I Fax: E-Mail: 3.2 Pullout Strength NpN = yc,p Np Np = 8 Abrg f'c f NpN Nua Variables yc,p 1,400 Calculations Np [lb] 58144 Results Npn [lb] 81402 fconcrete 0,700 f Npn [lb] 56981 Nua [lb] 33000 Abrg [in.2] 1,82 f'c [psi] 4000 ACI 318-08 Eq. (D-14) ACI 318-08 Eq. (D-15) ACI 318-08 Eq. (D-1) Page: Project: Sub-Project I Pos. No.: Date: 3

Profis Anchor 2.3.2

17/09/2012

3.3 Concrete Breakout Strength Ncb = A (A ) y

Nc Nc0 ed,N

yc,N ycp,N Nb

ACI 318-08 Eq. (D-4) ACI 318-08 Eq. (D-1) ACI 318-08 Eq. (D-6) ACI 318-08 Eq. (D-9) ACI 318-08 Eq. (D-11) ACI 318-08 Eq. (D-13) ACI 318-08 Eq. (D-8)

f Ncb Nua ANc see ACI 318-08, Part D.5.2.1, Fig. RD.5.2.1(b) ANc0 = 9 h2 ef 1 2 e'N 1,0 yec,N = 1+ 3 hef ca,min = 0,7 + 0,3 1,0 yed,N 1,5hef ca,min 1,5hef 1,0 ycp,N = MAX c , c ac ac 5/3 Nb = 16 l f'c hef

) )

Variables hef [in.] 22,000 cac [in.] Calculations ANc [in.2] 4356,00 Results Ncb [lb] 218490 fconcrete 0,700 f Ncb [lb] 152943 Nua [lb] 33000 ANc0 [in.2] 4356,00 yec1,N 1,000 yec2,N 1,000 yed,N 1,000 ycp,N 1,000 Nb [lb] 174792 ec1,N [in.] 0,000 kc 16 ec2,N [in.] 0,000 l 1 ca,min [in.] f'c [psi] 4000 yc,N 1,250

Input data and results must be checked for agreement with the existing conditions and for plausibility! PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

www.hilti.us Company: Specifier: Address: Phone I Fax: E-Mail: Page: Project: Sub-Project I Pos. No.: Date: 4

Profis Anchor 2.3.2

17/09/2012

4 Shear load

Steel Strength* Steel failure (with lever arm)* Pryout Strength* Concrete edge failure in direction ** * anchor having the highest loading Load Vua [lb] N/A N/A N/A N/A **anchor group (relevant anchors) Capacity fVn [lb] N/A N/A N/A N/A Utilization bV = Vua/fVn N/A N/A N/A N/A Status N/A N/A N/A N/A

5 Warnings

To avoid failure of the anchor plate the required thickness can be calculated in PROFIS Anchor. Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be sufficiently stiff, in order not to be deformed when subjected to the loading! Condition A applies when supplementary reinforcement is used. The factor is increased for non-steel Design Strengths except Pullout Strength and Pryout strength. Condition B applies when supplementary reinforcement is not used and for Pullout Strength and Pryout Strength. Refer to ACI 318, Part D.4.4(c). Checking the transfer of loads into the base material and the shear resistance are required in accordance with ACI318 or the relevant standard!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility! PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

www.hilti.us Company: Specifier: Address: Phone I Fax: E-Mail: Page: Project: Sub-Project I Pos. No.: Date: 5

Profis Anchor 2.3.2

17/09/2012

6 Installation data

Anchor plate, steel: Profile: Hole diameter in the fixture: Plate thickness (input): Recommended plate thickness: Cleaning: No cleaning of the drilled hole is required Coordinates Anchor in. Anchor 1 x 0,000 y 0,000 c-x c+x c-y c+y Anchor type and diameter: Hex Head ASTM F 1554 GR. 36, 1 1/4 Installation torque: -0,009 in.lb Hole diameter in the base material: - in. Hole depth in the base material: 22,000 in. Minimum thickness of the base material: 24,344 in.

7 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific application. You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility! PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Das könnte Ihnen auch gefallen

- Perhitungan Overhead CraneDokument46 SeitenPerhitungan Overhead CraneArinal9488% (17)

- GRDSLABDokument15 SeitenGRDSLABmjlazo0% (1)

- Steel Span - National Steel Bridge Alliance PDFDokument12 SeitenSteel Span - National Steel Bridge Alliance PDFmjlazo0% (1)

- 6a Padeye Aisc 360 2005Dokument6 Seiten6a Padeye Aisc 360 2005mjlazoNoch keine Bewertungen

- Eic CodesDokument2.401 SeitenEic CodesmjlazoNoch keine Bewertungen

- Tank and Dike Work BookDokument6 SeitenTank and Dike Work BookmjlazoNoch keine Bewertungen

- API 650 Baseplate DesignDokument3 SeitenAPI 650 Baseplate DesignmjlazoNoch keine Bewertungen

- EM 1110-3-174 - Sanitary and Industrial Waste Water Collection - Mobilization Construction - WebDokument31 SeitenEM 1110-3-174 - Sanitary and Industrial Waste Water Collection - Mobilization Construction - WebPDHLibraryNoch keine Bewertungen

- Tel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680Dokument48 SeitenTel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680gkdora57489% (9)

- Mechanical Vibration by Janusz KrodkiewskiDokument247 SeitenMechanical Vibration by Janusz KrodkiewskimjlazoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 3.5 T Bolier ManualDokument206 Seiten3.5 T Bolier Manualchandravadiyaketan150467% (3)

- Drive RefreshDokument5 SeitenDrive RefreshhmavisNoch keine Bewertungen

- CAT 2023 Question Paper Slot 2 With Answer Keys by Bodhee PrepDokument29 SeitenCAT 2023 Question Paper Slot 2 With Answer Keys by Bodhee PrepEmadNoch keine Bewertungen

- 305 Concrete Pavement Joints PDFDokument4 Seiten305 Concrete Pavement Joints PDFTim LinNoch keine Bewertungen

- Climbing FormworkDokument5 SeitenClimbing Formworksanjeev2812Noch keine Bewertungen

- Improving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)Dokument12 SeitenImproving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)IJRASETPublicationsNoch keine Bewertungen

- Av en PipeDokument60 SeitenAv en PipeDuy Nguyen Duc0% (1)

- Descon Engineering ReportDokument12 SeitenDescon Engineering ReportadnanNoch keine Bewertungen

- Trans Tech: PublicationsDokument48 SeitenTrans Tech: PublicationsSulochana KannanNoch keine Bewertungen

- IIIrd Year I Sem Regular & Supply Results PDFDokument133 SeitenIIIrd Year I Sem Regular & Supply Results PDFLALRAZ100% (1)

- Engineering Design QuizDokument2 SeitenEngineering Design QuizChoy Hau Yan100% (1)

- Outline CourseDokument2 SeitenOutline CourseFaiz MechyNoch keine Bewertungen

- Prestressed Precast1Dokument5 SeitenPrestressed Precast1mahmoud IbrahemNoch keine Bewertungen

- Engineering and The Mind's EyeDokument14 SeitenEngineering and The Mind's EyeRudolf Pinochet50% (2)

- 440.11-22 PreviewDokument10 Seiten440.11-22 Previewjcunha4740Noch keine Bewertungen

- Side Girt Design-RwphDokument23 SeitenSide Girt Design-Rwphasvenk309100% (1)

- 4 Years Marine Engineering Syllabus-BSMRMUDokument67 Seiten4 Years Marine Engineering Syllabus-BSMRMURahul DeyNoch keine Bewertungen

- Example Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression PDFDokument4 SeitenExample Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression PDFOprisor Costin100% (1)

- Truss SteelDokument10 SeitenTruss SteelIntrinsic CmcNoch keine Bewertungen

- Flyer - PCS-902 Line Distance RelayDokument3 SeitenFlyer - PCS-902 Line Distance RelayAyeshazahidhussainNoch keine Bewertungen

- BS5400!10!1980-Code of Practice For FatigueDokument78 SeitenBS5400!10!1980-Code of Practice For Fatiguezlq10081008Noch keine Bewertungen

- Method Statement For Erection WorksDokument7 SeitenMethod Statement For Erection WorksCobbinah Mark0% (1)

- Construction Equipment MaintenanceDokument13 SeitenConstruction Equipment MaintenanceSherwin NatinoNoch keine Bewertungen

- 11 Steel Connection Design As Per AISC 23052014Dokument2 Seiten11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri67% (3)

- Work ExperienceDokument1 SeiteWork ExperienceAnanya KrishnaNoch keine Bewertungen

- Introduction To Control SystemDokument51 SeitenIntroduction To Control SystemNorkarlina Binti Khairul AriffinNoch keine Bewertungen

- 4 Software Testing Terminology MethodologyDokument20 Seiten4 Software Testing Terminology MethodologyZINNIA MAZUMDER 19BIT0155Noch keine Bewertungen

- Advantages and Disadvantages of Reinforced Cement Concrete (R.C.C)Dokument5 SeitenAdvantages and Disadvantages of Reinforced Cement Concrete (R.C.C)awaw awawNoch keine Bewertungen

- 5 SoftwareTestingStrategiesDokument47 Seiten5 SoftwareTestingStrategiesSandy CyrusNoch keine Bewertungen

- VAxx 132 GYk 1 CH MHAHyut 1630730394Dokument32 SeitenVAxx 132 GYk 1 CH MHAHyut 1630730394Jerald LatorreNoch keine Bewertungen