Beruflich Dokumente

Kultur Dokumente

Suspension

Hochgeladen von

Priyal PatelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Suspension

Hochgeladen von

Priyal PatelCopyright:

Verfügbare Formate

Suspension Systems

Summaries

Suspension Systems Fundamental principles

Principles of suspension

Sprung mass refers to vehicle parts supported on the springs, such as the body, frame, and engine. Unsprung mass includes parts of the steering and suspension not supported by springs, such as wheels, tires, and brake assemblies.

Unsprung weight

Parts of a vehicle not supported by the suspension system are known as unsprung weight.

Suspension force

Leaf springs absorb applied force by flattening out under load. Coil springs absorb force of impact by twisting. Torsion bars twist around their center.

Wheel unit location

Driving thrust, braking torque, and cornering force operate to displace wheel units. These forces must be transferred to the vehicle frame, but the wheel units must stay aligned with each other, and with the frame.

Dampening

Dampening prevents or reduces the bouncing effect of oscillation by absorbing the energy from the oscillation.

Types of suspension

Suspension systems

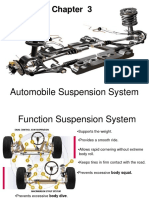

The purpose of the suspension system is to isolate the vehicle body from road bumps and vibrations, while keeping the wheels in contact with the road.

Solid axle

The solid, or beam, axle is used in the rear suspension of many front-engined, rear-wheel drive cars, and light commercial vehicles, and as the front suspension on many heavy commercial vehicles.

Dead axle

A dead axle only supports the vehicle and doesnt transmit any drive. With a live axle, the drive is transmitted through the final drive unit and axles to the wheels.

Independent suspension

Independent suspension helps keep unsprung mass low. Also, if a wheel hits an irregularity, it wont upset the opposite wheel on the same axle. It allows wheel camber to be adjusted, or designed into the suspension geometry.

Rear independent suspension

For independent suspension on the rear of a vehicle, many FWD cars use a McPherson strut at the rear. On RWD vehicles, the suspension has to allow for the external drive shafts.

2005 DVP Licensing Pty Ltd

page 1

Suspension Systems

Summaries

Suspension Systems Types of suspension (continued)

Rear-wheel drive independent suspension

On rear-wheel drive vehicles with independent suspension, the final drive unit is fixed to the vehicle frame. Drive is transmitted to each wheel by external drive shafts.

Adaptive air suspension

Adaptive air suspension is an electronically controlled air suspension system at all four wheels with a continuously adaptive damping system.

Adaptive air suspension operation

The height sensor uses the induction principle to constantly monitor the distance between the vehicles axle and its chassis.

Suspension system layouts

Driven rear suspension layouts

There are several different driven or live axle rear suspension system layouts.

Non-driven rear suspension layouts

There are several different non-driven or dead rear suspension system layouts.

Independent rear suspension layouts

There are several different layouts that use independent driven or live axle rear suspension systems.

Front suspension layouts

Front suspension layouts can use live or dead axle systems.

Suspension system components

Coil springs

The load-carrying ability of a coil spring depends on the wire diameter, the overall spring diameter, its shape, and the spacing of the coils. Coil springs can look alike but give very different load ratings, which are often color coded for identification.

Leaf springs

A leaf spring locates the axle housing longitudinally and laterally. It sustains torque reaction on acceleration, and braking torque on deceleration. Driving thrust transfers through the front half of the spring to the fixed shackle point.

Torsion bars

A torsion bar is fixed to the chassis or sub-frame at one end, and the suspension control arm at the other. Deflection of the suspension causes the bar to twist around its center, to provide the springing action.

2005 DVP Licensing Pty Ltd

page 2

Suspension Systems

Summaries

Suspension Systems Suspension system components (continued)

Rubber springs

Increasing the load on a suspension causes the rubber cone to act like a spring being deformed. When the load is removed, the rubbers elastic properties tend to return it to its original state.

Hydraulic shock absorbers

The dampening action of a hydraulic shock absorber comes from transferring oil, under pressure, through valves that restrict the oil flow. Resistance to motion is low when the piston moves slowly, and high when its velocity is high.

Gas-pressurised shock absorbers

Shock absorber dissolve can be reduced by pressurising the fluid with nitrogen.

Load-adjustable shock absorbers

The rubber air cylinder in the load-adjustable shock absorber can be pressurised to assist suspension springs that are under load. Changing the pressure in the cylinder can alter ride height, and the stiffness of the suspension.

Manual adjustable-rate shock absorbers

In a manual adjustable-rate shock absorber, the position of the valves in the piston can be changed, to vary the number of restrictions the oil has to pass through, and to vary the force needed to open the valves.

Electronic adjustable-rate shock absorbers

The electronic adjustable-rate shock absorber has a rotary solenoid that can alter dampening rate by changing the number of restrictions the oil must pass through, and varying the force needed to open the valves.

Automatic load-adjustable shock absorbers

Automatic load-adjustable shock absorbers maintain vehicle ride at a pre-set level, according to the load placed over the rear axle.

2005 DVP Licensing Pty Ltd

page 3

Das könnte Ihnen auch gefallen

- Toyota Suspension BasicsDokument26 SeitenToyota Suspension BasicsSunilkumar Reddy100% (2)

- Active Suspension System Power Point PresentationDokument30 SeitenActive Suspension System Power Point PresentationJAYNoch keine Bewertungen

- HW1 F15Dokument1 SeiteHW1 F15Prasanth Kumar Yadav0% (2)

- ! - Pay No Fine - A User Guide To Successfully Fighting Traffic TicketsDokument93 Seiten! - Pay No Fine - A User Guide To Successfully Fighting Traffic Ticketsdude0213557% (7)

- Automotive (2) Lab: Suspension SystemDokument8 SeitenAutomotive (2) Lab: Suspension SystemMohammad YahyaNoch keine Bewertungen

- Automobile: Semi Floating Suspension System in AutomobileDokument30 SeitenAutomobile: Semi Floating Suspension System in AutomobileFarhanNoch keine Bewertungen

- Suspension and Steering PPT 1Dokument32 SeitenSuspension and Steering PPT 1PARTHA SARATHI PANDANoch keine Bewertungen

- Suspension SystemsDokument85 SeitenSuspension SystemsWalter Tapfumanei MhosvahNoch keine Bewertungen

- System Under ChassisDokument6 SeitenSystem Under ChassisrheyNoch keine Bewertungen

- Chapter - Suspension System - Chasis-1Dokument9 SeitenChapter - Suspension System - Chasis-1karanragav12Noch keine Bewertungen

- Chapter No 3 Automobile Suspension SystemDokument36 SeitenChapter No 3 Automobile Suspension SystemAmit BhatiaNoch keine Bewertungen

- Drum Brake System Backing Plate: Braking PrincipleDokument3 SeitenDrum Brake System Backing Plate: Braking PrincipleSamiullah QureshiNoch keine Bewertungen

- Baithi AVCN 2Dokument37 SeitenBaithi AVCN 2Khanh ĐinhNoch keine Bewertungen

- Quá Trình - AVCN 2Dokument37 SeitenQuá Trình - AVCN 2tranquangg0608Noch keine Bewertungen

- Topic: Suspension System: Group 1 MembersDokument21 SeitenTopic: Suspension System: Group 1 MembersMilcentNoch keine Bewertungen

- Baithi AVCNDokument41 SeitenBaithi AVCNtranconghia1150Noch keine Bewertungen

- Bài 1 Rack and Pinion Steering SystemDokument34 SeitenBài 1 Rack and Pinion Steering SystemPham DuyNoch keine Bewertungen

- Chassis InformationDokument11 SeitenChassis InformationManny AnacletoNoch keine Bewertungen

- Assignment 3 AutomobileDokument11 SeitenAssignment 3 Automobilepawan sharmaNoch keine Bewertungen

- Yacob 12345Dokument57 SeitenYacob 12345Mangarapu YacobNoch keine Bewertungen

- MODULE V Lesson 1 3Dokument50 SeitenMODULE V Lesson 1 3Sleepy SpettoNoch keine Bewertungen

- Aayush Sable Mechanical EngineeringDokument40 SeitenAayush Sable Mechanical EngineeringAshish RawatNoch keine Bewertungen

- Automobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Dokument11 SeitenAutomobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Kirito CabelNoch keine Bewertungen

- Suspension & Brakes System: N. S. Surner SRES College of Engineering, KoprgaonDokument59 SeitenSuspension & Brakes System: N. S. Surner SRES College of Engineering, KoprgaonFiroz AminNoch keine Bewertungen

- 4-Wheel Steering MechanismDokument15 Seiten4-Wheel Steering MechanismMohseen KarcheNoch keine Bewertungen

- Suspension System by Nure JemalDokument35 SeitenSuspension System by Nure JemalNur JemsNoch keine Bewertungen

- Chapter-Seven: Steering SystemDokument46 SeitenChapter-Seven: Steering Systemyared admassuNoch keine Bewertungen

- AE Unit 2 Steering and Suspension System NotesDokument9 SeitenAE Unit 2 Steering and Suspension System Notessemmat1802Noch keine Bewertungen

- Ch-10-Steering and Front AxleDokument45 SeitenCh-10-Steering and Front Axlekeval patel100% (2)

- SuspensionDokument43 SeitenSuspensionyash1239100% (1)

- Good Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CDokument29 SeitenGood Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CSrikar ChinmayaNoch keine Bewertungen

- 5.design of Modification and Improvement On Automobile Suspension SystemDokument31 Seiten5.design of Modification and Improvement On Automobile Suspension SystemSumithra NaikNoch keine Bewertungen

- Suspension SystemDokument36 SeitenSuspension SystemRahul VermaNoch keine Bewertungen

- Automobile Suspension System: by Kharde R.B. S.E. Mechanical, Div: ADokument33 SeitenAutomobile Suspension System: by Kharde R.B. S.E. Mechanical, Div: AKharde RushikeshNoch keine Bewertungen

- A Comparative Study of The SuspensionDokument7 SeitenA Comparative Study of The SuspensionSivadanusNoch keine Bewertungen

- A496658235 - 19350 - 25 - 2020 - Unit-II Suspension SystemDokument63 SeitenA496658235 - 19350 - 25 - 2020 - Unit-II Suspension SystemDeepu SadasivuniNoch keine Bewertungen

- Suspension SystemsDokument37 SeitenSuspension SystemsPankajj PokhriyalNoch keine Bewertungen

- Suspension System PDFDokument9 SeitenSuspension System PDFBALAKRISHNAN ArchunanNoch keine Bewertungen

- Automotive Suspension ModifiedDokument46 SeitenAutomotive Suspension Modifiedregassa rajiNoch keine Bewertungen

- Automatic Air SuspentionDokument18 SeitenAutomatic Air Suspentionashu047Noch keine Bewertungen

- Suspension SystemDokument24 SeitenSuspension SystemkentNoch keine Bewertungen

- Suspension and SteeringDokument41 SeitenSuspension and Steeringboizone007Noch keine Bewertungen

- Soy Automotive Technology Act 2Dokument6 SeitenSoy Automotive Technology Act 2JOHN STEVEN SOYNoch keine Bewertungen

- Bma4723 Vehicle Dynamics Chap 7Dokument63 SeitenBma4723 Vehicle Dynamics Chap 7Fu HongNoch keine Bewertungen

- AUTO 201 Steering and Suspension SystemDokument6 SeitenAUTO 201 Steering and Suspension Systempig123Noch keine Bewertungen

- Project Report: - Suspension SystemDokument33 SeitenProject Report: - Suspension SystemAnil KumarNoch keine Bewertungen

- Suspension SystemsDokument35 SeitenSuspension SystemsMErdemDemirNoch keine Bewertungen

- Suspension SystemDokument28 SeitenSuspension SystemAaron Chin100% (1)

- Automotive Transmission SystemDokument94 SeitenAutomotive Transmission SystemTanzim Rafat AyonNoch keine Bewertungen

- TO Automotive Steering SystemDokument22 SeitenTO Automotive Steering SystemJ Naveen KumarNoch keine Bewertungen

- Ch-4 Propeller Shaft & Universal Joint: By, Deep Shah Sub: ATM (3330202)Dokument24 SeitenCh-4 Propeller Shaft & Universal Joint: By, Deep Shah Sub: ATM (3330202)mharitmsNoch keine Bewertungen

- Aen ReportDokument14 SeitenAen Reportv.v.ransing22Noch keine Bewertungen

- SteeringDokument24 SeitenSteeringapi-19890903Noch keine Bewertungen

- MCT 311 Lesson 5Dokument16 SeitenMCT 311 Lesson 5Moussa SaidNoch keine Bewertungen

- Automotive Steering Systems (Autosaved)Dokument18 SeitenAutomotive Steering Systems (Autosaved)Pradyumn MangalNoch keine Bewertungen

- Automotive Steering SystemsDokument18 SeitenAutomotive Steering SystemsPradyumn MangalNoch keine Bewertungen

- Chapter-Six: Suspension SystemDokument160 SeitenChapter-Six: Suspension SystemMikias BelaynehNoch keine Bewertungen

- Independent Suspension System Full ReportDokument21 SeitenIndependent Suspension System Full Reportmonikaneha12380% (5)

- Suspension System of Railway VehicleDokument9 SeitenSuspension System of Railway VehicleJoe m100% (1)

- Brakes: Automobile Engineering 14 Feb 2011Dokument27 SeitenBrakes: Automobile Engineering 14 Feb 2011Aditya KuchibhatlaNoch keine Bewertungen

- CH 3 SuspensionDokument85 SeitenCH 3 Suspensiondagem aragawNoch keine Bewertungen

- A Complete Introduction to Mountain Biking: Survival FitnessVon EverandA Complete Introduction to Mountain Biking: Survival FitnessNoch keine Bewertungen

- Engine: Learning ObjectivesDokument5 SeitenEngine: Learning ObjectivesPriyal PatelNoch keine Bewertungen

- Topic Beyond SyllabusDokument1 SeiteTopic Beyond SyllabusPriyal PatelNoch keine Bewertungen

- Sachith LorDokument3 SeitenSachith LorPriyal PatelNoch keine Bewertungen

- Sy Ty Be Me Odd Timetables 18 06 2018Dokument8 SeitenSy Ty Be Me Odd Timetables 18 06 2018Priyal PatelNoch keine Bewertungen

- Gujarat Technological University-Eg IntroDokument40 SeitenGujarat Technological University-Eg IntroPriyal PatelNoch keine Bewertungen

- Engine: Learning ObjectivesDokument5 SeitenEngine: Learning ObjectivesPriyal PatelNoch keine Bewertungen

- Call For Papers: April 8 - 10, 2014 - Detroit, Michigan USADokument1 SeiteCall For Papers: April 8 - 10, 2014 - Detroit, Michigan USAPriyal PatelNoch keine Bewertungen

- Overhead CraneDokument2 SeitenOverhead CranePriyal PatelNoch keine Bewertungen

- Engine: Learning ObjectivesDokument5 SeitenEngine: Learning ObjectivesPriyal PatelNoch keine Bewertungen

- Sem 4 ScheduleDokument1 SeiteSem 4 SchedulePriyal PatelNoch keine Bewertungen

- Overhead CraneDokument2 SeitenOverhead CranePriyal PatelNoch keine Bewertungen

- RTIDokument6 SeitenRTIPriyal PatelNoch keine Bewertungen

- Why Study Communication SkillsDokument23 SeitenWhy Study Communication SkillsPriyal PatelNoch keine Bewertungen

- Call For Papers: April 8 - 10, 2014 - Detroit, Michigan USADokument1 SeiteCall For Papers: April 8 - 10, 2014 - Detroit, Michigan USAPriyal PatelNoch keine Bewertungen

- UntitledDokument1 SeiteUntitledPriyal PatelNoch keine Bewertungen

- HiDokument15 SeitenHiPriyal PatelNoch keine Bewertungen

- IcetmeDokument2 SeitenIcetmePriyal PatelNoch keine Bewertungen

- FSAE Tutorial v1.1Dokument17 SeitenFSAE Tutorial v1.1Abhinav GaikwadNoch keine Bewertungen

- Pits BurgDokument8 SeitenPits BurgPriyal PatelNoch keine Bewertungen

- HiDokument15 SeitenHiPriyal PatelNoch keine Bewertungen

- Evaluation SystemDokument2 SeitenEvaluation SystemVignat VoraNoch keine Bewertungen

- RTIDokument6 SeitenRTIPriyal PatelNoch keine Bewertungen

- File ListDokument9 SeitenFile ListPriyal PatelNoch keine Bewertungen

- UntitledDokument1 SeiteUntitledPriyal PatelNoch keine Bewertungen

- ME Assessment Module FinalDokument2 SeitenME Assessment Module FinalPriyal PatelNoch keine Bewertungen

- Application Form D2D GujaratDokument4 SeitenApplication Form D2D Gujaratbrijpatel909Noch keine Bewertungen

- TTMA-100 General Specifications: I. ScopeDokument8 SeitenTTMA-100 General Specifications: I. ScopeKamalNoch keine Bewertungen

- Long Range Transportation PlanDokument1 SeiteLong Range Transportation PlanFooyNoch keine Bewertungen

- NAM31 Users ManualDokument101 SeitenNAM31 Users ManualAdrien LescanneNoch keine Bewertungen

- De ProjectsDokument20 SeitenDe ProjectsRaviraj Dodiya0% (1)

- List of Files (AD2-CANALS) Final-Addl FilesDokument33 SeitenList of Files (AD2-CANALS) Final-Addl FilesnidhisasidharanNoch keine Bewertungen

- New Jersey - Driver ManualDokument212 SeitenNew Jersey - Driver ManualDMV_exam_GUIDE_comNoch keine Bewertungen

- Rfi Report - For IcDokument5 SeitenRfi Report - For IcGera Amith KumarNoch keine Bewertungen

- Evaluation of The Facilities and Operation and Maintenance Program of The Bulaong City Terminal. The Problem and Its SettingDokument44 SeitenEvaluation of The Facilities and Operation and Maintenance Program of The Bulaong City Terminal. The Problem and Its SettingJohn CartagenaNoch keine Bewertungen

- Current Affairs Pocket PDF - November 2017 by AffairsCloudDokument40 SeitenCurrent Affairs Pocket PDF - November 2017 by AffairsCloudPs PadhuNoch keine Bewertungen

- The SignalDokument15 SeitenThe SignalAlexander RuggieNoch keine Bewertungen

- 13 Foth ZFDokument29 Seiten13 Foth ZFDaniel Alex SánchezNoch keine Bewertungen

- Cool Vietnam. Mid-2017 PDFDokument125 SeitenCool Vietnam. Mid-2017 PDFDuc Pham Viet100% (1)

- Example Proposal TemplateDokument12 SeitenExample Proposal TemplateNur HazimahNoch keine Bewertungen

- REVISTA 8GbDokument44 SeitenREVISTA 8GbFabrizio Torelli100% (2)

- LTN 1-09 Signal Controlled RoundaboutsDokument54 SeitenLTN 1-09 Signal Controlled RoundaboutsMichaelNoch keine Bewertungen

- Schwalbe 2024Dokument108 SeitenSchwalbe 2024Tramvaj SlavkoNoch keine Bewertungen

- Asphalt - Hot Mix Design - MarshallDokument61 SeitenAsphalt - Hot Mix Design - MarshallMizanul Hoque100% (1)

- Production and Characterization of Polyhydroxyalkanoates (PHAs) From Burkholderia Cepacia ATCC 17759 Grown On Renewable Feed StocksDokument154 SeitenProduction and Characterization of Polyhydroxyalkanoates (PHAs) From Burkholderia Cepacia ATCC 17759 Grown On Renewable Feed StocksIftikhar AliNoch keine Bewertungen

- Data Systems Manual - EngDokument164 SeitenData Systems Manual - EngOluwaloseyi SekoniNoch keine Bewertungen

- City of Peterborough Draft Official Plan Schedule B Major TransportationDokument1 SeiteCity of Peterborough Draft Official Plan Schedule B Major TransportationPeterborough ExaminerNoch keine Bewertungen

- Jingtang Port Expansion EiaDokument82 SeitenJingtang Port Expansion EiaSyed Noman AhmedNoch keine Bewertungen

- Staar-Eoc-2016test-English I-FDokument50 SeitenStaar-Eoc-2016test-English I-Fapi-237648007100% (2)

- Example:: Traffic Flow Levels of ServiceDokument2 SeitenExample:: Traffic Flow Levels of ServiceBora CobanogluNoch keine Bewertungen

- 2012.10.16 Vienna Final Progr DefDokument160 Seiten2012.10.16 Vienna Final Progr DefITSssstestNoch keine Bewertungen

- Other Names: Automatic Number Plate Recognition (ANPR See AlsoDokument6 SeitenOther Names: Automatic Number Plate Recognition (ANPR See AlsoJasmeet SandhuNoch keine Bewertungen

- DK Children The Big Book of Things That GoDokument34 SeitenDK Children The Big Book of Things That GoTrinh Oanh100% (3)

- List of State Highways in AssamDokument3 SeitenList of State Highways in AssamImran HussainNoch keine Bewertungen

- 2021-03-16 - Traffic Study Report - Bhartiya City Additional Area - R1Dokument32 Seiten2021-03-16 - Traffic Study Report - Bhartiya City Additional Area - R1gulrez94Noch keine Bewertungen