Beruflich Dokumente

Kultur Dokumente

Trispiral XT39

Hochgeladen von

Cerón Niño SantiagoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Trispiral XT39

Hochgeladen von

Cerón Niño SantiagoCopyright:

Verfügbare Formate

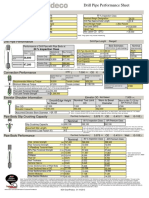

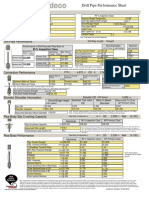

Heavy Weight Drill Pipe Performance Characteristics Workstrings International 2011 Version 1.

Pipe Size and Weight: Pipe Grade: Range: Tool Joint:

4.000" X 2.5625" Tri-Spiral Heavy Weight 55ksi Standard Heavy Weight 2 4.875" X 2.5625" XT39

Pipe Body New (Nominal) 4.000 0.719 2.563 25.188 407,600 27,600 22,080 17,301 16,218 New (Nominal) 7.409 12.566 5.157 5.225 10.450

OD (in) Wall Thickness (in) ID (in) Calculated Plain End Weight (lbs/ft) Tensile Strength (lbs) Torsional Strength (ft-lbs) 80% Torsional Strength (ft-lbs) Burst Pressure (psi) Collapse Pressure (psi)

25.188

Cross Sectional Area of Pipe Body (in2) 2 Cross Sectional Area of OD (in ) 2 Cross Sectional Area of ID (in ) 3 Section Modulus (in ) 3 Polar Section Modulus (in )

Tool Joint 120,000 psi Material Yield Strength XT39 OD (in) (i ) ID (in) Pin Tong Length (in) Box Tong Length (in) Torsional Strength (ft-lbs) Max Recommended Make-up Torque (ft-lbs) Min Recommended Make-up Torque (ft-lbs) Tensile Strength (lbs) Tool Joint/Drill Pipe Torsional Ratio (New Pipe) Balance OD (in) 4.875 4 875 2.563 24.0 24.0 37,000 22,200 12,400 729,700 1.34 4.992

Drill Pipe Assembly with Grant Prideco XT39 eXtreme Torque Connection

Adjusted Weight (lbs/ft) Approximate Length (ft) Fluid Displacement (gal/ft) Fluid Capacity (gal/ft) Fluid Capacity (bls/ft) Drift Size (in)

29.99 31.00 0.459 0.268 0.00638 2.3125

Note: Minimum make-up is based on shoulder separation caused by bending

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT. JCT 03-21-2011

Das könnte Ihnen auch gefallen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerVon EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerBewertung: 5 von 5 Sternen5/5 (1)

- D 2609 - 00 - Rdi2mdktukve PDFDokument5 SeitenD 2609 - 00 - Rdi2mdktukve PDFAndre CasteloNoch keine Bewertungen

- Drill Pipe Performance Data SheetDokument3 SeitenDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- IWCF Well Control Practice Test (ENFORM)Dokument12 SeitenIWCF Well Control Practice Test (ENFORM)Houssam Adjina88% (8)

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDokument14 SeitenAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Noch keine Bewertungen

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDokument3 Seiten4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNoch keine Bewertungen

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsDokument4 SeitenEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Drill CollarDokument1 SeiteDrill CollarGuillermo Rangel AvalosNoch keine Bewertungen

- Wild Well Control - Technical Date BookDokument57 SeitenWild Well Control - Technical Date Bookgabriel851007Noch keine Bewertungen

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNoch keine Bewertungen

- Xt39 Spec SheetDokument3 SeitenXt39 Spec SheetjdcomptonNoch keine Bewertungen

- G 26 Building Using ETABS 1673077361Dokument68 SeitenG 26 Building Using ETABS 1673077361md hussainNoch keine Bewertungen

- Drill pipe performance and operational limitsDokument3 SeitenDrill pipe performance and operational limitsGarcia C L AlbertoNoch keine Bewertungen

- Surface Stack Questions: IWCF Well Control Practice Test KeyDokument2 SeitenSurface Stack Questions: IWCF Well Control Practice Test KeyCerón Niño SantiagoNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance Sheetjinyuan74Noch keine Bewertungen

- Drill Pipe Performance Sheet 5.875 XT57 G105Dokument3 SeitenDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNoch keine Bewertungen

- Cumulative List of Notices to MarinersDokument2 SeitenCumulative List of Notices to MarinersResian Garalde Bisco100% (2)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresVon EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresBewertung: 5 von 5 Sternen5/5 (1)

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDokument3 Seiten5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNoch keine Bewertungen

- EPRI NP-5067 Good Bolting PracticesDokument84 SeitenEPRI NP-5067 Good Bolting Practicesstaplesjf100% (2)

- HeavyWeight 3.5 25.58lbs NC-38Dokument3 SeitenHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNoch keine Bewertungen

- Basic Principles of Local GovernmentDokument72 SeitenBasic Principles of Local GovernmentAnne Camille SongNoch keine Bewertungen

- Drill Pipe Performance and SpecificationsDokument3 SeitenDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNoch keine Bewertungen

- Concretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardDokument8 SeitenConcretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardVaibhav SengarNoch keine Bewertungen

- Anchor Design ManualDokument392 SeitenAnchor Design ManualveselinNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Best Practices Emerging For Erd WellsDokument4 SeitenBest Practices Emerging For Erd WellsgvgvgvgvrdrrdrNoch keine Bewertungen

- Best Practices Emerging For Erd WellsDokument4 SeitenBest Practices Emerging For Erd WellsgvgvgvgvrdrrdrNoch keine Bewertungen

- Handbook of Measurement in Science and Engineering, Volume 2Von EverandHandbook of Measurement in Science and Engineering, Volume 2Noch keine Bewertungen

- SSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANDokument2 SeitenSSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANIvica IndjinNoch keine Bewertungen

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDokument5 SeitenSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- AOAC 2012.11 Vitamin DDokument3 SeitenAOAC 2012.11 Vitamin DPankaj BudhlakotiNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Reflow Soldering: Apparatus and Heat Transfer ProcessesVon EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- 2.500 X 1.375 DC With MW20 SlickDokument1 Seite2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009Noch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetSaurav SenguptaNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokument2 Seiten5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- 5 7/8" VM-165 R2 Pipe SpecsDokument2 Seiten5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- 2.875 N80 6.51ppf EUEDokument1 Seite2.875 N80 6.51ppf EUEANSARAKUNoch keine Bewertungen

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDokument4 SeitenLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNoch keine Bewertungen

- Beam End Connection ReportDokument6 SeitenBeam End Connection ReportHibri HalimNoch keine Bewertungen

- Profis Anchor 2.6.1 Design SoftwareDokument5 SeitenProfis Anchor 2.6.1 Design SoftwareihpeterNoch keine Bewertungen

- Pipe Rack Hilti Bolt CalculationsDokument6 SeitenPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNoch keine Bewertungen

- Section 19 - Appendix C - FormsDokument52 SeitenSection 19 - Appendix C - Formsfivehours5Noch keine Bewertungen

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDokument14 SeitenITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengNoch keine Bewertungen

- IS8008 8reducing TeeDokument5 SeitenIS8008 8reducing TeeAshish TanejaNoch keine Bewertungen

- Steel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Dokument130 SeitenSteel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Giovanny100% (1)

- Section2 - Hydro TestersDokument8 SeitenSection2 - Hydro TestersMelele MuNoch keine Bewertungen

- PV Elite Vessel Analysis Program: Input DataDokument90 SeitenPV Elite Vessel Analysis Program: Input DatajahiranazriNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument8 SeitenDisclosure To Promote The Right To InformationCst WclNoch keine Bewertungen

- Technical Information ASSET DOC LOC 1543385Dokument21 SeitenTechnical Information ASSET DOC LOC 1543385Alfonso ChNoch keine Bewertungen

- Esr 2408Dokument41 SeitenEsr 2408rolandoriNoch keine Bewertungen

- Emergency Planning PDFDokument2 SeitenEmergency Planning PDFCerón Niño SantiagoNoch keine Bewertungen

- Env Assess and Studies (Soils) PDFDokument2 SeitenEnv Assess and Studies (Soils) PDFCerón Niño SantiagoNoch keine Bewertungen

- Reach Assistance PDFDokument2 SeitenReach Assistance PDFCerón Niño SantiagoNoch keine Bewertungen

- Hydrablast Howco H02323 PDFDokument2 SeitenHydrablast Howco H02323 PDFCerón Niño SantiagoNoch keine Bewertungen

- GRAVEL Packer Tool OperationDokument7 SeitenGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Rig Evaluation ReportDokument72 SeitenRig Evaluation ReportCerón Niño SantiagoNoch keine Bewertungen

- Rig Evaluation Cover SheetDokument29 SeitenRig Evaluation Cover SheetCerón Niño SantiagoNoch keine Bewertungen

- ALASKA Aquifer Aeo6a PDFDokument4 SeitenALASKA Aquifer Aeo6a PDFCerón Niño SantiagoNoch keine Bewertungen

- CaraCara6B - Service ReportDokument3 SeitenCaraCara6B - Service ReportCerón Niño SantiagoNoch keine Bewertungen

- 9JSA IFE Rig EvaluationDokument2 Seiten9JSA IFE Rig EvaluationCerón Niño SantiagoNoch keine Bewertungen

- Rig Evaluation Rules of Inspection: Item Action Safety Issue Assistance RequiredDokument3 SeitenRig Evaluation Rules of Inspection: Item Action Safety Issue Assistance RequiredCerón Niño SantiagoNoch keine Bewertungen

- IADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSDokument13 SeitenIADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSCerón Niño SantiagoNoch keine Bewertungen

- 00 - IWCF - Equipment B&W PDFDokument19 Seiten00 - IWCF - Equipment B&W PDFCerón Niño SantiagoNoch keine Bewertungen

- Telescopic JointDokument1 SeiteTelescopic JointCerón Niño SantiagoNoch keine Bewertungen

- How Well Control Impacts Seismic Inversion ResultsDokument9 SeitenHow Well Control Impacts Seismic Inversion ResultsCerón Niño SantiagoNoch keine Bewertungen

- PETREVEN Eng PDFDokument1 SeitePETREVEN Eng PDFCerón Niño SantiagoNoch keine Bewertungen

- Gavel Packer Technical GP Proposal Bengala 5 V1Dokument16 SeitenGavel Packer Technical GP Proposal Bengala 5 V1Cerón Niño SantiagoNoch keine Bewertungen

- Test - G8-3 EmfDokument4 SeitenTest - G8-3 EmfCerón Niño SantiagoNoch keine Bewertungen

- Search Results PACKOFFDokument10 SeitenSearch Results PACKOFFCerón Niño SantiagoNoch keine Bewertungen

- Telescopic JointDokument1 SeiteTelescopic JointCerón Niño SantiagoNoch keine Bewertungen

- Spot Heavy MudDokument1 SeiteSpot Heavy MudCerón Niño SantiagoNoch keine Bewertungen

- PETREVEN Eng PDFDokument1 SeitePETREVEN Eng PDFCerón Niño SantiagoNoch keine Bewertungen

- Drilling Rig ComponentsDokument2 SeitenDrilling Rig ComponentsCerón Niño SantiagoNoch keine Bewertungen

- 44 Sounds Aus EnglishDokument2 Seiten44 Sounds Aus EnglishAlfie Arabejo Masong LaperaNoch keine Bewertungen

- White Paper Without Track ChangesDokument7 SeitenWhite Paper Without Track Changesapi-609064761Noch keine Bewertungen

- Product CataloguepityDokument270 SeitenProduct CataloguepityRaghuRags100% (1)

- Template EbcrDokument7 SeitenTemplate EbcrNoraNoch keine Bewertungen

- District: Surkhet: PopulationDokument13 SeitenDistrict: Surkhet: PopulationkarunNoch keine Bewertungen

- Desiderata: by Max EhrmannDokument6 SeitenDesiderata: by Max EhrmannTanay AshwathNoch keine Bewertungen

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDokument36 SeitenCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNoch keine Bewertungen

- Science Section A UPSRDokument2 SeitenScience Section A UPSRvinno8556% (9)

- Kingspan Spectrum™: Premium Organic Coating SystemDokument4 SeitenKingspan Spectrum™: Premium Organic Coating SystemNikolaNoch keine Bewertungen

- ATEX Certified FiltersDokument4 SeitenATEX Certified FiltersMarco LoiaNoch keine Bewertungen

- Screenshot 2023-01-03 at 9.25.34 AM PDFDokument109 SeitenScreenshot 2023-01-03 at 9.25.34 AM PDFAzri ZakwanNoch keine Bewertungen

- Plow Moldboard or Disc PlowDokument7 SeitenPlow Moldboard or Disc PlowAdewaleNoch keine Bewertungen

- Civil ServiceDokument46 SeitenCivil ServiceLester Josh SalvidarNoch keine Bewertungen

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Dokument10 SeitenMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitNoch keine Bewertungen

- DerbyCityCouncil Wizquiz Presentation PDFDokument123 SeitenDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevNoch keine Bewertungen

- Technote Torsional VibrationDokument2 SeitenTechnote Torsional Vibrationrob mooijNoch keine Bewertungen

- 3 Variable Cramers Rule PDFDokument4 Seiten3 Variable Cramers Rule PDFElton DiocsonNoch keine Bewertungen

- The Relevance of Vivekananda S Thought IDokument16 SeitenThe Relevance of Vivekananda S Thought IJaiyansh VatsNoch keine Bewertungen

- Shanidham - In-Shanidham Pacify Lord ShaniDokument3 SeitenShanidham - In-Shanidham Pacify Lord ShanisubramanyaNoch keine Bewertungen

- Lectura Isaac NewtonDokument2 SeitenLectura Isaac NewtonCESAR MAURICIO RODRIGUEZNoch keine Bewertungen

- Jual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan ReviewDokument5 SeitenJual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan Reviewbramsalwa2676Noch keine Bewertungen

- Art-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationDokument4 SeitenArt-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationJohn Mark D. RoaNoch keine Bewertungen

- Company Profile 2Dokument7 SeitenCompany Profile 2R Saravana KumarNoch keine Bewertungen

- Porta by AmbarrukmoDokument4 SeitenPorta by AmbarrukmoRika AyuNoch keine Bewertungen

- Very Low Altitude Drag-Free Satellites: R D UpdatesDokument5 SeitenVery Low Altitude Drag-Free Satellites: R D Updatesraa2010Noch keine Bewertungen