Beruflich Dokumente

Kultur Dokumente

BD 5 Instructions

Hochgeladen von

kokiskoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BD 5 Instructions

Hochgeladen von

kokiskoCopyright:

Verfügbare Formate

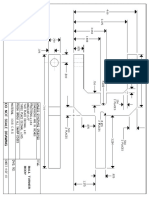

Instruction Manual

BD-5 specs: Wingspan= 30 short wing version = 36 long wing version Length= 26.5 Weight=20-22 oz. Wing area=146 sq/in short wing =175 sq/in long wing Wing loading= 20-22 oz/ft2 short wing = 16-18 oz/ft2 long wing

www.6mmFlyRC.com Get Ready To Fly

Wings

Glue one of the cut pieces onto a full sheet. Make four of these.

Mark each wing in while in the block so you can use the marks as guides later on. You will use these marks when you glue on the wing skins. Take the wing cores out of the blocks. Cut inch off the leading edge of each wing.

Make sure you have something to use for weight. Apply 15 minute epoxy generously on 2 wing skins, one for the top and one for the bottom. Make sure you make a top and a bottom skin. Place the bottom skin in the bottom of the block form the wing came in with the epoxy up, and with the leading edge skin flush with the forms edge. Put the foam core on the skin using the marks you made earlier as guides to line up the wing and form. Put the top skin, epoxy down, on the wing core. Put the top of the block form on using the marks you made earlier to line it up (see picture below). Put weight on top of the block form until the epoxy cures. The form will protect the wing and should support up to 30 lbs of weight. Be sure the weight is distributed evenly across the top of the form for the best results.

Cut one wing skin into four pieces. First, cut it in half and then cut each half diagonally.

Prepare to cut the trailing edge of the wing. Mark the trailing edge where the wing is 9/32 thick on both ends of the wing. Draw a line from end to end connecting the marks you just made. Cut this portion of the wing off and sand smooth. When making the opposite wing, use this first wing as your guide for the measurements because they must match up. Epoxy a 1/16 balsa strip to the trailing wing edge. (See below).

After the epoxy has cured, remove the wing from the block form and trim off excess skin from both ends of the wing. Trim off excess wing skin from the leading edge and sand to a smooth finish. Take care not to cut into the foam core!

Install x 3/8 balsa strip on the leading edge with epoxy making sure its centered. Secure with tape. Epoxy 1/2x1/4x3.5 balsa tip to the tip of the wing.

Inboard trailing edge: Cut a 2 inch piece of aileron off the stock provided. Make a mark on the wing 1 inch out from the inboard edge. Epoxy the 2 inch piece of aileron to the wing butting it up to the mark you just made to make a smooth airfoil. Trim off any excess. Sand down the entire wing half rounding the airfoil leading edge and the wing tip. Finally, sand with 220+ sand paper for a very smooth finish. Repeat steps to make the opposite wing. Be sure you make the opposite wing to match the first. This means you need to use the first wing as a guide as a measurement as using 9/32 on the second wing might not match up exactly. Wing dihedral

Trim the ailerons to fit the wing. Measure in 1/8 inch on the bottom leading edge of the aileron and trim off the shaded area as shown in picture above. Cover wings and aileron with monokote or favorite covering. Fuselage assembly

Identify the left and right hand fuselage sides. Each half has 2 dots that match up to the wing cutout template. Cut out the wing cutout template provided. Line up template dots with fuselage dots and trace around. Make sure the marks you traced are on the outside of both fuselage halves. See below.

Sand the inboard edge of one wing at an angle so you will have 1 inches lift at the tip of the wing for the 30 inch wings and 1 inches for the 36 inch wings (see drawing above). Epoxy the 2 halves together setting the correct dihedral for your wing length. Apply one inch fiberglass tape over the wings center section to help stiffen the wing.

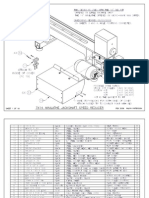

On either fuselage side, epoxy the bottom motor mount into place inch forward from the aft end of the fuselage and flush with the cutout.

Draw a line down from the aft canopy cut out.

Find F-1, F-2, F-3, motor mount bottom and top, and horizontal mount. Using F-3 as a guide, slightly bevel the forward side of the horizontal lower mount (HLM) until it butts up to F-3. Make a mark where the HLM ends on the aft fuselage. Draw a line along the bottom of the HLM. Using the marks you just made, epoxy the HLM into place with the HLM tilted slightly up

toward the top of the fuselage (see below). When you put both fuselage halves together, the HLM will level out. Do not install F-3 at this time.

Measure 4 inches aft from the forward fuselage and draw a line on the inside of both fuselage halves.

Epoxy F-1 and F-2 into place. Epoxy HLM to the opposite fuselage half, keeping it level. Epoxy the motor mount bottom to opposite fuselage half. Epoxy motor mount top into place. This will be a tight fit. Install it flush with the top of the cut out, skinny side aft. Epoxy F-3 into place. Dont glue the bottom inch sides or bottom as this will be cut out when the wing is installed.

Epoxy both fuselage sides to the fuselage bottom. Dont glue the fuselage sides together yet. Glue the fuselage sides to the aft bottom as shown below.

Epoxy the top aft fuselage into place, keeping it flush with F-3 at the front and flush with the aft portion of the fuselage top at the back. Sand the aft

top fuselage flush. From the scrap depron provided, add two layers to the aft top fuselage. See below.

From scrap depron, epoxy inch strip to the bottom inside forward fuselage between F-1 and F-2. Epoxy a 3/8 inch strip to the same location.

Using depron scrap, cut six pieces (three for each corner) to add to the forward cockpit. Cut 2 pieces of scrap for the center. Epoxy everything in place. Sand the fuselage into shape using these next six pictures as a guide.

Sand F-1 flush. Glue three pink nose cone pieces together and epoxy to the nose.

Your fuselage should now be sanded to the right shape.

Epoxy motor mount into the aft fuselage leaving at least 1 3/4 inches hanging out past the lower aft fuselage.

Get your canopy pieces together.

Do the same for the forward canopy mount. Draw an outline on both pieces to trim and fit to match the contours of the fuselage.

Place the aft canopy piece on the fuselage. Note the angle to bevel the lower edge of the piece. Bevel the lower edge of the aft canopy mount matching the fuselage cut out.

Place the canopy floor in fuselage cut out and outline the area to trim away. Epoxy three fuselage pieces together while these pieces are sitting in the fuselage cut out, and final sand to match the fuselage. Make sure you dont glue them to the fuselage. Trim the canopy to match the canopy floor. It may be necessary to add additional aft canopy pieces, from scrap, for a good windshield fit. Paint and mount the plastic canopy to the canopy frame. Note the canopy fit in the picture below (even though your plane isnt this far along yet.)

Cut out two holes in F-3 so you can epoxy the wing into place and run wires through later. Make sure the wing is centered in the fuselage and not crooked.

Cut out airfoil lines on the fuselage sides. Cut off the lower portion of F-3 so the wing will slide through. Using Dubro hinge tape (not included), tape each aileron to the wing. Install control horn on the top inner surface of each aileron.

Cut out an area big enough to fit your motor and the tail. A dremel helps out in this area. Trial fit motor to the motor mount. You will install the motor and wires after painting.

Trial fit the horizontal stab and check for good alignment. Mark where the horizontal stab meets up to the fuselage. Round the leading edges of the horizontal stab up to the marks. Epoxy the horizontal stab into place being sure to watch your alignment. Cut elevator stock provided to the correct length. Bevel the elevator the same way you did the ailerons. When finished, cover the elevator with monokote. Install the elevator with Dubro hinge tape in the same manner you did the ailerons.

Draw a center line down the horizontal stab as shown.

Center rudder on the turtle deck top and draw a line on either side. Cut out area to install rudder with a razor. A flat tipped screw driver works well to remove the cut out area. Epoxy the rudder into the fuselage being sure to watch your alignment. Paint your BD-5. We recommend using Krylon H2O from Wal-Mart. It is a water based latex paint that will not eat the foam. Be sure to test any other paint you use on a scrap piece of foam first.

With speed controller mounted in forward fuselage, run three motor wires to the aft fuselage to connect to the motor. Mount motor into position.

Cut a slot in the fuselage about midway along the top of the wing for a GWS naro standard servo or equivalent. Attach servo to control horn with the rod provided. Do the same to the other side. Cut a hole in the lower fuselage and lower aft fuselage for cooling air. Connect servo and speed control wires to receiver. Run antennae out to where it wont get caught in the propeller. Control throws and center of gravity Elevator control throws Low rate 3/8 inch up High rage 5/8 inch up Down travel as much as you can get. Cut out slot in aft fuselage below the horizontal stab for the servo elevator as shown. Attach a 12-18 inch servo extension to your GWS naro standard servo (or equivalent), and install into fuselage. Mount the elevator control horn straight back from elevator servo control horn. Attach control rod. Aileron control throws Low rate 3/8 inch up High rate inch up Low rate 5/16 inch down High rate 5/16 inch down Center of gravity Measure from the leading edge at the root 1 inch back. Hang your aircraft upside down when measuring center of gravity.

Power gear recommendations We recommend a battery of 1800-2100 mah three cell 11.1 volt lipo. This provides long flight times and plenty of power for this airplane. We recommend Himax brushless motors HA-2015 or HA-2025 in a gear box with a KV of 4200-5300 with an 8x6 prop. We recommend a 20-25 amp speed controller. We recommend GWS naro standard servos or Hitech HS-55 or HS-81 micro servos. Flight characteristics Fast. This is not a beginner aircraft. We recommend that you be an intermediate to expert flyer. Take off from the ground. Do not throw. We have never hand launched. Check for tip stalls on the first flight up high. This plane has little wing area and does not fly like a trainer. We have added washout to the wing tips to help prevent tip stalls. The short wing version will fly and land faster than the long wing version. Land with plenty of forward speed on your first landings and fly it to the ground until you get used to the flight characteristics. Enjoy, and fly safe!

Das könnte Ihnen auch gefallen

- Model Aeroplanes and Their Engines: A Practical Book for BeginnersVon EverandModel Aeroplanes and Their Engines: A Practical Book for BeginnersNoch keine Bewertungen

- F-107 Instructions FullDokument20 SeitenF-107 Instructions Fullmam73Noch keine Bewertungen

- RFFS-100 Micro Pitts SpecialDokument6 SeitenRFFS-100 Micro Pitts Specialmam73Noch keine Bewertungen

- F 15 ManualDokument17 SeitenF 15 Manualscimionetta0% (1)

- ERCO 415-A ErcoupeDokument8 SeitenERCO 415-A ErcoupeAviation/Space History LibraryNoch keine Bewertungen

- T-38 Park Jet Construction GuideDokument16 SeitenT-38 Park Jet Construction Guidemam73Noch keine Bewertungen

- Culver Cadet MonoplaneDokument5 SeitenCulver Cadet MonoplaneAviation/Space History LibraryNoch keine Bewertungen

- Vought V-143 FighterDokument9 SeitenVought V-143 FighterAviation/Space History LibraryNoch keine Bewertungen

- Gee Bee Super SportsterDokument8 SeitenGee Bee Super SportsterAviation/Space History LibraryNoch keine Bewertungen

- Douglas DB-7 BomberDokument8 SeitenDouglas DB-7 BomberAviation/Space History Library50% (2)

- Vought SBU-1 BomberDokument7 SeitenVought SBU-1 BomberAviation/Space History LibraryNoch keine Bewertungen

- F-14 Park Jet Construction GuideDokument23 SeitenF-14 Park Jet Construction Guidemam73100% (1)

- F-18 Park Jet Construction Guide Rev ADokument20 SeitenF-18 Park Jet Construction Guide Rev ASzymon WójcikNoch keine Bewertungen

- Taylorcraft L-2 GrasshopperDokument10 SeitenTaylorcraft L-2 GrasshopperAviation/Space History Library100% (1)

- MIG-31 Firefox Construciton ManualDokument9 SeitenMIG-31 Firefox Construciton ManualChrisNoch keine Bewertungen

- Bob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Dokument16 SeitenBob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Luiz Fernando MibachNoch keine Bewertungen

- XF A-4 Skyhawk: SpecificationsDokument65 SeitenXF A-4 Skyhawk: SpecificationsAyrton LopezNoch keine Bewertungen

- Gyro GliderDokument3 SeitenGyro GliderEmerson UR100% (1)

- SU-47 Parts 6mm Depron PDFDokument19 SeitenSU-47 Parts 6mm Depron PDFAlejandro LabléeNoch keine Bewertungen

- Paper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletDokument2 SeitenPaper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletFransiskus OrganisNoch keine Bewertungen

- Assembly InstructionsDokument27 SeitenAssembly InstructionsLorenzo Martinez ValenzuelaNoch keine Bewertungen

- Republic RC-3 SeabeeDokument4 SeitenRepublic RC-3 SeabeeAviation/Space History Library100% (2)

- Build Log Medicine Man - EnglishDokument13 SeitenBuild Log Medicine Man - Englishpatatduif100% (1)

- Assembly Instructions For V-2 Rocket: HistoryDokument4 SeitenAssembly Instructions For V-2 Rocket: HistoryEmerson URNoch keine Bewertungen

- HG Barnaby PDFDokument2 SeitenHG Barnaby PDFJeffNoch keine Bewertungen

- FT Mustang v1.1 Full-SizeDokument4 SeitenFT Mustang v1.1 Full-SizeAlejandro Lablée50% (2)

- Boeing P-12 BiplaneDokument9 SeitenBoeing P-12 BiplaneAviation/Space History Library100% (1)

- The Duck - A Free-Flight Model AirplaneDokument6 SeitenThe Duck - A Free-Flight Model AirplaneBob Kowalski100% (1)

- MRC P 51 MustangDokument12 SeitenMRC P 51 Mustangmiguelangel2015Noch keine Bewertungen

- Curtiss R-6 RacerDokument9 SeitenCurtiss R-6 RacerAviation/Space History LibraryNoch keine Bewertungen

- Bob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)Dokument15 SeitenBob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)erik gomezNoch keine Bewertungen

- Total Dash8Dokument14 SeitenTotal Dash8Luiz Fernando MibachNoch keine Bewertungen

- Bob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Dokument9 SeitenBob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Luiz Fernando MibachNoch keine Bewertungen

- T-38 Park Jet Plans (Parts Templates Tiled)Dokument15 SeitenT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewNoch keine Bewertungen

- Su-37 Park Jet Plans (Assembly Drawing Tiled)Dokument2 SeitenSu-37 Park Jet Plans (Assembly Drawing Tiled)coloNoch keine Bewertungen

- JMSDF AH-64 Apache Longbow by Papermodel - JPDokument2 SeitenJMSDF AH-64 Apache Longbow by Papermodel - JPPaperShock100% (1)

- Polaris Parts Templates (Tiled)Dokument20 SeitenPolaris Parts Templates (Tiled)Leandro AlvarengaNoch keine Bewertungen

- Fokker d7 ElectricDokument2 SeitenFokker d7 ElectricEmerson URNoch keine Bewertungen

- T-38 Park Jet Plans (Assembly Drawing)Dokument2 SeitenT-38 Park Jet Plans (Assembly Drawing)souheil_souNoch keine Bewertungen

- BSG ColonialOneDokument26 SeitenBSG ColonialOnePablo Espadero100% (1)

- Mistral HullDokument5 SeitenMistral HullmikeNoch keine Bewertungen

- Aerobatic Speed 400 Electric PlaneDokument14 SeitenAerobatic Speed 400 Electric PlaneScott Burel100% (1)

- T-38 Park Jet Plans (Parts Templates Tiled) BETA2Dokument16 SeitenT-38 Park Jet Plans (Parts Templates Tiled) BETA2Emerson URNoch keine Bewertungen

- Cessna 182 SkaylineDokument56 SeitenCessna 182 SkaylineJairo Ramos100% (1)

- Max JonDokument2 SeitenMax Jontwinscrewcanoe100% (1)

- ARES Paper ModelDokument1 SeiteARES Paper ModelHany ElGezawyNoch keine Bewertungen

- 16 Foot Apache Outboard - PlansDokument8 Seiten16 Foot Apache Outboard - PlansRolando DaclanNoch keine Bewertungen

- Cis2mr3 PDFDokument13 SeitenCis2mr3 PDFDauntiNoch keine Bewertungen

- AMEDEO Glider Instructions&Template-CardboardDokument5 SeitenAMEDEO Glider Instructions&Template-CardboardNoldy S L LohoNoch keine Bewertungen

- How To Build The Nose SectionDokument2 SeitenHow To Build The Nose SectionLorenzo MartinezNoch keine Bewertungen

- TOTAL TrackerDokument11 SeitenTOTAL TrackerLuiz Fernando MibachNoch keine Bewertungen

- FT Mini Corsair v1.0 AIODokument16 SeitenFT Mini Corsair v1.0 AIOariel marinNoch keine Bewertungen

- AP T45 Goshawk FullDokument8 SeitenAP T45 Goshawk FullYusf IbrahemNoch keine Bewertungen

- Spitfire MKI 1500 InstructionsDokument13 SeitenSpitfire MKI 1500 InstructionsSteven D100% (1)

- Biplane-R e A4Dokument4 SeitenBiplane-R e A4Sabri DuceNoch keine Bewertungen

- 12MB December 1980Dokument107 Seiten12MB December 1980Walter GutierrezNoch keine Bewertungen

- Aviation - Theorico-Practical text-book for studentsVon EverandAviation - Theorico-Practical text-book for studentsNoch keine Bewertungen

- Build Jet Wings with Sweep MechanismDokument23 SeitenBuild Jet Wings with Sweep MechanismJohn MondoNoch keine Bewertungen

- Ornithopter 2 PDFDokument1 SeiteOrnithopter 2 PDFMarco Antônio Gomes ApolinarioNoch keine Bewertungen

- Ball Turner PrintsDokument10 SeitenBall Turner PrintskokiskoNoch keine Bewertungen

- Evading Thermal Imaging and Radar Detection-1Dokument8 SeitenEvading Thermal Imaging and Radar Detection-1kokiskoNoch keine Bewertungen

- A Method of Dividing The Circumference of A CircleDokument3 SeitenA Method of Dividing The Circumference of A CirclekokiskoNoch keine Bewertungen

- Ball Turner Prints PDFDokument10 SeitenBall Turner Prints PDFkokiskoNoch keine Bewertungen

- GAA Bortone June02Dokument2 SeitenGAA Bortone June02kokiskoNoch keine Bewertungen

- UFODokument2 SeitenUFOkokiskoNoch keine Bewertungen

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDokument32 SeitenQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoNoch keine Bewertungen

- SMD Electrolysis PDFDokument1 SeiteSMD Electrolysis PDFkokiskoNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Assessing Potential Propulsion Breakthroughs: Marc G. MillisDokument21 SeitenAssessing Potential Propulsion Breakthroughs: Marc G. MillisnenucarqNoch keine Bewertungen

- Anti-Gravity PropulsionDokument16 SeitenAnti-Gravity PropulsionTony FreelandNoch keine Bewertungen

- RB 7x12 Minilathe BedwaysDokument2 SeitenRB 7x12 Minilathe BedwayskokiskoNoch keine Bewertungen

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDokument32 SeitenQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoNoch keine Bewertungen

- Anti-Gravity PropulsionDokument16 SeitenAnti-Gravity PropulsionTony FreelandNoch keine Bewertungen

- Mysteries of The Unknown - The UFO PhenomenonDokument162 SeitenMysteries of The Unknown - The UFO Phenomenonanaximandre06100% (3)

- 1769 Compound Rest AssyDokument1 Seite1769 Compound Rest AssykokiskoNoch keine Bewertungen

- Ralph Patterson Tailstock Camlock 2Dokument13 SeitenRalph Patterson Tailstock Camlock 2supremesportsNoch keine Bewertungen

- WO9010337 Magnetic MotorDokument23 SeitenWO9010337 Magnetic MotorAndras KondratNoch keine Bewertungen

- Morse Taper Dimensions and Drill Chuck ArborsDokument4 SeitenMorse Taper Dimensions and Drill Chuck ArborskokiskoNoch keine Bewertungen

- Cross slide nut modification for Grizzly 7x12/24 latheDokument3 SeitenCross slide nut modification for Grizzly 7x12/24 lathekokiskoNoch keine Bewertungen

- Ralph Patterson Speed Reducer 2Dokument27 SeitenRalph Patterson Speed Reducer 2kokiskoNoch keine Bewertungen

- Spindle, 7x10, 12 Mini LatheDokument1 SeiteSpindle, 7x10, 12 Mini LatheramaaramaaNoch keine Bewertungen

- Drive TroubleshootingDokument9 SeitenDrive TroubleshootingkokiskoNoch keine Bewertungen

- Change Gears Charts For Metric Threading On The 7x MiniDokument2 SeitenChange Gears Charts For Metric Threading On The 7x MinikokiskoNoch keine Bewertungen

- r8 5c Collet DimensionsDokument2 Seitenr8 5c Collet DimensionskokiskoNoch keine Bewertungen

- Rollies Dads MethodDokument4 SeitenRollies Dads Methodctin12Noch keine Bewertungen

- Metal Drilling Speed ChartDokument3 SeitenMetal Drilling Speed ChartkokiskoNoch keine Bewertungen

- Ball Turning Toolpost - Complete PDFDokument5 SeitenBall Turning Toolpost - Complete PDFRamanujam O SNoch keine Bewertungen

- How To Make Economical BateryDokument85 SeitenHow To Make Economical BaterykokiskoNoch keine Bewertungen

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Dokument9 SeitenPerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoNoch keine Bewertungen

- Sortie 128 (Basic IF) G1000Dokument17 SeitenSortie 128 (Basic IF) G1000Ethan PoonNoch keine Bewertungen

- Difference between Airbus and Boeing auto thrust systemsDokument2 SeitenDifference between Airbus and Boeing auto thrust systemsŞevval YalınNoch keine Bewertungen

- Aircraft Design Project 1Dokument74 SeitenAircraft Design Project 1sangeetha_baskaran96100% (1)

- Aircraft Structure ComponentsDokument48 SeitenAircraft Structure ComponentsMaheshNoch keine Bewertungen

- Nineteenth Semiannual Report To Congress 1 January - 30 June 1968Dokument257 SeitenNineteenth Semiannual Report To Congress 1 January - 30 June 1968Bob Andrepont100% (1)

- Gas Dynamics AssignmentDokument2 SeitenGas Dynamics AssignmentRaphael SmithNoch keine Bewertungen

- Shoe Box Glider ProjectDokument7 SeitenShoe Box Glider Projectapi-305237348Noch keine Bewertungen

- Boeing 747-8 vs Airbus A380: Comparing the World's Largest Passenger JetsDokument6 SeitenBoeing 747-8 vs Airbus A380: Comparing the World's Largest Passenger JetsRaj J DasNoch keine Bewertungen

- Higuey, Dom Rep Mdpc/Puj: .Eff.23.MayDokument5 SeitenHiguey, Dom Rep Mdpc/Puj: .Eff.23.MayVanessa Yumayusa0% (1)

- Flow Past A Rotating CylinderDokument32 SeitenFlow Past A Rotating CylinderSanjeet KumarNoch keine Bewertungen

- Khmer Pilot Training Syllabus Instrument RatingDokument94 SeitenKhmer Pilot Training Syllabus Instrument RatingChan HyNoch keine Bewertungen

- The Antonov An124 RuslanDokument2 SeitenThe Antonov An124 RuslanockeNoch keine Bewertungen

- Propeller momentum theory for thrust and powerDokument4 SeitenPropeller momentum theory for thrust and powerXTRA310% (1)

- Henderson 2006Dokument229 SeitenHenderson 2006akash shridhar143Noch keine Bewertungen

- Final LTA ReportDokument90 SeitenFinal LTA ReportangryTXNoch keine Bewertungen

- CAP 694 - Flight Planning GuideDokument120 SeitenCAP 694 - Flight Planning GuideSanderE100% (1)

- Cessna Citation Excel Light Jet Flexibility with Midsize Cabin ComfortDokument4 SeitenCessna Citation Excel Light Jet Flexibility with Midsize Cabin ComfortJuanOñateNoch keine Bewertungen

- Rear Fuselage StructureDokument17 SeitenRear Fuselage Structureaerogem618Noch keine Bewertungen

- 01 Takeoff Data 747 400 V10Dokument26 Seiten01 Takeoff Data 747 400 V10jeffmfNoch keine Bewertungen

- Flying Paper f15 PDFDokument4 SeitenFlying Paper f15 PDFAli khanNoch keine Bewertungen

- SOPs All E190Dokument19 SeitenSOPs All E190Carlos Perez FerrerNoch keine Bewertungen

- Diamond DA40 - Flight ManualDokument300 SeitenDiamond DA40 - Flight ManualAlexandru TeodorNoch keine Bewertungen

- Ohio's Aviation PioneersDokument13 SeitenOhio's Aviation PioneersAviation/Space History Library100% (1)

- Abnormal NotesDokument90 SeitenAbnormal NotesHaseeb Abu Alwan100% (2)

- ATR LM ClassDokument30 SeitenATR LM ClassKezia Sormin100% (1)

- YPAD (Adelaide Intl) YPAD (Adelaide Intl) : General Info Notebook InfoDokument22 SeitenYPAD (Adelaide Intl) YPAD (Adelaide Intl) : General Info Notebook InfoA340_600100% (1)

- Russian Space Program (Factsheet Via ModernRussia - Com)Dokument5 SeitenRussian Space Program (Factsheet Via ModernRussia - Com)thinkRUSSIANoch keine Bewertungen

- Topic 3Dokument181 SeitenTopic 3C KNoch keine Bewertungen

- OMAADokument65 SeitenOMAArezarachmatNoch keine Bewertungen

- Proyecto Libelula2020Dokument79 SeitenProyecto Libelula2020Herson Eufemio Guerra VillacortaNoch keine Bewertungen