Beruflich Dokumente

Kultur Dokumente

Tiles BS 5385

Hochgeladen von

KalinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tiles BS 5385

Hochgeladen von

KalinCopyright:

Verfügbare Formate

installation

6.1

Installation Information in this section is based on the recommendations given in the following Codes of Practice:

BS 5385-1: Code of Practice for the design and installation of internal ceramic and natural stone wall tiling and mosaics in normal conditions. BS 5385-2: Code of Practice for the design and installation of external ceramic wall tiling and mosaics (including terracotta and faience tiles). BS 5385-3: Code of Practice for the design and installation of ceramic floor tiles and mosaics. BS 5385-4: Code of Practice for tiling and mosaics in specific conditions.

BS 5385-5: Code of Practice for the design and installation of terrazzo tile and slab, natural stone and composition block floorings. BS EN 13888: Grouts for tiles. Definitions and specifications. In addition, the general principles of BS 8000: Part 11, Code of Practice for wall and floor tiling should be followed.

General

Handling and storage Ston-Ker tile ranges are rectified tiles. They therefore require careful handling and storage on site, to avoid nipped edges, chipping etc. Tools Choosing the correct tools to carry out proper installation of the tiles is essential a notched trowel, a rubber mallet for tapping pieces into place and a rubber trowel for grouting. The surface to be tiled must be completely free of dust, loose areas, significant cracks or any other substance that could detrimentally affect proper tile adhesion. If falls are required in the finish these should be incorporated in the substrate and not in the bedding system. Substrate drying times Before beginning tiling, it is important to ensure that the background or base has been allowed to cure properly. This effectively means drying out by exposure to air for a minimum period (a summarised list The substrate (wall or floor) to be tiled must be perfectly level, with no defects in planarity. BS 5385 recommends that local variations in level for a nominally flat floor should be such that, when checked with a 2 m straightedge, any gap under the straightedge between points of contact does not exceed 3 mm. Porcelanosa recommends that damp areas be waterproofed beforehand.

Substrate Concrete walls Brick/blockwork walls Rendered walls Rapid drying rendered walls Gypsum plaster walls Concrete base floors Screeded (non-modified) floors Minimum curing period 6 weeks 6 weeks 2 weeks 4 weeks 4 weeks 6 weeks 3 weeks

Substrates

is given below).

May 05 www.porcelanosa.co.uk technical and samples hotline t: 08702 240245

6.1

installation

Floors

General preparation Before commencing any work ensure that the background/base is: Sufficiently flat Suitable for the intended service conditions Sufficiently strong and rigid to support the tile finish Free from any contamination Clean Dry Cement: sand screeds For new screeds: Allow a minimum 3 weeks drying time. For exiting screeds: Cut out all loose or hollow portions and make good with a 1:3 cement: sand mortar applied over a slurry bonding coat* Remove any unsound adhesive residues without damaging the base.

* Slurry bonding coat:2:1 Portland cement: Butech universal agent by weight.

Wood overlaid tongue and groove floorboards Existing floorboards must be dry, securely screw fixed and acceptably level. Prior to fixing, seal the reverse side and edges of the plywood (WBP or marine grade at minimum 15mm thick) with Butech universal bonding agent. Lay sheets with cross joints staggered at a 0.5-1mm gap between boards. Screw down sheets at 300mm centres ensuring screw heads flush with surface.Walls Tongue & Groove floorboards The boards must be dry, securely fixed and rigid without protruding fixings. Boards must be screwed down to the supporting joists at 300mm centres. Seal board surface with two coats of Butech UNIVERSAL BONDING AGENT. Allow each coat to dry. Tiling onto heated screeds Allow a minimum 3 weeks drying time for Portland cement. The screed should be heated at a maximum 50C per day to 250C and maintained for 3 days before cooling down to room temperature. The heating system should be turned off 24 hours before tiling, or turned down to below 150C in cold weather. The floor can be grouted 8 days after tiling and after a further 6 days can be heated up to the operating temperature at a maximum 50C per day. Tiling to under tile heating system onto cement: sand screeds The base must be sufficiently strong and rigid to support the tile finish and free from contamination. Allow a minimum 6 weeks drying time for new concrete and 3 weeks for new cement:sand screeds. Prime highly absorbent cement: sand screeds with 2 coats of Butech

Asphalt bases The mastic asphalt should be sound, with a natural float finish and laid on a firm rigid base. The asphalt should be of flooring grade. The surface should be sufficiently regular to suit bedding depths of adhesive, Remove any surface contaminants. Ceramic/Quarry tile/Terrazzo/Natural stone bases Existing finish should be securely bonded to their base and must be in sound, clean condition. Any loose tiles should be removed and made good with a 1:3 cement: sand mortar applied over a slurry bonding coat*.

* Slurry bonding coat 2:1 Portland cement: butech UNIVERSAL BONDING AGENT by weight

Vinyl tile/sheet bases Existing vinyl tiles/sheets should be securely bonded to their base and must be in sound, clean condition. Any loose tiles should be removed and made good with a levelling compound.

universal bonding diluted with1:1 water. Level floors where necessary.

Concrete bases Allow a minimum 6 weeks drying time

www.porcelanosa.co.uk technical and samples hotline t: 08702 240245 May 05

installation

6.1

Cement:sand screeds

Butech 2-12 colorstuk Butech tixocem

Wood overlaid tongue and groove floorboards

Butech 2-12 colorstuk

Butech tile to wood Cement:sand screed

Concrete base Slurry bonding coat

Asphalt bases

Butech 2-12 colorstuk

Tongue and groove floorboards

Butech 2-12 colorstuk Butech universal bonding agent

Butech Super-one

Butech tile to wood

Ceramic/quarry tile/terrazzo/natural stone bases

Butech 2-12 colorstuk

Tiling onto heated screeds

Butech 2-12 colorstuk

Butech Super-one

Butech one-flex

Cement:sand screed

Vinyl tile/sheet bases

Butech 2-12 colorstuk

Tiling to under tile heating system onto cement: sand screeds

Butech 2-12 colorstuk Butech one-flex

Butech Super-one

Matting Floor leveller

Cement:sand screed Butech universal Concrete base

Concrete bases

Butech 2-12 colorstuk

Butech tixocem

Concrete base

May 05 www.porcelanosa.co.uk technical and samples hotline t: 08702 240245

6.1

installation

Walls

General preparation Before commencing any work ensure that the background/base is: Sufficiently flat Suitable for the intended service conditions Sufficiently strong and rigid to support the tile finish Free from any contamination Clean Dry Gypsum plaster Allow a minimum 4 week drying time for new plaster.

Butech 0-4 colorstuk

Painted walls Ensure that the paint is in a sound condition. Check by applying some carpet tape to the painted surface. Leave for 10 minutes before tearing off. If paint is removed with the tape, remove all areas of unsound paint by mechanical means. Do not use paint strippers.

Gypsum plaster

Gypsum plasterboard

The finish coat must be free from contaminants. Any defective areas should be made good. Plaster with a polished surface should be brushed with a stiff bristle brush and primed with a mixture of 1:4 Butech universal bonding agent: water. The weight of the tiling should not exceed 20kg/m2. Gypsum plasterboard Boards must be dry, securely fixed and rigid with no protruding fixings. The weight of tiling should not exceed 32kg/m2. Cement: sand rendering Allow a minimum 2 week drying time for new rendering (3 weeks for swimming pools) Glazed tiles/bricks Existing tiles/bricks should be securely bonded to their bed and must be in sound, clean condition. Any loose tiles should be removed and made good with 1:3 cement: sand mortar, applied over a slurry bonding coat (2:1 cement: Butech universal bonding agent) Plywood Sheets must be dry, securely fixed and rigid-screwed to a seasoned timber framework at 300mm centres.

Butech 0-4 colorstuk Butech BT-1000 Butech tixocem Rigid framework Plaster

Cement:sand rendering

Butech 0-4 colorstuk Butech one-flex Cement:sand rendering Slurry bonding coat

Glazed tiles/bricks

Butech 0-4 colorstuk Butech BT-3000

Plywood

Butech 0-4 colorstuk

Painted walls

Use moisture resistant or exterior grade boards.

Butech BT-3000

Butech 0-4 colorstuk

Seal the reverse side, edges and the surfaces to be tiled, with Butech universal bonding agent

Rigid framework

Butech BT-1000

Plywood

www.porcelanosa.co.uk technical and samples hotline t: 08702 240245 May 05

installation

6.1

Backgrounds and bases A cement-sand render or screed substrate is generally recommended for backgrounds and bases in which deviations from a true flat surface are to be expected and which may be too much to accommodate within the thickness of the bedding material. The more accurate surfaces that can be provided by such substrates permit the use of adhesive bedding, which has many advantages over traditional mortar bedding. Mosaics generally require flatness but not a high degree of dimensional accuracy; tiling requires both. The visual success of tiling depends on constant tile and joint sizes. . Although internal wall tiling can be successfully applied to plaster or plasterboard surfaces, cement: sand rendering provides a stronger background and is preferred. For advice on mix proportions and thickness of rendering see BS 5385-1 clause 3.3, BS 5385-2 clause 19 and NBS Section M20. For screeds see BS 5385-3 Appendix C, BS 8204-1 and NBS Sections M10 and M13.

Proprietary intermediate substrates tilebacker boards and matting The use of intermediate substrates between backgrounds/bases and tiles is widespread in continental Europe and North America. In recent years products have been introduced in the UK, some of which have British Board of Agrement (BBA) certification. Two basic types of product are available, tilebacker boards and mattings. Tilebacker boards have rigid cores (usually extruded polystyrene, or less frequently, cementitious material) and are faced with mortar/adhesive tolerant material reinforced with glass fibre mesh. All types of board provide a durable, flat and stable backing for tiling and are suitable for fixing boards to walls and floors. Matting made from polyethylene with an underside bonding fleece provides a layer that accommodates background/base movement without affecting tiles and bedding. Installed with sealed joints it can provide a waterproof layer for applications not exposed to constant water pressure. Matting can prepare new concrete or screed bases for tiling once they can accept foot traffic. However, adhesives suitable for bonding matting to green concrete and screed are very limited, with most negating the time saving aspects of the product by requiring curing and drying of the base in accordance with BS 8204-1. Once installed air channels on the underside of the matting allow the base to continue drying. Matting can also be used on timber boarded suspended floors. It is essential to consult the matting and adhesive manufacturers to determine the correct base preparation, adhesive and jointing specification.

May 05 www.porcelanosa.co.uk technical and samples hotline t: 08702 240245

6.1

installation

Butech Pro-dilata movement joints

www.porcelanosa.co.uk technical and samples hotline t: 08702 240245 May 05

installation

6.1

Movement joints

BS 5385-3 clauses 19 and 23.6 give advice on the location and design of movement joints in floors. In brief, joints will normally be positioned in the following locations: Over structural movement joints. Around the perimeter of floors and where floor tiling abuts fixed machinery and structural fixtures such as columns, steps etc. Where tiling abuts other materials. Where tiling is continuous across junctions of different base materials. At 30 m intervals in large floors with stress relieving joints at 10 m intervals or 6 m intervals externally. Over supporting walls and beams. Over structural movement joints Where the base substrate incorporates its own movement joints, structural joints should also be included between tiles, that coincide with the structural joints in the substrate. These joints should extend through the tile thickness, bed and screed (if there is one) through to the substrate. Minimum width should be at least that of the structural joints of the substrate (and at least 6 mm). Structural joints are usually finished by filling them with materials that have long-lasting elasticity (plastic or metal corner beads or profile sections, mastics, exterior fish plates, etc.). Perimeter joints and abutments to walls Perimeter joints should be incorporated at the edges of the horizontal surface to be tiled where it meets with walls, columns, fixed machinery, steps and curbs that may be left untiled. This is to prevent floor tiles and adhesives from coming into contact with these other elements, reducing the possibility of stress from building up. Perimeter joints are also necessary in areas where the ceramic covering is applied to two different adjoining substrates, changes in plane and where tiling abuts other materials. Lack of, or inadequate provision for, perimeter joints is one of the most frequent causes of failure of tiled floor surfaces. Perimeter joints should be continuous and their width should not be less than 6 mm. They can be rendered with a compressible material such as cellular polystyrene or grouted with silicone. They can be hidden by skirting. These joints should reach down to the substrate, except if this is covered with a stable, well-hardened material, such as plaster or gypsum. When tile installation is carried out using spacers (crosspieces) between tiles, enough time should be allowed for the adhesive to set before tiles can be walked on in order to be able to remove these spacers. The next step after this is to grout all joints. 1. They can absorb any deformation produced by the substrate. 2. They compensate for slight dimensional deviations in tile manufacture. Note: Joints less than 1.5 mm are not recommended. Intermediate expansion (stress relieving) joints Large areas to be tiled should be subdivided during tile installation into smaller areas delimited by intermediate expansion joints. The maximum recommended surface area to be tiled without intermediate expansion joints is 50 m2 to 70 m2 in interior applications (half this surface area for exterior applications), or else a maximum interval of 30 metres. The number of joints should be greater on those surfaces expected to experience significant temperature variations or vibrations. On suspended floors additional joints should be provided over supporting walls and beams. For floors subject to heavy foot traffic or hard-wheeled traffic, the position of joints should try to avoid where this traffic crosses, if possible; if this is not possible, profile sections with edges protected by metal should be specified. These partitions or joints should cut through the ceramic covering, the adhesive and the mortar bedding, and their width should be a minimum of 5 mm.

Installation joints

This is the gap between all contiguous tiles, either for functional or aesthetic reasons. They are necessary for the following reasons:

Selection of bedding, adhesive and grouting materials

Choice of bedding system will depend on the following factors: 1. Location e.g. interior or exterior; wall or floor. 2. The proposed use of the finished area, e.g. wet or dry; domestic, commercial or industrial. 3. The type of background or base e.g. rendered, plasterboarded, screeded. 4. The type of tile selected, e.g. high or low water absorption. Porcelanosa recommends: Butech

May 05 www.porcelanosa.co.uk technical and samples hotline t: 08702 240245

6.1

installation

Tiling walls setting out

As a general rule, tiling should be set out from the centre of the wall. This means there are two options: 1. either the centre of the tile in the centre of the wall, or 2. the centre joint between the two tiles positioned either side of the centre line.

Starting tiling

To spread the adhesive, hold your trowel at a 45 angle. Apply the adhesive to form straight ribs. Apply an area of adhesive to cover several tiles but no more than you will be able to tile within 20 minutes. Press the tiles firmly and evenly into the adhesive using a twisting/ sliding action ensuring that the adhesive forms a strong bond to the back of the tile.

A measuring gauge will help you plan the position of your tiles. To make the measuring gauge, take a length of timber and mark the width of your tiles including the spacers along it. Check each option to see which gives the most advantageous cuts to the ends at each side of the wall, the window and the border design. Fixing battens will help you to keep the tiling straight. Find the lowest point you are tiling to, e.g. a skirting board, position the nearest full tile at this point, mark above the tile and, using a spirit level, draw a level line. Nail a batten to the wall below the line to work to. Ensure that the batten is level because your first row of tiles will rest on it. Draw your centre line as a start point with the help of a spirit level to check the vertical line is straight. Either fix a vertical batten as a guide or use your pencil line to tile up to. Start your tiling where the two vertical and horizontal lines meet, in the centre point chosen on your wall.

Place a spacer between each tile, this allows an even gap for the grout to be applied later. Work sideways and upwards to complete fixing all the whole tiles. Whilst tiling, check with a spirit level that the tile surface is flat. Clean off any surplus adhesive which has formed on the surface of the tile with a damp sponge and remove any surplus from the grout joints. If the adhesive forms a skin before you have managed to place a tile, take off the adhesive and replace with new. Remove any guide battens and spacers carefully after 12 hours. Use a tile trim to give a neat finish at tile edges and corners. Tile trim is available in various thicknesses and is bedded into the tile adhesive.

Cutting tiles

You are now ready to tile the areas requiring cut tiles. To cut a tile, mark the front of the tile and score the glazed side of the tile to break the glaze, using a tile scriber and a rule or use a thin rail cutter. Tile nippers, and saws can be used to cut corners or curves out of tiles.

www.porcelanosa.co.uk technical and samples hotline t: 08702 240245 May 05

installation

6.1

Floor tiling

BS 5385-3 deals with the laying of ceramic tiles and mosaics, bedded on concrete, cement: sand screeds, timber, asphalt and existing floor finishes. Table 3 of the standard gives a summary of recommended bedding techniques for different base and traffic conditions. Please check with Porcelanosa before final selection of bedding material. Also refer to BS 5385-4 for floor tiling in specific conditions (e.g. wet, sterile, chemical attack). Installation The installation of ceramic tiles using the traditional thick-bed method with mortars remains popular throughout Europe, mainly down to traditional customs and habits. However, this system does not always offer the necessary quality guarantees. The recent use of special adhesives has stimulated a gradual shift to the thin-bed installation method, which offers clear advantages over the thick-bed method, particularly where adherence and durability are concerned. Adherence the strength of the bond between the ceramic piece and the substrate plays an extremely important role in the quality of tiled walls and floors. Proper adherence should ensure that pieces are firmly attached to the substrate. Durability entails the maintenance of proper adherence over time. The thin-bed installation method must be used, with a flexible adhesive. The use of cement glue will prevent the many problems that may arise using thick-bed installation with traditional mortar. When porcelain tiles are being installed, bonding materials specifically designed for use with this material should be used. The use of proper wedges and spacers will ensure proper piece alignment.

Grouting

Before grouting, ensure that the joints (between tile and tile) are empty and free of bonding materials and traces of dirt and grime. Joints should be grouted once tiles are fully bonded to the substrate, after the time necessary for this to happen has elapsed (before grouting, the adhesive used for installing tiles should already be dry, to avoid efflorescence forming, which will have a negative effect on the appearance of joints).

The grouting material should be applied with a rubber trowel. Grouting materials may be coloured using the proper pigments, so as to achieve a uniformity in colour of the tiled surface. Removing excess grouting material should be performed using a sponge dampened in water. This operation should be done in timely fashion, since if the grouting material is left on the glazed surface of tiles for too long, this could cause removal isses. The use of cleaning agents that contain hydrofluoric acid (HF) should be avoided. It is absolutely necessary that finished ceramic tile installations be protected with the proper means so as to prevent possible damages until the building project is complete, given the high likelihood that abrasive materials will be present and tools will constantly be moved back and forth, and the subsequent risk that this implies.

Surface treatments

BS 5385 recommends in general that surface treatment should be avoided. BS 5385 recognises that proprietary temporary sealers facilitate cleaning off ceramic tiles after laying and grouting. These sealers can be readily removed, but must be used in accordance with the manufacturers instructions. The application of any sealant, is likely to reduce slip resistance.

May 05 www.porcelanosa.co.uk technical and samples hotline t: 08702 240245

6.1

installation

Porcelanosa Group Limited www.porcelanosa.co.uk t: 08702 240245 f: 08702 240246 e: group@porcelanosa.co.uk

Colours shown in this brochure are as accurate as allowed for by the printing process. Actual samples are available on request. Porcelanosa has a policy of continually improving and developing product ranges, and reserves the right to change product specifications, without notice.

Das könnte Ihnen auch gefallen

- BS 5385-4Dokument44 SeitenBS 5385-4mohammad82% (11)

- BS 5628-3Dokument136 SeitenBS 5628-3Leed EN100% (5)

- BS 5385 - 2 Wall and Floor Tiling PDFDokument34 SeitenBS 5385 - 2 Wall and Floor Tiling PDFTom Yee100% (2)

- British Standards and Codes of Practice For The Installation of Wall Floor TilesDokument13 SeitenBritish Standards and Codes of Practice For The Installation of Wall Floor TilesmohammadNoch keine Bewertungen

- BS 8204-4-1993-In-Situ Floorings-Code of Practice For TerrazDokument22 SeitenBS 8204-4-1993-In-Situ Floorings-Code of Practice For Terrazgops1963100% (1)

- BS 3921-1985Dokument30 SeitenBS 3921-1985Peng Swan100% (4)

- Ceramic TilingDokument45 SeitenCeramic TilingFirdaus Pasro Radzi100% (2)

- Doors and Windows SpecsDokument3 SeitenDoors and Windows SpecsVelmurugan BalasubramanianNoch keine Bewertungen

- Specifying Ceramic Tile With ANSI and ISO StandardsDokument45 SeitenSpecifying Ceramic Tile With ANSI and ISO StandardsAlQuon for U100% (1)

- BS 5080-2 1986 Structural Fixings in Concrete and MasonryDokument18 SeitenBS 5080-2 1986 Structural Fixings in Concrete and MasonryDaniel CheungNoch keine Bewertungen

- BS en 13914-2-2005 (2006) PDFDokument26 SeitenBS en 13914-2-2005 (2006) PDFR Channel25% (4)

- BS 5628 Part 3 MasonryDokument132 SeitenBS 5628 Part 3 MasonryMohamed Habola79% (19)

- CP 00102-1973 (1999)Dokument34 SeitenCP 00102-1973 (1999)Stanislav PerevezentsevNoch keine Bewertungen

- Required StandardsDokument18 SeitenRequired StandardsPanchadcharam PushparubanNoch keine Bewertungen

- En-12004-2001-Adhessives For Tiles Definitions and SpecificaDokument26 SeitenEn-12004-2001-Adhessives For Tiles Definitions and SpecificaEfthymios Tatsis100% (4)

- BS 8204-3-2004-Screeds, Bases and Insitu FlooringsDokument30 SeitenBS 8204-3-2004-Screeds, Bases and Insitu Flooringsgops1963100% (1)

- Suspended Ceiling-Method StatementDokument6 SeitenSuspended Ceiling-Method StatementTATATAHERNoch keine Bewertungen

- BS 1243-1978 Metal Ties For Cavity WallDokument8 SeitenBS 1243-1978 Metal Ties For Cavity Wallnickdash09Noch keine Bewertungen

- Newton BS 8102 2022 Technical Paper Apr22Dokument19 SeitenNewton BS 8102 2022 Technical Paper Apr22nandanaNoch keine Bewertungen

- BS 5328 - 2Dokument12 SeitenBS 5328 - 2Sundeep Reddy100% (3)

- Pas 00024-2012Dokument92 SeitenPas 00024-2012Emre ÖzaydınNoch keine Bewertungen

- BS 5268 Part 5Dokument28 SeitenBS 5268 Part 5Pubudu100% (1)

- BS 1881 1983 Part 101Dokument10 SeitenBS 1881 1983 Part 101paladin7Noch keine Bewertungen

- Bsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsDokument14 SeitenBsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsEngr. Jahanzeb MaharNoch keine Bewertungen

- BS8500 BS8110Dokument8 SeitenBS8500 BS8110Ahmed Mostafa AL-Aboudy100% (1)

- 14411Dokument70 Seiten14411Ayman S. AshourNoch keine Bewertungen

- Astm c926 Mortar and PlasterDokument10 SeitenAstm c926 Mortar and PlasterFlavioMuhale100% (1)

- Bs en 772 - 2Dokument8 SeitenBs en 772 - 2ADtahmaz100% (1)

- BS 6100 Glossary of Building and Civil Eng TermsDokument107 SeitenBS 6100 Glossary of Building and Civil Eng TermsRavindra Dhanapala100% (2)

- Readymix Concrete BS EN 206-1Dokument66 SeitenReadymix Concrete BS EN 206-1Ajit Singh Rathore100% (8)

- Concrete Formwork and FinishesDokument15 SeitenConcrete Formwork and FinishesIm Chinith100% (1)

- Installation of Resilient Floor Coverings: Code of Practice ForDokument28 SeitenInstallation of Resilient Floor Coverings: Code of Practice ForDavid Tomlinson100% (1)

- Astm C90Dokument4 SeitenAstm C90carlos100% (1)

- BS 1881-101-Method of Sampling Fresh Concrete On SiteDokument11 SeitenBS 1881-101-Method of Sampling Fresh Concrete On SiteShazrul Nizam92% (12)

- BS 8414Dokument18 SeitenBS 8414amanduhqsm100% (1)

- BS 6399-3Dokument30 SeitenBS 6399-3muhammad iqbal60% (5)

- Method Statement ACP CladdingDokument3 SeitenMethod Statement ACP Claddingps bediNoch keine Bewertungen

- Astm C926Dokument14 SeitenAstm C926asdrecv75% (4)

- BRE Digest 361, Why Do Buildings CrackDokument12 SeitenBRE Digest 361, Why Do Buildings CrackAbd100% (4)

- Specifying Concrete StandardsDokument11 SeitenSpecifying Concrete StandardsKelvin Bong100% (1)

- BS 4254Dokument19 SeitenBS 4254gugaruban100% (4)

- BS 8218-1998 Mastic Asphalt RoofingDokument38 SeitenBS 8218-1998 Mastic Asphalt Roofingconst1Noch keine Bewertungen

- BS 743 - 1970 - Materials For Damp-Proof CoursesDokument13 SeitenBS 743 - 1970 - Materials For Damp-Proof CoursesPhyu Mar Thein Kyaw100% (1)

- BS 5628Dokument10 SeitenBS 5628chowchsNoch keine Bewertungen

- BS 476-4 (1970) - Fire Tests On Building Materials and Structures PDFDokument12 SeitenBS 476-4 (1970) - Fire Tests On Building Materials and Structures PDFdoubleNoch keine Bewertungen

- Tiling WorksDokument3 SeitenTiling WorksCindy AmyzaNoch keine Bewertungen

- METHOD OF STATEMENT FOR GRANITE LAYINGDokument4 SeitenMETHOD OF STATEMENT FOR GRANITE LAYINGjohn paulNoch keine Bewertungen

- Squash Court Finish PDFDokument5 SeitenSquash Court Finish PDFFrancis T. TolibasNoch keine Bewertungen

- Betec - Multiflow 120Dokument2 SeitenBetec - Multiflow 120Vantu-Voiculescu CristiNoch keine Bewertungen

- Install CeramicDokument13 SeitenInstall CeramicAzhar CivicNoch keine Bewertungen

- Wall Tiling GuideDokument32 SeitenWall Tiling GuideMoataz MedhatNoch keine Bewertungen

- Sample Grout Data Sheets-BETEC 110-140-180Dokument2 SeitenSample Grout Data Sheets-BETEC 110-140-180fjafarvandNoch keine Bewertungen

- 1 - Lightstreams Glass Tile Installation Guide - English - 2Dokument12 Seiten1 - Lightstreams Glass Tile Installation Guide - English - 2Michele WillisNoch keine Bewertungen

- Install Floor Tiles Like a ProDokument15 SeitenInstall Floor Tiles Like a ProAlin Iosif Ichim50% (2)

- Wall Tiling Installation GuideDokument30 SeitenWall Tiling Installation GuideScridbparshuNoch keine Bewertungen

- Installation ManualDokument21 SeitenInstallation ManualVarun H RaoNoch keine Bewertungen

- Condur EglpDokument4 SeitenCondur EglpbollidNoch keine Bewertungen

- Method Statement for Ceramic Tile InstallationDokument4 SeitenMethod Statement for Ceramic Tile InstallationAli SaifNoch keine Bewertungen

- Technical Specification For TravertineDokument3 SeitenTechnical Specification For TravertineGezim Gezim0% (1)

- Durock Cement Board Installation Guide en CB237 PDFDokument11 SeitenDurock Cement Board Installation Guide en CB237 PDFRonald KahoraNoch keine Bewertungen

- BlackBerry Q10 Smartphone User Guide 1337191904827 10.3.2 enDokument310 SeitenBlackBerry Q10 Smartphone User Guide 1337191904827 10.3.2 entutortNoch keine Bewertungen

- 2016 Yearly Calendar Landscape 07Dokument1 Seite2016 Yearly Calendar Landscape 07KalinNoch keine Bewertungen

- Usda Food Icon Advancer PrintDokument1 SeiteUsda Food Icon Advancer PrintPetruNoch keine Bewertungen

- Plumbing GlosaryDokument3 SeitenPlumbing GlosaryKalinNoch keine Bewertungen

- Weldlok Grating ManualDokument32 SeitenWeldlok Grating ManualtylerlhsmithNoch keine Bewertungen

- Silica FumeDokument3 SeitenSilica FumeKalinNoch keine Bewertungen

- Controlling Corrosion in Structures To Be BuiltDokument7 SeitenControlling Corrosion in Structures To Be BuiltKalinNoch keine Bewertungen

- 617 - 1.storm Water GuidelinesDokument63 Seiten617 - 1.storm Water GuidelinesKalinNoch keine Bewertungen

- The Risk PremiumDokument12 SeitenThe Risk PremiumKalinNoch keine Bewertungen

- Elementos PreesforzadosDokument42 SeitenElementos PreesforzadosJohn Steven Anaya InfantesNoch keine Bewertungen

- Abrasive Blast ReportDokument16 SeitenAbrasive Blast ReportThiagarajan50% (2)

- Microstructure Characterization and Quantitative Analysis of Copper Alloy Matrix Composites Reinforced With Wc-Xni Powders Prepared by Spontaneous InfiltrationDokument9 SeitenMicrostructure Characterization and Quantitative Analysis of Copper Alloy Matrix Composites Reinforced With Wc-Xni Powders Prepared by Spontaneous Infiltrationnorthpole_plNoch keine Bewertungen

- IGCSE ChemistryDokument297 SeitenIGCSE ChemistrysalmasomaNoch keine Bewertungen

- IJBE-9-3-2021 Bahrami Guillot 13 30Dokument18 SeitenIJBE-9-3-2021 Bahrami Guillot 13 30Elina EsfandiariNoch keine Bewertungen

- Bray Serie 35 - 36Dokument6 SeitenBray Serie 35 - 36Oscar Horta PolaniaNoch keine Bewertungen

- Hauzhin Samiei Activity 4Dokument3 SeitenHauzhin Samiei Activity 4hauzhiinNoch keine Bewertungen

- Chapter 6Dokument13 SeitenChapter 6aregawi weleabezgiNoch keine Bewertungen

- Hydrogen ProbeDokument4 SeitenHydrogen ProbemahiengNoch keine Bewertungen

- Marco Material Datasheet Z1216Dokument1 SeiteMarco Material Datasheet Z1216radziNoch keine Bewertungen

- Hooke's Law: The Extension Is Directly Proportional To The Stretching Force (Load)Dokument2 SeitenHooke's Law: The Extension Is Directly Proportional To The Stretching Force (Load)Shalini KulshresthaNoch keine Bewertungen

- Elektroenerģētikas TehnoloģijasDokument6 SeitenElektroenerģētikas TehnoloģijasMihails LarionovsNoch keine Bewertungen

- Summer Internship Project On Durian Laminates PDFDokument82 SeitenSummer Internship Project On Durian Laminates PDFShubham MittalNoch keine Bewertungen

- ChemicalDokument1 SeiteChemicalTimothy John IgnacioNoch keine Bewertungen

- Design Slab On Grade Postension (ACI 360R & PTI) : I. Input DataDokument2 SeitenDesign Slab On Grade Postension (ACI 360R & PTI) : I. Input DataVandaNoch keine Bewertungen

- Victor Welding and Heating NozzleDokument6 SeitenVictor Welding and Heating Nozzleagniva datta100% (1)

- Astm C 27 1998Dokument2 SeitenAstm C 27 1998joel estradosoNoch keine Bewertungen

- Horiba - XGT 9000 IIDokument1 SeiteHoriba - XGT 9000 IIAmanah WatiiNoch keine Bewertungen

- Keswick School 1Dokument12 SeitenKeswick School 1api-25909541Noch keine Bewertungen

- PJK Project 2011 Form 2 (Word 2010)Dokument30 SeitenPJK Project 2011 Form 2 (Word 2010)Charmaine Yeo Shern LiNoch keine Bewertungen

- Foundation Engineering-I Design of Shall PDFDokument44 SeitenFoundation Engineering-I Design of Shall PDFAhmed MohammedNoch keine Bewertungen

- Wet Scrubber Wet Scrubber Application Guide PDFDokument9 SeitenWet Scrubber Wet Scrubber Application Guide PDFJose Luis ChapasNoch keine Bewertungen

- A Pseudo 3D Analysis of The Indentation Rolling Resistance ProblemDokument12 SeitenA Pseudo 3D Analysis of The Indentation Rolling Resistance ProblemPetros IosifidisNoch keine Bewertungen

- Sodium Saccharin E-954: Material Safety Data SheetDokument5 SeitenSodium Saccharin E-954: Material Safety Data SheetHerdianNoch keine Bewertungen

- Glass Fiber SpecsDokument4 SeitenGlass Fiber SpecsJanus AntonioNoch keine Bewertungen

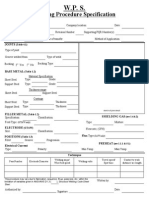

- WPS D1.3-2012 BlankDokument1 SeiteWPS D1.3-2012 BlankpjbedelNoch keine Bewertungen

- How To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtDokument55 SeitenHow To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtFrançois LeroyNoch keine Bewertungen

- Paroc Extra: Product DatasheetDokument2 SeitenParoc Extra: Product Datasheetturkertalayman1660Noch keine Bewertungen

- What is Diffusion? Understanding the Spreading ProcessDokument4 SeitenWhat is Diffusion? Understanding the Spreading ProcessccffyNoch keine Bewertungen