Beruflich Dokumente

Kultur Dokumente

ASME Pressure Vessel Joint Efficiencies

Hochgeladen von

Siva Venkateswara Rao Bolla0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten7 SeitenPressure Vessel Joint Efficiencies are linked to the radiography testing grades. There is a concession for full radiography testing as per the UW-11(a) (5) (b) clause. This article provides you the ASME Pressure Vessel Joint Efficiencies requirements and guidelines for the above clause.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPressure Vessel Joint Efficiencies are linked to the radiography testing grades. There is a concession for full radiography testing as per the UW-11(a) (5) (b) clause. This article provides you the ASME Pressure Vessel Joint Efficiencies requirements and guidelines for the above clause.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten7 SeitenASME Pressure Vessel Joint Efficiencies

Hochgeladen von

Siva Venkateswara Rao BollaPressure Vessel Joint Efficiencies are linked to the radiography testing grades. There is a concession for full radiography testing as per the UW-11(a) (5) (b) clause. This article provides you the ASME Pressure Vessel Joint Efficiencies requirements and guidelines for the above clause.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

Page 1 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

Global TPI Services

We Provide Pre-Shipment

Inspection, Vendor Inspection

and Commodity Inspection

Services. Click Here for More

Information

Home About Services Contact What's New! Privacy Policy

ASME Pressure Vessel Joint Efficiencies

The ASME Pressure Vessel Joint Efficiencies article provides you with

information about pressure vessel joint efficiency requirements and their

connection with radiography testing.

You may know Pressure Vessel Joint

Efficiencies are linked to the radiography

testing grades and there is a concession for

full radiography testing as per the UW-11(a)

(5) (b) clause which it is a little bit

confusing.

This article provides you the ASME

pressure vessel joint efficiencies requirements and guidelines for the

above clause.

Based on the ASME Code requirement, manufacturers have to mark the

type of RT i.e. RT1, RT2, RT3 and RT4 in the pressure vessel name

plate and state the same in Pressure Vessel Data Report.

We have seen many professionals, from

inspectors to quality control engineers

who are confused between RT1 and

RT2, specifically when they see ASME

Pressure Vessel Joint Efficiencies for

both RT1 and RT2 is the same and

equal to 1(E=1).

They say both RT1 and RT2 are categorized in the Full Radiography

part in UW-11 clause ...

So why are some joints in RT2 radiographed in spots?

We are making spot radiography, but it is categorized in full

radiography!!!

Select Language

Please Click the Facebook Like

and g +1 Recommend Buttons If

You Feel our Articles are Useful.

Home

General Articles

Pre-Shipment Inspection

Third Party Inspection

Goods Inspection

Vendor Inspection

Inspection and Test Plan

Shop Inspection

Factory Acceptance Test

Commodity Inspection

Industrial Quality Control

Industrial Inspection

Approved Vendor List

Plant Inspection

Fix Equipment Articles

Pressure Vessel

Heat Exchanger

Steam Boiler

Storage Tank

Piping System

Industrial Valve

Process Heater

Rotary Equipment Articles

Centrifugal Pump

Like

255

Sha

re

Page 2 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

So in this "ASME Pressure Vessel Joint Efficiencies" article we want to

answer this question in very simple way, but before this, we need review

joint categories and summarize them as below:

Category A:

All longitudinal welds in shell and nozzles

All welds in heads, Hemisph-head to shell weld joint

Category B:

All circumferential welds in shell and nozzles

Head to shell joint (other than Hemisph.)

Category C and D are flange welds and nozzle attachment welds

respectively

Longitudinal welds (Category A) are more critical than Circumferential

welds (Category B) because they are under double stress.

This the reason why in different part of ASME code we have stringent

rules in category A joint compared to category B joint.

See the following Fig. for joint categories:

Now let's get back to the ASME Pressure Vessel Joint Efficiencies

subject, to remove the above confusion about RT1 and RT2.

We need to know:

When and where is there a code requirement for full radiography?

Item 1: All butt welds in vessels used to contain a lethal substance

(UW-11(a)).Lethal substances have specific definitions in ASME Code

in UW-2 and it is the responsibility of the end user to determine if they

ordered a vessel that contains lethal substances.

Item 2: All butt welds in vessels in which the nominal thickness exceeds

specified values (UW-11(a). You can find these values in subsection C,

in UCS-57, UNF-57, etc. For example, this value for P-No.1 in UCS-57

is 1 inch.

Item 3: All butt welds in an unfired steam boiler with design pressure >

50 psi (UW-11(a)).

Centrifugal Compressor

Reciprocating

Compressor

Gas Turbine

Steam Turbine

Fan and Blower

Electrical Equipment

Articles

Electric Generator

Electric Motor

Power Transformer

Control Panel

Gas Circuit Breaker

Switchgear

Power Cable

Editor

About

Services

Contact

TPI Inspection Blog

Privacy Policy

[?]Subscribe To This Site

Sha

re

Page 3 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

Item 4: All category A and D butt welds in vessel when Full

Radiography optionally selected from table UW-12(column (a) in this

table is selected); and categories B and C which intersect Category A

shall meet the spot radiography requirement (UW-11(a) (5) (b)).

The point is this: items 1, 2 and 3 are similar, but item 4 is completely

different. In items 1, 2 and 3 it is mandated by code; to do full

radiography in all butt welds in vessel so it means it is mandatory for

designer to select column (a) in UW-12 table.

But in item 4, there is no mandating rule. A manufacturer with its own

decision has chosen to use column (a) in table UW-12 for full

radiography.

So here there is a concession or bonus to manufacturers for categories

B and C.

What is concept behind this concession or bonus in pressure vessel

RT test?

If you review item 1, 2 and 3 one more time, you will see that the

pressure vessel RT tests are related to the type of welds and services.

You can see the pressure vessels in these items are critical from a

safety point of view, one contains a lethal substance, the other one has

a high thickness, which implicates high pressure, and the last one is an

unfired steam boiler. But item 4 has no criticality like the other items

have.

But you should note all 4 items have been categorized in full

radiography clause( U-11(a)), so to differentiate item 1, 2 and 3 from

item 4, the RT symbols are used in Code (UG-116).

RT 1: Items 1, 2 and 3, (E=1), All butt welds-full length radiography

RT 2: Item 4 (E=1), Category A and D butt welds full length radiography

and category B and C butt welds spot Radiography

RT 3: (E=0.85), Spot radiography butt welds

RT 4: (E=0.7), Partial / No radiography

You need to consider the hemispherical head joint to shell as category A,

but ellipsoidal and torispherical head joint to shell as category B;

Do you know why? Why ASME considered the stringent rule for pressure

vessel RT test in hemispherical head joint?

It is because this joint is more critical, because the thickness obtained

from the formula for hemispherical head approximately would be half of

the shell thickness;

Sha

re

Page 4 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

It means if the shell thickness is 1 inch, the hemispherical head

thickness would be 0.5 inch.

For more detail, you may review the Pressure Vessel Heads article.

ASME Pressure Vessel Joint Efficiencies for welded Heads

For Welded Heads, the joint efficiency of the vessel will be 1(E=1), if all

welds within the head's full length are radiographed (since they are all

Cat. A welds). See above figure.

ASME Pressure Vessel Joint Efficiencies for Seamless Heads

For seamless heads, the joint efficiency of the vessel will be 1(E=1) if

the head to shell weld is fully radiographed for the hemispherical Head

(Cat A);

See the following Figure for RT types:

We Provide TPI Inspection Services in Most Industrial Areas Around

the Globe. Click Here for More Information

Spot radiographed for ellipsoidal and torispherical heads(Cat. B).

Weld Types:

Here is some clarification about the different type of welds that have

specific definitions in ASME Code SEC VIII DIV 1 and related to the

pressure vessel RT test.

The concept is to define the different types and then introduce some

restriction for using them.

For example, a Type 1 weld is defined as a full penetration weld,

typically double welded and Type 2 is welds with backing strips.

So when you go to service restriction for a vessel containing a lethal

substance, you see there is a restriction there that says all category A

joints shall be weld Type 1 and Category B and C shall be type 1 or type

2.

You should take this point in to account, which is this: the same joint

category with different weld types have different joint efficiencies.

Sha

re

Page 5 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

Summary of weld types:

Type 1: Full penetration welds (Typically Double welded)

Type 2: Welds with backing strip

Type 3: Single welded partial penetration welds

Type 4, 5 and 6: Various Lap welds (rarely used)

Recommend this on Google

Related Articles

Pressure Vessel Definition, Pressure Vessel Certification, Pressure Vessel Heads,

Pressure Vessel Handbook, Spherical Pressure Vessel, Pressure Vessel Plate

Material, ASME Code Section 8, ASME Impact Test Requirement, Pressure Vessel

RT Test , Vessel Pressure Testing, Third Party Inspection for Pressure Vessel,

Inspection and Test Plan for Pressure Vessel ,Third Party Inspection, Industrial

Inspection, Shop Inspection, Preshipment Inspection, Goods Inspection, Vendor

Inspection, Commodity Inspection, Industrial Quality Control, Quality Control Plan,

Quality Control Manual, Contractor Quality Control Plan, Quality Control Manual for

Contractors, 3rd Party Shop Inspection, Vendor Inspection Services, Quality Control

Forms

TPI in Germany, TPI in France, TPI in Belgium, TPI in Sweden, TPI in Switzerland, TPI in

Netherlands, TPI in Italy, TPI in Spain, TPI in Austria, TPI in UK, TPI in Turkey, TPI in USA,TPI

in Canada, TPI in Australia, TPI in China, TPI in India, TPI in Japan, TPI in South Korea, TPI in

Malaysia, TPI in Singapore, TPI in Kuwait, TPI in Oman, TPI in Qatar, TPI in Pakistan, TPI in

Saudi Arabia, TPI in UAE,

Return from ASME Pressure Vessel Joint Efficiencies to Pressure Vessel

Inspections

Return from ASME Pressure Vessel Joint Efficiencies to Inspection for Industry

Home

Recommend this on Google

New! Comments

Have your say about what you just read! Leave me a comment in the box below.

Share this page:

What's This?

Li

k

e

S

e

n

d

255 people like this.

Li

k

e

S

e

n

d

255 people like this.

Add a comment...

Sanjaykumar Lad Inspection Engineer at VELOSI LLC OMAN

good interpretation, its really help.

Reply Like January 3 at 2:38am

Gaurav Jha Rayan Collage of Engineering and Management

awsome!

Reply Like December 28, 2012 at 12:05am

Sha

re

Page 6 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

Enjoy this page? Please pay it forward. Here's how...

Facebook social plugin

Zulfadzli Tahir Works at 3B Ideation Sdn Bhd

Plant mana neh ?

Reply Like September 6, 2012 at 9:36pm

Nigar Ahmad Calgary, Alberta

Great work!

Reply Like July 10, 2012 at 4:04pm

go>o ml> _o Works at Suco

Nice,, thanks

Reply Like August 11, 2012 at 10:04pm

Sha

re

Page 7 ASME Pressure Vessel Joint Efficiencies

1/12/2013 4:46:36 PM http://www.inspection-for-industry.com/asme-pressure-vessel-joint-efficiencies.html

Inspection 4 Industry LLC

Tel International: 0037257536267

Tel USA: 0013106518570

Sha

re

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Perpab6-Spesifikasi AlatDokument38 SeitenPerpab6-Spesifikasi AlatardiNoch keine Bewertungen

- Saic A 2010Dokument13 SeitenSaic A 2010jerinNoch keine Bewertungen

- NeoDokument27 SeitenNeoDmitriy PeduretsNoch keine Bewertungen

- 07 Initial SULFUR RECOVERY UNIT Startup Valve Checklist REV 1Dokument33 Seiten07 Initial SULFUR RECOVERY UNIT Startup Valve Checklist REV 1Muhammad IrfanNoch keine Bewertungen

- Flow Straightener - : For Vortex Flow MetersDokument2 SeitenFlow Straightener - : For Vortex Flow MetersSugeng SNoch keine Bewertungen

- Ass 11Dokument1 SeiteAss 11Hawraa AlbahadlyNoch keine Bewertungen

- Acumulador de Freno - PruebasDokument1 SeiteAcumulador de Freno - PruebasLytmerAcuñaNoch keine Bewertungen

- Alarm MessageDokument12 SeitenAlarm MessageViết TrưởngNoch keine Bewertungen

- Manual Bomba de Aceite 1701053Dokument9 SeitenManual Bomba de Aceite 1701053ventas freyreNoch keine Bewertungen

- Posicionador 3570Dokument24 SeitenPosicionador 3570Capacitacion TodocatNoch keine Bewertungen

- Lecture 12 - SPRINKLER IRRIGATIONDokument51 SeitenLecture 12 - SPRINKLER IRRIGATIONIain Choong WKNoch keine Bewertungen

- RD9 PneumaticsDokument66 SeitenRD9 PneumaticsHussein MohamedNoch keine Bewertungen

- Classification of CompressorsDokument20 SeitenClassification of CompressorsDeepakNoch keine Bewertungen

- Part in Out Januari 2021Dokument384 SeitenPart in Out Januari 2021Jani WanganiaNoch keine Bewertungen

- Model Number Chart: Technical Service Manual: Installation, Operation & MaintenanceDokument25 SeitenModel Number Chart: Technical Service Manual: Installation, Operation & MaintenanceYerkin BagmanovNoch keine Bewertungen

- BobTail Fastener Pressure Chart - InchDokument8 SeitenBobTail Fastener Pressure Chart - Incherick montesNoch keine Bewertungen

- Mechanical Processes and Equipments MP - C7Dokument40 SeitenMechanical Processes and Equipments MP - C7PHƯƠNG ĐẶNG YẾNNoch keine Bewertungen

- Turbo CompressorsDokument8 SeitenTurbo CompressorskhibusinessdevelopmentNoch keine Bewertungen

- Artificial LiftDokument3 SeitenArtificial LiftsultanNoch keine Bewertungen

- CCI Control Valve HeatingDokument6 SeitenCCI Control Valve HeatingKarthick VelayuthamNoch keine Bewertungen

- Process DeliverablesDokument2 SeitenProcess DeliverablesMARK LESTER REALNoch keine Bewertungen

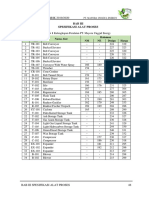

- Proposed Nugen 5 Storey Apartment Building Makati City Bill of Materials: Fire Protection System Item / Description Qty. / Unit Unit Cost AmountDokument4 SeitenProposed Nugen 5 Storey Apartment Building Makati City Bill of Materials: Fire Protection System Item / Description Qty. / Unit Unit Cost Amountroland09Noch keine Bewertungen

- BB1 Vs BB2Dokument1 SeiteBB1 Vs BB2bomthanhphuNoch keine Bewertungen

- Pump Training 2Dokument5 SeitenPump Training 2kevinGojiNoch keine Bewertungen

- Pumps Excerpts From Mihir's Handbook of CPE!Dokument18 SeitenPumps Excerpts From Mihir's Handbook of CPE!SathishkumarNoch keine Bewertungen

- Presentasi Coiled Tubing - Virnando Batu AraDokument20 SeitenPresentasi Coiled Tubing - Virnando Batu AraVirnando NainggolanNoch keine Bewertungen

- Sop Normally Opened Ball Valve Functionality TestDokument13 SeitenSop Normally Opened Ball Valve Functionality Testapi-538504186Noch keine Bewertungen

- Manpower Loading PlanDokument3 SeitenManpower Loading Planyanuar iskhakNoch keine Bewertungen

- Produts and List Prices 2004Dokument16 SeitenProduts and List Prices 2004jonNoch keine Bewertungen

- Total Head CalculationDokument16 SeitenTotal Head CalculationZaid Al RayesNoch keine Bewertungen