Beruflich Dokumente

Kultur Dokumente

New QC Notes

Hochgeladen von

mylinkOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

New QC Notes

Hochgeladen von

mylinkCopyright:

Verfügbare Formate

Quality Control (QC) in Garments

(Class Notes)

Table of Contents

No. 1. Lectures INTRODUCTION Page 3

2. 3.

TEXTILE PROCESSES FABRIC QUALITY INSPECTION

Quality Control Quality Assurance Measurement Anthropometry Input / Output Process

4 4 5 5 6 6 7 8 9 10 11 13 14 15 17 18

4. 5.

STEPS IN GARMENT PREPARATION CUTTING

Some common defects in Fabrics Methods to inspect the defects in Fabric

6.

SHIRT (TYPES & PARTS)

Cutting Process Notches Cut Plan

7.

SHIRT (Miscellaneous)

Types of Shirts Parts of Shirts Collar Neck Cuff Pleat Dart Fitting Drape Male Shirt Measurement

8.

SEAM

9.

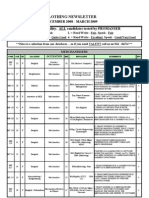

ORDER SHEET

Types of Seams ISO Stitches Classification

1. INTRODUCTION

Quality Control Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer. Quality Assurance Quality assurance (QA) is defined as a procedure or set of procedures intended to ensure that a product or service under development (before work is complete, as opposed to afterwards) meets specified requirements. QC is similar to, but not identical with, QA.QA & QC sometimes are expressed together as a single expression, quality assurance and control (QA/QC). Measurement

o 1 = 8 points (8 sutar)

o 10 mm = 1 cm o 1 = 2.54 cm o Metric measures (meter/centimeters) are used in UK & USA o Imperial measures (foot/Inches) are used in China & Korea o Anthropometry is the science that deals with measurement of the size, weight, and proportions of the human body. o 1 inch or 1 o 1 foot or 1 Anthropometry Anthropometry is the science dealing with measurement of the size, weight, and proportions of the human body.

Input / Output Process (Example)

2. TEXTILE PROCESSES Ginning/Synthesizing

Spinning Weaving/Loaming/Knitting Processing (Dying + Printing) Garments

3. FABRIC QUALITY INSPECTION

Some common defects in Fabrics Slub, Barre, Crease, Stains, Hole, Contamination, Others Methods to inspect the defects in Fabric

AQL (Acceptance Quality Level):

In this method defects are marked as Major, Minor & Critical. (Hole in fabric is always critical.)

4 Point System 0 3 defect is given 1 point 3 6 defect is given 2 point 6 9 defect is given 3 point 9 above inches defect is given 4 point (Hole in fabric secures 4 points) Suppose, a sample of fabric, taken from a selected role of fabric, secures 42 points; we can calculate the total points, secured by the rest of the role, as follows: Points secured by a Role of Fabric = Number of point x 39.36 x 100 Length of Role x Width of Fabric = 42 x 39.36 x 100 = 35 points approximately 83 x 57 Since the International Standard for acceptance is 30-33 points, and we know 35 > 30-33, so we will reject our selected Role of fabric.

o o o o GSD (General Sewing Data):

GSD (General Sewing Data) is a system that assists us in our continued improvement of quality and productivity. On completion every garment has a detailed method description for every operation in the sewing process, ensuring consistency in production and safeguarding quality standards. GSD is a computer database used for methods engineering and also provides accurate and consistent time standards. The GSD method describes the manufacture in terms of the exact motions required to produce garments in the required time and to the required quality standards. 4. STEPS IN GARMENT PREPARATION Pattern Making

Cutting Stitching/Sewing Washing Finishing Packing Dispatch 5. CUTTING Cutting Process

i.

Layering (Single layer of fabric is known as Ply)

o Relaxation (The relaxation time of Lycra is 8-24 times more than other fabrics)

o Alignment o Creasing o Types of layers Face to Face Face to Back ii. Tracing

o Firmly grip measuring instrument o Maximum use of fabric o Accurate usage of Pattern iii. Cutting

o Pitch (Alignment of Cutter) o Cutting Ratio

o Steps in Cutting 1. Small Parts 2. Front and Back Parts 3. Assembly iv. v.

Cut Parts Checking & Numbering Bundling

Notches (Notches are the cuts that are used to line up two or more pieces of fabric to ( join together.) o Slit: used in common dresses o V Notch: used in Curtains etc (Inner V Notch, Outer V Notch) o T Notch: used in Shoes o Castle Notch: used in heavy materials like leather jackets & uppers

Cut Plan For an order of 10000 pieces of garments having a consumption of 1.5 m/ piece, the Total Fabric Required will be 1.5 x 10000 = 15000 metres. If only 10000 metres of fabric is available in our inventory, how will we set our Cut Plan? Note: Fabric required for a piece of garment is known as consumption. Pieces = Available Fabric in Inventory / consumption = 10000 / 1.5 = 6667 pieces We know the ratio of size S 1 S = 1/6 x 6667 = 1111 pieces M = 2/6 x 6667 = 2222 pieces L = 2/6 x 6667 = 2222 pieces XL = 1/6 x 6667 = 1111 pieces : M 2 : L 2 : XL 1

6. SHIRT (TYPES & PARTS) Types of Shirts o T-Shirts

o Polo Shirts

Parts of Shirts

o Shirt (Front Parts)

o Shirt (Back Parts)

7. SHIRT (Miscellaneous) Collar o Two basic types of Collars: i. One piece collar ii. Two piece collar o Parts of a Collar:

o Miscellaneous Types of Collars

10

Neck o Types of Neck in garments (t.b.s)

11

Cuff

Pleat o Knife Pleat

o Box Pleat

12

o Inverted Pleat

o Side Pleat

o Miscellaneous Pleats

13

Dart

14

Fitting

15

o o o o o

Fitted Close Fitting Loose Fitting Semi Fitted Very Loose Fitting

Drape o Intro Drape is the way that fabric hangs. The process of draping involves sewing loosely hanging material to a garment to create a flowing look. Garment drape has received major attention of designers from the beginning. They have exploited this property of fabric in creating new styles according to changing fashion trends. Garment either hangs down from the shoulder or from the waist and drapes over the hip forming waves or folds at hemline. Quality of folds viz. number, shape and size of folds in a garment depends upon several factors. Garment either hangs down from the shoulder or from the waist and drapes over the hip forming waves or folds at hemline. Quality of folds viz. number, shape and size of folds in a garment depends upon several factors. o Two basic types of Drapes: i. ii. Natural Drape Induced drape

Male Shirt Measurement

16

8. SEAM

17

Seam is the series of stitches.

Types of Seams

There are four common types of Seams. o Super Imposed Seam

o Bounded Seam

o Flat Seam

o Lapped Seam

ISO Stitches Classification

18 1. Class 100: Single Thread Chain Stitch 2. 3. 4. 5.

6. 7.

It is used for bottom hamming in dressing pants etc. (Turpie) Class 200: Hand Stitch Class 300: Lock Stitch / Single Needle & Lock Stitch / Double Needle (common sewing machines) Class 400: Multi Thread Chain Stitch / Feed of the Arm machine / Feedo Machine Class 500: Over-edge Stitch i. Over-lock Machine (Three Thread Machine) One Needle, Two loppers thread ii. Safety Machine (Five Thread Machine) Two Needles, Three loppers thread Class 600: Flat Lock (Important in Knitting Industry) Class 700: Bar tack Machine (used for Strength and Design) SPI of Bar tack Machines is 35 to 70 stitches. (SPI = Stitches Per Inch)

9. ORDER SHEET

19

Das könnte Ihnen auch gefallen

- Quality Aspects of Garment - A ReviewDokument4 SeitenQuality Aspects of Garment - A ReviewSazid RahmanNoch keine Bewertungen

- Seam PuckeringDokument4 SeitenSeam PuckeringRavi Jain100% (1)

- ONLY:: Sample Consumption Follow-Up Sheet: Supplier: Style Name Brand NameDokument4 SeitenONLY:: Sample Consumption Follow-Up Sheet: Supplier: Style Name Brand NameRejaalNoch keine Bewertungen

- In-Plant Training Report PresentationDokument60 SeitenIn-Plant Training Report Presentationrajhossie9335100% (3)

- Carr and Latham's Technology of Clothing ManufactureVon EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerBewertung: 4 von 5 Sternen4/5 (1)

- Spme Denim TrouserDokument45 SeitenSpme Denim TrouserSupriya Nanda50% (2)

- Flow ChartDokument3 SeitenFlow ChartPrerna KhatriNoch keine Bewertungen

- Specification Sheet LayoutDokument9 SeitenSpecification Sheet LayoutSharvari ShankarNoch keine Bewertungen

- Puckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1Dokument14 SeitenPuckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1nubackNoch keine Bewertungen

- Different Grading System Used in Apparel IndustryDokument5 SeitenDifferent Grading System Used in Apparel Industryzain bajwaNoch keine Bewertungen

- Ladies' Blazer: Small Parts PreparationDokument4 SeitenLadies' Blazer: Small Parts PreparationMichael AlabadoNoch keine Bewertungen

- Unit - 3 Button Sewing Machine/button Attaching MachineDokument10 SeitenUnit - 3 Button Sewing Machine/button Attaching MachineAshu GrewalNoch keine Bewertungen

- HTM Womenswear Current-UpdatedDokument10 SeitenHTM Womenswear Current-UpdatedSujon SarkarNoch keine Bewertungen

- How To MeasureDokument73 SeitenHow To MeasureVarun Mehrotra100% (1)

- Stitch and SeamsDokument20 SeitenStitch and SeamsDelwar Hossain100% (1)

- CT MMB 198Dokument2 SeitenCT MMB 198Rosana BarakatNoch keine Bewertungen

- Stitch LengthDokument4 SeitenStitch LengthAjeet KumarNoch keine Bewertungen

- Fabric Defects & InspectionDokument23 SeitenFabric Defects & InspectionYogesh SharmaNoch keine Bewertungen

- Presentation On Stitch and Seam Details of Men's Formal ShirtDokument22 SeitenPresentation On Stitch and Seam Details of Men's Formal ShirtAkriti Dixit100% (1)

- Apparel Industrial EngineeringDokument4 SeitenApparel Industrial EngineeringkbalabalaNoch keine Bewertungen

- Tech PackDokument9 SeitenTech Packapi-283157444Noch keine Bewertungen

- Basic Garment Pattern Design ConsizpdfDokument11 SeitenBasic Garment Pattern Design ConsizpdfAhmad El TahanNoch keine Bewertungen

- Garment CostingDokument3 SeitenGarment CostingRejaalNoch keine Bewertungen

- Introd TextileDokument25 SeitenIntrod TextileNila Kumar SinghaNoch keine Bewertungen

- 2014-4-107 - P Fitting Evaluation of Pattern Making Systems According To Female Body Shapes PDokument5 Seiten2014-4-107 - P Fitting Evaluation of Pattern Making Systems According To Female Body Shapes PRobert Thompson100% (1)

- FM Assignment: Proto Tech PackDokument16 SeitenFM Assignment: Proto Tech Packluckyharsh19Noch keine Bewertungen

- All Trimmings Are Accessories But All Accessories Are Not TrimmingsDokument10 SeitenAll Trimmings Are Accessories But All Accessories Are Not TrimmingsAshraful Himel100% (1)

- 1.fabric Defects and IdentificationDokument16 Seiten1.fabric Defects and IdentificationRuhi gnextNoch keine Bewertungen

- Submitted To: Md. Emdad Sarker Lecturer Department of TextileDokument38 SeitenSubmitted To: Md. Emdad Sarker Lecturer Department of TextileMd Golam Kibria100% (1)

- Denim: Presented By:-Ashok Kumar Naresh KumarDokument23 SeitenDenim: Presented By:-Ashok Kumar Naresh Kumarknishant8Noch keine Bewertungen

- Mens ShirtDokument13 SeitenMens ShirtarunkadveNoch keine Bewertungen

- Sewing ThreadsDokument27 SeitenSewing ThreadsRikhil NagpalNoch keine Bewertungen

- Unit 3 - Design Development, Techpack & SamplesDokument8 SeitenUnit 3 - Design Development, Techpack & Samplesmaya_muthNoch keine Bewertungen

- Best Practice For Fabric InspectionDokument3 SeitenBest Practice For Fabric InspectionvinayakasisNoch keine Bewertungen

- Cantabil OS - by TJDokument96 SeitenCantabil OS - by TJYounus ahmedNoch keine Bewertungen

- Men Dress Shirt FlowchartDokument1 SeiteMen Dress Shirt FlowchartAvinash KumarNoch keine Bewertungen

- Tech Pack AssignmentDokument7 SeitenTech Pack Assignmentanisha gautamNoch keine Bewertungen

- Advanced GCDokument9 SeitenAdvanced GCSanjeev SinglaNoch keine Bewertungen

- Fabric and Garment FinishingDokument33 SeitenFabric and Garment FinishingSurya Bakshi100% (4)

- Apparel Quality Management: Assignment No.1Dokument11 SeitenApparel Quality Management: Assignment No.1Ravi SinghNoch keine Bewertungen

- Sewn Products Machinery and EquipmentDokument14 SeitenSewn Products Machinery and EquipmentBhaswati PandaNoch keine Bewertungen

- Spec Sheet 1285682994 Phpapp01Dokument1 SeiteSpec Sheet 1285682994 Phpapp01Tarun MehrotraNoch keine Bewertungen

- SeamsDokument17 SeitenSeamsNidhi Shah0% (1)

- Garments DefectDokument6 SeitenGarments DefectRajvi GhoghaniNoch keine Bewertungen

- Decoding The PatternDokument3 SeitenDecoding The PatternCherry Escolano0% (1)

- Consumption For FabricDokument5 SeitenConsumption For Fabrickimtienthao_26289Noch keine Bewertungen

- Notched Jacket LapelDokument6 SeitenNotched Jacket LapelwasyihunNoch keine Bewertungen

- Direct Costing of GarmentDokument6 SeitenDirect Costing of GarmentAmar Nath PrasadNoch keine Bewertungen

- GarmentDokument35 SeitenGarmentKottees WaranNoch keine Bewertungen

- Teach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsVon EverandTeach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsNoch keine Bewertungen

- Fabric RequirementDokument26 SeitenFabric RequirementCHARLES KINYERANoch keine Bewertungen

- Spec Sheet Tank TopDokument3 SeitenSpec Sheet Tank TopGurjeetNoch keine Bewertungen

- Defects in GarmentsDokument16 SeitenDefects in GarmentsarivaazhiNoch keine Bewertungen

- Textile Design Lecture 2Dokument10 SeitenTextile Design Lecture 2Muhammad Usama WaseemNoch keine Bewertungen

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Dokument25 SeitenKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNoch keine Bewertungen

- Seam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument12 SeitenSeam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (2)

- ............................. On The Clash of Civilizations ............................Dokument1 Seite............................. On The Clash of Civilizations ............................mylinkNoch keine Bewertungen

- NotesDokument5 SeitenNotesmylinkNoch keine Bewertungen

- ............................. On The Clash of Civilizations ............................Dokument1 Seite............................. On The Clash of Civilizations ............................mylinkNoch keine Bewertungen

- Moses With Horns Biblical MistranslationDokument2 SeitenMoses With Horns Biblical MistranslationmylinkNoch keine Bewertungen

- NBP Departments & GroupsDokument2 SeitenNBP Departments & GroupsmylinkNoch keine Bewertungen

- God, Allah or YahwehDokument1 SeiteGod, Allah or YahwehmylinkNoch keine Bewertungen

- Aiou FormateDokument1 SeiteAiou FormatemylinkNoch keine Bewertungen

- Fredrick Marks: The University of London BSC Building Studies - 2:1Dokument3 SeitenFredrick Marks: The University of London BSC Building Studies - 2:1mylinkNoch keine Bewertungen

- Style 6Dokument2 SeitenStyle 6mylinkNoch keine Bewertungen

- Style 5Dokument3 SeitenStyle 5mylinkNoch keine Bewertungen

- Style4 BlueDokument3 SeitenStyle4 BluemylinkNoch keine Bewertungen

- Style 2Dokument2 SeitenStyle 2mylinkNoch keine Bewertungen

- Style 1Dokument2 SeitenStyle 1mylinkNoch keine Bewertungen

- Cluck, Nancy Anne - Narrators in Drama of Tenessee WilliamsDokument11 SeitenCluck, Nancy Anne - Narrators in Drama of Tenessee Williamsoscar_gar75Noch keine Bewertungen

- The Adoration or Perversity of Childhood in Balthus's Paintings Andre PijetDokument9 SeitenThe Adoration or Perversity of Childhood in Balthus's Paintings Andre Pijetcadorna1Noch keine Bewertungen

- The Weathering WA19Dokument64 SeitenThe Weathering WA19Marko Goršćak100% (9)

- Graffiti ReaderDokument2 SeitenGraffiti ReadermeymoyoNoch keine Bewertungen

- Roundel 1955-07-08 Vol 7 No 7Dokument51 SeitenRoundel 1955-07-08 Vol 7 No 7TateNoch keine Bewertungen

- Picture Postcards and The Erotic Appeal of FirefightersDokument17 SeitenPicture Postcards and The Erotic Appeal of FirefightersJOHN A WALKER100% (1)

- Teapots by Design A Collectors CatalogueDokument168 SeitenTeapots by Design A Collectors CatalogueVasiliy Dyomin0% (1)

- Tiger LilliesDokument6 SeitenTiger LillieskovacsadriNoch keine Bewertungen

- Pato LaDokument38 SeitenPato LaTarkeshwar Singh100% (2)

- Escape The Dark Castle Health Point Tracks 1v0Dokument7 SeitenEscape The Dark Castle Health Point Tracks 1v0Juan Perdomo Aguiar100% (1)

- Nurturing Filipino Creativity: Philippine Education Policies in Support of The Creative IndustriesDokument18 SeitenNurturing Filipino Creativity: Philippine Education Policies in Support of The Creative IndustriesLoren AdonayNoch keine Bewertungen

- Symbols of FunctionDokument13 SeitenSymbols of FunctionQuenie Michubie ReyesNoch keine Bewertungen

- David Lomas - Notes On Dali and LeonardoDokument39 SeitenDavid Lomas - Notes On Dali and LeonardodorutNoch keine Bewertungen

- Denis Forman's Good Opera Guide - Eugene OneginDokument7 SeitenDenis Forman's Good Opera Guide - Eugene OneginThe GuardianNoch keine Bewertungen

- Crochet AppleDokument0 SeitenCrochet AppleAlxandra PinzaruNoch keine Bewertungen

- Grid WorksheetDokument2 SeitenGrid WorksheetacmcNoch keine Bewertungen

- Gifting It A Burning Embrace of Gift EconomyDokument13 SeitenGifting It A Burning Embrace of Gift EconomyRoxana ElenaNoch keine Bewertungen

- 9 - ReadingDokument6 Seiten9 - ReadingSasha StadnikovNoch keine Bewertungen

- Result 2019 CtsssDokument38 SeitenResult 2019 CtsssVishnu rajaNoch keine Bewertungen

- C. Tielsch & Co Wałbrzych - Pottery SignaturesDokument12 SeitenC. Tielsch & Co Wałbrzych - Pottery SignaturesMichal ZiemskiNoch keine Bewertungen

- JeansDokument11 SeitenJeansmehrdad100% (1)

- Mounting PrintsDokument2 SeitenMounting Prints65paulosalesNoch keine Bewertungen

- GRADE-8-ARTS-DLL-March 6-10,2023Dokument5 SeitenGRADE-8-ARTS-DLL-March 6-10,2023Meloueen Tolentino Osillos-AcdalNoch keine Bewertungen

- Specifications Analysis For Men's Ethnic WearDokument20 SeitenSpecifications Analysis For Men's Ethnic WearRAHUL16398Noch keine Bewertungen

- 1423652370naac Cmdpgcollege PDFDokument237 Seiten1423652370naac Cmdpgcollege PDFshreya sharmaNoch keine Bewertungen

- Artists Research PaperDokument4 SeitenArtists Research Papergz7vxzyz100% (1)

- Essentialism and Historicism in Danto's Philosophy of ArtDokument15 SeitenEssentialism and Historicism in Danto's Philosophy of ArtJacob EriksenNoch keine Bewertungen

- Guide To Figure SculptingDokument5 SeitenGuide To Figure SculptingMelquisedeth Tinjaca100% (1)

- Bhubaneswar (Ekamra - Kshetra) : Temple Town and Cultural Centre - Article ReviewDokument3 SeitenBhubaneswar (Ekamra - Kshetra) : Temple Town and Cultural Centre - Article ReviewangelhydNoch keine Bewertungen

- DIYFoxHead PDFDokument6 SeitenDIYFoxHead PDFEsteban QuinteroNoch keine Bewertungen