Beruflich Dokumente

Kultur Dokumente

Product Overview

Hochgeladen von

Anonymous MB5YbaLrBECopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Product Overview

Hochgeladen von

Anonymous MB5YbaLrBECopyright:

Verfügbare Formate

PipingSolutions, Inc.

6219 Brittmoore Road, Houston, Texas 77041-5114, U.S.A. Telephone: 713-849-3366 * FAX: 713-849-3806

E-mail: info@pipingsolutions.com * Website: www.pipingsolutions.com PipingSolutions develops, markets and distributes high quality, user-oriented Plant Engineering Design software for use in the process and power industries worldwide. PIPING

depending upon the shell and attachment geometry. TRI*TANK650- Designs or re-rates cylindrical tanks with sloped or flat-bottoms in accordance with API 650 standard. Wind and seismic loads can be applied in the rerating or design modes and the allowable criteria of several different wind and seismic standards can be applied.

TRIFLEX- is a Piping System Analysis and Design Program that provides user-friendly data entry screens, an extremely flexible output report generator as well as superior input and output graphics. In Static Analysis mode, TRIFLEX considers the effect of temperature change, pressure, weight, anchor and restraint movements as well as windload and support friction. TRIFLEX sizes and selects spring supports, computes stresses according to numerous piping codes and compares computed values with allowable stresses, computes equipment loading and compares with allowable load criteria. In Dynamic Analysis mode, TRIFLEX calculates mode shapes and frequencies, performs response spectrum and time history analysis, provides for the combination of results from the dynamic analysis with those of the static analysis and compares computed stresses with allowable stresses in accordance with the designated piping code.

PROCESS

TRI*HEADER- Designs and rates piping networks and emergency relief piping systems. TRI*HEADER uses automated mixture calculation driven by an integral Vapor Liquid Equilibrium (VLE) package to simulate high-speed two-phase flow and heat transfer. This software includes interactive screens and online help for fast and easy model building and analysis.

EQUIPMENT

WERCO*107-Calculates local bending and membrane stresses in spherical and cylindrical pressure vessel and tank shells as a result of externally applied forces and moments. Calculations are performed in accordance with the Welding Research Council Bulletin 107 or 297

PipingSolutions, Inc., has built its reputation by developing, marketing, and distributing high quality

user-oriented engineering design software since 1971.

Technical Support PipingSolutions prides itself in providing expert, comprehensive and personalized customer support. PipingSolutions technical support staff reviews any submitted relevant data and promptly responds to our user's needs.

and report of the physical conditions for all supports in your plant. Engineering Assessment Our engineers look at each support to ascertain if your supports or hangers are operating at their intended loads. Field Data Collection We present documentation about these supports and organize it for easy-to-understand analysis. Field Supervision We supply our expertise in the replacement of corroded and /or nonfunction supports hangers.

Client Training PipingSolutions provides detailed training seminars in selected fields of engineering specialization, as well as in the application of PipingSolutions software to solve specific problems in these fields. Our seminars include extensive "hands-on" time, with the attendees having access to a computer and software during the session. Consulting Services PipingSolutions provides piping and equipment design and analysis consulting services using the same expertise that characterizes our quality software. If your company requires such special assistance, contact PipingSolutions for detailed description of our services or for a confidential proposal.

Pipe Support Assessment Services This specialized service will provide a complete view

PipingSolutions, Inc. Software Solutions for the Processing Industry

Das könnte Ihnen auch gefallen

- Technical Note Two Phase FlowDokument3 SeitenTechnical Note Two Phase FlowAnonymous MB5YbaLrBENoch keine Bewertungen

- Asme Nuclear CodesDokument2 SeitenAsme Nuclear CodesAnonymous MB5YbaLrBENoch keine Bewertungen

- FEA - PresVesls - SCRBDDokument18 SeitenFEA - PresVesls - SCRBDAnonymous MB5YbaLrBENoch keine Bewertungen

- Agitator Nozzle Load Data SheetDokument1 SeiteAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENoch keine Bewertungen

- Data Required For Fatigue AnalysisDokument1 SeiteData Required For Fatigue AnalysisAnonymous MB5YbaLrBENoch keine Bewertungen

- Heater Outlet Vibration Analysis PDFDokument1 SeiteHeater Outlet Vibration Analysis PDFAnonymous MB5YbaLrBENoch keine Bewertungen

- FEA Tangetial Nozzle Brochure1Dokument1 SeiteFEA Tangetial Nozzle Brochure1Anonymous MB5YbaLrBE0% (1)

- Software Validation Test For Bearing StiffnessDokument2 SeitenSoftware Validation Test For Bearing StiffnessAnonymous MB5YbaLrBENoch keine Bewertungen

- AKCC 400E DimensionsDokument1 SeiteAKCC 400E DimensionsAnonymous MB5YbaLrBENoch keine Bewertungen

- Technical Basis For Reinforcing Pads Requirements On Nozzles Rev1Dokument1 SeiteTechnical Basis For Reinforcing Pads Requirements On Nozzles Rev1Anonymous MB5YbaLrBENoch keine Bewertungen

- MineralWoolInsulation Data SheetDokument18 SeitenMineralWoolInsulation Data SheetAnonymous MB5YbaLrBENoch keine Bewertungen

- Pipe Roughness ValueDokument1 SeitePipe Roughness ValueAnonymous MB5YbaLrBENoch keine Bewertungen

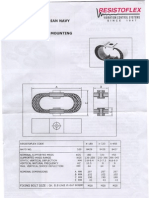

- Resistoflex x450Dokument2 SeitenResistoflex x450Anonymous MB5YbaLrBENoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- GateKeeping TheoryDokument7 SeitenGateKeeping TheoryFarah100% (1)

- Research: A Review and A PreviewDokument79 SeitenResearch: A Review and A PreviewJonathan SiguinNoch keine Bewertungen

- Famous Landmarks Vocabulary Cards Classroom Posters Conversation Topics Dialogs Flas - 72196Dokument1 SeiteFamous Landmarks Vocabulary Cards Classroom Posters Conversation Topics Dialogs Flas - 72196lolita digiacomo100% (1)

- n1 BrochureDokument4 Seitenn1 BrochureMatt JaskulskiNoch keine Bewertungen

- MIL-H-6875H Heat Treatment of SteelDokument29 SeitenMIL-H-6875H Heat Treatment of Steelgoathead61Noch keine Bewertungen

- D.ANDAN PS-PROJECT WATCH ActionPlan 2018-2019Dokument3 SeitenD.ANDAN PS-PROJECT WATCH ActionPlan 2018-2019Maria Fe PanuganNoch keine Bewertungen

- Learning Objectives: Plumbing SystemsDokument25 SeitenLearning Objectives: Plumbing Systemsanil horrisonNoch keine Bewertungen

- Abstract Yessy Marzona Icge VDokument21 SeitenAbstract Yessy Marzona Icge VYessy MarzonaNoch keine Bewertungen

- Arihant 9 Years JEE MainDokument666 SeitenArihant 9 Years JEE MainPG 么 SUSHANTH REDDYNoch keine Bewertungen

- Case Study MtotDokument15 SeitenCase Study MtotDotecho Jzo EyNoch keine Bewertungen

- Digital Finance and FinTech, Current Research and Future Research DirectionsDokument44 SeitenDigital Finance and FinTech, Current Research and Future Research DirectionsShambachew Omer HussenNoch keine Bewertungen

- Mouthwash, PEG, Sulfate, Betaine FreeDokument2 SeitenMouthwash, PEG, Sulfate, Betaine FreerekhilaNoch keine Bewertungen

- Comparative MatrixDokument3 SeitenComparative MatrixKristel RoseNoch keine Bewertungen

- Tesla - Tunguska Explosion 1908 PDFDokument9 SeitenTesla - Tunguska Explosion 1908 PDFMircea Gabriel BalanNoch keine Bewertungen

- 1best Practices For Migrating SAP Systems To Ora... - Oracle CommunityDokument4 Seiten1best Practices For Migrating SAP Systems To Ora... - Oracle CommunitymethukupallyNoch keine Bewertungen

- Ψηφιακός Γραμματισμός ΣταΟπτικοακουστικά Μέσα Σε Διαδικτυακά Περιβάλλοντα ΜάθησηςDokument19 SeitenΨηφιακός Γραμματισμός ΣταΟπτικοακουστικά Μέσα Σε Διαδικτυακά Περιβάλλοντα ΜάθησηςSofos LoisosNoch keine Bewertungen

- GL2012 - 001-High Volume Short Stay Surgery Model ToolkitDokument30 SeitenGL2012 - 001-High Volume Short Stay Surgery Model ToolkitPankaj MittalNoch keine Bewertungen

- AL59 157 SQMM Transmission Line SpecificationDokument2 SeitenAL59 157 SQMM Transmission Line SpecificationMohamed RafiNoch keine Bewertungen

- Edla English Unit 2019Dokument44 SeitenEdla English Unit 2019api-506409356Noch keine Bewertungen

- 6 SBMA V RodriguezDokument9 Seiten6 SBMA V RodriguezLexNoch keine Bewertungen

- Anti LeproticDokument9 SeitenAnti LeproticMeenakshi shARMANoch keine Bewertungen

- Larry Stylinson Proof.Dokument174 SeitenLarry Stylinson Proof.arantxaNoch keine Bewertungen

- HRM AssignmentDokument3 SeitenHRM AssignmentakshitNoch keine Bewertungen

- Bill Book SystermDokument10 SeitenBill Book SystermNiraj MishraNoch keine Bewertungen

- Marketing Case StudiesDokument10 SeitenMarketing Case StudiesSwati ChamariaNoch keine Bewertungen

- Importance of Being Hydrated To Weight ManagementDokument3 SeitenImportance of Being Hydrated To Weight ManagementAlastair MoltenNoch keine Bewertungen

- IDOC As Web ServiceDokument40 SeitenIDOC As Web ServiceUmesh Nanjaiah100% (2)

- Dual 15A/Single 30A Step-Down Power Module: ISL8225MDokument34 SeitenDual 15A/Single 30A Step-Down Power Module: ISL8225MAnonymous QakmLc3kTINoch keine Bewertungen

- Sustainable Transportation and Electric VehiclesDokument17 SeitenSustainable Transportation and Electric Vehicless131744Noch keine Bewertungen

- Marketing Plan Rental LaptopDokument15 SeitenMarketing Plan Rental LaptopDany AkbarNoch keine Bewertungen