Beruflich Dokumente

Kultur Dokumente

Ap 2 Slide

Hochgeladen von

Milectron IonOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ap 2 Slide

Hochgeladen von

Milectron IonCopyright:

Verfügbare Formate

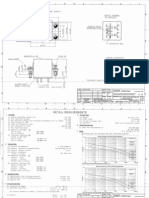

Fundamentals of Power Electronics

Appendix 2

Magnetics Design Tables

Geometrical data for several standard ferrite core shapes are listed here. The

geometrical constant K g is a measure of core size, useful for designing inductors and

transformers which attain a given copper loss [1]. The K g method for inductor design is

described in Chapter 13. Kg is defined as

Kg =

A 2c WA

MLT

(A2.1)

where Ac is the core cross-sectional area, WA is the window area, and MLT is the winding

mean-length-per-turn. The geometrical constant K gfe is a similar measure of core size,

which is useful for designing ac inductors and transformers when the total copper plus core

loss is constrained. The Kgfe method for magnetics design is described in Chapter 14. K gfe

is defined as

1 / )

WA A 2(1

c

K gfe =

u()

MLT l 2e /

(A2.2)

where le is the core mean magnetic path length, and is the core loss exponent:

Pfe = K fe B max

(A2.3)

For modern ferrite materials, typically lies in the range 2.6 to 2.8. The quantity u() is

defined as

u() =

+2

2

+2

+2

(A2.4)

u() is equal to 0.305 for = 2.7. This quantity varies by roughly 5% over the range 2.6

2.8. Values of Kgfe are tabulated for = 2.7; variation of Kgfe over the range 2.6

2.8 is typically quite small.

Appendix 2. Magnetics Design Tables

A 2 . 1 Pot core data

A

Core

type

Geometrical

constant

Geometrical

constant

(AH)

(mm)

Kg

cm5

K gfe

cmx

-6

704

0.73810

905

0.18310-3

-3

1107

0.66710

1408

2.10710-3

-3

1.6110

-6

Crosssectional

area

Ac

(cm2)

Bobbin

winding

area

WA

(cm2)

-3

Mean

length

per turn

MLT

(cm)

Magnetic

path

length

lm

(cm)

Thermal

resistance

Core

weight

R th

(C/W)

(g)

1.46

1.0

0.5

0.070

0.2210

25610-6

0.101

0.034

1.90

1.26

1.0

-6

0.167

0.055

2.30

1.55

1.8

1.110-3

0.251

0.097

2.90

2.00

100

3.2

-3

0.433

0.187

3.71

2.60

60

7.3

55410

1811

9.4510

2.610

2213

27.110-3

4.910-3

0.635

0.297

4.42

3.15

38

13

2616

69.110-3

8.210-3

0.948

0.406

5.28

3.75

30

20

-3

1.38

0.587

6.20

4.50

23

34

3019

0.180

14.210

3622

0.411

21.710-3

2.02

0.748

7.42

5.30

19

57

-3

2.66

1.40

8.60

6.81

13.5

104

4229

1.15

41.110

Appendix 2. Magnetics Design Tables

A 2 . 2 EE core data

A

Core

type

Geometrical

constant

Geometrical

constant

(A)

(mm)

Kg

cm5

K gfe

cmx

-3

EE12

0.73110

EE16

2.0210-3

EE19

4.0710

-3

EE22

EE30

85.710

EE40

0.209

EE50

0.909

Crosssectional

area

Ac

(cm2)

Bobbin

winding

area

WA

(cm2)

Mean

length

per turn

MLT

(cm)

Magnetic

path

length

lm

(cm)

Core

weight

-3

0.14

0.085

2.28

2.7

2.34

0.84210-3

0.45810

(g)

0.19

0.190

3.40

3.45

3.29

-3

0.23

0.284

3.69

3.94

4.83

8.2610-3

1.810-3

0.41

0.196

3.99

3.96

8.81

-3

-3

1.09

0.476

6.60

5.77

32.4

11.810-3

1.27

1.10

8.50

7.70

50.3

28.410-3

2.26

1.78

10.0

9.58

116

-3

2.47

2.89

12.8

11.0

135

3.24

6.75

14.0

9.0

280

1.310

6.710

EE60

1.38

36.410

EE70/68/19

5.06

12710-3

A 2 . 3 EC core data

Core

type

Geometrical

constant

Geometrical

constant

(A)

(mm)

Kg

cm5

K gfe

cmx

EC35

0.131

9.910-3

Crosssectional

area

Ac

(cm2)

Bobbin

winding

area

WA

(cm2)

Mean

length

per turn

MLT

(cm)

Magnetic

path

length

lm

(cm)

Thermal

resistance

Core

weight

R th

(C/W)

(g)

0.843

0.975

5.30

7.74

18.5

35.5

-3

1.21

1.35

5.30

8.93

16.5

57.0

EC41

0.374

19.510

EC52

0.914

31.710-3

1.80

2.12

7.50

10.5

11.0

111

-3

2.79

4.71

12.9

14.4

7.5

256

EC70

2.84

56.210

Appendix 2. Magnetics Design Tables

A 2 . 4 ETD core data

A

Core

type

Geometrical

constant

Geometrical

constant

(A)

(mm)

Kg

cm5

K gfe

cmx

-3

Crosssectional

area

Ac

(cm2)

Bobbin

winding

area

WA

(cm2)

Mean

length

per turn

MLT

(cm)

Magnetic

path

length

lm

(cm)

0.76

0.903

5.33

7.20

Thermal

resistance

Core

weight

R th

(C/W)

(g)

ETD29

0.0978

8.510

ETD34

0.193

13.110-3

0.97

1.23

6.00

7.86

19

40

ETD39

0.397

19.810

-3

1.25

1.74

6.86

9.21

15

60

ETD44

0.846

30.410-3

1.74

2.13

7.62

10.3

12

94

-3

2.11

2.71

8.51

11.4

11

124

ETD49

1.42

41.010

30

A 2 . 5 PQ core data

A1

2D

Core

type

Geometrical

constant

Geometrical

constant

(A1/2D)

(mm)

Kg

cm5

K gfe

cmx

-3

Bobbin

winding

area

WA

(cm2)

Mean

length

per turn

MLT

(cm)

Magnetic

path

length

lm

(cm)

Core

weight

-3

0.62

0.256

4.4

3.74

13

(g)

PQ 20/16

22.410

PQ 20/20

33.610-3

4.810-3

0.62

0.384

4.4

4.54

15

PQ 26/20

83.910

-3

-3

1.19

0.333

5.62

4.63

31

PQ 26/25

0.125

9.410-3

1.18

0.503

5.62

5.55

36

PQ 32/20

0.203

11.710-3

1.70

0.471

6.71

5.55

42

PQ 32/30

0.384

18.610

-3

1.61

0.995

6.71

7.46

55

PQ 35/35

0.820

30.410-3

1.96

1.61

7.52

8.79

73

-3

2.01

2.50

8.39

10.2

95

PQ 40/40

1.20

3.710

Crosssectional

area

Ac

(cm2)

7.210

39.110

Appendix 2. Magnetics Design Tables

A 2 . 6 American wire gauge data

AWG#

0000

000

00

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Bare area,

10-3 cm2

1072.3

850.3

674.2

534.8

424.1

336.3

266.7

211.5

167.7

133.0

105.5

83.67

66.32

52.41

41.60

33.08

26.26

20.02

16.51

13.07

10.39

8.228

6.531

5.188

4.116

3.243

2.508

2.047

1.623

1.280

1.021

0.8046

0.6470

0.5067

0.4013

0.3242

0.2554

0.2011

0.1589

0.1266

0.1026

0.08107

0.06207

0.04869

0.03972

0.03166

0.02452

Resistance,

10-6 /cm

1.608

2.027

2.557

3.224

4.065

5.128

6.463

8.153

10.28

13.0

16.3

20.6

26.0

32.9

41.37

52.09

69.64

82.80

104.3

131.8

165.8

209.5

263.9

332.3

418.9

531.4

666.0

842.1

1062.0

1345.0

1687.6

2142.7

2664.3

3402.2

4294.6

5314.9

6748.6

8572.8

10849

13608

16801

21266

27775

35400

43405

54429

70308

Diameter,

cm

1.168

1.040

0.927

0.825

0.735

0.654

0.583

0.519

0.462

0.411

0.366

0.326

0.291

0.267

0.238

0.213

0.190

0.171

0.153

0.137

0.122

0.109

0.0948

0.0874

0.0785

0.0701

0.0632

0.0566

0.0505

0.0452

0.0409

0.0366

0.0330

0.0294

0.0267

0.0241

0.0236

0.0191

0.0170

0.0152

0.0140

0.0124

0.0109

0.0096

0.00863

0.00762

0.00685

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Design For AssemblyDokument19 SeitenDesign For AssemblyJavierNoch keine Bewertungen

- Search Codes - WazeDokument2 SeitenSearch Codes - WazeJavierNoch keine Bewertungen

- Extenso MetersDokument22 SeitenExtenso MetersJavierNoch keine Bewertungen

- tt610 PDFDokument4 Seitentt610 PDFJavierNoch keine Bewertungen

- Mentorpaper 35429Dokument13 SeitenMentorpaper 35429JavierNoch keine Bewertungen

- CETAVER Adhesive Tape Specifications and ApplicationsDokument1 SeiteCETAVER Adhesive Tape Specifications and ApplicationsJavierNoch keine Bewertungen

- Topology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006Dokument9 SeitenTopology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006JavierNoch keine Bewertungen

- National Instr Tutorial 3092Dokument4 SeitenNational Instr Tutorial 3092JavierNoch keine Bewertungen

- SS304 304L Data SheetDokument2 SeitenSS304 304L Data SheetPrakash KumarNoch keine Bewertungen

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDokument32 SeitenTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNoch keine Bewertungen

- Ethernet Train Bus ArticleDokument6 SeitenEthernet Train Bus ArticleJavierNoch keine Bewertungen

- Loctite 235564 Do It Right Users GuideDokument44 SeitenLoctite 235564 Do It Right Users GuideJavierNoch keine Bewertungen

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDokument32 SeitenTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNoch keine Bewertungen

- Therm6.3 10211 ValidationDokument7 SeitenTherm6.3 10211 ValidationJavierNoch keine Bewertungen

- Omnicon Sneak Analysis BrochureRevA8.5x11Dokument2 SeitenOmnicon Sneak Analysis BrochureRevA8.5x11JavierNoch keine Bewertungen

- Loctite 235564 Do It Right Users GuideDokument44 SeitenLoctite 235564 Do It Right Users GuideJavierNoch keine Bewertungen

- Safety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDDokument25 SeitenSafety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDJavierNoch keine Bewertungen

- Imeko WC 2012 TC4 O18Dokument5 SeitenImeko WC 2012 TC4 O18JavierNoch keine Bewertungen

- Understanding Boost Power StagesDokument32 SeitenUnderstanding Boost Power StagesphanioletyNoch keine Bewertungen

- Lessons in Electric Circuits, Volume I - DCDokument560 SeitenLessons in Electric Circuits, Volume I - DCyoonghmNoch keine Bewertungen

- Omnicon Sneak Analysis BrochureRevA8.5x11Dokument2 SeitenOmnicon Sneak Analysis BrochureRevA8.5x11JavierNoch keine Bewertungen

- Mentor Paper 52590 BGA Fanout BreakoutDokument192 SeitenMentor Paper 52590 BGA Fanout BreakoutMiriam DrathNoch keine Bewertungen

- Iwnicki 01 12Dokument63 SeitenIwnicki 01 12JavierNoch keine Bewertungen

- Overvoltage Protection in Railway ABBDokument32 SeitenOvervoltage Protection in Railway ABBJavierNoch keine Bewertungen

- LC ThesisDokument73 SeitenLC ThesisJavierNoch keine Bewertungen

- IUIa GiV EnglDokument3 SeitenIUIa GiV EnglJavierNoch keine Bewertungen

- WP BScan For Designers enDokument5 SeitenWP BScan For Designers enJavierNoch keine Bewertungen

- Model Number Structure: Enclosed SwitchDokument10 SeitenModel Number Structure: Enclosed SwitchJavierNoch keine Bewertungen

- Non Latching Relay - Leach InternationalDokument2 SeitenNon Latching Relay - Leach InternationalJavierNoch keine Bewertungen

- Model Number Structure: Enclosed SwitchDokument10 SeitenModel Number Structure: Enclosed SwitchJavierNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)