Beruflich Dokumente

Kultur Dokumente

CAC Tomato Concentrate

Hochgeladen von

Sunil GirdharCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CAC Tomato Concentrate

Hochgeladen von

Sunil GirdharCopyright:

Verfügbare Formate

CODEX STAN 57

Page 1 of 5

CODEX STANDARD FOR PROCESSED TOMATO CONCENTRATES (CODEX STAN 57-1981) 1 SCOPE

This Standard applies to the product as defined in Section 2 below, and offered for direct consumption, including for catering purposes or for repacking if required. This Standard also applies to the product when indicated as being intended for further processing. The Standard does not include products that contain seeds and skins such as pizza toppings and other homestyle products as well as products commonly known as tomato sauce, chilli sauce, and ketchup, or similar products which are highly seasoned products of varying concentrations containing characterising ingredients such as pepper, onions, vinegar, etc., in quantity that materially alter the flavour, aroma and taste of the tomato component. 2 2.1 DESCRIPTION PRODUCT DEFINITION Processed tomato concentrate is the product: (a) prepared by concentrating the juice 1 or pulp obtained from substantially sound, mature red tomatoes (Lycopersicon/Lycopersicum esculentum P. Mill) strained or otherwise prepared to exclude the majority of skins, seeds and other coarse or hard substances in the finished product; and preserved by physical means.

(b)

The tomato concentration shall be 7% or more of natural total soluble solids 2 , but not dehydrated to a dry powder or flake form. 2.2 PRODUCT DESIGNATION

Tomato concentrate may be considered Tomato Puree or Tomato Paste when the concentrate meets these requirements: 2.2.1 Tomato Puree Tomato concentrate that contains no less than 7% but less than 24% of natural total soluble solids. 2.2.2 Tomato Paste Tomato concentrate that contains at least 24% of natural total soluble solids. 3 3.1 ESSENTIAL COMPOSITION AND QUALITY FACTORS COMPOSITION

3.1.1 Basic Ingredients Processed tomato concentrate as defined in Section 2.1. 3.1.2 Other Permitted Ingredients (a) (b) (c) (d) salt (sodium chloride) in accordance with the Codex Standard for Food Grade Salt (CODEX STAN 150-1985); spices and aromatic herbs (such as basil leaf, etc.) and their natural extracts; lemon juice (single strength or concentrated) used as an acidulant; and water.

In this Standard, juice must not be intended as the fruit juice (including tomato juice) as defined in the Codex General Standard for Fruit Juices and Nectars (CODEX STAN 247-2005). The concentrations are measured on the product without added salt. Formerly CAC/RS 57-1972. Revision 2007.

CODEX STAN 57

Page 2 of 5

3.2

QUALITY CRITERIA

Processed tomato concentrates shall have good flavour and odour, fairly good red colour, and shall possess a homogeneous (evenly divided) texture, characteristic of the product. 3.2.1 Definition of Defects Processed tomato concentrates shall be prepared in accordance with good manufacturing practices (GMP), from such materials and under such practices that the product is substantially free of extraneous plant materials, this including other objectionable material and shall be practically free of mineral impurities. Consistent with its intended use, these conditions are fulfilled when: (a) (b) (c) (d) the product is practically free of objectionable tomato peel; the product is practically free of seeds or particles of seeds; the presence of any extraneous plant material other than seed and peel and other than those used as seasonings cannot be detected by the naked eye, and can only be seen under microscope; and the product is practically free of dark specks or scale-like particles.

3.2.2 Defects and Allowances 3.2.2.1 Mineral impurities 3 The mineral impurity content does not exceed 0.1% of the natural total soluble solids content. 3.2.2.2 Lactic Acid The content of lactic acid (total) does not exceed 1% of the natural total soluble solids content. 3.2.2.3 Mould Count Mould count for processed tomato concentrates to be set according to the legislation of the country of retail sale. 3.2.2.4 pH The pH must be below 4.6. 3.3 CLASSIFICATION OF DEFECTIVES

A container that fails to meet the natural total soluble solids requirements, as set out in Section 2.2, and/or one or more of the applicable quality requirements, as set out in Section 3.2, should be considered as a defective. 3.4 when: (a) (b) the number of defectives, as defined in Section 3.3, does not exceed the acceptance number (c) of the appropriate sampling plan with an AQL of 6.5; and the maximum allowance for mould count is not exceeded (see Section 3.2.2.3). LOT ACCEPTANCE A lot should be considered as meeting the applicable quality requirements referred to in Section 3.2

These acceptance criteria do not apply to non-retail containers.

Sand, soil and any other impurities insoluble in hydrochloric acid.

CODEX STAN 57

Page 3 of 5

4 4.1

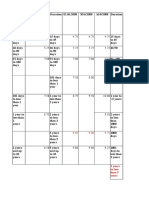

FOOD ADDITIVES ACIDITY REGULATORS INS No. 330 331(i) 331(iii) 332(i) 332(iii) 333 Name of the Food Additive Citric Acid Sodium dihydrogen citrate Trisodium citrate Potassium dihydrogen citrate Tripotassium citrate Calcium citrates GMP Maximum Level

5 5.1

CONTAMINANTS PESTICIDE RESIDUES

5.1.1 The product covered by the provisions of this Standard shall comply with those maximum pesticide residue limits established by the Codex Alimentarius Commission for this product. 5.1.2 In order to consider the concentration of the product, the determination of the maximum pesticide residue limits shall take into account the natural total soluble solids, the reference value being 4.5 for fresh fruit. 5.2 OTHER CONTAMINANTS

5.2.1 The product covered by the provisions of this Standard shall comply with those maximum levels for contaminants established by the Codex Alimentarius Commission for this product. 5.2.2 In order to consider the concentration of the product, the determination of the maximum levels for contaminants shall take into account the natural total soluble solids, the reference value being 4.5 for fresh fruit. 6 HYGIENE

6.1 It is recommended that the products covered by the provisions of this Standard be prepared and handled in accordance with the appropriate sections of the Recommended International Code of Practice General Principles of Food Hygiene (CAC/RCP 1-1969), and other relevant Codex texts such as codes of hygienic practice and codes of practice. 6.2 The products should comply with any microbiological criteria established in accordance with the Principles for the Establishment and Application of Microbiological Criteria for Foods (CAC/GL 21-1997). 7 7.1 WEIGHTS AND MEASURES 4 FILL OF CONTAINER

7.1.1 Minimum Fill The container should be well filled with the product which should occupy not less than 90% (minus any necessary head space according to good manufacturing practices) of the water capacity of the container. The water capacity of the container is the volume of distilled water at 20oC which the sealed container will hold when completely filled. 7.1.2 Classification of Defectives A container that fails to meet the requirement for minimum fill of Section 7.1.1 should be considered as a defective.

The provisions in this Section do not apply to non-retail containers.

CODEX STAN 57

Page 4 of 5

7.1.3 Lot Acceptance A lot should be considered as meeting the requirement of Section 7.1.1 when the number of defectives, as defined in Section 7.1.2, does not exceed the acceptance number (c) of the appropriate sampling plan with an AQL of 6.5. 8 LABELLING

8.1 The product covered by the provisions of this Standard shall be labelled in accordance with the Codex General Standard for the Labelling of Prepackaged Foods (CODEX STAN 1-1985). In addition, the following specific provisions apply: 8.2 NAME OF THE PRODUCT The name of the product shall be: (a) (b) (c) (d) Tomato Puree if the food contains not less than 7% but less than 24% natural total soluble solids; Tomato Paste if the food contains not less than 24% natural total soluble solids; Another denomination usually employed in the country accompanied by the declaration of the percentage of the natural total soluble solids; or If an added ingredient, as defined in Section 3.1.2, alters the flavour characteristic of the product, the name of the food shall be accompanied by the term flavoured with X or X flavoured as appropriate.

8.3

DECLARATION OF THE PERCENTAGE OF NATURAL TOTAL SOLUBLE SOLIDS The percentage solids may be included on the label in either of the following manners: (a) (b) The minimum percentage of natural total soluble solids (example: Minimum Solids - 20%). A range within 2% of the natural total soluble solids (example: Solids - 20% to 22%).

8.4

LABELLING OF NON-RETAIL CONTAINERS

Information for non-retail containers shall be given either on the container or in accompanying documents, except that the name of the product, lot identification, and the name and address of the manufacturer, packer, distributor or importer, as well as storage instructions, shall appear on the container. However, lot identification, and the name and address of the manufacturer, packer, distributor or importer may be replaced by an identification mark, provided that such a mark is clearly identifiable with the accompanying documents. 9 METHODS OF ANALYSIS AND SAMPLING PROVISION METHOD CAC/RM 46-1972 (Codex General Method for processed fruits and vegetables) EN 2631:1999 AOAC 971.33 (Codex General Method for processed fruits and vegetables) PRINCIPLE TYPE

Fill of containers

Weighing

Lactic acid Mineral impurities (sand)

Enzymatic determination

II

Gravimetry

CODEX STAN 57

Page 5 of 5

PROVISION

METHOD

PRINCIPLE

TYPE

Mould count

AOAC 965.41

Howard mould count

NMKL 179:2005 pH AOAC 981.12 ISO 3634:1979 expressed as sodium chloride (Codex General Method) AOAC 970.59 Potentiometry

II III

Sodium Chloride Tomato soluble solids

Potentiometry

III

Refractometry

DETERMINATION OF WATER CAPACITY OF CONTAINERS (CAC/RM 46-1972 5 ) 1. SCOPE This method applies to glass containers 6 . 2. DEFINITION

The water capacity of a container is the volume of distilled water at 20C which the sealed container will hold when completely filled. 3. 3.1 3.2 PROCEDURE Select a container which is undamaged in all respects. Wash, dry and weigh the empty container.

3.3 Fill the container with distilled water at 20C to the level of the top thereof, and weigh the container thus filled. 4. CALCULATION AND EXPRESSION OF RESULTS

Subtract the weight found in 3.2 from the weight found in 3.3. The difference shall be considered to be the weight of water required to fill the container. Results are expressed as ml of water.

5 6

As amended by the Committee on Methods of Analysis and Sampling, ALINORM 03/23, Appendix VI-H. For determination of water capacity in metal containers the reference method is ISO 90.1:1986.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Sauces - A Global HistoryDokument160 SeitenSauces - A Global HistoryСдружение ХепАктив100% (6)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- HeinzDokument11 SeitenHeinzKavita Rao100% (2)

- The Technical Study KetchupDokument4 SeitenThe Technical Study KetchupdaralkhalafNoch keine Bewertungen

- THE CHEMISTRY OF BAKING REVEALEDDokument8 SeitenTHE CHEMISTRY OF BAKING REVEALEDmajikNoch keine Bewertungen

- Bahasa Inggeris Tingkatan 1Dokument6 SeitenBahasa Inggeris Tingkatan 1Nur Adilah Dila50% (4)

- The Parable of The PipelineDokument8 SeitenThe Parable of The PipelineAtlasVending100% (21)

- What Time Did You Go To Bed Last Night?Dokument2 SeitenWhat Time Did You Go To Bed Last Night?Sunil Girdhar50% (2)

- Suka ni Pedro Marketing PlanDokument24 SeitenSuka ni Pedro Marketing PlanMickey Mae RetardoNoch keine Bewertungen

- Marketing Strategy For Failed Product of Young's Food (Ketchup)Dokument19 SeitenMarketing Strategy For Failed Product of Young's Food (Ketchup)PinkAlert100% (11)

- Doing Science Is Fun PDFDokument124 SeitenDoing Science Is Fun PDFSunil GirdharNoch keine Bewertungen

- Doing Science Is Fun PDFDokument124 SeitenDoing Science Is Fun PDFSunil GirdharNoch keine Bewertungen

- Tle8 Module 6 Substitution of IngredientsDokument11 SeitenTle8 Module 6 Substitution of IngredientsRodenfiel Christan BautistaNoch keine Bewertungen

- Six Favorable & Unfavorable PrinciplesDokument3 SeitenSix Favorable & Unfavorable PrinciplesSunil GirdharNoch keine Bewertungen

- Six Favorable & Unfavorable PrinciplesDokument3 SeitenSix Favorable & Unfavorable PrinciplesSunil GirdharNoch keine Bewertungen

- Interest Rates For 10 YrsDokument19 SeitenInterest Rates For 10 YrsKrishna YadavNoch keine Bewertungen

- The Best Fonts For BooksDokument6 SeitenThe Best Fonts For BooksSunil GirdharNoch keine Bewertungen

- Pradhan Mantri Shram Yogi Maandhan Yojana ApplicationDokument1 SeitePradhan Mantri Shram Yogi Maandhan Yojana ApplicationSunil GirdharNoch keine Bewertungen

- Humble OfferingDokument22 SeitenHumble OfferingSunil GirdharNoch keine Bewertungen

- How To Be A Disciple of H.H. B.V.SDokument3 SeitenHow To Be A Disciple of H.H. B.V.SSunil GirdharNoch keine Bewertungen

- Vedic Evidence of Lord Chaitanya's IncarnationDokument9 SeitenVedic Evidence of Lord Chaitanya's IncarnationSunil GirdharNoch keine Bewertungen

- Light of The Bhagavata PDFDokument38 SeitenLight of The Bhagavata PDFramkiscribdNoch keine Bewertungen

- How To Be A Disciple of H.H. B.V.SDokument3 SeitenHow To Be A Disciple of H.H. B.V.SSunil GirdharNoch keine Bewertungen

- Gopi GitaDokument9 SeitenGopi GitaSanjay AnandaNoch keine Bewertungen

- B G Day 1Dokument23 SeitenB G Day 1ABTNNoch keine Bewertungen

- Delhi Metro Route MapDokument1 SeiteDelhi Metro Route Mapnakulyadav7Noch keine Bewertungen

- smaranikaSP Web PDFDokument20 SeitensmaranikaSP Web PDFSunil GirdharNoch keine Bewertungen

- GurvashtakamDokument4 SeitenGurvashtakamSunil GirdharNoch keine Bewertungen

- Krisna Kathamrita Bindu 001Dokument4 SeitenKrisna Kathamrita Bindu 001Szabó PiroskaNoch keine Bewertungen

- Eight Rules For Better Japa - Hare Krishna JapaDokument2 SeitenEight Rules For Better Japa - Hare Krishna JapaSunil Girdhar100% (1)

- Gopi GitaDokument9 SeitenGopi GitaSanjay AnandaNoch keine Bewertungen

- Nine Stages of BhaktiDokument2 SeitenNine Stages of BhaktiSunil GirdharNoch keine Bewertungen

- Road Traffic Signs Recognition ChartDokument2 SeitenRoad Traffic Signs Recognition Chartsks1969100% (2)

- Qualities of A Sadhu or Vaishnava Discussed in 11th CantoDokument5 SeitenQualities of A Sadhu or Vaishnava Discussed in 11th CantoSunil Girdhar100% (1)

- The Fault Lies WithinDokument1 SeiteThe Fault Lies WithinAbhishek TrivediNoch keine Bewertungen

- Krsna BookDokument536 SeitenKrsna BookSparsh Mittal100% (1)

- Aflatoxin PDFDokument1 SeiteAflatoxin PDFSunil GirdharNoch keine Bewertungen

- Aflatoxin PDFDokument1 SeiteAflatoxin PDFSunil GirdharNoch keine Bewertungen

- Case Study On Comsumer InsightDokument7 SeitenCase Study On Comsumer InsightviqaralibaigNoch keine Bewertungen

- Marketing Plan for Expanding Red Gold Ketchup into the US MarketDokument11 SeitenMarketing Plan for Expanding Red Gold Ketchup into the US MarketraneshNoch keine Bewertungen

- APN 2.11.01 Tomato - KetchupDokument2 SeitenAPN 2.11.01 Tomato - KetchupHouari Brahim100% (1)

- FullDokument7 SeitenFullđức linh VuNoch keine Bewertungen

- Heinz Plant BottleDokument10 SeitenHeinz Plant BottleAris SolisNoch keine Bewertungen

- Foods To Be AvoidedDokument8 SeitenFoods To Be AvoidedemruzzamanNoch keine Bewertungen

- Turkey Sloppy Joes RecipeDokument15 SeitenTurkey Sloppy Joes RecipemscarreraNoch keine Bewertungen

- Heinz Ketchup: Pricing The Product Line (Abridged) : An Iconic BrandDokument4 SeitenHeinz Ketchup: Pricing The Product Line (Abridged) : An Iconic BrandprogisNoch keine Bewertungen

- Kinds of Concept PaperDokument3 SeitenKinds of Concept PaperFrhea mae Alcayde100% (1)

- Maggi, Nestle and other popular brands product list with pricesDokument14 SeitenMaggi, Nestle and other popular brands product list with pricesPushpendra MaratheNoch keine Bewertungen

- Delivery Program: Agrana StarchDokument8 SeitenDelivery Program: Agrana StarchKSXNoch keine Bewertungen

- Recipe Slow Cooker Chicken TacosDokument10 SeitenRecipe Slow Cooker Chicken TacosVincent ReyesNoch keine Bewertungen

- 2nd Sem Notes Nfood Production PDFDokument43 Seiten2nd Sem Notes Nfood Production PDFaman vermaNoch keine Bewertungen

- How To Succeed in Your SariDokument14 SeitenHow To Succeed in Your SariLorie BautistaNoch keine Bewertungen

- 2015 Malawi Standards Catalogue - 1Dokument208 Seiten2015 Malawi Standards Catalogue - 1Mzee Boydd Mkaka MwabutwaNoch keine Bewertungen

- EAPP FINAL EXAMINATION KeyDokument6 SeitenEAPP FINAL EXAMINATION KeyJames AlmazanNoch keine Bewertungen

- Main Food Menu - Allergen, Ingredients and Nutrition Information - 0Dokument21 SeitenMain Food Menu - Allergen, Ingredients and Nutrition Information - 0Sponge BobNoch keine Bewertungen

- Semiotics Analysis 2Dokument2 SeitenSemiotics Analysis 2api-464492750Noch keine Bewertungen

- CHAPTER 2 Business ReviewDokument17 SeitenCHAPTER 2 Business ReviewRoseAnn Jose Dela FuenteNoch keine Bewertungen

- CDRDokument8 SeitenCDRapi-242491875Noch keine Bewertungen

- Pran Company Report: Marketing, Sales, Products, StrategiesDokument24 SeitenPran Company Report: Marketing, Sales, Products, StrategiesNuzhat AhmedNoch keine Bewertungen

- Stain Removal - From Discovery EducationDokument6 SeitenStain Removal - From Discovery EducationstanhopekrisNoch keine Bewertungen

- Functionlsity Starch in Snak Food1-2Dokument21 SeitenFunctionlsity Starch in Snak Food1-2Adinda LarasatiNoch keine Bewertungen