Beruflich Dokumente

Kultur Dokumente

F5 CW3 22 Nov 2012 - Answer

Hochgeladen von

Leo ChanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

F5 CW3 22 Nov 2012 - Answer

Hochgeladen von

Leo ChanCopyright:

Verfügbare Formate

F.

5 A/B

1) Stress = 2) Strain = 3)

No.:

Name:

Hand in 23 th Nov. 2012 Friday

6.

Define ductile based on the stress-strain curve - Material undergoes lots of plastic deformaiton under stress. - This is permanent deformation.

P.1

Physics CW3 (Unit 1 topic 2) Force cross-section Area Extension Original length

Tensile Stress = Tensile Strain

7.

Define Brittle based on the stress-strain curve - Material undergoes no / little plastic deformation under stress. - break after elastic limit / break at yield point.

Young Modulus =

Compressive Stress Compressive Strain

What is the meaning of Young Modulus? Young modulus is the mathematical description of an object or substance's tendency to be deformed elastically when a force is applied to it. Young modulus is a quantity used to characterize materials. 4) Tensile stress is Tensile stress = Tensile strain = Tensile Force (F) cross-section Area(A) Extension (x) Original length(X) A F x X

P69, Textbook Question 2: The wire in a new guitar 'string' is made of a 90 cm steel wire of diameter 1mm. When the string is fitted to the guitar, the string is put under a tension of 75N by winding it round a peg and this also stretches it by 0.5mm. a) what is the stress in the wire? Tensile Force (F) Tensile stress = cross-section Area(A) = 75 N (1.0 mm/ 2 ) 2 = 95 x 104 Pa

b) what is the wire strain? Tensile strain = Extension (x) Original length(X) 0.5 mm = 90 cm

= 5.6 x 10-4

5)

Compressive stress is Compressive Force (F) compressive stress = cross-section Area(A) compressive stain = Shorten length (x) Original length(X) x A

c) what is the Young modulus for this kind of steel? 75 N (1.0 mm/ 2 ) 2 Tensile stress = Young modulus = Tensile strain 0.5 mm 90 cm

= 1.7 x109 Pa

F.5 A/B

No.:

Name:

Hand in 23 th Nov. 2012 Friday

P.2

Physics CW3 (Unit 1 topic 2)

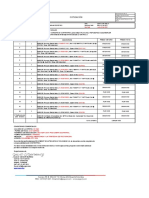

Stress-Strain curve of a ductile material

Actual breaking point

Elastic Behaviour

Plastics Behaviour

Necking

Actual breaking strength

tensile stress ()

At this point The material shows a large increase in strain for a (very...very) small increase in stress. i.e. Once stretched beyond this point the material begins to change shape permanently with very small increment in load. Yield point

(Ultimate) tensile strength

breaking stress / breaking strength (rupture stress / Fracture strength) breaking point (rupture point / failure point)

Elastic limit At this point (1) The material stops behaving elastically.

Lin ea r re gio n

(2) begins to behave plastically. (3) When the stress is removed the material does not return to its original length.

Limit of Proportionality (1) (2) A straight line passing through the origin. Follow Hooke's law i.e. Force extension (Why? Check with the equation of Young's Modulus.) After the Limit of Proportionality, Hooke's law doesn't apply; Stress is not proportional to strain.

(3)

Aluminium

tensile strain ()

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Power Cycles IceDokument11 SeitenPower Cycles Icecarlverano0428Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Design and Analysis of Single Plate Friction ClutchDokument29 SeitenDesign and Analysis of Single Plate Friction ClutchSagar BhoiteNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Clap Users Manual Rev 4Dokument68 SeitenClap Users Manual Rev 4Birendra KumarNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Heat EnergyDokument18 SeitenHeat EnergyCrazzy RamNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- BID ESG 21 048 Rev. 0 (Jun082021)Dokument1 SeiteBID ESG 21 048 Rev. 0 (Jun082021)Alexander Charry GiraldoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Sling Psychrometer: Micro Project ReportDokument11 SeitenSling Psychrometer: Micro Project Reporttanvi tamhane100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Creep and Creep TestingDokument4 SeitenCreep and Creep TestingMuhammed SulfeekNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Section 3Dokument5 SeitenSection 3Aduchelab AdamsonuniversityNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 76 - Race (With Solution)Dokument6 Seiten76 - Race (With Solution)amankumar24200Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- "Study of Convergent-Divergent Nozzle": A Minor Project ReportDokument67 Seiten"Study of Convergent-Divergent Nozzle": A Minor Project Reportchinna570% (1)

- Comparison of Structural Behaviour of Flat Plate System and Flat Slab System For Reinforced Concrete BuildingDokument5 SeitenComparison of Structural Behaviour of Flat Plate System and Flat Slab System For Reinforced Concrete BuildingNan Shwe Kyi HtweNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Testing Methods For CompositesDokument26 SeitenTesting Methods For CompositesRupayan RoyNoch keine Bewertungen

- Comparative Study of Steel Structures Design Using IS 800 PDFDokument8 SeitenComparative Study of Steel Structures Design Using IS 800 PDFshivarajNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Pas Hink in 2003Dokument16 SeitenPas Hink in 2003石皓瑋Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Worksheet G11 Chemistry 11.1Dokument3 SeitenWorksheet G11 Chemistry 11.1some guy on the internetNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Statics: Vector Mechanics For EngineersDokument40 SeitenStatics: Vector Mechanics For EngineersArdaNoch keine Bewertungen

- PM P1 D5 - Problemas Deformación PlásticaDokument4 SeitenPM P1 D5 - Problemas Deformación PlásticaAnggieGarcésNoch keine Bewertungen

- Catalogo Aisladores PDFDokument75 SeitenCatalogo Aisladores PDFCamilo AguilarNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Heat Loss in Bare and Lagged Pipes PDFDokument13 SeitenHeat Loss in Bare and Lagged Pipes PDFjamaiiica100% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Constitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Dokument12 SeitenConstitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Jose ManuelNoch keine Bewertungen

- Conversion And: Gas LawsDokument17 SeitenConversion And: Gas LawsLynne Joie Laroza TapayNoch keine Bewertungen

- Practica de Lugeon Cap. VDokument7 SeitenPractica de Lugeon Cap. VKarl MejíaNoch keine Bewertungen

- Air Drying by Pressure Swing Adsorption - Chihara-SuzukiDokument7 SeitenAir Drying by Pressure Swing Adsorption - Chihara-SuzukiAndri SaputraNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- MCQ Thermodynamics Compressible FlowDokument4 SeitenMCQ Thermodynamics Compressible FlowTochi Krishna Abhishek100% (1)

- 7 - Psy - Chart - XLS Cooling CoilDokument28 Seiten7 - Psy - Chart - XLS Cooling CoilRanu JanuarNoch keine Bewertungen

- 4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDDokument5 Seiten4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDKiran KumarNoch keine Bewertungen

- ACI 318 08 Design of Retaining Wall With CounterfortDokument9 SeitenACI 318 08 Design of Retaining Wall With CounterfortfaumijkNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- (103 Marks) : (1 Mark)Dokument21 Seiten(103 Marks) : (1 Mark)Ahmad OmarNoch keine Bewertungen

- Solution - Shape FactorDokument6 SeitenSolution - Shape FactorVenkata DineshNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)