Beruflich Dokumente

Kultur Dokumente

Trough Transition Lenghts

Hochgeladen von

Jigneshkumar PatelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Trough Transition Lenghts

Hochgeladen von

Jigneshkumar PatelCopyright:

Verfügbare Formate

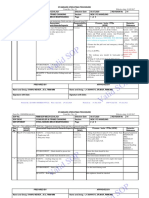

TROUGH TRANSITION LENGTH

The distance between the first full trough station and the drive pulley or the tail pulley must be adjusted to avoid an excess tension of the edges in the transition area or compression of the central part if the tension is weak. There are two trough transition length possibilities.

Case no. 1 Minimum trough transition length with upper generatrix of the pulley in the axis of the generatrix of the centre roller of the carrying stations.

TROUGH TRANSITION LENGTH

EDGE OF BELT

FULL TROUGH DEPTH

CENTRE OF BELT

LAST TROUGH SUPPORT

CENTRE LINE HEAD PULLEY

Textile belts

TRANSPLY MULTIPLY MULTITRANS / EP BIATHLON TRIATHLON RIP-STOP TRANSFLAM TRANSTHERM TRANSOIL TRANSPROFIL

Percentage of rated tension

30 degrees

TROUGH ANGLE 35 degrees

45 degrees

> 90 %

1.5 x I

1.9 x I

2.8 x I

60 to 90 %

1.3 x I

1.5 x I

2.2 x I

< 60 %

1.0 x I

1.2 x I

1.7 x I

Metal belts

METALCORD M METALTRANS M AUTOSTABLE M TRANSTHERM MWH METALCORD E METALTRANS E

Percentage of rated tension > 90 % 60 to 90 % < 60 % > 90 % 60 to 90 % < 60 %

30 degrees 1.7 x I 1.5 x I 1.3 x I 2.1 x I 1.9 x I 1.6 x I

TROUGH ANGLE 35 degrees 2.1 x I 1.9 x I 1.6x I 2.5 x I 2.2 x I 1.8 x I

45 degrees 3.0 x I 2.6 x I 2.3 x I 3.4 x I 3.1 x I 2.7 x I

l : width of belt

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our customers. The information stated therein is state of the art and the results of different tests carried out over several years. Individual operating conditions affect any product, which means that a product can only offer the safety that can be expected on the basis of the data provided in our product information. In the event that the product is used otherwise than in conformity with the specifications, such safety may not be assumed. Our responsibility is limited exclusively to delivery of the conveyor belt in accordance with the specifications. The figures stated in our documents are mean approximate values for information but no specified or warranted values.

Please note: Before using the product in new areas of application which are not covered by the product information a Sempertrans engineer MUST be asked for advice. Stocking, care and maintenance of all our products must be performed according to our stocking, care and maintenance guidelines and according to ISO 5285 standard ; Subject to errors and printing errors. Reproduction of any kind - also of excerpts - only upon express written consent of Sempertrans. The brochure shall remain the property of Sempertrans and is the most recent version. All transactions shall be exclusively subject to our general terms and conditions. Date of publication 06/2007 1st edition Subject to changes.

82

Case no. 2 Minimum trough transition length with centre line of the pulley raised with respect to the face of the centre roller of the carrying idlers by one third of the height of the trough.

TROUGH TRANSITION LENGTH

EDGE OF BELT CENTRE OF BELT

CENTRE LINE

LAST TROUGH SUPPORT

MID-DEPTH OF TROUGH

HEAD PULLEY

Textile belts

TRANSPLY MULTIPLY MULTITRANS / EP BIATHLON TRIATHLON RIP-STOP TRANSFLAM TRANSTHERM TRANSOIL TRANSPROFIL PP POLYAMIDE

Percentage of rated tension

30 degrees

TROUGH ANGLE 35 degrees

45 degrees

> 90 %

1.2 x I

1.5 x I

2.3 x I

60 to 90 %

1.1 x I

1.2 x I

1.8 x I

< 60 % All tensions Percentage of rated tension > 90 % 60 to 90 % < 60 % > 90 % 60 to 90 % < 60 % All tensions

0.8 x I 0.9 x I

1.0 x I 1.1 TROUGH ANGLE 35 degrees 1.7 x I 1.5 x I 1.3 x I 2.0 1.8 1.5 2.0 x x x x I I I I

1.4 x I 1.3 x I

Metal belts

METALCORD M METALTRANS M AUTOSTABLE M TRANSTHERM MWH METALCORD E METALTRANS E

30 degrees 1.3 x I 1.2 x I 1.0 x I 1.7 x I 1.5 x I 1.3 x I 1.75 x I

45 degrees 2.4 x I 2.1 x I 1.8 x I 2.7 x I 2.5 x I 2.2 x I 2.55 x I

ST STEELCORD l : width of belt

Elevation of pulley with respect to face of centre roller of carrying idlers: the table below indicates this value for 30 and 45 troughs in mm.

Trough angle 30 45 Width of belt 1200 1400 1600 56 68 78 72 87 100

500 22 ////

650 31 40

800 36 47

1000 48 62

1800 89 114

2000 100 127

2250 115 147

2400 125 157

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our customers. The information stated therein is state of the art and the results of different tests carried out over several years. Individual operating conditions affect any product, which means that a product can only offer the safety that can be expected on the basis of the data provided in our product information. In the event that the product is used otherwise than in conformity with the specifications, such safety may not be assumed. Our responsibility is limited exclusively to delivery of the conveyor belt in accordance with the specifications. The figures stated in our documents are mean approximate values for information but no specified or warranted values.

Please note: Before using the product in new areas of application which are not covered by the product information a Sempertrans engineer MUST be asked for advice. Stocking, care and maintenance of all our products must be performed according to our stocking, care and maintenance guidelines and according to ISO 5285 standard ; Subject to errors and printing errors. Reproduction of any kind - also of excerpts - only upon express written consent of Sempertrans. The brochure shall remain the property of Sempertrans and is the most recent version. All transactions shall be exclusively subject to our general terms and conditions. Date of publication 06/2007 1st edition Subject to changes.

83

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 1000sr Spare Parts Manual (Elec. Dwg@AMTC) - Ilovepdf-Compressed PDFDokument147 Seiten1000sr Spare Parts Manual (Elec. Dwg@AMTC) - Ilovepdf-Compressed PDFS Sathish KumarNoch keine Bewertungen

- Best Practice Conveyor Belt SystemsDokument50 SeitenBest Practice Conveyor Belt SystemsDaneshwer Verma100% (1)

- Beam DeflectionDokument5 SeitenBeam DeflectionChinna ValleNoch keine Bewertungen

- 12 - SprocketsDokument24 Seiten12 - SprocketsJigneshkumar PatelNoch keine Bewertungen

- 12 - SprocketsDokument24 Seiten12 - SprocketsJigneshkumar PatelNoch keine Bewertungen

- 1 ZMC Engineering DataDokument23 Seiten1 ZMC Engineering DataJigneshkumar PatelNoch keine Bewertungen

- 12 - SprocketsDokument24 Seiten12 - SprocketsJigneshkumar PatelNoch keine Bewertungen

- Beam DeflectionDokument5 SeitenBeam DeflectionChinna ValleNoch keine Bewertungen

- 1 ZMC Engineering DataDokument23 Seiten1 ZMC Engineering DataJigneshkumar PatelNoch keine Bewertungen

- Deep Groove Ball Bearings, Single Row, Shield On Both SidesDokument1 SeiteDeep Groove Ball Bearings, Single Row, Shield On Both SidesJigneshkumar PatelNoch keine Bewertungen

- 3948Dokument20 Seiten3948Jigneshkumar PatelNoch keine Bewertungen

- DesignDokument4 SeitenDesignJigneshkumar PatelNoch keine Bewertungen

- 2 03 007 88Dokument14 Seiten2 03 007 88Jigneshkumar PatelNoch keine Bewertungen

- Conveyor Belt SystemsDokument6 SeitenConveyor Belt SystemsJigneshkumar PatelNoch keine Bewertungen

- Steelcord splice design standardDokument10 SeitenSteelcord splice design standardREZANoch keine Bewertungen

- Technical Information 1: Storage, Finishing, FittingDokument12 SeitenTechnical Information 1: Storage, Finishing, FittingSebastian QuintanaNoch keine Bewertungen

- Electro-Pneumatic Lift and Carry Conveying SystemDokument4 SeitenElectro-Pneumatic Lift and Carry Conveying SystemIJSTENoch keine Bewertungen

- Papers - Pipe Conveyors - Development and AdvantagesDokument8 SeitenPapers - Pipe Conveyors - Development and AdvantagesJulie WillisNoch keine Bewertungen

- Introduction to Storage, Dosing, Extraction and Transfer SystemsDokument20 SeitenIntroduction to Storage, Dosing, Extraction and Transfer SystemsbulentbulutNoch keine Bewertungen

- Extec Turbo (Wheeled) Manual enDokument39 SeitenExtec Turbo (Wheeled) Manual enadasrafalskiNoch keine Bewertungen

- Y-Puratek Telescoping Belt ConveyorDokument4 SeitenY-Puratek Telescoping Belt ConveyorYousef AlipourNoch keine Bewertungen

- Metal Detector Instruction ManualDokument21 SeitenMetal Detector Instruction ManualLuis Felipe Turriate Alvarado100% (1)

- DMR Instruction On FiresDokument5 SeitenDMR Instruction On FiresJon DaviesNoch keine Bewertungen

- Packing PlantDokument19 SeitenPacking PlantValipireddy NagarjunNoch keine Bewertungen

- Booklet Trimmer F1 Parts ListDokument86 SeitenBooklet Trimmer F1 Parts ListMarlos BonillaNoch keine Bewertungen

- Welcome: Advanced Bulk Material Conveying Technologies in Cement IndustryDokument15 SeitenWelcome: Advanced Bulk Material Conveying Technologies in Cement Industry1977julNoch keine Bewertungen

- Conveyor Belt Maintenance ManualDokument45 SeitenConveyor Belt Maintenance ManualRajam Raju Vegesna100% (1)

- Apron ChainDokument39 SeitenApron ChainRobel Firew100% (1)

- Idler Selection PDFDokument13 SeitenIdler Selection PDFkhuong_unoNoch keine Bewertungen

- Pro ME Parts Rev4Dokument82 SeitenPro ME Parts Rev4Saul MendozaNoch keine Bewertungen

- Belt FabricsDokument14 SeitenBelt FabricsEstihak Bhuiyan EftiNoch keine Bewertungen

- Glossary CorreiaDokument41 SeitenGlossary CorreiaAmilton filho100% (1)

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDokument19 SeitenBelt Conveyors: Mechanical Engineering Department Carlos III UniversityMohamed MaherNoch keine Bewertungen

- Inclined Belt Conveyors For Underground Mass Mining OperationsDokument6 SeitenInclined Belt Conveyors For Underground Mass Mining OperationsIsmaelNoch keine Bewertungen

- Kalyan A RamanDokument4 SeitenKalyan A RamanKalyanaraman RamakrishnanNoch keine Bewertungen

- Conveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationDokument27 SeitenConveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationARAVINDRAJ V RNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument41 SeitenDisclosure To Promote The Right To InformationCaspian DattaNoch keine Bewertungen

- Telescopic Conveyor System-140ft Design, Specification and Documenting of Telescopic Conveyor System-140ft Creo & PulseDokument2 SeitenTelescopic Conveyor System-140ft Design, Specification and Documenting of Telescopic Conveyor System-140ft Creo & Pulseppd9890Noch keine Bewertungen

- Guideline Management Crushing and Screening Feb10 1Dokument10 SeitenGuideline Management Crushing and Screening Feb10 1Karin AndersonNoch keine Bewertungen

- Technical Specification PC 3: Atlas Copco PowercrusherDokument4 SeitenTechnical Specification PC 3: Atlas Copco PowercrusheralmirNoch keine Bewertungen

- Coal Feeding AreaDokument75 SeitenCoal Feeding AreaAamir HayatNoch keine Bewertungen

- 621-CC#09 Idler and Frame ChangingDokument4 Seiten621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)