Beruflich Dokumente

Kultur Dokumente

Kinetic studies on Corrosion of Mild Steel in Pure and Mixed Aqueous Media of Urea, Sodium Chloride, Potassium Chloride and Glycine S. Ghosh and A. K. Ghosh Volume - 1 , Number - 1 Publication Year: 2012 , Page(s): 26 - 33

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kinetic studies on Corrosion of Mild Steel in Pure and Mixed Aqueous Media of Urea, Sodium Chloride, Potassium Chloride and Glycine S. Ghosh and A. K. Ghosh Volume - 1 , Number - 1 Publication Year: 2012 , Page(s): 26 - 33

Copyright:

Verfügbare Formate

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

Kinetic studies on Corrosion of Mild Steel in Pure and Mixed Aqueous Media of Urea, Sodium Chloride, Potassium Chloride and Glycine

S. Ghosh1, A. K. Ghosh2

1

National Institute of Technology, Jamshedpur, India 2 University of Burdwan, Burdwan, India

Abstract: Corrosion of mild steel in industries, mainly in chemical and allied industries

has tremendous impact in terms of economical point of view. In oder to establish the corrosion behavior and mechanism, a series of experiments have been carried out on corrosion of mild-steel in various conditions systematically. Corrosion of mild steel in mixed and aqueous solution of urea, sodium chloride, potassium chloride and glycine depends upon variation of temperature, concentration and also with time. A comprehensive survey on corrosion of mild steel has been conducted for about six months. The variation in temperature, concentration, time etc. have been studied and utilized in explaining the corrosion of mild steel. The corrosion products was analyzed spectrophotometrically to arrive the reaction mechanism and kinetics. Spectrophotometry was taken into consideration to determine the rate of corrosion under different environments. The rate constants for different systems have been calculated and from the temperature dependence of the rate constants activation parameters have been calculated systematically using Arrhenius equation. Keywords: Corrosion; Mild steel; Kinetics; Glycine; Potassium chloride; Urea; Activation energy.

INTRODUCTION

Increasing attention is being given now-a-days to the deterioration of infrastructure exposed to actual hostile environments. As a result interest of structural engineers has been increased in the rate of loss of strength in infrastructure systems, although protective measures are not wholly effective for the loss of material (mainly made up of mild steel) in short-term exposures [1]. Mild steel is most versatile, low cost material and widely used engineering material which has found to be extensive application in various industries [2]. It has large application in nuclear power plant, transportation, sugar industries, automotive engines using methanol fuel, pipelines, chemical processing, petroleum production and refining industries etc [3-9]. Due to the less corrosive resistance of mild steel problems are generated in the related industries [10]. Mild steel have a natural tendency to revert back to combined states: During this process mostly, oxides are formed through electrochemical process which may result due to presence of impurities. Corrosion is an electrochemical process, reverse process of metallurgy and formation of rust (Fe2O3, xH2O) or scale is most familiar example of corrosion when iron is exposed to atmospheric conditions [11]. Most important reaction mechanism of corrosion of metals in normal condition involves the role of water, providing the basis of cathodic reaction, i.e. 26 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

F O2 + 2H2O + 4e-

Fe+2 + 2e- (Anode) 4OH- (Cathode)

Recently the US Federal Highway Administration released a study, entitled Corrosion Costs and Preventive Strategies in the United States, in 2002 on the direct costs associated with metallic corrosion in nearly every U.S. industry sector. The study showed that for 1998 the total annual estimated direct cost of corrosion in the U.S. was approximately $276 billion (approximately 3.2% of the US gross domestic product [12]. Similarly for India it is also reported that one ton of steel is lost in every 12 seconds due to corrosion which is estimated to around 70000 crores per year at present. It is not only the money but also loss of productions, higher cost of plant maintenance and risk to human lives are other adverse effects, which are additional burden to national economy. Apart from the economic standpoint it is necessary to minimize corrosion rate by using corrosion inhibitors, a reliable control device and some accurate predictive tools of the corrosion rate are required [13]. Corrosion of mild steel in environments mainly in marine environment was the prime objects in the past recent few years [14]. This type of corrosion is quite extensive and normally proceeds very rapidly to begin with and then levels off to a linear relationship. The corrosion of mild steel in sea water that contains sodium chloride, potassium chloride etc. is under cathodic control [15]. Any action, which affects the rate of delivery of the oxygen needed to depolarize cathodic regions, can have a marked effect on the rate of the attack. Apart from the marine environment the urinal outlets of office and private sectors are made up of mild steel. Due to the presence of urea, sodium chloride, potassium chloride, glycine in urine, there causes an adverse impact of corrosion on the conveying lines and outlets [16]. Although increase in concentration and temperature results in higher corrosivity of the mild steel and lead to reduce lifetime of several technical materials and product conveying lines. Thus there is a need to characterize the outlook of corrosion and to determine the relationship between the degradation of materials and the main parameters on which corrosion rate depends [17]. The study on corrosion of mild steel under different conditions like varying time, temperatures and concentrations are rare. Attempts have been made to study the status of the corrosion of mild steel in different atmospheres. The nature of corrosion of mild steel and the mechanism in the said type of corrosion appear to be interesting. Thus the present study is aimed at finding out the kinetics and corrosion behavior of mild steel in different chemical environments analogous to an industrial belt and also in private sectors, which may help us in understanding the extent of corrosion due to the presence of different chemicals present in urinal or parallel effluents like solutions of urea, sodium chloride, potassium chloride, glycine as a function of time, solution concentration and temperature. The destruction of mild steel follows the first order kinetics [18]. The corrosion rate was analyzed spectrophotometrically and activation energy was determined systematically.

EXPERIMENTAL

Rectangular test specimen (or coupons) of mild steel with 3.75 cm2 and thickness of 0.20 cm were utilized in the present study. The chemical compositions of the test sample are given in Table 1. Surface preparation is basically the cleaning of the surface of exposure of the coupons. 27 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

The coupons were successively polished with coarse emery paper (No. 60, 80) and then into the grinding wheel and belt. Finally, the mild steel sheets were cleaned with acetone. For conducting the experiments, the solutions of urea, sodium chloride, potassium chloride, and glycine of different concentrations, i.e., 0.05 (M), 0.10 (M), 0.15 (M), 0.20 (M) were prepared. The morphological structure of mild steel surface was studied by making polarizing opticalmicrograph of the surface before and after immersion in test solutions at a fixed concentration. The specimens were dried well before examined using an optical microscope (Leica DM-4500). Fe 99.94 S 0.025 Mn 0.01 C 0.012 P 0.005

Table 1: Chemical composition (%) of Mild steel coupon/sheet. Kinetic studies of the sample have been done at three different temperatures and concentrations by weight loss method which is further supported by spectrophotometric method. The spectral measurements have been performed by Shimadzu UV 2100 spectrophotometer. The results in both cases are found to be similar. The rate constants for different systems have been calculated and activation parameters have determined from the temperature dependence of the rate constants using Arrhenius equation. Rate constants are determined by plotting ln a/(a-x) vs time at different temperatures and concentrations and consequently activation energy is determined by plotting ln k vs 1/T.

RESULT AND DISCUSSIONS

Urinal outlets and chemical industries are generally made up of mild steel. The corrosion of pipelines is generally occurred by pitting corrosion, which is investigated through weight loss method, linear polarization resistance (LPR), electrochemical impedance spectroscopy (EIS), electrochemical noise (EN) etc. [19]. The weight loss method is most reliable technique for monitoring the effect of corrosion rate of pipelines which are made up of mild steel. This technique is not affected by solution conductivity. No assumptions, other than uniform surface area, are made in converting weight losses to corrosion rates. It is a time-averaged method, some prior wetness and judgement is required regarding duration of coupon exposures and it can be make confirm also by the spectrophotometric method. The corrosion of mild steel in urinal outlets and chemical industries is a natural phenomenon due to the presence of urea, sodium chloride, potassium chloride, glycine etc. In this study corrosion rate is determined by recording the difference in weight of initial and final weight of the sample (mild steel). This is also called weight loss which comes into the solution [20]. In order to establish the weight loss method or corrosion with time, primarily mild steel sheet has been dipped into solution of urea, sodium chloride, potassium chloride, glycine solution as a function of time which shows that corrosion occurs significantly with time as shown in Figure 1. The loss in weight of mild steel has been determined at 400C and a solution concentration of 0.20 (M). 28 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

0.8 0.7 0.6

Wt. Loss (in gm)

0.5 0.4 0.3 0.2 0.1 0.0 0

Urea NaCl KCl Glycine Nacl+Urea (1:1)

10 15 20 Time (Day)

25

30

Figure 1: Extent of corrosion of mild steel in different solutions of 0.20 (M) at 400C. After watching the meaningful corrosion or dissolution of mild steel sheet, further experiments have been carried out. In order to determine the reaction kinetics, urea solution of different concentrations have been chosen first and rate constant determined at different temperatures. The results are depicted in Figure 2. The result shows that with gradual increase in temperature and solution concentration, rate constant increases and activation energy decreases.

0.05 (M) 0.10 (M) 0.15 (M) 0.20 (M)

0.000048 0.000045

(A)

22

Urea sol at 45 C

(B)

20

k (hr-1)

0.000042 0.000039 0.000036

Ea (kJ)

40 42 44 46

o

18

16

0.000033 48 50

14 0.05 0.10 0.15 0.20

Temperature ( C)

Concentration (M)

Figure 2: (A) Plot of rate constant of corrosion in different concentration urea solutions at 400C, 450C, 500C and (B) variation of activation energy of urea solution at 450C as a function of solution concentration. Similar types of results are observed for the corrosion of mild steel in presence of sodium chloride solution as a function of solution concentration and temperature as shown in Figure 3. With increasing solution concentration corrosion increases which attribute to the fact that oxidation increases in the metal surface. Increase in solution concentration also affects the 29 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

corrosion rate. With increasing temperature, the reversible equilibrium potential becomes more negative which governs the corrosion rate.

0.000040 0.000036 0.000032

k (hr-1)

0.05 (M) 0.10 (M) 0.15 (M) 0.20 (M)

33 30 27

Ea (kJ)

NaCl sol at 45 C

0.000028 0.000024

24 21 18

0.000020 0.000016 40 42 44 46 o Temperature ( C) 48 50

15 12 0.05 0.10 0.15 Concentration (M) 0.20

Figure 3: (A) Plot of rate constant of corrosion in different concentration NaCl solutions at 400C, 450C, 500C and (B) variation of activation energy of NaCl solution at 450C as a function of solution concentration. A similar series of experiments were conducted by the presence of glycine solution and an equimolar mixture (1:1) of urea and sodium chloride. The results depict the corrosion nature of mild steel sheet in presence of corroding environment. The rate of corrosion has been described at four different concentrations which are varied at differing temperatures as seen in Figure 4. With the increasing temperature, corrosion rate increases for the two systems but corrosion rate is somehow faster in presence of glycine due to the increase rate of localized corrosion. Although it is observed that after 8-10 hrs, rate of corrosion decreases due to the formation of film or corroded product formed on the surface of the mild steel sheet.

0.000060 0.000056 0.000052

k (hr-1)

0.05 (M) 0.10 (M) 0.15 (M) 0.20 (M)

0.000085 0.000080 0.000075

k (hr-1)

0.05 (M) 0.10 (M) 0.15 (M) 0.20 (M)

0.000048 0.000044 0.000040 40 42 44 46 o Temperature ( C) 48 50

0.000070 0.000065 0.000060 0.000055 0.000050 40 42 44 46 o Temperature ( C) 48 50

Figure 4: Plot of rate constant of corrosion in different concentration (A) Urea-NaCl solutions (1:1) and (B) glycine solution as a function of solution temperature. Further we have plotted the corrosion rate in terms of activation energy (Ea) of glycine solution in four different concentrated solutions. For this case temperature was taken as constant to 30 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

determine the corrosion rate under certain conditions which reveals that activation energy is less for the higher concentrated solution i.e., high corrosion rate. The results are illustrated in Figure 5. The activation energy increases linearly with the decreasing concentration of solution which further supports the nature of corrosion rate of mild steel in different concentrated solution at a fixed temperature. The result also depict that at 0.20 (M) glycine solution there occurs rapid changes in electrochemical phenomena followed by the formation of corroded product. In Figure 6 we have described the corrosion nature of mild steel at a fixed concentration and temperature in a graphical form. The results (Figure 6) include the corrosion nature of mild steel in different media.

24 21 18

Ea (kJ)

Glycine sol at 45 C

15 12 9 0.05 0.10 0.15 Concentration (M) 0.20

Figure 5: Plot of variation of activation energy (Ea) of glycine solution at 450C as a function of solution concentration.

7 6 5 4 3 2

l a aC aC l KC re a+ G lyc U N N in e l

Extent of corrosion of Mild Steel in different solution 0 (0.2M) at 40 C

k (hr )

-1

Figure 6: Extent of corrosion of mild steel in different solution (0.2 M) at 400C. Microstructural studies for mild steel surface was performed before and after immersing the mild steel coupon at 400C for 4 hrs. The micrographs are described in Figure 7. Clean polished steel surface was immersed to the test solution before exposure as seen in Figure 7(A). 31 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

re

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

Examination of Figure 7(B) revealed that the corrosion attack (uniform and pitting corrosion) becomes more pronounced with time. It is also observed that at high temperature and moderate solution concentration (0.2 M) the pits become very large and full of black corrosion product. These observations can be explained on the basis of additives activity and the extent of its contribution in accelerating metal dissolution due to corrosion [21].

Figure 7: Optical micrograph of mild steel surface (A) before immersion and (B) after immersion for 4 hrs at 400C of glycine solution (0.2 M).

CONCLUSION

Involvement of great number of parameters in corrosion of mild steel, it is very difficult to express particularly but a conclusive remark can be made based on the study carried out and the correlations of test results obtained. Corrosion product films are generated at the periphery of the mild steel sheet due to corrosion under different conditions and the mechanism is taught to be less significant. Based on the experimental results and the performances of corrosion of mild steel in different solutions it is observed that dipping of mild steel into a solution of urea or sodium chloride, the rate constant increases gradually with increasing temperature and concentration whereas activation energy decreases. The results correspond to the increases of corrosion rate of mild steel with the gradual increases of temperature and solution concentration. From the above studies it is observed that the corrosion rate of mild steel is less in case of potassium chloride solution and higher for the glycine solution which reveals that there occurs a rapid electrochemical reaction between the upper surface of mild steel and glycine solution, where activation energy decreases rapidly. In general, when the concentration and temperature of the medium increases, the rate of corrosion increases; which is evident from the data. Thus it can be said that corrosion rates vary from temperature to temperature, from time to time and from concentration to concentration. Equally important, this complexity makes meaningful results from laboratory experiments very difficult to obtain.

32 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

International Journal of Creative Mathematical Sciences & Technology (IJCMST) 1(1): 26-33, 2012

ISSN (P): 2319 7811, ISSN (O): 2319 782X

ACKNOWLEDGEMENT

The authors would like to thank Chemistry Department, NIT Durgapur and CRF, IIT Kharagpur for experimental and laboratory facilities.

REFERENCES

[1]. [2]. [3]. [4]. [5]. [6]. [7]. [8]. [9]. [10]. [11]. [12]. [13]. [14]. [15]. [16]. [17]. [18]. [19]. [20]. [21]. H. Shokry, 2009, Chem. Met. Alloys, 2, 202. R.A. Prabhu et al, 2008, Journal of Corrosion Science, 50 (12), 3356. S. D. Shetty, P. Shetty, H. V. S. Nayak, 2006, J. Serb. Chem. Soc., 71 (10), 1073. H. O. Teeple, 1957, Corrosion, 13, 79. R. Nyborg, 2002, Corrosion, paper no. 02233. B. M. Kermani, A. Morshed, 2004, Corrosion, 59, 659. A. Groysman, N. Erdman, 2000, Corrosion, 56, 1266. K. Otto, L. Bartosiewicz, R. O. Carter III, 1985, Corr. Sci, 25, 117. P. Goel et al, 2007, Inter Sugar J, CIX, 449. K. J. Schaffler et al, 1988, Proc 62nd Annual Congress, S Africa Sugar Technol. Assoc., 9. P. Schweitzer, Corrosion Engineering Handbook, Dekker, 1996. FHWA Report Number: FHWA-RD-01-156. K. Aramaki, T. Shimura, 2006, Corros. Sci., 48, 209. (a) F. O. Aramide, 2009, Leonardo Journal of Sciences, 15, 47, (b) C. C. Nathan, 1973, Corrosion Inhibitors, National Association of Corrosion Engineers (NACE), pp. 279. F. L. LaQue, 1975, "Marine corrosion and prevention", p. 116, John Wiley & Sons. American Society of Mechanical Engineers. ASME B31.4 2006, Pipeline transportation systems for liquid hydrocarbon and other liquids. L. Caceres, T. Vargas, L. Herrera, 2007, Corrosion Science, 49 (8), 3168. P. Matheswaran, A. K. Ramasamy, 2010, E-Journal of Chemistry, 7 (3), 1090. F. Kuang et al, 20110, Recent Patents on Corrosion Science, 2, 34-39. W. B. Wannik et al, 2011, International Journal of Basic & Applied Sciences IJBASIJENS, 11 (6), 75. R. J. Chin, K. Nobe, 1972, J. Electrochem. Soc.119 (11), 1457.

33 Corresponding Author: S. Ghosh, National Institute of Technology, Jamshedpur, India

Das könnte Ihnen auch gefallen

- Computations in Quotient RingsDokument7 SeitenComputations in Quotient RingsInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- HRD Climate Survey in Private Engineering Colleges of OdishaDokument8 SeitenHRD Climate Survey in Private Engineering Colleges of OdishaInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Artificial Neural Network Methodology For Modeling and Resource Use Optimization in Rice YieldDokument7 SeitenArtificial Neural Network Methodology For Modeling and Resource Use Optimization in Rice YieldInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Entrepreneurial India: An Overview of Pre - Post Independence and Contemporary Small-Scale EnterprisesDokument8 SeitenEntrepreneurial India: An Overview of Pre - Post Independence and Contemporary Small-Scale EnterprisesInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- A Review On Transliteration For Indian LanguagesDokument6 SeitenA Review On Transliteration For Indian LanguagesInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Localization of N-Hexadecyl-4 - (P-N, N-Dimethyl Aminostyryl) Pyridinium Bromide in Anionic SDS Micelle: Fluorescence Quenching MethodV2N1-02Dokument9 SeitenLocalization of N-Hexadecyl-4 - (P-N, N-Dimethyl Aminostyryl) Pyridinium Bromide in Anionic SDS Micelle: Fluorescence Quenching MethodV2N1-02International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Effect of Mixed Solvent and Surfactants On The Dissociation Constant of ParacetamolDokument7 SeitenEffect of Mixed Solvent and Surfactants On The Dissociation Constant of ParacetamolInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Jacobi Stability of Different Competition Models K. MishraDokument8 SeitenJacobi Stability of Different Competition Models K. MishraInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Steady-State Statistical Approach To The Prediction of Physico-Chemical Properties of Fly-Ash For Eroded Soil Reclamation and VegetationDokument5 SeitenSteady-State Statistical Approach To The Prediction of Physico-Chemical Properties of Fly-Ash For Eroded Soil Reclamation and VegetationInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Voltage Dip Ride Through of The Double Fed Induction Generator Using Crowbar Protection in A Wind Turbine During Grid FaultDokument9 SeitenVoltage Dip Ride Through of The Double Fed Induction Generator Using Crowbar Protection in A Wind Turbine During Grid FaultInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Analysis of Water Quality Parameters of Ground and Surface Water in Siltara Industrial Area, Raipur, Chhattisgarh, INDIADokument8 SeitenAnalysis of Water Quality Parameters of Ground and Surface Water in Siltara Industrial Area, Raipur, Chhattisgarh, INDIAInternational Journal of Creative Mathematical Sciences and Technology100% (1)

- Localization of N-Hexadecyl-4 - (P-N, N-Dimethyl Aminostyryl) Pyridinium Bromide in Anionic SDS Micelle: Fluorescence Quenching MethodV2N1-02Dokument9 SeitenLocalization of N-Hexadecyl-4 - (P-N, N-Dimethyl Aminostyryl) Pyridinium Bromide in Anionic SDS Micelle: Fluorescence Quenching MethodV2N1-02International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Editorial MemberDokument1 SeiteEditorial MemberInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Table of Content Volume 2/number 1Dokument1 SeiteTable of Content Volume 2/number 1International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Surface Roughness Analysis in Machining of Glass Fiber Reinforced Epoxy Composite With Carbide Tool Using Taguchi A. K. Parida Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 67 - 73Dokument7 SeitenSurface Roughness Analysis in Machining of Glass Fiber Reinforced Epoxy Composite With Carbide Tool Using Taguchi A. K. Parida Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 67 - 73International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Computational Intelligence Is A Gift To Banking Sector" For Its HRD and Talent Management During Modernized Era B. Swain Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 74 - 79Dokument6 SeitenComputational Intelligence Is A Gift To Banking Sector" For Its HRD and Talent Management During Modernized Era B. Swain Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 74 - 79International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Urdhva Triyakbhyam Sutra: Application of Vedic Mathematics For A High Speed Multiplier R. Senapati and B. K. Bhoi Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 59 - 66Dokument8 SeitenUrdhva Triyakbhyam Sutra: Application of Vedic Mathematics For A High Speed Multiplier R. Senapati and B. K. Bhoi Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 59 - 66International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- The Role of Machine Learning Tools On Biological Systems: J. K. Meher, P. Mishra, M.K.Raval and G.N.DashDokument9 SeitenThe Role of Machine Learning Tools On Biological Systems: J. K. Meher, P. Mishra, M.K.Raval and G.N.DashInternational Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Resource Productivity, Return To Scale and Resource Use Efficiency in Rice (Paddy) Farms K. K. Pradhan Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 47 - 58Dokument12 SeitenResource Productivity, Return To Scale and Resource Use Efficiency in Rice (Paddy) Farms K. K. Pradhan Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 47 - 58International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- New Row Maxima Method To Solve Multi-Objective Transportation Problem Under Fuzzy Conditions A. J. Khan and D. K. Das Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 42 - 46Dokument5 SeitenNew Row Maxima Method To Solve Multi-Objective Transportation Problem Under Fuzzy Conditions A. J. Khan and D. K. Das Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 42 - 46International Journal of Creative Mathematical Sciences and Technology100% (1)

- Acid Dissociation Constant of N-Alkyl-Bis(Styryl) Pyridinium Bromide Dyes in Surfactant Solutions S. N. Panda, P. K. Behera and S. B. Seth Volume - 1 , Number - 1 Publication Year: 2012 , Page(s): 1 - 8Dokument8 SeitenAcid Dissociation Constant of N-Alkyl-Bis(Styryl) Pyridinium Bromide Dyes in Surfactant Solutions S. N. Panda, P. K. Behera and S. B. Seth Volume - 1 , Number - 1 Publication Year: 2012 , Page(s): 1 - 8International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Kinetic Study of Carboxylate Ester With Hydroxamate Ions in Cationic Micro-Emulsion System D. K. Pandey, C. S. Meshram and S. Biswas Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 34 - 41Dokument8 SeitenKinetic Study of Carboxylate Ester With Hydroxamate Ions in Cationic Micro-Emulsion System D. K. Pandey, C. S. Meshram and S. Biswas Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 34 - 41International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- Performance Analysis of OFDMDokument9 SeitenPerformance Analysis of OFDMEr. Saumyakanta SarangiNoch keine Bewertungen

- Optimization of Process Parameters in Laser Percussion Drilling B. B. Satapathy, J. Rana, K. P. Maity and S. Biswal Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 17 - 25Dokument9 SeitenOptimization of Process Parameters in Laser Percussion Drilling B. B. Satapathy, J. Rana, K. P. Maity and S. Biswal Volume - 1, Number - 1 Publication Year: 2012, Page(s) : 17 - 25International Journal of Creative Mathematical Sciences and TechnologyNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- MUltis EP 2Dokument1 SeiteMUltis EP 2dnoaisapsNoch keine Bewertungen

- Heraklith CatalogueDokument54 SeitenHeraklith CatalogueN P SrinivasaraoNoch keine Bewertungen

- Acasestudyon Process Condensate Stripperin Ammonia PlantDokument8 SeitenAcasestudyon Process Condensate Stripperin Ammonia Plantdeepak ojhaNoch keine Bewertungen

- Chlorine Dioxide PDFDokument4 SeitenChlorine Dioxide PDFSudhakar Rao100% (1)

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDokument1 SeiteCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımNoch keine Bewertungen

- Materials for shoes, optical lenses and water bottlesDokument3 SeitenMaterials for shoes, optical lenses and water bottlesJpricarioNoch keine Bewertungen

- Automatic Wall Painting MachineDokument9 SeitenAutomatic Wall Painting MachineaalekhNoch keine Bewertungen

- DPW G2 Multi Pole Spec SheetDokument2 SeitenDPW G2 Multi Pole Spec SheetlNoch keine Bewertungen

- Hapter: Occurrence of Noble GasesDokument10 SeitenHapter: Occurrence of Noble GasesSandipan SahaNoch keine Bewertungen

- Sample Problem Mod 3 CPCDokument6 SeitenSample Problem Mod 3 CPCAman PratikNoch keine Bewertungen

- Chemical Formulae ExplainedDokument47 SeitenChemical Formulae ExplainedZheng JoeyNoch keine Bewertungen

- Bronze Castings For Bridges and TurntablesDokument4 SeitenBronze Castings For Bridges and TurntablesmatiullahNoch keine Bewertungen

- GKSDokument8 SeitenGKSDota NgNoch keine Bewertungen

- Chemical Proces-WPS OfficeDokument58 SeitenChemical Proces-WPS OfficeMuhammad Ahmed50% (2)

- Conectores y Accesorios Hoke-GyrolokDokument56 SeitenConectores y Accesorios Hoke-GyrolokJordan YPNoch keine Bewertungen

- Housekeeping & Accommodation StudiesDokument15 SeitenHousekeeping & Accommodation StudiesCaleb MukaviNoch keine Bewertungen

- Closures Technical Manual 14nov2008Dokument37 SeitenClosures Technical Manual 14nov2008jjescudero100% (1)

- Pds Tial m80Dokument2 SeitenPds Tial m80Yan FerizalNoch keine Bewertungen

- Brosur Globond Alumunium Composite PanelDokument8 SeitenBrosur Globond Alumunium Composite PanelDede SubhanNoch keine Bewertungen

- J Est 2018 11 027Dokument14 SeitenJ Est 2018 11 027Hiraya HaeldrichNoch keine Bewertungen

- k3) Luxatherm5600 7954Dokument2 Seitenk3) Luxatherm5600 7954Syed FaridNoch keine Bewertungen

- CPVC - Cat VIKING Conexiones UL FM BlazemasterDokument28 SeitenCPVC - Cat VIKING Conexiones UL FM BlazemasterpvaldezmtzNoch keine Bewertungen

- X17CrNi16 2Dokument2 SeitenX17CrNi16 2madodandembeNoch keine Bewertungen

- 04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Dokument420 Seiten04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Marin IonutNoch keine Bewertungen

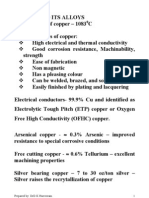

- Copper and It's AlloysDokument5 SeitenCopper and It's AlloysReza MortazaviNoch keine Bewertungen

- Estimation of Undrained Shear Strength For Peat Using CPTDokument4 SeitenEstimation of Undrained Shear Strength For Peat Using CPTLaura RossNoch keine Bewertungen

- 08 Askeland Chap PDFDokument12 Seiten08 Askeland Chap PDFMaiefnbNoch keine Bewertungen

- Design of Biogas DigestersDokument22 SeitenDesign of Biogas DigestersSharath Chandra100% (5)

- Feng 2020Dokument9 SeitenFeng 2020Gerapi EraNoch keine Bewertungen

- Microencapsulation in Textiles Provides Health and Performance BenefitsDokument2 SeitenMicroencapsulation in Textiles Provides Health and Performance BenefitsAswathy UnnikrishnanNoch keine Bewertungen