Beruflich Dokumente

Kultur Dokumente

EECD0107

Hochgeladen von

Miguel ChaconOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EECD0107

Hochgeladen von

Miguel ChaconCopyright:

Verfügbare Formate

1

SERVICE BULLETIN

FUEL INJECTION PUMP

TECHNICAL HINT

DENSO AUTHORIZED ECD SERVICE DEALER ONLY

ECD 01-07 April, 2001

SUBJECT: ECD-V4 Pump Adjustment Instruction with DST-1

This bulletin provides the new procedure for adjusting the ECD-V4 with using DST-1. Refer to the respective Test Specification for confirmation when adjuting pumps, though DST-1 displays specifications on the screen.

Table of Contents

1. Adjustment Preparation 2. New Pump Adjustment Procedure with DST-1 2 2

QC1113

SERVICE DEPARTMENT 0104-IT-100 Printed in Japan QAANC-02

1. Adjustment Preparation

(1) Connect DST-1 to the conventional adjustment system with ECD controller on the bench.

DST-1

Back of ECD controller

QC1114

2. New Pump Adjustment Procedure with DST-1

(1) Turn on DST-1 and confirm that the display shows appropriate application & version or not. After entering the password to make DST-1 active for the following adjustment procedures, press the enter key to proceed.

QC1115

(2) Follow the message and turn on ECD controller.

QC1116

(3) Select the system application (ECD-V4) to be calibrated.

QC1117

(4) Select the part number of injection pump to be calibrated. ( In this case, the following specifications are all for 098000-0300.)

QC1118

(5) Confirm the part number again and press + key if its OK.

QC1119

(6) Select 1.PUMP ADJUST. NOTE: At this moment, ROM cannot be writable due to no calibration. NOTE: 3.PUMP ROM DATA LIST is directly displayed the data in the ROM.

This circle means Not writable

QC1120

2-1.Pump Adjustment

The test condition is displayed as SETUP CONDITION, and press enter key after confirming each item.

QC1121

2-1-1.BASIC CHECK

(1) Select 1.BASIC CHECK.

QC1122

(2) The calibration starts at this procedure RUNNING without referring to the conventional test specifications. Follow all procedures to complete the calibration.

QC1123

(3) Follow the displayed running points.

QC1124

(4) The detail condition is displayed at each point.

QC1125

QC1126

(5) The display shows the completion after the running. Proceed to the next by pressing + key.

QC1127

(6) Press enter key to check fuel temperature sensor displayed as 2.FUEL TEMP. NOTE: The mark * means the completion of the procedure. It always appear every time when completing each calibration procedure.

QC1128

(7) Refer to the condition for the sensor check. Press enter key and check the resistance.

QC1129

QC1130

(8) Press + key if its OK and proceed to the next.

QC1131

(9) Check the NE sensor in the same way as former checkings.

QC1132

QC1133

QC1134

(10) Press + key if its OK and proceed to the next.

QC1135

(11) Check the internal pressure.

QC1136

QC1137

QC1138

(12) Press + key if its OK and proceed to the next.

QC1139

(13) Check the overflow quantity.

QC1140

QC1141

QC1142

QC1143

(14) Press return key when completing all checkings of BASIC CHECK as shown in the figure.

QC1144

QC1145

10

2-1-2.IN COMING Q CHECK

(1) Select 2.IN COMING Q CHECK. This checking should be done for the confirmation of original specifications when it comes.

QC1146

(2) Confirm that TCV should be disconnected as display shows

QC1147

(3) Follow each check points as display shows.

QC1148

QC1149

11

(4) Check all points as display shows.

QC1150

(5) After finishing all points, press + key and proceed to the next ( In this case, check points are 14 as shown in the display.).

QC1151

2-1-3.CAM ANGLE

(1) Press enter key to adjust the cam angle along the display guidance.

QC1152

QC1153

12

(2) Confirm the conditions for No.1 Cam Angle Preset & No.2 Cam Angle Adjustment.

QC1154

(3) Check the cam angle preset. If its out of the specification, change the command value with using + & - keys. NOTE: At first, the displayed command value is the original one of the pump. + key increases the command value and - key decreases it.

QC1155

(4) Attach pressure sensor.

QC1156

(5) DST-1 checks the cam angle automatically. If the display doesnt show OK but NG, return to the cam angle preset procedure and adjust the command value again.

QC1157

13

(6) Disconnect the pressure sensor not to damage.

QC1158

(7) Press + key if its OK and proceed to the next.

QC1159

Reference: When both cam angle preset and cam angle adjustment are completed, the mark * appears at the marked position on the display.

QC1160

2-1-4.Q ADJUST

(1) Select 4.Q ADJUST.

QC1161

14

(2) Disconnect TCV connector.

QC1162

(3) The first adjustment point and the following points are displayed. And, press enter key.

QC1163

(4) Check the delivery quantity. If its out of the specification, change the command value with using + & - keys.

QC1164

(5) The following points are also adjusted in the same way as the first point.

QC1165

15

(6) Confirm that the delivery quantity is OK or not at the check points as shown in the figure.

QC1166

(7) Press + key if its OK and proceed to the next.

QC1167

2-1-5.TIMER ADJUST

(1) Select 5.TIMER ADJUST.

QC1168

(2) Connect TCV connector.

QC1169

16

(3) The first adjustment point and the following points are displayed. And, press enter key.

QC1170

(4) Initialize the DST-1 & ECD controller before the adjustment. Wait for a while to stabilize the pump angle ( cam angle).

QC1171

(5) Confirm that the pump angle ( cam angle ) is within the specification.

QC1172

(6) Stop the pump before proceeding the next point.

QC1173

17

(7) Proceed to the next point according to the display.

QC1174

QC1175

(8) Continue the initializing and confirming alternately along displayed procedures.

QC1176

(9) After checking all points, press + key if its OK.

QC1177

18

(10) Press return key when completing all checkings including TIMER ADJUST as shown in the right figure.

QC1178

2-2.Write Pump ROM Data

(1) After verifying all the adjustment points, select WRITE PUMP ROM DATA in the menu.

QC1179

(2) Select 1.WRITE RECORDING DATA.. NOTE: 2.WRITE TO NEW PUMP ROM is selected when copying ROM data simply.

QC1180

(3) Re-confirm to write adjusted data in the ROM.

QC1181

19

QC1182

(4) The completion message of writing the data in the ROM appears.

QC1183

Das könnte Ihnen auch gefallen

- Control Elec Ecd-V3Dokument21 SeitenControl Elec Ecd-V3Fabian Henao Calle100% (1)

- EDokument34 SeitenEEdinson Ariel Chavarro Quintero100% (1)

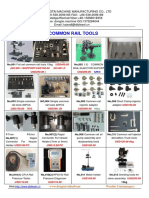

- Nantai Catalog NewDokument30 SeitenNantai Catalog Newspalomos100% (1)

- Bosch Inline Piezo Injector Delivery PlanDokument9 SeitenBosch Inline Piezo Injector Delivery PlandieseldvNoch keine Bewertungen

- Catalogue 2016 EngDokument256 SeitenCatalogue 2016 Engdiagnopro100% (2)

- Lucas Diesel Systems Powering Ahead GloballyDokument44 SeitenLucas Diesel Systems Powering Ahead GloballyEphrem Michael100% (1)

- Modifikacii HP 3Dokument5 SeitenModifikacii HP 3pankituna5487Noch keine Bewertungen

- SABRE BASE OPTIONS AND PARTSDokument10 SeitenSABRE BASE OPTIONS AND PARTSHong Seok ChoiNoch keine Bewertungen

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDokument63 SeitenERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNoch keine Bewertungen

- lt1000d6 PDFDokument3 Seitenlt1000d6 PDFJo Ferry0% (1)

- Pe and Tics Type Injection Pump Connector Part Numbers For North AmericaDokument9 SeitenPe and Tics Type Injection Pump Connector Part Numbers For North AmericaSubhojit Samonta100% (1)

- Ricambi DensoDokument10 SeitenRicambi DensoSprinter Transit Van100% (1)

- China Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Dokument4 SeitenChina Factory Dlla149p1515 Nozzle Fit For Common Rail Volvo Fuel Injector 0445110259Alen HuangNoch keine Bewertungen

- Manual Diesel Test BenchDokument18 SeitenManual Diesel Test BenchMelchor EstradaNoch keine Bewertungen

- SI471Dokument2 SeitenSI471Subhojit SamontaNoch keine Bewertungen

- Injector Numbers and Spec-1Dokument1 SeiteInjector Numbers and Spec-1Michael RauschNoch keine Bewertungen

- 740 4010Dokument6 Seiten740 4010Miguel ChaconNoch keine Bewertungen

- History and Working of Unit Injector SystemDokument26 SeitenHistory and Working of Unit Injector SystemKumar ByesNoch keine Bewertungen

- Denso Control Valve & Rod 2016Dokument4 SeitenDenso Control Valve & Rod 2016Екатерина КалашниковаNoch keine Bewertungen

- TICS Pump Electrical Part Resistance For HINODokument35 SeitenTICS Pump Electrical Part Resistance For HINOBala Equal BalanceNoch keine Bewertungen

- EE4760Dokument2 SeitenEE4760OFFICE DANACNoch keine Bewertungen

- Service Bulletin: Fuel Injection PumpDokument28 SeitenService Bulletin: Fuel Injection PumpKrunoslavNoch keine Bewertungen

- Plunger Element 090150-5681Dokument1 SeitePlunger Element 090150-5681dieselinjectionNoch keine Bewertungen

- Bosch ESI (Tronic) 1Q.2015 News PDFDokument2 SeitenBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelNoch keine Bewertungen

- Fuel Injection Pump Technical Hint for Land CruiserDokument45 SeitenFuel Injection Pump Technical Hint for Land CruiserВячеслав ГлушакNoch keine Bewertungen

- 2 SP NHStampDokument32 Seiten2 SP NHStampEdinson Ariel Chavarro Quintero100% (2)

- Moocoowooodoo 987Dokument32 SeitenMoocoowooodoo 987scribbedd55Noch keine Bewertungen

- Engine Spect MitsubishiDokument4 SeitenEngine Spect MitsubishiFalgon IslamNoch keine Bewertungen

- ESI 2.0 Pricing OverviewDokument5 SeitenESI 2.0 Pricing OverviewAmr MohamedNoch keine Bewertungen

- Bosch EP test values for diesel fuel injection equipmentDokument3 SeitenBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- SOLENOIDS Publication PDFDokument3 SeitenSOLENOIDS Publication PDFalcoholahmedNoch keine Bewertungen

- vp44 Pump Detail Schematic PDF FreeDokument7 Seitenvp44 Pump Detail Schematic PDF Freepablo pérezNoch keine Bewertungen

- Makalah Wirausahawan SuksesDokument6 SeitenMakalah Wirausahawan SuksesSurya IrawanNoch keine Bewertungen

- 2.5HP 50 Litre Belt Drive Air Compressor: Instruction ManualDokument13 Seiten2.5HP 50 Litre Belt Drive Air Compressor: Instruction ManualmogsiNoch keine Bewertungen

- Despiece CrinDokument7 SeitenDespiece Crinjhonatan sanmartinNoch keine Bewertungen

- Adjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2Dokument11 SeitenAdjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2duongbk24 luu quang duongNoch keine Bewertungen

- FLAG Common Rail Catalog 2014 PDFDokument40 SeitenFLAG Common Rail Catalog 2014 PDFMiljkovic Nesa100% (1)

- 00000889Dokument182 Seiten00000889Владимир ШтыкNoch keine Bewertungen

- Cat Sleeve Metering - April 2010 PDFDokument32 SeitenCat Sleeve Metering - April 2010 PDFMas Inyeccion Electronica100% (1)

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDokument10 SeitenPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicNoch keine Bewertungen

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Dokument4 SeitenS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовNoch keine Bewertungen

- Fit For The Future:: Everything For Diesel ServiceDokument68 SeitenFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- CZ 2012 2013 DieselDokument14 SeitenCZ 2012 2013 DieselSoeAyeNoch keine Bewertungen

- Test BenchesDokument7 SeitenTest BenchesAnderson LondonNoch keine Bewertungen

- Service Bulletin: Fuel Injection Pump Tightening Torque ChangeDokument2 SeitenService Bulletin: Fuel Injection Pump Tightening Torque ChangeDenisEcheverri100% (1)

- Jaggi Crdi ReadingDokument5 SeitenJaggi Crdi ReadingjassNoch keine Bewertungen

- Dpico: Inj. Pump Calibration DataDokument6 SeitenDpico: Inj. Pump Calibration DataGiovaniBalzaniNoch keine Bewertungen

- CR Tools and Spare Parts NEWDokument21 SeitenCR Tools and Spare Parts NEWeber granadosNoch keine Bewertungen

- CRT075-EN BOSCH Third Measuring Tool 9pcs KitDokument8 SeitenCRT075-EN BOSCH Third Measuring Tool 9pcs KitLuc Mutombo MukuluNoch keine Bewertungen

- 093400-5350 Mitsubishi PDFDokument2 Seiten093400-5350 Mitsubishi PDFBaytolgaNoch keine Bewertungen

- EPS100Dokument4 SeitenEPS100basilio obregon lopezNoch keine Bewertungen

- DIESEL FUEL PUMPS, INJECTORS AND ACCESSORIES GUIDEDokument82 SeitenDIESEL FUEL PUMPS, INJECTORS AND ACCESSORIES GUIDEJuan Gabriel OchoaNoch keine Bewertungen

- HL070 (En)Dokument104 SeitenHL070 (En)Ryo ChannelNoch keine Bewertungen

- Worshop Manual DPS Fuel Injection Pum PDFDokument139 SeitenWorshop Manual DPS Fuel Injection Pum PDFDaniel Falcones100% (1)

- Dokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualDokument117 SeitenDokumen - Tips - Bomba Ve VRZ Ee14e 11162 VRZ Service ManualAntonio GasparNoch keine Bewertungen

- DTC P0011Dokument7 SeitenDTC P0011Internal88Noch keine Bewertungen

- Commissioning Procedure of Boiler Ignition SystemDokument7 SeitenCommissioning Procedure of Boiler Ignition SystemJ Bagien100% (1)

- Engagement Pressure For The Transmission Clutch - CalibrateDokument8 SeitenEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNoch keine Bewertungen

- Bell Prover Gas Meter Test Bench Operation GuideDokument24 SeitenBell Prover Gas Meter Test Bench Operation GuideArya EndaNoch keine Bewertungen

- DTC P0011 Ivt ControlDokument4 SeitenDTC P0011 Ivt ControlRonald MoonNoch keine Bewertungen

- Vo Ling Micro MetroDokument1 SeiteVo Ling Micro MetroMiguel ChaconNoch keine Bewertungen

- DITEX Catalogue2005 PDFDokument193 SeitenDITEX Catalogue2005 PDFMiguel ChaconNoch keine Bewertungen

- Evinrude Johnson Gale ID ChartDokument80 SeitenEvinrude Johnson Gale ID ChartMichaelNoch keine Bewertungen

- Wingle Engine ServicemanualDokument196 SeitenWingle Engine ServicemanualJoch Caso Alvariño85% (13)

- Calibrating Nozzle Holder AssyDokument1 SeiteCalibrating Nozzle Holder AssyMiguel ChaconNoch keine Bewertungen

- Great Wall Service ManualDokument484 SeitenGreat Wall Service ManualJeison Isaza100% (1)

- Aplic Bombas ChinasDokument2 SeitenAplic Bombas ChinasMiguel ChaconNoch keine Bewertungen

- Torque Specifications Chart for Acura, Alfa Romeo, and Allis Chalmers EnginesDokument124 SeitenTorque Specifications Chart for Acura, Alfa Romeo, and Allis Chalmers EnginesZack Leon85% (13)

- Great Wall Service ManualDokument484 SeitenGreat Wall Service ManualJeison Isaza100% (1)

- Kubota Manual 9Y011-02153 PDFDokument124 SeitenKubota Manual 9Y011-02153 PDFMiguel Chacon100% (2)

- Mini 05 03M V3 PDFDokument75 SeitenMini 05 03M V3 PDFMiguel Chacon100% (1)

- 58a447service ManualDokument132 Seiten58a447service ManualMiguel Chacon100% (2)

- Stanadyne Inyectores y ToberasDokument70 SeitenStanadyne Inyectores y ToberasMas Inyeccion Electronica100% (1)

- Service Manual Common Rail System Isuzu 4HK1 6HK1Dokument48 SeitenService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- CR Calibration GasketsDokument4 SeitenCR Calibration GasketsMiguel ChaconNoch keine Bewertungen

- Service Manual Common Rail System (CRS) - DensoDokument134 SeitenService Manual Common Rail System (CRS) - DensoThang Tong86% (7)

- Owners Manual: AppendixDokument84 SeitenOwners Manual: AppendixMiguel ChaconNoch keine Bewertungen

- PDFDokument47 SeitenPDFMiguel Chacon100% (2)

- PDFDokument47 SeitenPDFMiguel Chacon100% (2)

- L'Orange Assembling and Test Stand Combines 3 FunctionsDokument6 SeitenL'Orange Assembling and Test Stand Combines 3 FunctionsMiguel ChaconNoch keine Bewertungen

- Evpump PDFDokument34 SeitenEvpump PDFMiguel ChaconNoch keine Bewertungen

- Daewoo Korando Service ManualDokument1.462 SeitenDaewoo Korando Service Manualzambila4088% (17)

- Kamaz Civil VehiclesDokument84 SeitenKamaz Civil VehiclesTudor Costin100% (1)

- L'Orange Assembling and Test Stand Combines 3 FunctionsDokument6 SeitenL'Orange Assembling and Test Stand Combines 3 FunctionsMiguel ChaconNoch keine Bewertungen

- PDFDokument16 SeitenPDFMiguel Chacon100% (1)

- Supplier Self Assessment Productive Material PDFDokument2 SeitenSupplier Self Assessment Productive Material PDFMiguel ChaconNoch keine Bewertungen

- 2010 NEXIQ Catalog PDFDokument12 Seiten2010 NEXIQ Catalog PDFMiguel ChaconNoch keine Bewertungen

- M2 2007 Electrical Body Builder Manual Rev NewDokument20 SeitenM2 2007 Electrical Body Builder Manual Rev NewRoger Lechado Garcia93% (29)

- Inyeccion CombustibleDokument38 SeitenInyeccion CombustiblehenryvilchezvalenciaNoch keine Bewertungen

- TE30 Data Sheet en 2016-03Dokument4 SeitenTE30 Data Sheet en 2016-03Christian AguirreNoch keine Bewertungen

- On Teaching Digital Image Processing With MATLAB: January 2014Dokument10 SeitenOn Teaching Digital Image Processing With MATLAB: January 2014Ghalia HayetNoch keine Bewertungen

- Example Curriculum VitaeDokument4 SeitenExample Curriculum VitaeGugun NugrahaNoch keine Bewertungen

- HP LJ P2035 P2055 PartslistDokument21 SeitenHP LJ P2035 P2055 PartslistalbathorresNoch keine Bewertungen

- Digital Design Through Verilog HDLDokument4 SeitenDigital Design Through Verilog HDLmukesh_sonuNoch keine Bewertungen

- Wesern Digital RaptorDokument2 SeitenWesern Digital RaptorcedlanioNoch keine Bewertungen

- DevOps с Laravel 3. KubernetesDokument92 SeitenDevOps с Laravel 3. Kubernetesagris.markusNoch keine Bewertungen

- Storage Area NetworkDokument109 SeitenStorage Area Networksunil kumarNoch keine Bewertungen

- For loops guide: Learn Python loopingDokument10 SeitenFor loops guide: Learn Python loopingDJEFOUO FOUODJI ANGE MAGLOIRENoch keine Bewertungen

- Sharepoint Quick Reference-CheatsheetDokument3 SeitenSharepoint Quick Reference-Cheatsheethabeeb_matrixNoch keine Bewertungen

- QlinkDokument37 SeitenQlinkAndreia RochaNoch keine Bewertungen

- Diagnostics For Dell Optiplex 780Dokument7 SeitenDiagnostics For Dell Optiplex 780Andima Jeff HardyNoch keine Bewertungen

- Software ProcessDokument25 SeitenSoftware ProcessHarsha VardhanNoch keine Bewertungen

- The Best Open Source Project Management Tool Zentao 2020Dokument4 SeitenThe Best Open Source Project Management Tool Zentao 2020wajid hussainNoch keine Bewertungen

- Grillage Analogy MethodDokument43 SeitenGrillage Analogy Methodkhx2Noch keine Bewertungen

- TPD2 Catalog 86C0Dokument4 SeitenTPD2 Catalog 86C0Manuel VieiraNoch keine Bewertungen

- Log File Analysis of VoIP Application on AndroidDokument809 SeitenLog File Analysis of VoIP Application on AndroidLove KoNoch keine Bewertungen

- NVIDIA DGX Systems Avitas GE AI InfographicDokument1 SeiteNVIDIA DGX Systems Avitas GE AI InfographicAbraham LamaNoch keine Bewertungen

- Quotations Are Commonly Printed As A Means of Inspiration and To Invoke Philosophical Thoughts From The ReaderDokument24 SeitenQuotations Are Commonly Printed As A Means of Inspiration and To Invoke Philosophical Thoughts From The ReaderC SNoch keine Bewertungen

- Critical Path Method (CPM) in Project ManagementDokument27 SeitenCritical Path Method (CPM) in Project ManagementendhaNoch keine Bewertungen

- An Online Mobile Shopping Application For Uchumi Supermarket in UgandaDokument9 SeitenAn Online Mobile Shopping Application For Uchumi Supermarket in UgandaKIU PUBLICATION AND EXTENSIONNoch keine Bewertungen

- ConvertersDokument32 SeitenConvertersJeff's SKiNoch keine Bewertungen

- Computer Network Q - A Part-1Dokument7 SeitenComputer Network Q - A Part-1Avi DahiyaNoch keine Bewertungen

- 312 50 DemoDokument9 Seiten312 50 DemoTomasVileikisNoch keine Bewertungen

- Datasheet MX 880Dokument3 SeitenDatasheet MX 880jorge_chavez01Noch keine Bewertungen

- HRMS Comparison GuideDokument160 SeitenHRMS Comparison GuideSudheer Reddy ReddypalliNoch keine Bewertungen

- ARMS TSA Brochure Final 4Dokument2 SeitenARMS TSA Brochure Final 4Hugo AlemanNoch keine Bewertungen

- Novakovic Srbi I TurciDokument415 SeitenNovakovic Srbi I TurciBorisSubNoch keine Bewertungen

- SMR Online Users Guide PDFDokument48 SeitenSMR Online Users Guide PDFniku100% (1)

- r05321204 Data Warehousing and Data MiningDokument5 Seitenr05321204 Data Warehousing and Data MiningSRINIVASA RAO GANTANoch keine Bewertungen