Beruflich Dokumente

Kultur Dokumente

vr1047 Er 2

Hochgeladen von

Mike StewartOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

vr1047 Er 2

Hochgeladen von

Mike StewartCopyright:

Verfügbare Formate

The exhaust fans and open windows should be used whenever bathing, dishwashing, cooking, or similar activities are

occurring. Excessive condensation can damage interior surfaces and provide conditions for mould or other fungal colonies to propagate. Some mould or fungal species are toxic to some humans. It is beyond MAEs area of expertise to comment on mould or fungal colonies. During the course of our interior inspections we noted that all of the units that were inspected have been provided with bathroom and kitchen fans. 4.5 WALLS

For the purposes of this investigation, wall assembles have been categorized into thee types one below grade wall assembly, and two above grade wall assemblies: stucco on steel stud framing and mass concrete walls. 4.5.1 Stucco on Steel Stud Framing

The components that make up the stucco wall assembly are listed and shown schematically in Figure 1 below. The schematic detail below has been reproduced from the Architectural drawings provided for our review.

Figure 1 - Stucco Wall Assembly Plan View

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 14

09/30/2011

The stucco walls assemblies can be described as face-sealed assemblies. The outer face of the stucco is the primary defense against water ingress with no provision to handle any moisture ingress once it occurs. Historically, face sealed wall assemblies have not performed well in our climate. The stucco appears to be a pebble-dash stucco and dates back to the original construction period. It should be noted that the Construction Drawings do not show the presence of building paper or a sheathing membrane, which is typical for this type of wall assembly. The Construction Drawings indicate that the original sheathing is a rigid mineral sheathing. While performing the invasive testing, plywood sheathing was observed at many locations. Batt insulation along with poly vapour barrier were also typically observed in the exploratory openings. The paragraphs below describe some of the components that are found in the wall assemblies followed by descriptions of the expected behavior of the above grade walls. Wall Sheathing The sheathing provides backing for stucco attachment and also provides lateral support for the steel studs. If the wall sheathing is exposed to moisture for an extended period of time it will deteriorate. Furthermore, moisture may be able to travel through the sheathing to the underlying structural components, causing them to deteriorate. If the sheathing is allowed to deteriorate, the structural capacity of the steel studs, and the fasteners that connect the stucco to the studs, can be compromised. A reduction in the structural capacity of the studs and/or fasteners would compromise public safety. During the course of our investigation we observed no evidence to suggest that structural integrity had been compromised. Steel Studs The steel studs form part of the buildings exterior walls and are not designed to carry building loads. The studs must transfer gravity loads from the weight of the wall assemblies along with wind and seismic loads. Batt Insulation The insulation reduces heat flow between the inner and outer sides of the wall assembly. The batt insulations effectiveness would be reduced if it becomes water damaged.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 15

09/30/2011

Vapour Barrier The vapour barrier resists the movement of water vapour through the assembly. If warm water vapour is allowed to come into contact with colder components, such as the inside face of the exterior sheathing, condensation could occur, which may allow liquid water to accumulate within the hidden sections of the wall assembly. Vapour barriers are generally not required within uninsulated wall assemblies that enclose unheated spaces. Expected Behaviour Stucco Walls This is the walls exterior surface and its primary defense against water infiltration. Wire mesh is embedded into the stucco and is mechanically fastened, through the exterior sheathing, to the studs. The mesh fasteners must be strong enough to resist vertical, outward, and horizontal forces that may be imparted on the wall. The mesh performs two primary functions: it controls stucco cracking and it connects the stucco to the buildings structural components. Stucco wall assemblies as described above are commonly referred to as a face sealed assembly. In a face sealed assembly, resistance to water penetration is controlled by the continuity of the outer cladding. This system typically incorporates limited flashings not to direct water out of the wall assembly but rather away from the assembly. The disadvantages of these assemblies are: In a face sealed assembly, in order to effectively resist water infiltration, the outer cladding and penetrations through the outer cladding, such as windows or similar openings, must remain watertight. In practice, complete water tightness of the outer cladding is difficult to achieve. In a face sealed assembly, the addition of flashings is meant to assist in directing water away from the wall assembly. In practice, however, the lack of a drainage plane behind the stucco cladding traps water between the back of the cladding and the sheathing membrane. As such, moisture behind the cladding is unable to flow down to the flashings to be directed out of the wall assembly.

The behavior of a typical face sealed stucco clad wall is described below: The stucco, acting like a sponge, has the ability to absorb a certain amount of water. If the amount of water that the stucco must absorb exceeds its capacity, the excess water may be driven inward through cracks or other breaches in the cladding. The driving force can be supplied by wind, unbalanced inward vapour pressures that can occur if the exterior face of the wall heats up from solar energy, or from other unbalanced air pressures. Once the moisture has migrated through the breaches to the stuccos inner surface, wind or other unbalanced pressures can

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 16

09/30/2011

continue to drive the moisture to the sheathing. The exterior sheathing has a limited a capacity to resist water damage. If the stucco stops being wetted before its capacity to absorb water is reached, a drying process begins whereby the stucco may be able to dry to the exterior and water ingress may desist. This system can work provided the drying process is long enough and the wetting process is short enough. The likelihood of water damage to vulnerable components will increase if a long wet winter is followed by an unusually wet or cloudy summer. Stucco, like other cementitious building materials, expands and contracts with changing ambient temperatures and humidity levels. If appropriate allowances are not made for the expansion/contraction forces, the stucco will crack. If the cracks are deep enough, the cracks will breach the cladding. The expansion/contraction forces are usually accounted for by providing appropriately spaced and detailed control joints. The control joints may be located beside window or door openings. The British Columbia Wall and Ceiling Association, in the 1993 edition of its Stucco Resource Guide, recommends that On walls, where the length of stucco surface exceeds 4,500 mm provide vertical control joints not more than 3,000 mm on centre. It is worthy of note that the 1997 edition of the Stucco Resource Guide recommends that joints be installed in framed and sheathed construction so as to create stucco panels of approximately 14 m2 to 17 m2 in as square a configuration as possible... Control joints should be wide enough to accommodate the expected movement in the adjacent stucco panels. The joints should be flexible enough to accommodate the expected expansion and contraction of adjacent panels. The recommended style of control joint is usually w shaped and accommodates movement in the materials while being fully embedded in stucco and limiting water ingress. 4.5.2 Mass Concrete Wall

The components that make up the concrete wall assembly are listed and shown schematically in Figure 2 on the following page. The schematic detail below has been reproduced from the Architectural drawings provided for our review.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 17

09/30/2011

Figure 2 Mass Concrete Wall Assembly Plan View The exposed concrete walls at Chelsea Terrace have an exterior coating applied to provide protection from the elements. For descriptions of remaining wall assembly components, refer to the descriptions in Section 4.5.1. Expected Behaviour Concrete Walls If the concrete has not been coated with elastomeric or similar sealer, it will absorb moisture like a sponge. Wind can drive absorbed moisture inward or outward, depending on its direction. Heat from the sun can remove the moisture from the concrete through an evaporation process. Mass concrete walls are generally considered to be robust especially if they are properly coated. Moisture absorption, within reason, is not generally thought to be detrimental to the structural capacity of the walls provided the exposed face of the concrete is maintained in good condition. 4.5.2 Below Grade Walls

The below grade wall assemblies enclose the parking garage and some areas of the suites. The Architectural Drawings do not indicate how the below grade walls resist water ingress; however, typical below grade wall assemblies have some form of dampproofing.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 18

09/30/2011

A thin bituminous damp-proof membrane appears be adhered to the exterior face of most the concrete walls at Chelsea Terrace. The presence of a damp-proof membrane was verified at most exposed walls, and some areas appear to have had more recent repairs performed. If present, the membrane provides the primary resistance to water infiltration. According to the Construction Drawings, a drainage pipe is located below the wall to collect ground water and transport it away from the building. In the event that there is no damp-proof membrane or that it becomes overwhelmed, the concrete wall has the capacity to store a certain amount of moisture within its thickness before allowing water to penetrate to the interior. Below grade concrete wall assemblies can perform well provided that: The drainpipes do not become clogged. Clogged drainpipes could allow a build-up of hydrostatic pressure; The damp-proofing membrane is present and does not break down. Like all building components, the membrane has a finite reliable life expectancy. In the absence information regarding the existing membrane, it is difficult to estimate its reliable life expectancy. A broad estimate of the reliable service of the membrane would be 20 to 30 years; The interface between the above grade framing components and the below grade concrete wall remains watertight.

4.6 4.6.1

WINDOWS AND DOORS Windows

The exterior windows at Chelsea Terrace are double glazed, aluminum-framed assemblies. The operable windows are predominantly sliders and some are hinged awning style. Good quality aluminum windows should provide approximately 20 years of reliable service. Notation on the window frames indicates that they were manufactured in 1981, thus, at 30 years of age, they have reached their expected reliable life span. Aluminum window frames are generally assembled from four separate extruded aluminum components two jamb components, one head component and one sill component. The four components are connected together at the four corners of the assembly and sealed against water ingress with small joint sealant (caulking). Eventually, the small joint sealant breaks down and is no longer effective.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 19

09/30/2011

Window frames are generally flush with the exterior face of adjacent walls and are typically surrounded by continuous stucco cladding. Photo 4 shows a typical exterior window/wall interface. Head flashing has been installed at window heads, however the lack of end dams has significantly reduced the effectiveness of the head flashing. Windowsill flashing was not present at the building. A good portion of the windows are located directly beneath roof/balcony overhangs, which provides the windows with protection from bulk water penetration.

Photo 4 Typical windowsill/ wall interface.

Photo 5 Typical Window head and head flashing detail.

The Architectural Drawings do not indicate how window assemblies interface with adjacent wall assemblies. Sealant has generally been used at the window-to-wall interfaces to provide protection against air and water infiltration. The condition of the sealant ranged from fair to poor. Deteriorated sealant will increase the likelihood of water infiltration and allow air to pass through the window-to-wall interfaces. Water ingress can deteriorate interior finishes and structural components, while the increased air flow will: Increase the likelihood of water infiltration; Reduce the buildings energy efficiency; Increase the likelihood of condensation on the inside face of the window assemblies, and; Increase the cold drafts in the vicinity of windows.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 20

09/30/2011

4.6.2

Doors

Suspended balconies and patios are accessed via aluminum framed sliding glass doors. The majority of the sliding glass doors are located beneath roof or balcony overhangs and are thus protected from wind driven rain. Sliding glass door details are similar to window details. The exterior doors at Chelsea Terrace are typically metal assemblies that have been mounted in metal frames. The overhang varied from door to door, but was generally present. The main entrance doors are glazed storefront assemblies under a large overhang.

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 21

09/30/2011

5.0

OBSERVATIONS, DISCUSSIONS, AND RECOMMENDATIONS

This section describes relevant observations and, where applicable, our recommendations to address observed deficiencies. Time frames for implementation of the recommendations are given. Delaying the implementation of these recommendations may, over time, increase the magnitude of the noted deficiencies, which in turn will increase the eventual cost of implementation. Each recommendation is presented with an order of magnitude budget, which has been derived from our perusal of the Construction Drawings and our experience with similar projects. It is difficult to provide an accurate cost estimate without some preliminary design work and a clearly defined scope of work. The actual cost of the work cannot be known until material quantities have been reliably estimated, project drawings and specifications have been produced, contractors have bid on the project, and the extent of any hidden damage is known. Where applicable, budget values account for consulting fees, taxes, and contingency for hidden damages, but do not account for inflation.

5.1

OCCUPANT SURVEY

All of the completed occupant surveys have been reproduced in Appendix C. A summary of the survey results is presented in Table 4. Table 4 Occupant Survey Results

Total number of units at Chelsea Terrace: Total number of units that responded to the survey: ANALYZED DATA # of Responses Units reporting signs of interior water stains Possible water leaks Probable window condensation 19 7 14 % of Units That Responded 33% 12% 25% % of Total # of Units 17% 6% 13% 112 57 (51%)

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 22

09/30/2011

A review of Table 4 and the raw data that is presented in Appendix C indicates that one third of the collected surveys report some evidence of leakage or condensation, which is 17 percent of the total units in the building.

5.2

ROOFS

The low-slope roofs will be divided into two categories for this report: the main roofs and the lower tier roofs. The roofs are comprised of SBS sheet membrane over a concrete substrate. The main roof will include the large roof above the ninth level (including the mechanical room roofs), the roof above the eighth level (west side and southeast corner), and the roof above the fifth level (west side). The lower tier roofs will include all the smaller roofs projecting from the building. Refer to Drawing A2 for the roof plan. The main roofs appear are roughly 14 years old. A good quality 2-ply SBS roof membrane that has been properly maintained should provide 20 years of effective service. The roofs are generally in good condition for their age. Refer to Photo 6. The roofs cover the majority of the building and have few mechanical penetrations compared to their size, which provides a simple roof configuration and drainage plan. No leaks were reported from the main roofs during our investigation.

Photo 6 Main roof above ninth level.

Photo 7 Roof penetration detail on upper mechanical roof required some maintenance.

The main roofs should receive regular maintenance to ensure they reach their expected service life. It was noted that some SBS cap sheet is beginning to delaminate at the seams of some penetrations, which should be addressed as a maintenance item. Refer to Photo 7. Additionally, a patio furniture set was observed set up on the roof above the eighth level, west side. Refer to Photo 8. The roof membrane is not designed to accommodate such point loads and foot traffic

Building Envelope Condition Assessment for Chelsea Terrace 1040 Pacific Street, Vancouver, British Columbia Page 23

09/30/2011

Das könnte Ihnen auch gefallen

- 2011 03 Mccowan Kivela PDFDokument11 Seiten2011 03 Mccowan Kivela PDFNaveen Karki100% (1)

- Building Facade Failures: Ice ProceedingsDokument7 SeitenBuilding Facade Failures: Ice ProceedingsmguzzojrNoch keine Bewertungen

- Expansion Joints in RoofingDokument10 SeitenExpansion Joints in Roofingwaterproofing_bestNoch keine Bewertungen

- Wall Detailing in Radaition FalloutDokument9 SeitenWall Detailing in Radaition FallouthammedNoch keine Bewertungen

- Curtain Wall: From Wikipedia, The Free EncyclopediaDokument10 SeitenCurtain Wall: From Wikipedia, The Free Encyclopediaar1janiNoch keine Bewertungen

- Functions of CladdingDokument11 SeitenFunctions of CladdingSafrinaz SafryNoch keine Bewertungen

- Waterproofing Buildings GuideDokument26 SeitenWaterproofing Buildings GuideRichard WalkerNoch keine Bewertungen

- Masonry: Building Weather-Resistant Masonry WallsDokument4 SeitenMasonry: Building Weather-Resistant Masonry WallsghchgNoch keine Bewertungen

- TCH Seminar Cavity WallDokument30 SeitenTCH Seminar Cavity WallSachin AbhiramNoch keine Bewertungen

- Causes and Solutions for Masonry CrackingDokument8 SeitenCauses and Solutions for Masonry CrackingVenkatesh ArunaNoch keine Bewertungen

- Cracks in ConcreteDokument13 SeitenCracks in ConcreteJoshi MayurNoch keine Bewertungen

- On Brick Construction: Technical NotesDokument10 SeitenOn Brick Construction: Technical NotesMekonnen SileshiNoch keine Bewertungen

- BCN 3224 - Exam 3 ReviewDokument34 SeitenBCN 3224 - Exam 3 Reviewmgwin17Noch keine Bewertungen

- Chapter 03-Wall and Cladding Systems-RSCDokument21 SeitenChapter 03-Wall and Cladding Systems-RSCWylieNoch keine Bewertungen

- Echelon Masonry Veneer DetailsDokument7 SeitenEchelon Masonry Veneer DetailsRanj N HassanNoch keine Bewertungen

- Presentation 3 1Dokument12 SeitenPresentation 3 1Ni Ni AungNoch keine Bewertungen

- Articulated WallingDokument24 SeitenArticulated WallingYT LokeNoch keine Bewertungen

- NCMA TEK 19-4A Water Penetration Resistance (2008)Dokument4 SeitenNCMA TEK 19-4A Water Penetration Resistance (2008)B0B_PNoch keine Bewertungen

- T2.1 FacadesDokument13 SeitenT2.1 FacadesPaula de la PeñaNoch keine Bewertungen

- Types of Cracks in WallsDokument9 SeitenTypes of Cracks in Wallsswapnil gandhiNoch keine Bewertungen

- Curtain WallDokument38 SeitenCurtain Walledbern20005873100% (4)

- Historical Roof Decks - Clay TileDokument7 SeitenHistorical Roof Decks - Clay TileMichael SchultzNoch keine Bewertungen

- Study Questions for Advanced Building Technology CourseDokument10 SeitenStudy Questions for Advanced Building Technology CourseMuze LuNoch keine Bewertungen

- Rehabilitation and The Building Enclosure: National Research Conseil Nationat Council Canada de Recherches CanadaDokument8 SeitenRehabilitation and The Building Enclosure: National Research Conseil Nationat Council Canada de Recherches CanadasagarsunkaraNoch keine Bewertungen

- Facades and InterfacesDokument43 SeitenFacades and Interfacesissamoune100% (2)

- Case Study - Lester Lazo (MSCE-SE)Dokument7 SeitenCase Study - Lester Lazo (MSCE-SE)Lester LazoNoch keine Bewertungen

- Assgment 1 BSDokument6 SeitenAssgment 1 BSShazey HenixyNoch keine Bewertungen

- Cast in Place Concrete StructuresDokument17 SeitenCast in Place Concrete Structuresmusiomi2005Noch keine Bewertungen

- A Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are NonDokument23 SeitenA Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are Nonbisrat meseretNoch keine Bewertungen

- Differences between live and dead loadsDokument4 SeitenDifferences between live and dead loadsJeedaran Arshaad100% (1)

- Damp Proofing Lecture NotesDokument16 SeitenDamp Proofing Lecture NotesPromise J LawalNoch keine Bewertungen

- Defects in Building:: A) Structural DefectDokument12 SeitenDefects in Building:: A) Structural DefectkalimNoch keine Bewertungen

- How To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Dokument10 SeitenHow To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Cimpureanu FlorinNoch keine Bewertungen

- Building Defects and RemediesDokument22 SeitenBuilding Defects and Remediesruksar100% (1)

- Concrete Joint Types: Construction, Expansion, Contraction & IsolationDokument7 SeitenConcrete Joint Types: Construction, Expansion, Contraction & IsolationbotchNoch keine Bewertungen

- In Construction: Waterproofing Is The Process of Making An Object or Structure Waterproof or Water-Resistant SoDokument63 SeitenIn Construction: Waterproofing Is The Process of Making An Object or Structure Waterproof or Water-Resistant SoSuhaimi BohariNoch keine Bewertungen

- CAUSES AND PREVENTION OF CRACKS IN BUILDINGSDokument35 SeitenCAUSES AND PREVENTION OF CRACKS IN BUILDINGSharNoch keine Bewertungen

- Prefabricated Construction SystemDokument13 SeitenPrefabricated Construction SystemHimani GaurNoch keine Bewertungen

- Design in Brickwork: Non-Loadbearing WallsDokument4 SeitenDesign in Brickwork: Non-Loadbearing Wallsharicv019Noch keine Bewertungen

- Introduction DPCDokument10 SeitenIntroduction DPCPrashanth PinnojiNoch keine Bewertungen

- Concrete Joint Types at KIST Building & Civil DeptDokument5 SeitenConcrete Joint Types at KIST Building & Civil DeptDenzel OwuorNoch keine Bewertungen

- Detailingmasonryparapets 2Dokument3 SeitenDetailingmasonryparapets 2dawitgggNoch keine Bewertungen

- Masonry repair techniquesDokument39 SeitenMasonry repair techniquesMekonnen SileshiNoch keine Bewertungen

- Cavity Walls PDFDokument23 SeitenCavity Walls PDFAsghar Hussain Shah100% (1)

- Building Envelope Failure Case Studies in High-Rise ConstructionDokument13 SeitenBuilding Envelope Failure Case Studies in High-Rise ConstructionAriep MontolivoNoch keine Bewertungen

- Construction Defects and Remedies PresentationDokument14 SeitenConstruction Defects and Remedies PresentationShobhit Agarwal79% (14)

- Building Defects and RemediesDokument24 SeitenBuilding Defects and RemediesAbhimanyu Bhardwaj87% (15)

- To Maintain Your GuttersDokument42 SeitenTo Maintain Your GuttersMurtesa KumaNoch keine Bewertungen

- Chapter SixDokument20 SeitenChapter SixTemesgen YohannesNoch keine Bewertungen

- Bulletin673 Cavity BattensDokument8 SeitenBulletin673 Cavity BattensStephen MaartenszNoch keine Bewertungen

- How Prolonged Rain Can Affect Your BuildingDokument9 SeitenHow Prolonged Rain Can Affect Your BuildingJason toraldeNoch keine Bewertungen

- Earthquake Design and Brick WallsDokument7 SeitenEarthquake Design and Brick WallsIftekhar ShadNoch keine Bewertungen

- Summary On Causes of Cracks and RecommendationDokument2 SeitenSummary On Causes of Cracks and RecommendationBonzibit Zibit0% (1)

- Curtain Wall SystemsDokument28 SeitenCurtain Wall SystemsKarvy Yadav90% (10)

- Causes of decay and damage in old buildingsDokument13 SeitenCauses of decay and damage in old buildingstwinkle4545100% (2)

- Unit 2 DampnessDokument39 SeitenUnit 2 DampnessTara Chandra PanjiyarNoch keine Bewertungen

- Retaining Wall BayuDokument5 SeitenRetaining Wall BayurionovNoch keine Bewertungen

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcVon EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcBewertung: 5 von 5 Sternen5/5 (1)

- September 2015 REBGV Statistics Package Mike StewartDokument9 SeitenSeptember 2015 REBGV Statistics Package Mike StewartMike StewartNoch keine Bewertungen

- February 2015 Stats PackageDokument9 SeitenFebruary 2015 Stats PackageMaggie ChandlerNoch keine Bewertungen

- REBGV Stats Package, March 2015Dokument9 SeitenREBGV Stats Package, March 2015Mike StewartNoch keine Bewertungen

- Wohlsein Vancouver Presale Floor Plans Mike Stewart RealtorDokument24 SeitenWohlsein Vancouver Presale Floor Plans Mike Stewart RealtorMike StewartNoch keine Bewertungen

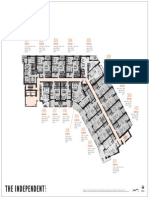

- Independent Presale Condo Floorplate Mike StewartDokument13 SeitenIndependent Presale Condo Floorplate Mike StewartMike StewartNoch keine Bewertungen

- Bennington House Floor Plans Mike Stewart Vancouver Presale Condos PDFDokument20 SeitenBennington House Floor Plans Mike Stewart Vancouver Presale Condos PDFMike StewartNoch keine Bewertungen

- REBGV Stats Package January 2015 Mike Stewart Vancouver RealtorDokument9 SeitenREBGV Stats Package January 2015 Mike Stewart Vancouver RealtorMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan H Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan H Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Villa Floor Plans Mike StewartDokument4 SeitenAperture Vancouver Presale Condo Villa Floor Plans Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan F Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan F Mike StewartMike StewartNoch keine Bewertungen

- REBGV Stats Package December 2014Dokument9 SeitenREBGV Stats Package December 2014Vancouver Real Estate PodcastNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan B Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan B Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan E Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan E Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan G Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan G Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan D Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan D Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan I Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan I Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan C Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan C Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan M Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan M Mike StewartMike StewartNoch keine Bewertungen

- 41 West Floor Plans Mike Stewart Vancouver PresalesDokument11 Seiten41 West Floor Plans Mike Stewart Vancouver PresalesMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan L Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan L Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan K Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan K Mike StewartMike StewartNoch keine Bewertungen

- Northwest Floor Plans Mike StewartDokument8 SeitenNorthwest Floor Plans Mike StewartMike StewartNoch keine Bewertungen

- Mercer by Cressey All Floor Plans Mike Stewart Vancouver Presale Condo RealtorDokument10 SeitenMercer by Cressey All Floor Plans Mike Stewart Vancouver Presale Condo RealtorMike Stewart100% (1)

- Aperture Vancouver Presale Condo Floor Plan J Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan J Mike StewartMike StewartNoch keine Bewertungen

- Aperture Vancouver Presale Condo Floor Plan A Mike StewartDokument1 SeiteAperture Vancouver Presale Condo Floor Plan A Mike StewartMike StewartNoch keine Bewertungen

- REBGV Stats Package November 2014 Mike Stewart Vancouver RealtorDokument9 SeitenREBGV Stats Package November 2014 Mike Stewart Vancouver RealtorMike StewartNoch keine Bewertungen

- REBGV Stats Package October 2014 Mike Stewart RealtorDokument9 SeitenREBGV Stats Package October 2014 Mike Stewart RealtorMike StewartNoch keine Bewertungen

- Underground Oil Storage Tank Removal Bulletin City of VancouverDokument3 SeitenUnderground Oil Storage Tank Removal Bulletin City of VancouverMike StewartNoch keine Bewertungen

- REBGV Stats Package, September 2014 Mike StewartDokument9 SeitenREBGV Stats Package, September 2014 Mike StewartMike StewartNoch keine Bewertungen

- Fuel Storage Tank Bylaw Matrix, July 2014 Mike Stewart Vancouver RealtorDokument3 SeitenFuel Storage Tank Bylaw Matrix, July 2014 Mike Stewart Vancouver RealtorMike StewartNoch keine Bewertungen

- WOR300Dokument56 SeitenWOR300indyukNoch keine Bewertungen

- D 1817 - 01 - Rde4mtcDokument3 SeitenD 1817 - 01 - Rde4mtcDr. Ahmed Abdel-HakimNoch keine Bewertungen

- GebremariamDokument10 SeitenGebremariamnasridin abdiNoch keine Bewertungen

- SRP Brochure Hydraulic System enDokument20 SeitenSRP Brochure Hydraulic System enFiruze AliyevaNoch keine Bewertungen

- Test Bank For Microbiology An Introduction 13th by TortoraDokument21 SeitenTest Bank For Microbiology An Introduction 13th by Tortorahieugiaoau0mNoch keine Bewertungen

- Coleman Above Gound Steel Frame PoolDokument12 SeitenColeman Above Gound Steel Frame PoolSam IamNoch keine Bewertungen

- Propagating Deciduous and Evergreen Shrubs, Trees, and Vines With Stem CuttingsDokument16 SeitenPropagating Deciduous and Evergreen Shrubs, Trees, and Vines With Stem CuttingsFilip Ivanovski100% (1)

- Alccofine 1108 KR TDS V2Dokument3 SeitenAlccofine 1108 KR TDS V2Siddhesh Kamat MhamaiNoch keine Bewertungen

- 10 Points To Save EarthDokument15 Seiten10 Points To Save EarthanilNoch keine Bewertungen

- Child BathingDokument2 SeitenChild Bathingrommelloves58Noch keine Bewertungen

- GASKILL 2014 - Examining The Effects of PH and Macrophyte Diversity On BenthicDokument24 SeitenGASKILL 2014 - Examining The Effects of PH and Macrophyte Diversity On BenthicLuana MarinaNoch keine Bewertungen

- Water Application Value EngineDokument11 SeitenWater Application Value EngineArul KumarNoch keine Bewertungen

- Waterhammer PDFDokument4 SeitenWaterhammer PDFsbalu12674Noch keine Bewertungen

- Paper tube adhesive composition increases strengthDokument4 SeitenPaper tube adhesive composition increases strengthProduction SHVPMNoch keine Bewertungen

- Griha: Presented byDokument43 SeitenGriha: Presented byvandy nehaliaNoch keine Bewertungen

- Mold and Bread Science ExperimentDokument10 SeitenMold and Bread Science ExperimentxfaixalxNoch keine Bewertungen

- Settlement Monitoring of Embankment DamsDokument7 SeitenSettlement Monitoring of Embankment DamsIsabela BalanNoch keine Bewertungen

- Peninsular River System or Peninsular Drainage: Theory 1Dokument4 SeitenPeninsular River System or Peninsular Drainage: Theory 1Rakesh KumarNoch keine Bewertungen

- An Oily Menace at EnnoreDokument9 SeitenAn Oily Menace at EnnoreNaresh SingaraveluNoch keine Bewertungen

- MSDS-RIPSTAR 122-Part 2Dokument6 SeitenMSDS-RIPSTAR 122-Part 2Ankita Baban GavadeNoch keine Bewertungen

- Final Year Project Report (Solar Cooker)Dokument31 SeitenFinal Year Project Report (Solar Cooker)Deborshi ParasorNoch keine Bewertungen

- Maintain PW100 Engine Oil SystemDokument7 SeitenMaintain PW100 Engine Oil SystemSaid AdingniNoch keine Bewertungen

- Experiment Charles LawDokument3 SeitenExperiment Charles LawZaiwati Othman0% (1)

- Hydrologic CycleDokument42 SeitenHydrologic CycleMr EngineerNoch keine Bewertungen

- Finefocus 800: Instruction ManualDokument64 SeitenFinefocus 800: Instruction ManualMURAT ORMANNoch keine Bewertungen

- Reading Material Passage 1: Questions 1-10: Read The Following PassageDokument2 SeitenReading Material Passage 1: Questions 1-10: Read The Following PassageDương Thị Mỹ MỹyNoch keine Bewertungen

- Catalog, Steam Hot Water Unit Heaters MODINEDokument28 SeitenCatalog, Steam Hot Water Unit Heaters MODINECab_de_?Noch keine Bewertungen

- Shahidzadeh Bonn2008Dokument7 SeitenShahidzadeh Bonn2008Nadia fadlNoch keine Bewertungen

- Sediment Distribution and Accumulation in Lake Naivasha, Kenya Over The Past 50 YearsDokument11 SeitenSediment Distribution and Accumulation in Lake Naivasha, Kenya Over The Past 50 YearsskyaNoch keine Bewertungen

- River RestorationDokument60 SeitenRiver RestorationShraddha BahiratNoch keine Bewertungen