Beruflich Dokumente

Kultur Dokumente

Calibration

Hochgeladen von

Madhavan RamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calibration

Hochgeladen von

Madhavan RamCopyright:

Verfügbare Formate

1.

PURPOSE This document provides instructions for controlling the verification, calibration, and maintenance of inspection, measuring, and test equipment to ensure proper functioning and continued accuracy.

2.0

SCOPE This document applies to all measuring equipment (mechanical, electrical and digital) used for verification of part and product acceptability. Employee owned equipment must conform to the requirements of this document.

3.0

RESPONSIBILITY Primary: Support: Quality Assurance Engineering Operations Purchasing

4.0

REFERENCES Documents (See Administrative Document Master List 05-ML-001 for latest revision.) 09-SP-003 10-SP-002 13-SP-001 11-RC-001 11-RC-002 11-RC-003 11-RC-004 11-RC-005 11-RC-06 Processes and Equipment Qualification Receiving Inspection Control of Nonconforming Product Equipment Location and Recall Database Calibration/Service Record Calibration Label Reference Only Label Calibration Recall Notice Out of Service Label

5.0

DEFINITIONS Accuracy The degree of conformity of a measurement to a standard or a true value. Calibration

A comparison of measuring equipment with a standard of higher accuracy to detect, correlate, adjust, rectify, and document the accuracy of the equipment being compared. Custodian The function or person responsible for overall control of an equipment item. Equipment As used in this procedure, Equipment means Inspection, Measuring, and Test Equipment. Inspection, Measuring, and Test Equipment All devices used to measure, gauge, test, inspect, or otherwise examine items to determine compliance with specifications that have been deemed critical to the control of a process. Equipment referred to in this document includes, but is not limited to, gages, test equipment, instruments, gage blocks, torque wrenches, micrometers, "go/no-go" gauges, depth gages, vernier calipers, dial indicators, jigs, fixtures, templates, software, and mylars. Inspection, measuring and test equipment includes all types of devices used by any supplier or subcontractor personnel to check materials, products, processes, or other inspection, measuring, and test equipment. This includes test hardware, test software, automated test equipment (ATE) and plotters used to produce inspection media. Personally owned equipment is not used for product acceptance. (D1-9000, Rev A.) Precision The degree of refinement with which a measurement is stated. It is used to measure the consistency or reproducibility of measurement. Reference Standard Standards of the highest order accuracy in a calibration system that establishes the basic accuracy values for that system. Transfer Standard Designated measuring equipment used in a calibration system as a medium for transferring the basic value of reference standards to lower echelon standards for measuring and test equipment. User The person who has operational control of equipment for the time that it is needed to perform a specific job. 6.0 REQUIREMENTS

6.1

Determining Measurement Requirements The QA Manager determines measurements needed, accuracy required, and the selection of appropriate equipment and methods.

6.2

Traceability to Standards All equipment, that is used to accept product to specified requirements, will be calibrated to a nationally or internationally recognized standard. The system provides for the prevention of inaccuracy by detection of deficiencies and timely implementation of corrective action.

6.3

Calibration Schedule Quality Assurance Department controls all Calibration. The QA Manager on the basis of stability, purpose, usage, time, and/or the manufacturers recommendation will create a Calibration Schedule. The schedule can be adjusted based on the calibration history of the item. If the equipment remains accurate during successive calibrations, the interval may be lengthened. If the equipment requires frequent adjustments or repairs, or is found to be nonconforming in successive calibrations, the interval will be shortened. If the equipment is used infrequently, it may be designated for calibration prior to use instead of establishing a set schedule for calibration.

6.4

Environmental Considerations Inspection, measuring, and test equipment as well as measuring standards will be calibrated and used in an environment controlled to the extent necessary to assure continued measurements of required accuracy considering temperature, humidity, vibration, cleanliness, and other factors affecting precision measurements. The calibration environment must be similar to the environment in which the equipment is being used or a compensating correction or equivalent technique will be identified justifying the difference in calibration conditions.

6.5

Outside Calibration A commercial standards laboratory is used for calibration and repair that cannot be accomplished in-house. Regardless of the location of the calibration, the facility must comply with a nationally or internationally recognized calibration laboratory standard and will be evaluated by Quality Assurance. Calibration certificates are required.

6.6

Work Instructions Internally created work instructions for in-house calibration where the equipment manufacturer has not supplied procedures will be the responsibility of the Engineering and/or Quality Assurance departments.

6.7

Handling, Preservation, and Storage The user and the custodian of the equipment must ensure that handling, preservation, and storage is accomplished in such a manner that the accuracy and fitness for use is maintained. They also safeguard the equipment from adjustments that would invalidate the calibration settings.

6.8

Unscheduled Calibration Calibration is accomplished earlier than schedule if there is any reason to suspect that the equipment needs recalibration (erratic readings, gauge is dropped, etc.). If the equipment is inaccurate, damaged, or tampered with, the user and/or the custodian is responsible for notifying the QA Manager that an unscheduled recalibration is necessary and the reason for it.

7.0 7.1

PROCEDURE Equipment Qualification Equipment used for inspection, measuring, and test must be qualified in accordance with the procedure for Qualification of Processes and Equipment. The QA Manager insures that all new, reworked, repaired, or modified equipment is calibrated before use in production or test.

7.2

Calibration Records The QA Manager maintains records of the custodian, status, and history of all equipment used for the inspection or verification of product. A number is assigned to each equipment item for control purposes and is marked on the item. The Calibration/Service Record (11-RC-002) will contain the date, as-received condition, and result of all calibrations. A list of inspection, measuring and test equipment, including where appropriate, test devices and tools supplied by the customer is maintained by Quality Assurance in the computer.

7.3

Labeling Equipment Each piece of equipment will be marked with the most recent calibration date and the date for the next scheduled calibration. Only equipment with a current label is used.

The Calibration Label (11-RC-003 or Laboratory Label) is invalid if it is incomplete or illegible. If the item is too small for marking, the label can be placed on the storage case for the equipment. 7.4 Calibration Recall The QA Manager notifies the Custodian verbally or through a recall notice that calibration is scheduled prior to expiration of the current calibration. The Custodian is responsible for delivery of the equipment to the QA Manager (Tool Control) before the specified time. 7.5 Current Calibration The User is responsible for assuring that the equipment has a current calibration date prior to use. Measurements cannot be accepted from uncalibrated equipment or equipment that has exceeded its calibration date. 7.6 Control of Outside Calibration The QA Manager directs or initiates a purchase requisition for outside calibration and maintenance. The Purchasing Manager verifies that the supplier will comply with the requirements of this document and include the requirements in purchasing documents.

8.0

NONCONFORMING EQUIPMENT Unserviceable equipment that cannot be immediately corrected is identified with an Out of Service label and placed in a secured location to prevent its use. Out of Service equipment is dispositioned in accordance with the procedure for Control of Nonconforming Product (13-SP-001).

8.1

Labeling Out of Date Equipment Any equipment found with an expired calibration due date is identified with an Out of Service Label (11-RC-006) and removed from use.

8.2

Notification The QA Manager is responsible to notify the Custodian of the degree of nonconformance of the equipment if it is found to be out of the calibration specification.

When equipment is found to be out of calibration, product that has been verified with it is suspect. Previous inspection results must be assessed and documented. Corrective action is performed as necessary and the customer notified. 8.3 Reference

Inspection, measuring or test equipment that is not used for verification of part and product acceptability is identified with a REFERENCE ONLY label (11-RC004) label. If the equipment is too small for a label, than the letter R is inscribed in a conspicuous place on the equipment.

Das könnte Ihnen auch gefallen

- 11.01.00 Calibration of Inspection Measuring and Test EquipmentDokument11 Seiten11.01.00 Calibration of Inspection Measuring and Test EquipmentSanjeev Reddy Kasula100% (1)

- Procedure For Equipment Calibration and MaintenanceDokument9 SeitenProcedure For Equipment Calibration and MaintenanceAli HadiNoch keine Bewertungen

- Annexure - 31 Calibration ProcedureDokument5 SeitenAnnexure - 31 Calibration Proceduresrikanta ksNoch keine Bewertungen

- Calibration Master Plan Guide for Pharmaceutical InstrumentsDokument18 SeitenCalibration Master Plan Guide for Pharmaceutical InstrumentsDoan Chi Thien100% (2)

- Control of Monitoring and Measuring EquipmentDokument6 SeitenControl of Monitoring and Measuring EquipmentJaved Iqbal0% (1)

- Calibration Procedure PDFDokument3 SeitenCalibration Procedure PDFS Sinha Ray100% (1)

- P-ECM Equipment Calibration ProcedureDokument9 SeitenP-ECM Equipment Calibration Procedureomar sadiq100% (1)

- Control of Measuring, Inspection and Test EquipmentDokument3 SeitenControl of Measuring, Inspection and Test EquipmentAnonymous rSvCmFNoch keine Bewertungen

- QSCP-92 - Welding MachinesDokument3 SeitenQSCP-92 - Welding Machineszaheeruddin_mohdNoch keine Bewertungen

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Von EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Bewertung: 4.5 von 5 Sternen4.5/5 (2)

- SOP 006 Rev - NC Calibration & Verification of EquipmentDokument5 SeitenSOP 006 Rev - NC Calibration & Verification of EquipmentmeongNoch keine Bewertungen

- NIST Stopwatch & Timer Calibrations 2009Dokument82 SeitenNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- Calibrate Outside MicrometersDokument2 SeitenCalibrate Outside MicrometerserharsinghNoch keine Bewertungen

- SOP For Calibration of InstrumentDokument2 SeitenSOP For Calibration of InstrumentRAVI KUMAR Carpenter100% (1)

- CalibrationDokument6 SeitenCalibrationListen TawandaNoch keine Bewertungen

- Sop For Operation and Calibration of Analytical BalanceDokument2 SeitenSop For Operation and Calibration of Analytical BalanceDolly BijaniNoch keine Bewertungen

- Calibration and Maintenance of Measuring and Monitoring Devices SOPDokument3 SeitenCalibration and Maintenance of Measuring and Monitoring Devices SOPBPG Service100% (1)

- Equipment and CalibrationDokument17 SeitenEquipment and CalibrationLyne LerinNoch keine Bewertungen

- Standard Operating Procedure: CalibrationDokument22 SeitenStandard Operating Procedure: CalibrationMaryanthony NamyaloNoch keine Bewertungen

- Q2-760-01-Control of Monitoring and Measuring DevicesDokument5 SeitenQ2-760-01-Control of Monitoring and Measuring DevicesAlineNoch keine Bewertungen

- Validation of Calibration MethodsDokument7 SeitenValidation of Calibration Methodssarwar hossainNoch keine Bewertungen

- QUA-PRO-002-00 SOP For CalibrationDokument4 SeitenQUA-PRO-002-00 SOP For Calibrationmrugeshj100% (1)

- SOP-QAD-001 - Inhouse CalibrationDokument4 SeitenSOP-QAD-001 - Inhouse Calibrationdanaka00750% (2)

- Calibration Policy SOPDokument3 SeitenCalibration Policy SOPYousifNoch keine Bewertungen

- Internal Audit ProcedureDokument3 SeitenInternal Audit ProcedureAnkur DhirNoch keine Bewertungen

- Control of Monitoring and Measuring EquipmentDokument18 SeitenControl of Monitoring and Measuring EquipmentFranklyn OnyeneNoch keine Bewertungen

- CLAUSE 8.5 Production and Service ProvisionDokument10 SeitenCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNoch keine Bewertungen

- Pfizer Ireland calibration policyDokument35 SeitenPfizer Ireland calibration policyDoan Chi ThienNoch keine Bewertungen

- Calibration ProcedureDokument2 SeitenCalibration ProcedureSairam Edupuganti100% (1)

- Hindalco Industries Corrective Action ProcedureDokument8 SeitenHindalco Industries Corrective Action ProcedureGhulam MustafaNoch keine Bewertungen

- SOP For Inhouse CalibrationDokument7 SeitenSOP For Inhouse Calibrationvasudeva yasas80% (5)

- EPA Thermometer Calibration ProceduresDokument7 SeitenEPA Thermometer Calibration ProceduresGilberto Andrés Jurado100% (1)

- Control of Nonconformance ProcedureDokument3 SeitenControl of Nonconformance ProcedurehendrabudimanNoch keine Bewertungen

- Calibration ProcedureDokument1 SeiteCalibration Procedurechrisbulman5474Noch keine Bewertungen

- Vernier CaliperDokument2 SeitenVernier CaliperMechtek LabNoch keine Bewertungen

- PRO-CAL-01 Measuring Equipment Calibration ProgramDokument2 SeitenPRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaNoch keine Bewertungen

- Calibration Procedure.Dokument7 SeitenCalibration Procedure.Mohammed Kamal71% (7)

- CalibrationDokument49 SeitenCalibrationChanchal SharmaNoch keine Bewertungen

- Calibration requirements for critical process sensorsDokument1 SeiteCalibration requirements for critical process sensors이진수Noch keine Bewertungen

- 01 Quality Objectives SummaryDokument1 Seite01 Quality Objectives SummaryDenny Dagger100% (1)

- 1.SOP For Calibratioon of Pressure GaugesDokument3 Seiten1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- Preventive Action Procedure - ReferenceDokument6 SeitenPreventive Action Procedure - Referencenorlie100% (1)

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Dokument12 SeitenChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalNoch keine Bewertungen

- Employee Training Tracking Log 2Dokument6 SeitenEmployee Training Tracking Log 2Hiko AdillaNoch keine Bewertungen

- MP12 Monitoring, Measurment and ImprovementDokument6 SeitenMP12 Monitoring, Measurment and ImprovementSuchhanda SarkarNoch keine Bewertungen

- Quality Objectives and Planning ProcedureDokument5 SeitenQuality Objectives and Planning ProcedureIta Dwian YunitaNoch keine Bewertungen

- Calibration Procedure PDFDokument17 SeitenCalibration Procedure PDFsyedfahadraza627100% (1)

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Dokument34 SeitenQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNoch keine Bewertungen

- Method Statement For Conductivity MeterDokument2 SeitenMethod Statement For Conductivity MeterMuhamed RasheedNoch keine Bewertungen

- Site ChecklistDokument18 SeitenSite Checklistagus kurniawanNoch keine Bewertungen

- SOP For CalibirationDokument3 SeitenSOP For CalibirationMuhammad Nisar100% (2)

- Control of Nonconforming ProductsDokument2 SeitenControl of Nonconforming ProductsPrince Moni100% (1)

- Procedure For SamplingDokument3 SeitenProcedure For SamplingWaqarAhmedButtNoch keine Bewertungen

- Calibration Procedure PDFDokument10 SeitenCalibration Procedure PDFmira100% (1)

- Control of Measuring Equipment ProcedureDokument3 SeitenControl of Measuring Equipment Proceduretony s100% (2)

- Calibrating Instruments EffectivelyDokument23 SeitenCalibrating Instruments Effectivelyzuniar ahmadNoch keine Bewertungen

- NRC Inspection Manual: DWM/HLWBDokument5 SeitenNRC Inspection Manual: DWM/HLWBAymeeenNoch keine Bewertungen

- QM 11.2.10 CalibrationDokument3 SeitenQM 11.2.10 CalibrationEtta JeneeNoch keine Bewertungen

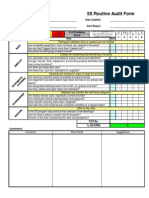

- 5S Audit FormDokument2 Seiten5S Audit FormcomyahoothanhNoch keine Bewertungen

- Supplier Delivery Performance Rating ManualDokument134 SeitenSupplier Delivery Performance Rating ManualMadhavan RamNoch keine Bewertungen

- Toilet Cleaning ChecklistDokument1 SeiteToilet Cleaning ChecklistMadhavan Ram50% (2)

- FMEA HomeworkDokument7 SeitenFMEA HomeworkMadhavan RamNoch keine Bewertungen

- Rolled Throughput Yield (Training)Dokument7 SeitenRolled Throughput Yield (Training)Madhavan RamNoch keine Bewertungen

- g8d FormatDokument1 Seiteg8d FormatMadhavan RamNoch keine Bewertungen

- Losses in TransformerDokument1 SeiteLosses in TransformerMadhavan RamNoch keine Bewertungen

- Formulae For Vendor RatingDokument3 SeitenFormulae For Vendor RatingMadhavan RamNoch keine Bewertungen

- House Rent ReceiptDokument1 SeiteHouse Rent ReceiptMadhavan RamNoch keine Bewertungen

- Austin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013Dokument123 SeitenAustin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013megamaster2010Noch keine Bewertungen

- HHK Report: Coral Bay Nickel CorporationDokument1 SeiteHHK Report: Coral Bay Nickel CorporationAlvin Garcia PalancaNoch keine Bewertungen

- Muhammad Afzal Meo: Advanced Internal Auditing WorkshopDokument101 SeitenMuhammad Afzal Meo: Advanced Internal Auditing WorkshopMadhavan Ram100% (1)

- ON-SITE EMERGENCY PLANDokument49 SeitenON-SITE EMERGENCY PLANKumar RaviNoch keine Bewertungen

- Voltage Transformer Theory - How Potential Transformers WorkDokument1 SeiteVoltage Transformer Theory - How Potential Transformers WorkMadhavan RamNoch keine Bewertungen

- Losses in TransformerDokument1 SeiteLosses in TransformerMadhavan RamNoch keine Bewertungen

- List of Captive Generation Plants in Tamil NaduDokument1 SeiteList of Captive Generation Plants in Tamil NaduMadhavan RamNoch keine Bewertungen

- VA Chap 2 WMDokument85 SeitenVA Chap 2 WMMadhavan RamNoch keine Bewertungen

- Risk Assessment Guidance: Health and Safety ServicesDokument31 SeitenRisk Assessment Guidance: Health and Safety Servicesnaief1234Noch keine Bewertungen

- KYTDokument6 SeitenKYTMadhavan RamNoch keine Bewertungen

- JICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderDokument3 SeitenJICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderMadhavan RamNoch keine Bewertungen

- Document Coding Practice (Draft) : Aa / Aaa BB/BBB CCCDokument2 SeitenDocument Coding Practice (Draft) : Aa / Aaa BB/BBB CCCMadhavan RamNoch keine Bewertungen

- Safety Manual (CBRE)Dokument105 SeitenSafety Manual (CBRE)Shaik Mushtaq100% (2)

- JICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderDokument3 SeitenJICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderMadhavan RamNoch keine Bewertungen

- KYTDokument6 SeitenKYTMadhavan RamNoch keine Bewertungen

- Is Codes Related To E&HSDokument2 SeitenIs Codes Related To E&HSMadhavan RamNoch keine Bewertungen

- JICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderDokument3 SeitenJICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderMadhavan RamNoch keine Bewertungen

- KYTDokument6 SeitenKYTMadhavan RamNoch keine Bewertungen

- JICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderDokument3 SeitenJICOSH - Case Studies - Good Practice - Tire Chain Attachment Tool For A Wheel LoaderMadhavan RamNoch keine Bewertungen

- Employee Safety: Lost Time / RecordableDokument1 SeiteEmployee Safety: Lost Time / RecordableMadhavan RamNoch keine Bewertungen

- Correction, CAPADokument4 SeitenCorrection, CAPAMadhavan RamNoch keine Bewertungen

- Dowex Marathon CDokument2 SeitenDowex Marathon CMuhammad ImranNoch keine Bewertungen

- Romi BPMN 02 Elements Mar2016Dokument169 SeitenRomi BPMN 02 Elements Mar2016SuperbejoNoch keine Bewertungen

- Development of Reciprocating Parts and Crankshaft in Honda's Third Formula One EraDokument10 SeitenDevelopment of Reciprocating Parts and Crankshaft in Honda's Third Formula One EraBlaze123xNoch keine Bewertungen

- 30m3 Standart Drawing Penawaran 01.03.22Dokument1 Seite30m3 Standart Drawing Penawaran 01.03.22medtsl.cppNoch keine Bewertungen

- Safety and Health Manual in ConstructionDokument99 SeitenSafety and Health Manual in ConstructionQuoc Anh100% (2)

- Development of Auxiliary Automobile Air Conditioning System by Solar EnergyDokument7 SeitenDevelopment of Auxiliary Automobile Air Conditioning System by Solar EnergyRivhan NugrohoNoch keine Bewertungen

- Access To Space ISRODokument23 SeitenAccess To Space ISROGanesan SNoch keine Bewertungen

- Chapter IV FinalDokument4 SeitenChapter IV FinalJohn Patrick Sanay NunezNoch keine Bewertungen

- Chapter 6Dokument1 SeiteChapter 6Vala PratikNoch keine Bewertungen

- Systemverilog OVM UVM 3day TrainingDokument10 SeitenSystemverilog OVM UVM 3day TrainingTC SurendharNoch keine Bewertungen

- DICOM Conformance StatementDokument7 SeitenDICOM Conformance StatementHugo MoralesNoch keine Bewertungen

- Vibration Analysis Report OnDokument7 SeitenVibration Analysis Report OnCesar SampaioNoch keine Bewertungen

- ZM - Instructions For Installation, Operation, Maintenance and Inspection PDFDokument40 SeitenZM - Instructions For Installation, Operation, Maintenance and Inspection PDFIvan DulicNoch keine Bewertungen

- Friedel-Crafts Alkylation of Xylenes With Tert-Butanol Over Me So Porous Superacid UDCaT-5Dokument22 SeitenFriedel-Crafts Alkylation of Xylenes With Tert-Butanol Over Me So Porous Superacid UDCaT-5S Bharadwaj ReddyNoch keine Bewertungen

- Brochure Cardio-Aid 200Dokument2 SeitenBrochure Cardio-Aid 200Juan Carlos Isaza GarciaNoch keine Bewertungen

- Surveying Work Method StatementDokument5 SeitenSurveying Work Method StatementKelvin TanNoch keine Bewertungen

- Saes J 002Dokument31 SeitenSaes J 002madinah123100% (1)

- Gpu ProgrammingDokument96 SeitenGpu ProgrammingJino Goju Stark100% (2)

- TE651: Transportation Economics and Project Evaluation: Total Hrs. 48Dokument2 SeitenTE651: Transportation Economics and Project Evaluation: Total Hrs. 48Melinda RupianiNoch keine Bewertungen

- Create Quotation From DP81 - For Project PDFDokument6 SeitenCreate Quotation From DP81 - For Project PDFvittoriojayNoch keine Bewertungen

- COMAU Arc-Tin Kem en ManualDokument84 SeitenCOMAU Arc-Tin Kem en ManualcabecavilNoch keine Bewertungen

- Treatment of Primary and Secondary Stresses in Fracture AssessmentDokument29 SeitenTreatment of Primary and Secondary Stresses in Fracture AssessmentYoun Seok ChoiNoch keine Bewertungen

- A35G, A40G: Volvo Articulated Haulers 34.5-39 T 457-476 HPDokument20 SeitenA35G, A40G: Volvo Articulated Haulers 34.5-39 T 457-476 HPMorriesNoch keine Bewertungen

- Eurotherm 2132i 2116i Alarm Units Manual HA026248Dokument6 SeitenEurotherm 2132i 2116i Alarm Units Manual HA026248restor3dNoch keine Bewertungen

- 2022 E-Z Line Product Catalog PDFDokument35 Seiten2022 E-Z Line Product Catalog PDFKyle Shepard100% (3)

- 03/2008 - Art. Nr. 13 013 477CDokument56 Seiten03/2008 - Art. Nr. 13 013 477CВадим БалабанNoch keine Bewertungen

- Kuliah Reliability, Availability, Maintain AbilityDokument50 SeitenKuliah Reliability, Availability, Maintain AbilitySumarlin Hari Wibowo100% (2)

- MATE 280 Characterization of Powders and Porous MaterialsDokument65 SeitenMATE 280 Characterization of Powders and Porous MaterialsAnissa Adiwena100% (1)

- Catalogue Lelit ANGDokument68 SeitenCatalogue Lelit ANGmhcormier100% (1)