Beruflich Dokumente

Kultur Dokumente

Micron RLDRAM 576mb

Hochgeladen von

RealiZMCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Micron RLDRAM 576mb

Hochgeladen von

RealiZMCopyright:

Verfügbare Formate

Advance

576Mb: x18, x36 RLDRAM 3 Features

RLDRAM 3

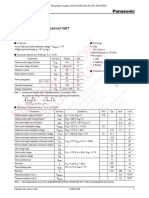

MT44K32M18 2 Meg x 18 x 16 Banks MT44K16M36 1 Meg x 36 x 16 Banks Features

1066 MHz DDR operation (2133 Mb/s/ball data rate) 76.8 Gb/s peak bandwidth (x36 at 1066 MHz clock frequency) Organization 32 Meg x 18, and 16 Meg x 36 common I/O (CIO) 16 banks 1.2V center-terminated push/pull I/O 2.5V V EXT, 1.35V V DD, 1.2V V DDQ I/O Reduced cycle time (tRC (MIN) = 8 - 12ns) SDR addressing Programmable READ/WRITE latency (RL/WL) and burst length Data mask for WRITE commands Differential input clocks (CK, CK#) Free-running differential input data clocks (DKx, DKx#) and output data clocks (QKx, QKx#) On-die DLL generates CK edge-aligned data and differential output data clock signals 64ms refresh (128K refresh per 64ms) 168-ball FBGA package 40 or 60 matched impedance outputs Integrated on-die termination (ODT) Single or multibank writes Extended operating range (2001066 MHz) READ training register Multiplexed and non-multiplexed addressing capabilities Mirror function Output driver and ODT calibration JTAG interface (IEEE 1149.1-2001)

Options1

Clock cycle and tRC timing 0.93ns and tRC (MIN) = 8ns (RL3-2133) 0.93ns and tRC (MIN) = 10ns (RL3-2133) 1.07ns and tRC (MIN) = 8ns (RL3-1866) 1.07ns and tRC (MIN) = 10ns (RL3-1866) 1.25ns and tRC (MIN) = 10ns (RL3-1600) 1.25ns and tRC (MIN) = 12ns (RL3-1600) Configuration 32 Meg x 18 16 Meg x 36 Operating temperature Commercial (TC = 0 to +95C) Industrial (TC = 40C to +95C) Package 168-ball FBGA 168-ball FBGA (Pb-free) Revision

Note:

Marking

-093E -093 -107E -107 -125E -125 32M18 16M36 None IT PA RB :A

1. Not all options listed can be combined to define an offered product. Use the part catalog search on www.micron.com for available offerings.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Products and specifications discussed herein are for evaluation and reference purposes only and are subject to change by Micron without notice. Products are only warranted by Micron to meet Micron's production data sheet specifications.

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

Figure 1: 576Mb RLDRAM 3 Part Numbers

Example Part Number: MT44K16M36PA-093E MT44K Configuration Package Speed Temp

Configuration 32 Meg x 18 16 Meg x 36 Package 168-ball FBGA 168-ball FBGA (Pb-free) PA RB 32M18 16M36

Temperature Commercial Industrial Speed Grade -093E tCK = 0.93ns (8ns tRC) -093 -107 -125

tCK

None IT

= 0.93ns (10ns tRC) = 1.07ns (10ns tRC) = 1.25ns (12ns tRC)

-107E tCK = 1.07ns (8ns tRC)

tCK

-125E tCK = 1.25ns (10ns tRC)

tCK

BGA Part Marking Decoder

Due to space limitations, BGA-packaged components have an abbreviated part marking that is different from the part number. Microns BGA Part Marking Decoder is available on Microns Web site at www.micron.com.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

Contents

General Description ......................................................................................................................................... 8 General Notes .............................................................................................................................................. 8 State Diagram .................................................................................................................................................. 9 Functional Block Diagrams ............................................................................................................................. 10 Ball Assignments and Descriptions ................................................................................................................. 12 Package Dimensions ....................................................................................................................................... 16 Electrical Characteristics IDD Specifications .................................................................................................. 17 Electrical Specifications Absolute Ratings and I/O Capacitance ..................................................................... 21 Absolute Maximum Ratings ........................................................................................................................ 21 Input/Output Capacitance .......................................................................................................................... 21 AC and DC Operating Conditions .................................................................................................................... 22 AC Overshoot/Undershoot Specifications .................................................................................................... 24 Slew Rate Definitions for Single-Ended Input Signals ................................................................................... 27 Slew Rate Definitions for Differential Input Signals ...................................................................................... 29 ODT Characteristics ....................................................................................................................................... 30 ODT Resistors ............................................................................................................................................ 30 ODT Sensitivity .......................................................................................................................................... 32 Output Driver Impedance ............................................................................................................................... 33 Output Driver Sensitivity ............................................................................................................................ 35 Output Characteristics and Operating Conditions ............................................................................................ 36 Reference Output Load ............................................................................................................................... 39 Slew Rate Definitions for Single-Ended Output Signals ..................................................................................... 40 Slew Rate Definitions for Differential Output Signals ........................................................................................ 41 Speed Bin Tables ............................................................................................................................................ 42 AC Electrical Characteristics ........................................................................................................................... 43 Temperature and Thermal Impedance Characteristics ..................................................................................... 48 Command and Address Setup, Hold, and Derating ........................................................................................... 50 Data Setup, Hold, and Derating ....................................................................................................................... 56 Commands .................................................................................................................................................... 62 MODE REGISTER SET (MRS) Command ......................................................................................................... 63 Mode Register 0 (MR0) .................................................................................................................................... 64 tRC ............................................................................................................................................................. 65 Data Latency .............................................................................................................................................. 65 DLL Enable/Disable ................................................................................................................................... 65 Address Multiplexing .................................................................................................................................. 65 Mode Register 1 (MR1) .................................................................................................................................... 67 Output Drive Impedance ............................................................................................................................ 67 DQ On-Die Termination (ODT) ................................................................................................................... 67 DLL Reset ................................................................................................................................................... 67 ZQ Calibration ............................................................................................................................................ 68 ZQ Calibration Long ................................................................................................................................... 69 ZQ Calibration Short ................................................................................................................................... 69 AUTO REFRESH Protocol ............................................................................................................................ 70 Burst Length (BL) ....................................................................................................................................... 70 Mode Register 2 (MR2) .................................................................................................................................... 72 READ Training Register (RTR) ..................................................................................................................... 72 WRITE Protocol .......................................................................................................................................... 74 WRITE Command .......................................................................................................................................... 74 Multibank WRITE ....................................................................................................................................... 75 READ Command ............................................................................................................................................ 75

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

AUTO REFRESH Command ............................................................................................................................ 77 INITIALIZATION Operation ............................................................................................................................ 79 WRITE Operation ........................................................................................................................................... 82 READ Operation ............................................................................................................................................. 86 AUTO REFRESH Operation ............................................................................................................................. 89 Multiplexed Address Mode .............................................................................................................................. 92 Data Latency in Multiplexed Address Mode ................................................................................................. 97 REFRESH Command in Multiplexed Address Mode ..................................................................................... 97 Mirror Function ............................................................................................................................................ 101 RESET Operation ........................................................................................................................................... 101 IEEE 1149.1 Serial Boundary Scan (JTAG) ....................................................................................................... 102 Disabling the JTAG Feature ........................................................................................................................ 102 Test Access Port (TAP) ................................................................................................................................ 102 TAP Controller ........................................................................................................................................... 103 Performing a TAP RESET ............................................................................................................................ 105 TAP Registers ............................................................................................................................................ 105 TAP Instruction Set .................................................................................................................................... 106

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

Figure 1: 576Mb RLDRAM 3 Part Numbers ..................................................................................................... 2 Figure 2: Simplified State Diagram ................................................................................................................... 9 Figure 3: 32 Meg x 18 Functional Block Diagram ............................................................................................. 10 Figure 4: 16 Meg x 36 Functional Block Diagram ............................................................................................. 11 Figure 5: 168-Ball FBGA ................................................................................................................................. 16 Figure 6: Single-Ended Input Signal ............................................................................................................... 23 Figure 7: Overshoot ....................................................................................................................................... 24 Figure 8: Undershoot .................................................................................................................................... 24 Figure 9: V IX for Differential Signals ................................................................................................................ 25 Figure 10: Single-Ended Requirements for Differential Signals ........................................................................ 26 Figure 11: Definition of Differential AC Swing and tDVAC ................................................................................ 26 Figure 12: Nominal Slew Rate Definition for Single-Ended Input Signals .......................................................... 28 Figure 13: Nominal Differential Input Slew Rate Definition for CK, CK#, DKx, and DKx# .................................. 29 Figure 14: ODT Levels and I-V Characteristics ................................................................................................ 30 Figure 15: Output Driver ................................................................................................................................ 33 Figure 16: DQ Output Signal .......................................................................................................................... 38 Figure 17: Differential Output Signal .............................................................................................................. 39 Figure 18: Reference Output Load for AC Timing and Output Slew Rate ........................................................... 39 Figure 19: Nominal Slew Rate Definition for Single-Ended Output Signals ....................................................... 40 Figure 20: Nominal Differential Output Slew Rate Definition for QKx, QKx# ..................................................... 41 Figure 21: Example Temperature Test Point Location ...................................................................................... 49 Figure 22: Nominal Slew Rate and tVAC for tIS (Command and Address - Clock) ............................................... 52 Figure 23: Nominal Slew Rate for tIH (Command and Address - Clock) ............................................................ 53 Figure 24: Tangent Line for tIS (Command and Address - Clock) ...................................................................... 54 Figure 25: Tangent Line for tIH (Command and Address - Clock) ..................................................................... 55 Figure 26: Nominal Slew Rate and tVAC for tDS (DQ - Strobe) .......................................................................... 58 Figure 27: Nominal Slew Rate for tDH (DQ - Strobe) ........................................................................................ 59 Figure 28: Tangent Line for tDS (DQ - Strobe) ................................................................................................. 60 Figure 29: Tangent Line for tDH (DQ - Strobe) ................................................................................................ 61 Figure 30: MRS Command Protocol ............................................................................................................... 63 Figure 31: MR0 Definition for Non-Multiplexed Address Mode ........................................................................ 64 Figure 32: MR1 Definition for Non-Multiplexed Address Mode ........................................................................ 67 Figure 33: ZQ Calibration Timing (ZQCL and ZQCS) ....................................................................................... 69 Figure 34: Read Burst Lengths ........................................................................................................................ 71 Figure 35: MR2 Definition for Non-Multiplexed Address Mode ........................................................................ 72 Figure 36: READ Training Function - Back-to-Back Readout ............................................................................ 73 Figure 37: WRITE Command ......................................................................................................................... 74 Figure 38: READ Command ........................................................................................................................... 76 Figure 39: Bank Address-Controlled AUTO REFRESH Command ..................................................................... 77 Figure 40: Multibank AUTO REFRESH Command ........................................................................................... 78 Figure 41: Power-Up/Initialization Sequence ................................................................................................. 80 Figure 42: WRITE Burst ................................................................................................................................. 82 Figure 43: Consecutive WRITE Bursts ............................................................................................................. 83 Figure 44: WRITE-to-READ ............................................................................................................................ 83 Figure 45: WRITE - DM Operation .................................................................................................................. 84 Figure 46: Consecutive Quad Bank WRITE Bursts ........................................................................................... 85 Figure 47: Interleaved READ and Quad Bank WRITE Bursts ............................................................................. 85 Figure 48: Basic READ Burst .......................................................................................................................... 86 Figure 49: Consecutive READ Bursts (BL = 2) .................................................................................................. 87 Figure 50: Consecutive READ Bursts (BL = 4) .................................................................................................. 87

List of Figures

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

Figure 51: Figure 52: Figure 53: Figure 54: Figure 55: Figure 56: Figure 57: Figure 58: Figure 59: Figure 60: Figure 61: Figure 62: Figure 63: Figure 64: Figure 65: Figure 66: Figure 67: Figure 68: Figure 69: Figure 70: Figure 71: READ-to-WRITE ............................................................................................................................ 88 Read Data Valid Window ................................................................................................................ 88 Bank Address-Controlled AUTO REFRESH Cycle ............................................................................. 89 Multibank AUTO REFRESH Cycle ................................................................................................... 89 READ Burst with ODT .................................................................................................................... 90 READ-NOP-READ with ODT .......................................................................................................... 91 Command Description in Multiplexed Address Mode ..................................................................... 92 Power-Up/Initialization Sequence in Multiplexed Address Mode ..................................................... 93 MR0 Definition for Multiplexed Address Mode ................................................................................ 94 MR1 Definition for Multiplexed Address Mode ................................................................................ 95 MR2 Definition for Multiplexed Address Mode ................................................................................ 96 Bank Address-Controlled AUTO REFRESH Operation with Multiplexed Addressing .......................... 97 Multibank AUTO REFRESH Operation with Multiplexed Addressing ................................................ 97 Consecutive WRITE Bursts with Multiplexed Addressing ................................................................. 98 WRITE-to-READ with Multiplexed Addressing ................................................................................ 99 Consecutive READ Bursts with Multiplexed Addressing ................................................................... 99 READ-to-WRITE with Multiplexed Addressing ............................................................................... 100 TAP Controller State Diagram ........................................................................................................ 104 TAP Controller Functional Block Diagram ..................................................................................... 104 JTAG Operation - Loading Instruction Code and Shifting Out Data ................................................. 107 TAP Timing .................................................................................................................................. 108

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Features

List of Tables

Table 1: 32 Meg x 18 Ball Assignments 168-Ball FBGA (Top View) .................................................................. 12 Table 2: 16 Meg x 36 Ball Assignments 168-Ball FBGA (Top View) .................................................................. 13 Table 3: Ball Descriptions .............................................................................................................................. 14 Table 4: IDD Operating Conditions and Maximum Limits ................................................................................ 17 Table 5: Absolute Maximum Ratings .............................................................................................................. 21 Table 6: Input/Output Capacitance ................................................................................................................ 21 Table 7: DC Electrical Characteristics and Operating Conditions ..................................................................... 22 Table 8: Input AC Logic Levels ........................................................................................................................ 22 Table 9: Control and Address Balls ................................................................................................................. 24 Table 10: Clock, Data, Strobe, and Mask Balls ................................................................................................. 24 Table 11: Differential Input Operating Conditions (CK, CK# and DKx, DKx#) ................................................... 25 Table 12: Allowed Time Before Ringback ( tDVAC) for CK, CK#, DKx, and DKx# ................................................. 27 Table 13: Single-Ended Input Slew Rate Definition .......................................................................................... 27 Table 14: Differential Input Slew Rate Definition ............................................................................................. 29 Table 15: ODT DC Electrical Characteristics ................................................................................................... 30 Table 16: RTT Effective Impedances ................................................................................................................ 31 Table 17: ODT Sensitivity Definition .............................................................................................................. 32 Table 18: ODT Temperature and Voltage Sensitivity ........................................................................................ 32 Table 19: Driver Pull-Up and Pull-Down Impedance Calculations ................................................................... 34 Table 20: Output Driver Sensitivity Definition ................................................................................................. 35 Table 21: Output Driver Voltage and Temperature Sensitivity .......................................................................... 35 Table 22: Single-Ended Output Driver Characteristics ..................................................................................... 36 Table 23: Differential Output Driver Characteristics ........................................................................................ 37 Table 24: Single-Ended Output Slew Rate Definition ....................................................................................... 40 Table 25: Differential Output Slew Rate Definition .......................................................................................... 41 Table 26: RL3 Speed Bins ............................................................................................................................... 42 Table 27: AC Electrical Characteristics ............................................................................................................ 43 Table 28: Temperature Limits ......................................................................................................................... 48 Table 29: Thermal Impedance ........................................................................................................................ 48 Table 30: Command and Address Setup and Hold Values Referenced at 1 V/ns AC/DC-Based ........................ 50 Table 31: Derating Values for tIS/tIH AC150/DC100-Based ............................................................................ 51 Table 32: Minimum Required Time tVAC Above V IH(AC) (or Below V IL(AC)) for Valid Transition ............................ 51 Table 33: Data Setup and Hold Values at 1 V/ns (DKx, DKx# at 2V/ns) AC/DC-Based ..................................... 56 Table 34: Derating Values for tDS/tDH AC150/DC100-Based ......................................................................... 57 Table 35: Minimum Required Time tVAC Above V IH(AC) (or Below V IL(AC)) for Valid Transition ............................ 57 Table 36: Command Descriptions .................................................................................................................. 62 Table 37: Command Table ............................................................................................................................. 62 Table 38: tRC_MRS MR0[3:0] values ................................................................................................................ 65 Table 39: Address Widths of Different Burst Lengths ....................................................................................... 70 Table 40: Address Mapping in Multiplexed Address Mode ............................................................................... 96 Table 41: 32 Meg x 18 Ball Assignments with MF Ball Tied HIGH ..................................................................... 101 Table 42: TAP Input AC Logic Levels .............................................................................................................. 108 Table 43: TAP AC Electrical Characteristics .................................................................................................... 108 Table 44: TAP DC Electrical Characteristics and Operating Conditions ............................................................ 109 Table 45: Identification Register Definitions .................................................................................................. 109 Table 46: Scan Register Sizes ......................................................................................................................... 110 Table 47: Instruction Codes .......................................................................................................................... 110 Table 48: Boundary Scan (Exit) ..................................................................................................................... 110

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 General Description

General Description

The Micron RLDRAM 3 is a high-speed memory device designed for high-bandwidth data storagetelecommunications, networking, cache applications, etc. The chips 16bank architecture is optimized for sustainable high-speed operation. The DDR I/O interface transfers two data bits per clock cycle at the I/O balls. Output data is referenced to the READ strobes. Commands, addresses, and control signals are also registered at every positive edge of the differential input clock, while input data is registered at both positive and negative edges of the input data strobes. Read and write accesses to the RL3 device are burst-oriented. The burst length (BL) is programmable to 2, 4, or 8 by a setting in the mode register. The device is supplied with 1.35V for the core and 1.2V for the output drivers. The 2.5V supply is used for an internal supply. Bank-scheduled refresh is supported with the row address generated internally. The 168-ball FBGA package is used to enable ultra-high-speed data transfer rates.

General Notes

The functionality and the timing specifications discussed in this data sheet are for the DLL enable mode of operation. Any functionality not specifically stated is considered undefined, illegal, and not supported, and can result in unknown operation. Nominal conditions are assumed for specifications not defined within the figures shown in this data sheet. Throughout this data sheet, the terms "RLDRAM," "DRAM, and "RLDRAM 3" are all used interchangeably and refer to the RLDRAM 3 SDRAM device. References to DQ, DK, QK, DM, and QVLD are to be interpeted as each group collectively, unless specifically stated otherwise. This includes true and complement signals of differential signals. Non-multiplexed operation is assumed if not specified as multiplexed.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 State Diagram

State Diagram

Figure 2: Simplified State Diagram

Initialization sequence

NOP

WRITE

READ

RESET#

MRS

AREF

Automatic sequence Command sequence

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Functional Block Diagrams

Figure 3: 32 Meg x 18 Functional Block Diagram

REF# WE#

Command decode

Column decoder

18 18

Input logic

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

ZQ RZQ ZQCL, ZQCS

ODT control

ZQ CAL

ZQ CAL

CK CK# CS# Control logic

VDDQ/2

Bank 15 Bank 14

MF RESET# Mode register 24 13 Refresh counter 13 Rowaddress MUX

13

RTT

ODT control CK/CK# (0 ....17)

Bank 1 Bank 0 Bank 0 rowaddress latch and decoder Bank 0 memory array (8192 x 32 x 8 x 18)2 144 READ n logic n

18 18 DQ latch

8192

ZQ CAL 18 4 QK/QK# generator

DLL

10

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

A[19:0]1 BA[3:0]

SENSE amplifiers Sense AMPLIFIERS

8192

READ Drivers

QVLD QK0/QK0#,QK1/QK1#

144 I/O gating DQM mask logic

2 1

VDDQ/2 RTT

DQ[17:0]

24

Address register

Bank control logic

16 16

32 144 WRITE FIFO and drivers

CLK in 21

ODT control 18 RCVRS 4 (0...3) DK0/DK0#, DK1/DK1#

576Mb: x18, x36 RLDRAM 3 Functional Block Diagrams

VDDQ/2 RTT

8 TCK TMS TDI JTAG Logic and Boundary Scan Register

71

Columnaddress counter/ latch

71

ODT control 2 DM[1:0] TDO

Notes:

1. Example for BL = 2; column address will be reduced with an increase in burst length. 2. 8 = (length of burst) x 2^ (number of column addresses to WRITE FIFO and READ logic).

Advance

Functional Block Diagrams

Figure 4: 16 Meg x 36 Functional Block Diagram

REF# WE#

Command decode

Column decoder

36 36

8

TCK TMS TDI

61

Columnaddress counter/ latch

61 11

CLK in

Input logic

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

ZQ RZQ ZQCL, ZQCS

ODT control

ZQ CAL

ZQ CAL

CK CK# CS# Control logic

VDDQ/2

Bank 15 Bank 14 MF RESET# Mode register 23 13 Refresh counter 13 Rowaddress MUX

13

RTT ODT control CK/CK# (0 ....35)

Bank 1 Bank 0 Bank 0 rowaddress latch and decoder Bank 0 memory array (8192 x 32 x 4 x 36)2 144 READ n logic n

36 36 DQ latch

8192

ZQ CAL 36 8 QK/QK# generator

DLL

SENSE AMPLIFIERS Sense amplifiers

8192

READ Drivers

QVLD[1:0] QK0/QK0#, QK1/QK1# QK2/QK2#, QK3/QK3#

11

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

A[18:0]1

VDDQ/2 RTT DQ[35:0]

144 I/O gating DQM mask logic

11 ODT control

23

Address register

Bank control logic

16 16

(0...3)

32 144 WRITE FIFO and drivers

4 RCVRS

DK0/DK0#, DK1/DK1#

36

576Mb: x18, x36 RLDRAM 3 Functional Block Diagrams

VDDQ/2 RTT

JTAG Logic and Boundary Scan Register

ODT control 2 DM[1:0] TDO

Notes:

1. Example for BL = 2; column address will be reduced with an increase in burst length. 2. 4 = (length of burst) x 2^ (number of column addresses to WRITE FIFO and READ logic).

Advance

Advance

576Mb: x18, x36 RLDRAM 3 Ball Assignments and Descriptions

Ball Assignments and Descriptions

Table 1: 32 Meg x 18 Ball Assignments 168-Ball FBGA (Top View)

1 A B C D E F G H J K L M N VEXT VDD A11 VSS A7 VSS A19 VDDQ NF VDD VEXT VSS 2 VSS VSS NF VSSQ A0 NF(A20) A15 VDD NF VSSQ NF VSS TCK Notes:

1

3 VDD NF VDDQ NF VSSQ VDD A6 A14 VSSQ NF VDDQ NF VDD

4 NF VSSQ NF VDDQ NF A2 VSS A16 NF VDDQ NF VSSQ TDO

5 VDDQ NF VSSQ NF VDDQ A1 BA1 VDD VDDQ NF VSSQ NF VDDQ

6 NF VDDQ NF VSSQ NF WE# VSS BA3 NF VSSQ NF VDDQ NF

7 VREF DM0 DK0# DK0 MF ZQ CK# CK VSS DK1 DK1# DM1 VREF

8 DQ7 VDDQ DQ2 VSSQ QK0# REF# VSS BA2 QK1# VSSQ DQ12 VDDQ DQ17

9 VDDQ DQ5 VSSQ QK0 VDDQ A3 BA0 VDD VDDQ QK1 VSSQ DQ15 VDDQ

10 DQ8 VSSQ DQ3 VDDQ DQ1 A4 VSS A17 DQ9 VDDQ DQ13 VSSQ TDI

11 VDD DQ6 VDDQ DQ0 VSSQ VDD A8 A12 VSSQ DQ10 VDDQ DQ16 VDD

12 VSS VSS DQ4 VSSQ CS# A5 A18 VDD QVLD VSSQ DQ14 VSS TMS

13 RESET# VEXT VDD A13 VSS A9 VSS A10 VDDQ DQ11 VDD VEXT VSS

1. Location of the additional address signal (A20) required on the 1Gb RLDRAM 3 x18 configuration. Internally connected so it can mirror the A5 address signal when MF is asserted HIGH. Has parasitic characteristics of an address pin. 2. NF balls for the x18 configuration are internally connected and have parasitic characteristics of an I/O. Balls may be connected to VSSQ. 3. MF is assumed to be tied LOW for this ball assignment.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

12

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Ball Assignments and Descriptions

Table 2: 16 Meg x 36 Ball Assignments 168-Ball FBGA (Top View)

1 A B C D E F G H J K L M N VEXT VDD A11 VSS A7 VSS NF(A19)2 VDDQ DQ29 VDD VEXT VSS 2 VSS VSS DQ22 VSSQ A0 NF(A20) A15 VDD QVLD1 VSSQ DQ32 VSS TCK

1

3 VDD DQ24 VDDQ DQ18 VSSQ VDD A6 A14 VSSQ DQ28 VDDQ DQ34 VDD

4 DQ26 VSSQ DQ21 VDDQ DQ19 A2 VSS A16 DQ27 VDDQ DQ31 VSSQ TDO

5 VDDQ DQ23 VSSQ QK2 VDDQ A1 BA1 VDD VDDQ QK3 VSSQ DQ33 VDDQ

6 DQ25 VDDQ DQ20 VSSQ QK2# WE# VSS BA3 QK3# VSSQ DQ30 VDDQ DQ35

7 VREF DM0 DK0# DK0 MF ZQ CK# CK VSS DK1 DK1# DM1 VREF

8 DQ7 VDDQ DQ2 VSSQ QK0# REF# VSS BA2 QK1# VSSQ DQ12 VDDQ DQ17

9 VDDQ DQ5 VSSQ QK0 VDDQ A3 BA0 VDD VDDQ QK1 VSSQ DQ15 VDDQ

10 DQ8 VSSQ DQ3 VDDQ DQ1 A4 VSS A17 DQ9 VDDQ DQ13 VSSQ TDI

11 VDD DQ6 VDDQ DQ0 VSSQ VDD A8 A12 VSSQ DQ10 VDDQ DQ16 VDD

12 VSS VSS DQ4 VSSQ CS# A5 A18 VDD QVLD0 VSSQ DQ14 VSS TMS

13 RESET# VEXT VDD A13 VSS A9 VSS A10 VDDQ DQ11 VDD VEXT VSS

Notes:

1. Location of the additional address signal (A20) required on the 1Gb RLDRAM 3 x18 configuration. Internally connected so it can mirror the A5 address signal when MF is asserted HIGH. Has parasitic characteristics of an address pin. 2. NF ball for x36 configuration is internally connected and has parasitic characteristics of an address (A19 for x18 configuration). Ball may be connected to VSSQ. 3. MF is assumed to be tied LOW for this ball assignment.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

13

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Ball Assignments and Descriptions

Table 3: Ball Descriptions

Symbol A[19:0] Type Input Description Address inputs: A[19:0] define the row and column addresses for READ and WRITE operations. During a MODE REGISTER SET, the address inputs define the register settings along with BA[3:0]. They are sampled at the rising edge of CK. Bank address inputs: Select the internal bank to which a command is being applied. Input clock: CK and CK# are differential input clocks. Addresses and commands are latched on the rising edge of CK. Chip select: CS# enables the command decoder when LOW and disables it when HIGH. When the command decoder is disabled, new commands are ignored, but internal operations continue. Data input: The DQ signals form the 36-bit data bus. During READ commands, the data is referenced to both edges of QK. During WRITE commands, the data is sampled at both edges of DK. Input data clock: DKx and DKx# are differential input data clocks. All input data is referenced to both edges of DKx. For the x36 device, DQ[8:0] and DQ[26:18] are referenced to DK0 and DK0#, and DQ[17:9] and DQ[35:27] are referenced to DK1 and DK1#. For the x18 device, DQ[8:0] are referenced to DK0 and DK0#, and DQ[17:9] are referenced to DK1 and DK1#. DKx and DKx# are free-running signals and must always be supplied to the device. Input data mask: DM is the input mask signal for WRITE data. Input data is masked when DM is sampled HIGH. DM0 is used to mask the lower byte for the x18 device and DQ[8:0] and DQ[26:18] for the x36 device. DM1 is used to mask the upper byte for the x18 device and DQ[17:9] and DQ[35:27] for the x36 device. Tie DM[1:0] to VSS if not used. IEEE 1149.1 clock input: This ball must be tied to VSS if the JTAG function is not used. IEEE 1149.1 test inputs: These balls may be left as no connects if the JTAG function is not used. Command inputs: Sampled at the positive edge of CK, WE# and REF# (together with CS#) define the command to be executed. Reset: RESET# is an active LOW CMOS input referenced to VSS. RESET# assertion and deassertion are asynchronous. RESET# is a CMOS input defined with DC HIGH 0.8 x VDD and DC LOW 0.2 x VDDQ. External impedance: This signal is used to tune the devices output impedance and ODT. RZQ needs to be 240, where RZQ is a resistor from this signal to ground. Output data clocks: QK and QK# are opposite-polarity output data clocks. They are free-running signals and during READ commands are edge-aligned with the DQs. For the x36 device, QK0, QK0# align with DQ[8:0]; QK1, QK1# align with DQ[17:9]; QK2, QK2# align with DQ[26:18]; QK3, QK3# align with DQ[35:27]. For the x18 device, QK0, QK0# align with DQ[8:0]; QK1, QK1# align with DQ[17:9]. Data valid: The QVLD ball indicates that valid output data will be available on the subsequent rising clock edge. There is a single QVLD ball for the x18 device and two, QVLD0 and QVLD1, for the x36 device. QVLD0 aligns with DQ[17:0]; QVLD1 aligns with DQ[35:18]. Mirror function: The mirror function ball is a DC input used to create mirrored ballouts for simple dual-loaded clamshell mounting. If the ball is tied to VSS, the address and command balls are in their true layout. If the ball is tied to VDDQ, they are in the complement location. MF must be tied HIGH or LOW and cannot be left floating. MF is a CMOS input defined with DC HIGH 0.8 x VDD and DC LOW 0.2 x VDDQ.

BA[3:0] CK/CK# CS#

Input Input Input

DQ[35:0] DKx, DKx#

I/O Input

DM[1:0]

Input

TCK TMS, TDI WE#, REF# RESET#

Input Input Input Input

ZQ QKx, QKx#

Input Output

QVLDx

Output

MF

Input

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

14

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Ball Assignments and Descriptions

Table 3: Ball Descriptions (Continued)

Symbol TDO VDD VDDQ VEXT VREF VSS VSSQ NC NF Type Output Supply Supply Supply Supply Supply Supply Description IEEE 1149.1 test output: JTAG output. This ball may be left as no connect if the JTAG function is not used. Power supply: 1.35V nominal. See Table 7 (page 22) for range. DQ power supply: 1.2V nominal. Isolated on the device for improved noise immunity. See Table 7 (page 22) for range. Power supply: 2.5V nominal. See Table 7 (page 22) for range. Input reference voltage: VDDQ/2 nominal. Provides a reference voltage for the input buffers. Ground. DQ ground: Isolated on the device for improved noise immunity. No connect: These balls are not connected to the DRAM. No function: These balls are connected to the DRAM, but provide no functionality.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

15

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Package Dimensions

Package Dimensions

Figure 5: 168-Ball FBGA

Seating plane

0.12 A

168X 0.55 Dimensions apply to solder balls postreflow on 0.40 NSMD ball pads.

Ball A1 ID

13 12 11 10 9 8 7 6 5 4 3 2 1 A B C D

Ball A1 ID

13.5 0.1 12 CTR

E F G H

J

K L

1 TYP 1 TYP 12 CTR

M N

1.1 0.1 0.325 MIN

13.5 0.1

Note:

1. All dimensions are in millimeters.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

16

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Electrical Characteristics IDD Specifications

Table 4: IDD Operating Conditions and Maximum Limits

Notes 16 apply to the entire table Description Condition Standby current Clock active standby current Operational current: BL2 = idle; All banks idle; No inputs toggling CS# = 1; No commands; Bank address incremented and half address/data change once every four clock cycles BL = 2; Sequential bank access; Bank transitions once every tRC; Half address transitions once every tRC; Read followed by write sequence; Continuous data during WRITE commands BL = 4; Sequential bank access; Bank transitions once every tRC; Half address transitions once every tRC; Read followed by write sequence; Continuous data during WRITE commands BL = 8; Sequential bank access; Bank transitions once every tRC; Half address transitions once every tRC; Read followed by write sequence; Continuous data during WRITE commands Sixteen bank cyclic refresh using Bank Address Control AREF protocol; Command bus remains in refresh for all sixteen banks; DQs are High-Z and at VDDQ/2; Addresses are at VDDQ/2

tCK

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Symbol ISB1 (VDD) x18 ISB1 (VDD) x36 ISB1 (VEXT) ISB2 (VDD) x18 ISB2 (VDD) x36 ISB2 (VEXT) IDD1 (VDD) x18 IDD1 (VDD) x36 IDD1 (VEXT)

-093E 125 125 30 870 895 30 1175 1185 35

-093 125 125 30 870 895 30 1115 1125 35

-107E 125 125 30 815 835 30 1100 1110 35

-107 125 125 30 815 835 30 1045 1055 35

-125E 125 125 30 725 740 30 940 950 35

-125 125 125 30 725 740 30 915 925 35

Units mA

Notes 7

mA

mA

576Mb: x18, x36 RLDRAM 3 Electrical Characteristics IDD Specifications

Operational current: BL4

IDD2 (VDD) x18 IDD2 (VDD) x36 IDD2 (VEXT)

1205 1215 35

1145 1155 35

1130 1140 35

1075 1080 35

970 980 35

945 950 35

mA

17

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Operational current: BL8

IDD3 (VDD) x18 IDD3 (VDD) x36 IDD3 (VEXT)

1300 NA 35

1220 NA 35

1200 NA 35

1130 NA 35

1030 NA 35

1000 NA 35

mA

Burst refresh current

IREF1 (VDD) x18 IREF1 (VDD) x36 IREF1 (VEXT)

1550 1570 80

1550 1570 80

1400 1420 75

1400 1420 75

1230 1245 70

1230 1245 70

mA

Advance

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Table 4: IDD Operating Conditions and Maximum Limits (Continued)

Notes 16 apply to the entire table Description Condition Distributed refresh current Single bank refresh using Bank Address Control AREF protocol; Sequential bank access every 0.489s; DQs are High-Z and at VDDQ/2; Addresses are at VDDQ/2 Symbol IREF2 (VDD) x18 IREF2 (VDD) x36 IREF2 (VEXT) -093E 855 875 30 -093 855 875 30 -107E 800 815 30 -107 800 815 30 -125E 710 725 30 -125 710 725 30 Units mA Notes

Multibank refresh current: 4 bank refresh

Quad bank refresh using MultiIMBREF4 (VDD) x18 bank AREF protocol; BL = 4; Cyclic IMBREF4 (VDD) x36 bank access; Subject to tSAW and IMBREF4 (VEXT) tMMD specifications; DQs are HighZ and at VDDQ/2; Bank addresses are at VDDQ/2 BL = 2; Cyclic bank access; Half of address bits change every clock cycle; Continuous data; Measurement is taken during continuous WRITE BL = 4; Cyclic bank access; Half of address bits change every two clock cycles; Continuous data; Measurement is taken during continuous WRITE BL = 8; Cyclic bank access; Half of address bits change every four clock cycles; Continuous data; Measurement is taken during continuous WRITE BL = 4; Cyclic bank access using Dual Bank WRITE; Half of address bits change every two clock cycles; Continuous data; Measurement is taken during continuous WRITE IDD2W (VDD) x18 IDD2W (VDD) x36 IDD2W (VEXT) IDD4W (VDD) x18 IDD4W (VDD) x36 IDD4W (VEXT) IDD8W (VDD) x18 IDD8W (VDD) x36 IDD8W (VEXT) IDBWR (VDD) x18 IDBWR (VDD) x36 IDBWR (VEXT)

1965 2155 130

1965 2155 130

1895 1915 115

1895 1915 115

1650 1665 105

1650 1665 105

mA

Operating burst write current : BL2

2110 2290 80

2110 2290 80

1910 2070 75

1910 2070 75

1665 1805 70

1665 1805 70

mA

576Mb: x18, x36 RLDRAM 3 Electrical Characteristics IDD Specifications

18

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Operating burst write current : BL4

1730 1815 55

1730 1815 55

1590 1665 55

1590 1665 55

1395 1460 50

1395 1460 50

mA

Operating burst write current :BL8

1475 NA 45

1475 NA 45

1335 NA 40

1335 NA 40

1190 NA 40

1190 NA 40

mA

Multibank write current: Dual bank write

2305 2400 80

2305 2400 80

2170 2250 75

2170 2250 75

1885 1960 70

1885 1960 70

mA

Advance

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

Table 4: IDD Operating Conditions and Maximum Limits (Continued)

Notes 16 apply to the entire table Description Condition Multibank write current: Quad bank write BL = 4; Cyclic bank access using Quad Bank WRITE; Half of address bits change every two clock cycles; Continuous data; Measurement is taken during continuous WRITE; Subject to tSAW specification BL = 2; Cyclic bank access; Half of address bits change every clock cycle; Continuous data; Measurement is taken during continuous READ BL = 4; Cyclic bank access; Half of address bits change every two clock cycles; Continuous data; Measurement is taken during continuous READ BL = 8; Cyclic bank access; Half of address bits change every four clock cycles; Continuous data; Measurement is taken during continuous READ Symbol IQBWR (VDD) x18 IQBWR (VDD) x36 IQBWR (VEXT) -093E 2965 3195 130 -093 2965 3195 130 -107E 2890 3000 115 -107 2890 3000 115 -125E 2525 2615 100 -125 2525 2615 100 Units mA Notes

Operating burst read current example Operating burst read current example

IDD2R (VDD) x18 IDD2R (VDD) x36 IDD2R (VEXT) IDD4R (VDD) x18 IDD4R (VDD) x36 IDD4R (VEXT) IDD8R (VDD) x18 IDD8R (VDD) x36 IDD8R (VEXT)

2250 2395 80

2250 2395 80

2045 2180 75

2045 2180 75

1785 1895 70

1785 1895 70

mA

1740 1835 55

1740 1835 55

1595 1685 55

1595 1685 55

1400 1475 50

1400 1475 50

mA

576Mb: x18, x36 RLDRAM 3 Electrical Characteristics IDD Specifications

19

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Operating burst read current example

1450 NA 45

1450 NA 45

1315 NA 40

1315 NA 40

1175 NA 40

1175 NA 40

mA

Advance

Advance

576Mb: x18, x36 RLDRAM 3 Electrical Characteristics IDD Specifications

Notes: 1. IDD specifications are tested after the device is properly initialized. 0C TC +95C; +1.28V VDD +1.42V,+1.14V VDDQ +1.26V,+2.38V VEXT +2.63V,VREF = VDDQ/2. 2. IDD mesurements use tCK (MIN), tRC (MIN), and minimum data latency (RL and WL). 3. Input slew rate is 1V/ns for single ended signals and 2V/ns for differential signals. 4. Definitions for IDD conditions: LOW is defined as VIN VIL(AC)MAX. HIGH is defined as VIN VIH(AC)MIN. Continuous data is defined as half the DQ signals changing between HIGH and LOW every half clock cycle (twice per clock). Continuous address is defined as half the address signals changing between HIGH and LOW every clock cycle (once per clock). Sequential bank access is defined as the bank address incrementing by one every tRC. Cyclic bank access is defined as the bank address incrementing by one for each command access. For BL = 2 this is every clock, for BL = 4 this is every other clock, and for BL = 8 this is every fourth clock. 5. CS# is HIGH unless a READ, WRITE, AREF, or MRS command is registered. CS# never transitions more than once per clock cycle. 6. IDD parameters are specified with ODT disabled. 7. Upon exiting standby current conditions, at least one NOP command must be issued with stable clock prior to issuing any other valid command.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

20

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Electrical Specifications Absolute Ratings and I/O Capacitance

Electrical Specifications Absolute Ratings and I/O Capacitance

Absolute Maximum Ratings

Stresses greater than those listed may cause permanent damage to the device. This is a stress rating only, and functional operation of the device at these or any other conditions outside those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may adversely affect reliability. Table 5: Absolute Maximum Ratings

Symbol VDD VDDQ VIN,VOUT VEXT Parameter VDD supply voltage relative to VSS Voltage on VDDQ supply relative to VSS Voltage on any ball relative to VSS Voltage on VEXT supply relative to VSS Min 0.4 0.4 0.4 0.4 Max 1.975 1.66 1.66 2.8 Units V V V V

Input/Output Capacitance

Table 6: Input/Output Capacitance

Notes 1 and 2 apply to entire table RL3-2133 Capacitance Parameters CK/CK# C: CK to CK# Single-ended I/O: DQ, DM Input strobe: DK/DK# Output strobe: QK/QK#, QVLD C: DK to DK# C: QK to QK# C: DQ to QK or DQ to DK Inputs (CMD, ADDR) C: CMD_ADDR to CK JTAG balls RESET#, MF balls Notes: Symbol CCK CDCK CIO CIO CIO CDDK CDQK CDIO CI CDI_CMD_ADDR CJTAG CI Min 1.3 0 1.9 1.9 1.9 0 0 0.5 1.25 0.5 1.5 Max 2.1 0.15 2.9 2.9 2.9 0.15 0.15 0.3 2.25 0.3 4.5 3.0 RL3-1866 Min 1.3 0 1.9 1.9 1.9 0 0 0.5 1.25 0.5 1.5 Max 2.1 0.15 3.0 3.0 3.0 0.15 0.15 0.3 2.25 0.3 4.5 3.0 RL3-1600 Min 1.3 0 2.0 2.0 2.0 0 0 0.5 1.25 0.4 1.5 Max 2.2 0.15 3.1 3.1 3.1 0.15 0.15 0.3 2.25 0.4 4.5 3.0 Units pF pF pF pF pF pF pF pF pF pF pF pF 4 5 6 7 3 Notes

1. +1.28V VDD +1.42V, +1.14V VDDQ 1.26V, +2.38V VEXT +2.63V, VREF = VSS, f = 100 MHz, TC = 25C, VOUT(DC) = 0.5 VDDQ, VOUT (peak-to-peak) = 0.1V. 2. Capacitance is not tested on ZQ ball. 3. DM input is grouped with the I/O balls, because they are matched in loading. 4. CDIO = CIO(DQ) - 0.5 (CIO [QK] + CIO [QK#]). 5. Includes CS#, REF#, WE#, A[19:0], and BA[3:0]. 6. CDI_CMD_ADDR = CI (CMD_ADDR) - 0.5 (CCK [CK] + CCK [CK#]). 7. JTAG balls are tested at 50 MHz.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

21

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

AC and DC Operating Conditions

Table 7: DC Electrical Characteristics and Operating Conditions

Note 1 applies to the entire table; Unless otherwise noted: 0C TC +95C; +1.28V VDD +1.42V Description Symbol Min Max Supply voltage Supply voltage Isolated output buffer supply Reference voltage Input HIGH (logic 1) voltage Input LOW (logic 0) voltage Input leakage current: Any input 0V VIN VDD, VREF ball 0V VIN 1.1V (All other balls not under test = 0V) Reference voltage current Notes: VEXT VDD VDDQ VREF VIH(DC) VIL(DC) ILI IREF 2.38 1.28 1.14 0.49 VDDQ VREF + 0.10 VSS 2 5 2.63 1.42 1.26 0.51 VDDQ VDDQ VREF - 0.10 2 5 Units V V V V V V A A 2, 3 Notes

1. All voltages referenced to VSS (GND). 2. The nominal value of VREF is expected to be 0.5 VDDQ of the transmitting device. VREF is expected to track variations in VDDQ. 3. Peak-to-peak noise (non-common mode) on VREF may not exceed 2% of the DC value. DC values are determined to be less than 20 MHz. Peak-to-peak AC noise on VREF should not exceed 2% of VREF(DC). Thus, from VDDQ/2, VREF is allowed 2% VDDQ/2 for DC error and an additional 2% VDDQ/2 for AC noise. The measurement is to be taken at the nearest VREF bypass capacitor.

Table 8: Input AC Logic Levels

Notes 1-3 apply to entire table; Unless otherwise noted: 0C TC +95C; +1.28V VDD +1.42V Description Symbol Min Max Input HIGH (logic 1) voltage Input LOW (logic 0) voltage Notes: VIH(AC) VIL(AC) VREF + 0.15 VREF - 0.15 Units V V

1. All voltages referenced to VSS (GND). 2. The receiver will effectively switch as a result of the signal crossing the AC input level, and will remain in that state as long as the signal does not ring back above/below the DC input LOW/HIGH level. 3. Single-ended input slew rate = 1 V/ns; maximum input voltage swing under test is 900mV (peak-to-peak).

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

22

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

Figure 6: Single-Ended Input Signal

VIL and VIH levels with ringback 1.60V VDDQ + 0.4V narrow pulse width

1.20V Minimum VIL and VIH levels 0.750V VIH(AC) 0.750V

VDDQ

VIH(AC)

0.70V

VIH(DC)

0.70V

VIH(DC)

0.624V 0.612V 0.60V 0.588V 0.576V

0.624V 0.612V 0.60V 0.588V 0.576V

VREF + AC noise VREF + DC error VREF - DC error VREF - AC noise

0.50V

VIL(DC)

0.50V

VIL(DC)

0.45V

VIL(AC)

0.450V

VIL(AC)

0.0V

VSS VSS - 0.4V narrow pulse width

0.40V

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

23

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions AC Overshoot/Undershoot Specifications

Table 9: Control and Address Balls

Parameter Maximum peak amplitude allowed for overshoot area Maximum peak amplitude allowed for undershoot area Maximum overshoot area above VDDQ Maximum undershoot area below VSS/VSSQ RL3-2133 0.4V 0.4V 0.25 Vns 0.25 Vns RL3-1866 0.4V 0.4V 0.28 Vns 0.28 Vns RL3-1600 0.4V 0.4V 0.33 Vns 0.33 Vns

Table 10: Clock, Data, Strobe, and Mask Balls

Parameter Maximum peak amplitude allowed for overshoot area Maximum peak amplitude allowed for undershoot area Maximum overshoot area above VDDQ Maximum undershoot area below VSS/VSSQ RL3-2133 0.4V 0.4V 0.10 Vns 0.10 Vns RL3-1866 0.4V 0.4V 0.11 Vns 0.11 Vns RL3-1600 0.4V 0.4V 0.13 Vns 0.13 Vns

Figure 7: Overshoot

Volts (V)

Maximum amplitude

Overshoot area

VDDQ Time (ns)

Figure 8: Undershoot

VSS/VSSQ Volts (V) Maximum amplitude Time (ns)

Undershoot area

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

24

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

Table 11: Differential Input Operating Conditions (CK, CK# and DKx, DKx#)

Notes 1 and 2 apply to entire table Parameter/Condition Differential input voltage logic HIGH slew Differential input voltage logic LOW slew Differential input voltage logic HIGH Differential input voltage logic LOW Differential input crossing voltage relative to VDD/2 Single-ended HIGH level Single-ended LOW level Notes: 1. 2. 3. 4. Symbol VIH,diff_slew VIL,diff_slew VIH,diff(AC) VIL,diff(AC) VIX VSEH VSEL Min +200 n/a 2 (VIH(AC) - VREF) VSSQ VREF(DC) - 150 VIH(AC) VSSQ Max n/a -200 VDDQ 2 (VIL(AC) - VREF ) VREF(DC) + 150 VDDQ VIL(AC) Units mV mV mV mV mV mV mV Notes 3 3 4 5 6 4 5

CK/CK# and DKx/DKx# are referenced to VDDQ and VSSQ. Differential input slew rate = 2 V/ns. Defines slew rate reference points, relative to input crossing voltages. Maximum limit is relative to single-ended signals; overshoot specifications are applicable. 5. Minimum limit is relative to single-ended signals; undershoot specifications are applicable. 6. The typical value of VIX is expected to be about 0.5 VDDQ of the transmitting device and VIX is expected to track variations in VDDQ. VIX indicates the voltage at which differential input signals must cross.

Figure 9: VIX for Differential Signals

VDDQ CK#, DKx# VDDQ CK#, DKx#

X

VIX VDDQ/2

VIX

X

VIX

VDDQ/2

X

CK, DKx VSSQ

VIX CK, DKx VSSQ

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

25

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

Figure 10: Single-Ended Requirements for Differential Signals

VDDQ VSEH,min

VDDQ/2 VSEL,max

VSEH

CK or DKx

VSS

VSEL

Figure 11: Definition of Differential AC Swing and tDVAC

tDVAC VIH,diff(AC)min

VIH,diff_slew,min CK - CK# DKx - DKx#

0.0

VIL,diff_slew,max

VIL,diff(AC)max half cycle tDVAC

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

26

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

Table 12: Allowed Time Before Ringback (tDVAC) for CK, CK#, DKx, and DKx#

Slew Rate (V/ns) >4.0 4.0 3.0 2.0 1.9 1.6 1.4 1.2 1.0 <1.0 MIN tDVAC (ps) at |VIH/VIL,diff(AC)| 175 170 167 163 162 161 159 155 150 150

Slew Rate Definitions for Single-Ended Input Signals

Setup (tIS and tDS) nominal slew rate for a rising signal is defined as the slew rate between the last crossing of V REF and the first crossing of V IH(AC)min. Setup (tIS and tDS) nominal slew rate for a falling signal is defined as the slew rate between the last crossing of V REF and the first crossing of V IL(AC)max. Hold (tIH and tDH) nominal slew rate for a rising signal is defined as the slew rate between the last crossing of V IL(DC)max and the first crossing of V REF. Hold (tIH and tDH) nominal slew rate for a falling signal is defined as the slew rate between the last crossing of V IH(DC)min and the first crossing of V REF (see Figure 12 (page 28)). Table 13: Single-Ended Input Slew Rate Definition

Input Slew Rates (Linear Signals) Input Setup Hold Edge Rising Falling Rising Falling From VREF VREF VIL(DC)max VIH(DC)min Measured To VIH(AC)min VIL(AC)max VREF VREF Calculation [VIH(AC)min - VREF]/TRS [VREF - VIL(AC)max]/TFS [VREF - VIL(DC)max]/TRH [VIH(DC)min - VREF]/TFH

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

27

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions

Figure 12: Nominal Slew Rate Definition for Single-Ended Input Signals

TRS

Setup

Single-ended input voltage (DQ, CMD, ADDR)

VIH(AC)min VIH(DC)min

VREF

VIL(DC)max VIL(AC)max

TFS

TRH

Hold

Single-ended input voltage (DQ, CMD, ADDR)

VIH(AC)min VIH(DC)min

VREF

VIL(DC)max VIL(AC)max

TFH

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

28

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 AC and DC Operating Conditions Slew Rate Definitions for Differential Input Signals

Input slew rate for differential signals (CK, CK# and DKx, DKx#) are defined and measured as shown in the following two tables. The nominal slew rate for a rising signal is defined as the slew rate between V IL,diff,max and V IH,diff,min. The nominal slew rate for a falling signal is defined as the slew rate between V IH,diff,min and V IL,diff,max. Table 14: Differential Input Slew Rate Definition

Differential Input Slew Rates (Linear Signals) Input CK and DK reference Edge Rising Falling From VIL,diff_slew,max VIH,diff_slew,min

Measured To VIH,diff_slew,min VIL,diff_slew,max Calculation [VIH,diff_slew,min - VIL,diff_slew,max]/TRdiff [VIH,diff_slew,min - VIL,diff_slew,max]/TFdiff

Figure 13: Nominal Differential Input Slew Rate Definition for CK, CK#, DKx, and DKx#

TRdiff

Differential input voltage (CK, CK#; DKx, DKx#)

VIH,diff_slew,min

VIL,diff_slew,max

TFdiff

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

29

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 ODT Characteristics

ODT Characteristics

ODT effective resistance, RTT, is defined by MR1[4:2]. ODT is applied to the DQ, DM, and DKx, DKx# balls. The individual pull-up and pull-down resistors (R TTPU and RTTPD) are defined as follows: RTTPU =(VDDQ - VOUT) / |IOUT|, under the condition that RTTPD is turned off RTTPD = (VOUT) / |IOUT|, under the condition that RTTPU is turned off Figure 14: ODT Levels and I-V Characteristics

Chip in termination mode ODT VDDQ IPU To other circuitry such as RCV, . . . RTTPU IOUT = IPD - IPU DQ RTTPD IPD VSSQ IOUT VOUT

Table 15: ODT DC Electrical Characteristics

Parameter/Condition RTT effective impedance from VIL(AC) to VIH(AC) Deviation of VM with respect to VDDQ/2 Notes: Symbol RTT_EFF Vm -5 Min Nom Max +5 Units % Notes 1, 2 3

See Table 16 (page 31).

1. Tolerance limits are applicable after proper ZQ calibration has been performed at a stable temperature and voltage. Refer to ODT Sensitivity (page 32) if either the temperature or voltage changes after calibration. 2. Measurement definition for RTT: Apply VIH(AC) to ball under test and measure current I[VIH(AC)], then apply VIL(AC) to ball under test and measure current I[VIL(AC)]:

RTT =

VIH(AC) - VIL(AC)

|I[VIH(AC)] - I[VIL(AC)]|

2 VM - 1 100 VDDQ

3. Measure voltage (VM) at the tested ball with no load:

VM =

ODT Resistors

The on-die termination resistance is selected by MR1[4:2]. The following table provides an overview of the ODT DC electrical characteristics. The values provided are not speciPDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

30

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 ODT Characteristics

fication requirements; however, they can be used as design guidelines to indicate what RTT is targeted to provide: RTT 120 is made up of RTT120(PD240) and RTT120(PU240). RTT 60 is made up of RTT60(PD120) and RTT60(PU120). RTT 40 is made up of RTT40(PD80) and RTT40(PU80). Table 16: RTT Effective Impedances

RTT 120 Resistor RTT120(PD240) VOUT 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ RTT120(PU240) 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ 120 60 RTT60(PD120) VIL(AC) to VIH(AC) 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ RTT60(PU120) 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ 60 40 RTT40(PD80) VIL(AC) to VIH(AC) 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ RTT40(PU80) 0.2 x VDDQ 0.5 x VDDQ 0.8 x VDDQ 40 VIL(AC) to VIH(AC) Min 0.6 0.9 0.9 0.9 0.9 0.6 0.9 0.6 0.9 0.9 0.9 0.9 0.6 0.9 0.6 0.9 0.9 0.9 0.9 0.6 0.9 Nom 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 Max 1.1 1.1 1.4 1.4 1.1 1.1 1.6 1.1 1.1 1.4 1.4 1.1 1.1 1.6 1.1 1.1 1.4 1.4 1.1 1.1 1.6 Units RZQ/1 RZQ/1 RZQ/1 RZQ/1 RZQ/1 RZQ/1 RZQ/2 RZQ/2 RZQ/2 RZQ/2 RZQ/2 RZQ/2 RZQ/2 RZQ/4 RZQ/3 RZQ/3 RZQ/3 RZQ/3 RZQ/3 RZQ/3 RZQ/6

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

31

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 ODT Characteristics ODT Sensitivity

If either temperature or voltage changes after I/O calibration, then the tolerance limits listed in Table 15 (page 30) and Table 16 (page 31) can be expected to widen according to Table 17 (page 32) and Table 18 (page 32). Table 17: ODT Sensitivity Definition

Symbol RTT Min 0.9 - dRTTdT |DT| - dRTTdV |DV| Note: Max 1.6 + dRTTdT |DT| + dRTTdV | DV| Units RZQ/(2,4,6)

1. DT = T - T(@ calibration), DV = VDDQ - VDDQ(@ calibration) or VDD - VDD(@ calibration).

Table 18: ODT Temperature and Voltage Sensitivity

Change dRTTdT dRTTdV Min 0 0 Max 1.5 0.15 Units %/C %/mV

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

32

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Output Driver Impedance

Output Driver Impedance

The output driver impedance is selected by MR1[1:0] during initialization. The selected value is able to maintain the tight tolerances specified if proper ZQ calibration is performed. Output specifications refer to the default output driver unless specifically stated otherwise. A functional representation of the output buffer is shown below. The output driver impedance RON is defined by the value of the external reference resistor RZQ as follows: RON,x = RZQ/y (with RZQ = 240 1%; x = 40 or 60 with y = 6 or 4, respectively) The individual pull-up and pull-down resistors (RON(PU) and RON(PD)) are defined as follows: RON(PU) = (VDDQ - V OUT)/|IOUT|, when RON(PD) is turned off RON(PD) = (VOUT)/|IOUT|, when RON(PU) is turned off Figure 15: Output Driver

Chip in drive mode Output Driver VDDQ

IPU To other circuitry such as RCV, . . . RON(PU) IOUT RON(PD) IPD

DQ VOUT

VSSQ

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

33

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Output Driver Impedance

Table 19: Driver Pull-Up and Pull-Down Impedance Calculations

RON RZQ/6 = (240 1%)/6 RZQ/4 = (240 1%)/4 Driver 40 pull-down VOUT 0.2 VDDQ 0.5 VDDQ 0.8 VDDQ 40 pull-up 0.2 VDDQ 0.5 VDDQ 0.8 VDDQ 60 pull-down 0.2 VDDQ 0.5 VDDQ 0.8 VDDQ 60 pull-up 0.2 VDDQ 0.5 VDDQ 0.8 VDDQ Min 39.6 59.4 Min 24 36 36 36 36 24 36 54 54 54 54 36 Nom 40 60 Nom 40 40 40 40 40 40 60 60 60 60 60 60 Max 40.4 60.6 Max 44 44 56 56 44 44 66 66 84 84 66 66 Units Units

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

34

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Output Driver Impedance Output Driver Sensitivity

If either the temperature or the voltage changes after ZQ calibration, then the tolerance limits listed in Table 19 (page 34) can be expected to widen according to Table 20 (page 35) and Table 21 (page 35). Table 20: Output Driver Sensitivity Definition

Symbol RON(PD) @ 0.2 VDDQ RON(PD) @ 0.5 VDDQ RON(PD) @ 0.8 VDDQ RON(PU) @ 0.2 VDDQ RON(PU) @ 0.5 VDDQ RON(PU) @ 0.8 VDDQ Note: Min 0.6 - dRONdTH DT - dRONdVH DV 0.9 - dRONdTL DT - dRONdVL DV 0.9 - dRONdTH DT - dRONdVH DV 0.6 - dRONdTL DT - dRONdVL DV Max 1.1 + dRONdTH DT + dRONdVH DV 1.4 + dRONdTL DT + dRONdVL D 1.4 + dRONdTH DT + dRONdVH DV 1.1 + dRONdTL DT + dRONdVL DV Units RZQ/(6, 4) RZQ/(6, 4) RZQ/(6, 4) RZQ/(6, 4) RZQ/(6, 4) RZQ/(6, 4)

0.9 - dRONdTM DT - dRONdVM DV 1.1 + dRONdTM DT + dRONdVM DV

0.9 - dRONdTM DT - dRONdVM DV 1.1 + dRONdTM DT + dRONdVM DV

1. DT = T - T(@ calibration), DV = VDDQ - VDDQ(@ calibration) or VDD - VDD(@ calibration).

Table 21: Output Driver Voltage and Temperature Sensitivity

Change dRONdTM dRONdVM dRONdTL dRONdVL dRONdTH dRONdVH Min 0 0 0 0 0 0 Max 1.5 0.15 1.5 0.15 1.5 0.15 Unit %/C %/mV %/C %/mV %/C %/mV

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

35

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Output Characteristics and Operating Conditions

Output Characteristics and Operating Conditions

Table 22: Single-Ended Output Driver Characteristics

Note 1 and 2 apply to entire table Parameter/Condition Output leakage current; DQ are disabled; Any output ball 0V VOUT VDDQ; ODT is disabled; All other balls not under test = 0V Output slew rate: Single-ended; For rising and falling edges, measures between VOL(AC) = VREF - 0.1 VDDQ and VOH(AC) = VREF + 0.1 VDDQ Single-ended DC high-level output voltage Single-ended DC mid-point level output voltage Single-ended DC low-level output voltage Single-ended AC high-level output voltage Single-ended AC low-level output voltage Impedance delta between pull-up and pull-down for DQ and QVLD Test load for AC timing and output slew rates Notes: Symbol IOZ Min 5 Max 5 Units A Notes

SRQSE

2.5

V/ns

4, 5

VOH(DC) VOM(DC) VOL(DC) VOH(AC) VOL(AC) MMPUPD

0.8 VDDQ 0.5 VDDQ 0.2 VDDQ VTT + 0.1 VDDQ VTT - 0.1 VDDQ 10 10

V V V V V %

6 6 6 7, 8, 9 7, 8, 9 3 9

Output to VTT (VDDQ/2) via 25 resistor

1. All voltages are referenced to VSS. 2. RZQ is 240 (1%) and is applicable after proper ZQ calibration has been performed at a stable temperature and voltage. 3. Measurement definition for mismatch between pull-up and pull-down (MMPUPD). Measure both RON(PU) and RON(PD) at 0.5 VDDQ:

MMPUPD =

RonPU - RonPD RonNOM

x 100

4. The 6 V/ns maximum is applicable for a single DQ signal when it is switching either from HIGH to LOW or LOW to HIGH while the remaining DQ signals in the same byte lane are either all static or switching the opposite direction. For all other DQ signal switching combinations, the maximum limit of 6 V/ns is reduced to 5 V/ns. 5. See Table 24 (page 40) for output slew rate. 6. See the Driver Pull-Up and Pull-Down Impedance Calculations table for IV curve linearity. Do not use AC test load. 7. VTT = VDDQ/2 8. See Figure 16 (page 38) for an example of a single-ended output signal. 9. See Figure 18 (page 39) for the test load configuration.

PDF: 09005aef84003617 576mb_rldram3.pdf Rev. B 1/12 EN

36

Micron Technology, Inc. reserves the right to change products or specifications without notice. 2011 Micron Technology, Inc. All rights reserved.

Advance

576Mb: x18, x36 RLDRAM 3 Output Characteristics and Operating Conditions

Table 23: Differential Output Driver Characteristics

Notes 1 and 2 apply to entire table Parameter/Condition Output leakage current; DQ are disabled; Any output ball 0V VOUT VDDQ; ODT is disabled; All other balls not under test = 0V Output slew rate: Differential; For rising and falling edges, measures between VOL,diff(AC) = 0.2 VDDQ and VOH,diff(AC) = +0.2 VDDQ Output differential cross-point voltage Differential high-level output voltage Differential low-level output voltage Delta resistance between pull-up and pull-down for QK/QK# Test load for AC timing and output slew rates Notes: Symbol IOZ Min 5 Max 5 Units A Notes

SRQdiff

12

V/ns

VOX(AC) VOH,diff(AC) VOL,diff(AC) MMPUPD

VREF - 150

VREF + 150

mV V V %

6 6 6 3 4

+0.2 VDDQ 0.2 VDDQ 10 10

Output to VTT (VDDQ/2) via 25 resistor

1. All voltages are referenced to VSS. 2. RZQ is 240 (1%) and is applicable after proper ZQ calibration has been performed at a stable temperature and voltage. 3. Measurement definition for mismatch between pull-up and pull-down (MMPUPD). Measure both RON(PU) and RON(PD) at 0.5 x VDDQ:

MMPUPD =

RonPU - RonPD RonNOM

x 100

4. See Figure 18 (page 39) for the test load configuration. 5. See Table 25 (page 41) for the output slew rate. 6. See Figure 17 (page 39) for an example of a differential output signal.