Beruflich Dokumente

Kultur Dokumente

Design of Bolts

Hochgeladen von

Serjoe N. RosalOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Bolts

Hochgeladen von

Serjoe N. RosalCopyright:

Verfügbare Formate

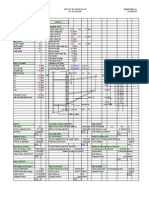

# 1. Input Data 1.

1 Design Constant: Yield Strength, fy Tension Capacity of bolts, ftb Shear Capacity of bolts, fvb Ultimate Strength, Fu

= = = =

275 560 375 344

MPa MPa MPa MPa

Diameter of Bolts, f Number of rows, Nr Number of colums, Nc Total No. of Bolts, n

= = = =

3 1 3

pcs

X1

X2

X3 Y1 Y2 Y2 Y3 Row Row Row

Col.

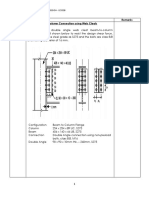

1.2 Plate Properties and Spacing of Bolts: Height of Plate, h: Width of plate, w: Thickness of plate, t: 1 = = = 350 120 16 mm mm mm X1 X2 X3 = = = 60 0 60 mm mm mm Sh

Col.

Y1 = Y2 = Y3 = = 30

50 125 50 mm

mm mm mm

Consider slotted hole parallel to tension Tu for plate? Y / N/A Note: Sh should be equal to zero (0) if not applicable. 0 Nominal Hole Diameter, Nd: mm Note: Nd is set to zero (0) if slotted hole was applicable. 2. Verification on Bolts: 2.1 ULS Design Forces for Bolts: Tensile Force, Tu Shear Force, Vu1 Shear Force, Vu2 Resultant, Vu 2.2 Verification against Tension: Tension Capacity of Bolts, Tb Tensile Force, Tu Tension force per Bolt, Tub Check: Tub < Tb = OK!!! Consider: = = = 58.9 kN 137.63 kN 45.88 kN Ratio: Vub / Vb = = = 70.3 kN 53 kN 17.67 kN Ratio: Tub / Tb

Single Shear

= = = =

53 69.24 118.94 137.63

kN kN kN kN

Vu1

Tu

Vu2

0.25

Double Shear

2.3 Verification against Shear: Shear Capacity of Bolts, Vb Shear Force, Vu Shear force per Bolts, Vub Check: Vub < Vb = OK!!!

0.78

3. Verification on Plate: 3.1 ULS Design Forces for plate: Tensile Force, Tu Shear Force, Vu1

= 69.24 kN = 130.214 kN

3.2 Check tensile stress of the plate: 3.2.1 Due to tension Tu: Net width, w: Thickness, t: Net area of Plate, At: Actual tensile stress, ft Allowable tensile stress, Ft: Check: ft < Ft = = = = = 296 16 4736 14.62 165 mm mm mm MPa MPa

2

[ Tu / At ] [ 0.60 x fy ] Line of failure

= OK!!!

3.2.2 Due to shear Vu: Net width, w: Thickness, t: Net area of Plate, Av: Actual shear stress, fv: Allowable shear stress, Fv: Check: fv < Fv = = = = = 90 16 1440 90.43 165 mm mm mm2 MPa MPa [ Vu / Av ] [ 0.60 x fy ] Line of failure = OK!!!

3.3 Check bearing of plate: 3.3.1 due to tesion Tu: Distance of bolt to edge, Lce: Distance between bolt, Lco: Thickness of plate, t: Bolts at edge: Rne = Rne1 = = Rne2 = = Rne = = Rn = = = = = 45 0 16 mm mm mm reduction factor, : coefficient, c: diameter of bolts, d = = = 0.75 2.4 16

min ( Rne1, Rne2 ) x 1.2 x Fu x Lce x t 222.91 kN x c x d x Fu x tm 158.52 kN min ( Rne1, Rne2 ) x Nr 475.55 kN Rne + Rno 475.55 kN > Tu OK!!!

Bolts at middle: Rno = min ( Rno1, Rno2 ) Rno1 = x 1.2 x Fu x Lco x t 0.00 kN = Rno2 = x c x d x Fu x t = 158.52 kN Rno = min( Rno1, Rno2 )x(Nr x (Nc - 1)) 0.00 kN =

Check: Rn

Ratio:

Rn / Tu

6.87

3.3.2 due to shear Vu: Distance of bolt to edge, Lce: Distance between bolt, Lco: Thickness of plate, t: Bolts at edge: Rne = Rne1 = = Rne2 = = Rne = = Rn = = = = = 41 107 16 mm mm mm reduction factor, : coefficient, c: diameter of bolts, d = = = 0.75 2.4 16

min ( Rne1, Rne2 ) x 1.2 x Fu x Lce x t 203.1 kN x c x d x Fu x tm 158.52 kN min ( Rne1, Rne2 ) x Nc 158.52 kN Rne + Rno 475.55 kN > Tu OK!!!

Bolts at middle: Rno = min ( Rno1, Rno2 ) Rno1 = x 1.2 x Fu x Lco x t = 530.04 kN Rno2 = x c x d x Fu x t = 158.52 kN Rno = min( Rno1, Rno2 )x(Nc x (Nr -1 )) = 317.03 kN

Check: Rn

Ratio:

Rn / Tu

3.65

Das könnte Ihnen auch gefallen

- Design of Horizontal BracingDokument1 SeiteDesign of Horizontal BracingdsanandaNoch keine Bewertungen

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDokument9 SeitenPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCНемања КараклајићNoch keine Bewertungen

- Base PlateDokument2 SeitenBase PlateLam TranNoch keine Bewertungen

- Base Plate & BoltsDokument3 SeitenBase Plate & BoltsarvnndNoch keine Bewertungen

- Anchor Bolt (CSA) Rev1.1Dokument10 SeitenAnchor Bolt (CSA) Rev1.1coolkaisyNoch keine Bewertungen

- HSS Flange Plate Moment Connection - Temporary SteelDokument9 SeitenHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNoch keine Bewertungen

- AASHTO Simplified Shear CalcDokument9 SeitenAASHTO Simplified Shear CalcSharyn PolleyNoch keine Bewertungen

- Bolted Moment Connection 2x2Dokument22 SeitenBolted Moment Connection 2x2Немања Караклајић100% (1)

- FinPlate Type Cleat ConnectionDokument81 SeitenFinPlate Type Cleat ConnectionRajveer SinghNoch keine Bewertungen

- End Plate DesignDokument4 SeitenEnd Plate DesignAgnon Fung100% (4)

- Gantry Girder DesignDokument6 SeitenGantry Girder DesignpandianNoch keine Bewertungen

- Moment Connection DETAIL 2Dokument8 SeitenMoment Connection DETAIL 2amachmouchiNoch keine Bewertungen

- Combined Gusset Plate DesignDokument3 SeitenCombined Gusset Plate Designkalpanaadhi100% (3)

- Rafter Splice DesignDokument2 SeitenRafter Splice DesignkalpanaadhiNoch keine Bewertungen

- Base Plate DesignDokument4 SeitenBase Plate DesignAnonymous 1HFV185Sl4Noch keine Bewertungen

- Bolt Design (Blodget)Dokument4 SeitenBolt Design (Blodget)Mayuresh KudveNoch keine Bewertungen

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDokument1 SeiteChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNoch keine Bewertungen

- Building - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEDokument18 SeitenBuilding - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEmaheshbandhamNoch keine Bewertungen

- ConnectionDokument7 SeitenConnectionasad_naqviNoch keine Bewertungen

- Welded Connection With I BeamDokument8 SeitenWelded Connection With I BeamНемања КараклајићNoch keine Bewertungen

- Bolted ConnectionDokument79 SeitenBolted ConnectionMEPNoch keine Bewertungen

- Anchor Bolt CHKDokument17 SeitenAnchor Bolt CHKPriya GNoch keine Bewertungen

- Design of ConnectionDokument4 SeitenDesign of ConnectionMark EngNoch keine Bewertungen

- Input: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100Dokument11 SeitenInput: KN.M 59.00 ### KN KN MM 500 MM 200 MM 24 MM 16 MM 24 MM 100 MM 100maheshbandhamNoch keine Bewertungen

- Design of Base Plate & Anchor Bolt (Crusher House)Dokument5 SeitenDesign of Base Plate & Anchor Bolt (Crusher House)titir bagchiNoch keine Bewertungen

- ANCHOR BOLTS DESIGN - FixedDokument2 SeitenANCHOR BOLTS DESIGN - FixedsathishNoch keine Bewertungen

- Simple Bracing ConnectionDokument33 SeitenSimple Bracing ConnectionRohit SinghNoch keine Bewertungen

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Dokument3 SeitenHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariNoch keine Bewertungen

- Project: Designed By: Sheet - of - Checked By: Date: Job No: Part of Structure: Horizontal JointDokument2 SeitenProject: Designed By: Sheet - of - Checked By: Date: Job No: Part of Structure: Horizontal JointPankaj ChopraNoch keine Bewertungen

- Anchor Bolt BiAxialDokument10 SeitenAnchor Bolt BiAxialALPHYL BALASABASNoch keine Bewertungen

- Base Plate1Dokument6 SeitenBase Plate1jobees7850Noch keine Bewertungen

- Beam-Column Using Double Angle CleatDokument7 SeitenBeam-Column Using Double Angle CleatNur Syahira100% (1)

- W12x30 Beam To BeamDokument6 SeitenW12x30 Beam To BeamWin ThanNoch keine Bewertungen

- Extended Fin Plate Connection - LRFDDokument22 SeitenExtended Fin Plate Connection - LRFDkalpanaadhiNoch keine Bewertungen

- RAM Connection Input With CommentsDokument6 SeitenRAM Connection Input With CommentsAhmed Saeed OokaNoch keine Bewertungen

- Steeltek ConnectionDokument5 SeitenSteeltek ConnectionSudip ShresthaNoch keine Bewertungen

- Fin Plate Connection DesignDokument10 SeitenFin Plate Connection DesigncklconNoch keine Bewertungen

- Design of Base Plate 2Dokument2 SeitenDesign of Base Plate 2Andro RebuyasNoch keine Bewertungen

- 5 - Flush End Plate Shear ConnectionDokument10 Seiten5 - Flush End Plate Shear Connectionabdul khaderNoch keine Bewertungen

- Precast Rib Beam DesignDokument1 SeitePrecast Rib Beam Designanshutomar7915100% (1)

- Combined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Dokument60 SeitenCombined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Karthik Kala KondaNoch keine Bewertungen

- Isolated Footing Design: Forces DetailsDokument7 SeitenIsolated Footing Design: Forces DetailsMukhlish AkhatarNoch keine Bewertungen

- Connection DesignDokument6 SeitenConnection DesignbuildconNoch keine Bewertungen

- TEG Consulting Engineers Pty LTD ACN: 122 938 783 ABN9657 6103 689 PO Box 49, Innisfail QLD 4860 P: 0740618276Dokument10 SeitenTEG Consulting Engineers Pty LTD ACN: 122 938 783 ABN9657 6103 689 PO Box 49, Innisfail QLD 4860 P: 0740618276sean edwardsNoch keine Bewertungen

- Moment Connection Calculation TypeDokument17 SeitenMoment Connection Calculation TypesamNoch keine Bewertungen

- Etabs Steel Column Design Compair EtabsDokument10 SeitenEtabs Steel Column Design Compair EtabsSumedha MayadunnaNoch keine Bewertungen

- Moment Connection DesignDokument52 SeitenMoment Connection DesignKakaNoch keine Bewertungen

- Vertical Movement Connection-TopDokument2 SeitenVertical Movement Connection-TopНемања Караклајић100% (1)

- Steel Stanchion Design Calcsheet v.0Dokument2 SeitenSteel Stanchion Design Calcsheet v.0Olusegun S. Ajibola100% (2)

- STP Rusayl Oman: Double Shell Combined Circular TankDokument1 SeiteSTP Rusayl Oman: Double Shell Combined Circular TankRahulNoch keine Bewertungen

- Design of RCC Footing As Per ACI 318 95 EdDokument2 SeitenDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofNoch keine Bewertungen

- b2b SpliceDokument21 Seitenb2b SplicePrasad Dayalamoorthy DNoch keine Bewertungen

- Connection Design SheetDokument47 SeitenConnection Design SheetStephen James100% (1)

- Weld ConnectionDokument70 SeitenWeld ConnectionSudhakar KrishnamurthyNoch keine Bewertungen

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Dokument1 SeiteDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNoch keine Bewertungen

- SL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic InputDokument8 SeitenSL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic Inputkushaljp8989Noch keine Bewertungen

- Bolts For Base PlateDokument12 SeitenBolts For Base Platehemantkle2u50% (2)

- End Plate Moment ConnectionDokument16 SeitenEnd Plate Moment ConnectionAbdul HameedNoch keine Bewertungen

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDokument11 SeitenRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalNoch keine Bewertungen

- Laz 231027 PLDokument5 SeitenLaz 231027 PLSerjoe N. RosalNoch keine Bewertungen

- CATALOGUE For TransferDokument3 SeitenCATALOGUE For TransferSerjoe N. RosalNoch keine Bewertungen

- Laz 231024 WBDokument8 SeitenLaz 231024 WBSerjoe N. RosalNoch keine Bewertungen

- Truth in Lending Act: Choose The Bpi Express Credit Card That'S Right For You!Dokument4 SeitenTruth in Lending Act: Choose The Bpi Express Credit Card That'S Right For You!Serjoe N. RosalNoch keine Bewertungen

- Truth in Lending Act: Choose The Bpi Express Credit Card That'S Right For You!Dokument4 SeitenTruth in Lending Act: Choose The Bpi Express Credit Card That'S Right For You!Serjoe N. RosalNoch keine Bewertungen

- Annex B List of Registered Topical Antiseptics and Antibacterials PDFDokument15 SeitenAnnex B List of Registered Topical Antiseptics and Antibacterials PDFSerjoe N. RosalNoch keine Bewertungen

- Annex A of FA 2020-422 Updated As of 7april2020 PDFDokument19 SeitenAnnex A of FA 2020-422 Updated As of 7april2020 PDFSerjoe N. RosalNoch keine Bewertungen

- Design of Isolated FootingDokument4 SeitenDesign of Isolated FootingSerjoe N. RosalNoch keine Bewertungen

- China-Visa Application PDFDokument3 SeitenChina-Visa Application PDFSerjoe N. RosalNoch keine Bewertungen

- Shopee PH - FDA Prohibited Items PDFDokument105 SeitenShopee PH - FDA Prohibited Items PDFSerjoe N. RosalNoch keine Bewertungen

- Determination of Base Shear: Vertical Force Distribution of A 15 Storey BuildingDokument8 SeitenDetermination of Base Shear: Vertical Force Distribution of A 15 Storey BuildingSerjoe N. RosalNoch keine Bewertungen

- S - 4 S - 4 S - 4 S - 4: SLAB MARK (2nd To 5th Level)Dokument4 SeitenS - 4 S - 4 S - 4 S - 4: SLAB MARK (2nd To 5th Level)Serjoe N. RosalNoch keine Bewertungen

- Considering 1 Meter Strip: Loads AnalysisDokument2 SeitenConsidering 1 Meter Strip: Loads AnalysisSerjoe N. RosalNoch keine Bewertungen

- MZ & Partners: Long Term Deflection CalculationDokument1 SeiteMZ & Partners: Long Term Deflection CalculationSerjoe N. RosalNoch keine Bewertungen

- Design of Floor Joist 1: L M Fy 248Dokument4 SeitenDesign of Floor Joist 1: L M Fy 248Serjoe N. RosalNoch keine Bewertungen

- Calculation of Crack WidthDokument1 SeiteCalculation of Crack WidthSerjoe N. Rosal100% (1)

- EASA Essay Technique M7 9 10Dokument16 SeitenEASA Essay Technique M7 9 10Ram C HumagainNoch keine Bewertungen

- Metric Heavy Hex Nuts: ASME B18.2.4.6M-2010Dokument16 SeitenMetric Heavy Hex Nuts: ASME B18.2.4.6M-2010CarlitosNoch keine Bewertungen

- LCR - Iq Masterload - Iq Product Manual 03sep2019 LoresDokument180 SeitenLCR - Iq Masterload - Iq Product Manual 03sep2019 Loresnormal tigaNoch keine Bewertungen

- Fabrication Procedure Steel Structure TSEDokument21 SeitenFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- BS6579-1 1988Dokument33 SeitenBS6579-1 1988satheeshvm100% (1)

- 12-Samss-008 2020Dokument6 Seiten12-Samss-008 2020asimazami69Noch keine Bewertungen

- CPP-NA2-PM-PLN-0007 Procedure For Under Ground RTRDokument33 SeitenCPP-NA2-PM-PLN-0007 Procedure For Under Ground RTRAdil IjazNoch keine Bewertungen

- Vortech Super Charger Install 2001-2005 Lexus IS300 (4LA020-010v1.1)Dokument38 SeitenVortech Super Charger Install 2001-2005 Lexus IS300 (4LA020-010v1.1)TwitchEd1100% (1)

- Allis Chalmers 7g Crawler Loader Parts CatalogDokument20 SeitenAllis Chalmers 7g Crawler Loader Parts Catalogjose100% (50)

- Maryland Metrics KeensertsDokument60 SeitenMaryland Metrics KeensertsThor InternationalNoch keine Bewertungen

- Noctua NH U12s ManualDokument6 SeitenNoctua NH U12s ManualJavier Torres MaldonadoNoch keine Bewertungen

- Parts List: Model: Ddl-8000A List No: 1728-01Dokument49 SeitenParts List: Model: Ddl-8000A List No: 1728-01АнатолийNoch keine Bewertungen

- Operation Manual of Overhead Crane EnglishDokument21 SeitenOperation Manual of Overhead Crane EnglishParthiban Karuna83% (6)

- Cleaning ScrewsDokument6 SeitenCleaning ScrewsRodolfoAntonioLeónCárdenasNoch keine Bewertungen

- Machine Design TutorialDokument1 SeiteMachine Design TutorialAkash PatelNoch keine Bewertungen

- A Semi-Detailed Lesson Plan in Industrial Arts I Davao Oriental State College of Science and Technology Prepared By: I. ObjectivesDokument8 SeitenA Semi-Detailed Lesson Plan in Industrial Arts I Davao Oriental State College of Science and Technology Prepared By: I. ObjectivesJyra Mia CEMINENoch keine Bewertungen

- TB175C - Engine 4TNV98-VTBZCDokument38 SeitenTB175C - Engine 4TNV98-VTBZCsobirinNoch keine Bewertungen

- Output Transfer Gears - Disassemble: Disassembly and AssemblyDokument8 SeitenOutput Transfer Gears - Disassemble: Disassembly and AssemblyMbahdiro KolenxNoch keine Bewertungen

- Catalog Appleton Efs Non Sealed Tumbler Switches en 1277652Dokument8 SeitenCatalog Appleton Efs Non Sealed Tumbler Switches en 1277652jabrix09Noch keine Bewertungen

- TLVA REPORT SHS01 (STR)Dokument43 SeitenTLVA REPORT SHS01 (STR)Raghvendra Singh YadavNoch keine Bewertungen

- Meter PD Series m16-s1 s3 s5 s6 Po01024Dokument8 SeitenMeter PD Series m16-s1 s3 s5 s6 Po01024gabo mangoNoch keine Bewertungen

- Tehnologia Materialelor F41Dokument22 SeitenTehnologia Materialelor F41andreeaoana45Noch keine Bewertungen

- Lookshit - Terms (1-75)Dokument75 SeitenLookshit - Terms (1-75)Christopher Lennon Dela CruzNoch keine Bewertungen

- Suspended Ceilings Construction GuideDokument4 SeitenSuspended Ceilings Construction GuideHassan RahilNoch keine Bewertungen

- TLE 6 3rd PTDokument6 SeitenTLE 6 3rd PTJoy Carol MolinaNoch keine Bewertungen

- Amco TunnelDokument18 SeitenAmco Tunnelengsam777Noch keine Bewertungen

- D - SC Sander: Owner'S ManuawDokument10 SeitenD - SC Sander: Owner'S ManuawJT AlexanderNoch keine Bewertungen

- Whistler Trail StandardsDokument12 SeitenWhistler Trail StandardsschneidieNoch keine Bewertungen

- Sc500 PartsDokument46 SeitenSc500 PartsЕвгений НалимовNoch keine Bewertungen

- Boulevard 50 2T: Workshop ManualDokument154 SeitenBoulevard 50 2T: Workshop ManualLasseBSætre100% (1)