Beruflich Dokumente

Kultur Dokumente

Firction

Hochgeladen von

kahutzed666Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Firction

Hochgeladen von

kahutzed666Copyright:

Verfügbare Formate

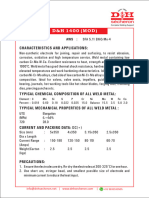

EKagrip TECHNICAL DATA

Functional Properties Material properties Delivery form Hard particle type Mean particle size avg. concentration of diamonds on the surface Matrix material Thickness of matrix x Total layer thickness y Heat treatment Hardness of nickelphosphorus matrix Color Shim material ( preferably ) Thickness d of shim Total thickness of coated shim (based on uncoated shim 0.1 mm 0.01 mm) Base part processed by Surface roughness Rz of counterpart ( transversal to direction of machining ) Min. contact pressure Max. service temperature

Friciton-enhancing electroless nickel diamant coating EKagrip EKagrip 10 Shim with EKagrip 10 coating Diamond 10 m 8 16 % Electroless nickel phosphorus 5 9 m 10 20 m 150 C / 350 C 10 C 600 / 900 HV 0.03 silver gray metallic C 75 S ( acc. to EN 10132-4 ) Standard 0.1 mm 0.01 mm (others upon request) 0.13 mm 0.02 mm EKagrip 25 PLUS Shim with EKagrip 25 PLUS coating Diamond 25 m 8 25 % Electroless nickel phosphorus 13 - 17 m 25 - 35 m 150 C / 350 C 10 C 600 / 900 HV 0.03 silver gray metallic C 75 S ( acc. to EN 10132-4 ) Standard 0.1 mm 0.01 mm (others upon request) 0.16 mm 0.02 mm EKagrip 35 PLUS Shim with EKagrip 35 PLUS coating Diamond 35 m 10 30 % Electroless nickel phosphorus 14 - 22 m 35 - 50 m 150 C / 350 C 10 C 600 / 900 HV 0.03 silver gray metallic C 75 S ( acc. to EN 10132-4 ) Standard 0.1 mm 0.01 mm (others upon request) 0.185 mm 0.025 mm

Laser cutting or stamping R z << 10 m

Laser cutting or stamping R z << 25 m

Laser cutting or stamping R z << 35 m

p > 50 MPa 400 C

p > 50 MPa 400 C

p > 50 MPa 400 C

The figures are intended as a guide. On request, we will be pleased to provide you with a drawing frame for your specification.

Diagram of an EKagrip friction shim

Diamond

Steel foil

Nickel matrix

The data presented in this leaflet are in accordance with the present state of our knowledge, but do not absolve the user from carefully checking all supplies immediately on receipt. We reserve the right to alter product constants within the scope of technical progress or new developments. The recommendations made in this leaflet should be checked by preliminary trials because of conditions during processing over which we have no control, especially where other companies raw materials are also being used. The recommendations do not absolve the user from the obligation of investigating the possibility of infringement of third parties rights and, if necessary, clarifying the position. Recommendations for use do not constitute a warranty, either express or implied, of the fitness or suitability of the products for a particular purpose.

Managementsystem zertifiziert nach ISO TS 16949, DIN EN ISO 14001. EKagrip ist eine eingetragene Marke der ESK Ceramics GmbH Co. KG.

ESK Ceramics GmbH & Co. KG Max-Schaidhauf-Strae 25 87437 Kempten, Germany www.esk.com, info@esk.com

TDS/ EKagrip / e - 11 2010

d + 2x d

d + 2y

Das könnte Ihnen auch gefallen

- Machinery HandbookDokument8 SeitenMachinery HandbookCasian Balaban10% (10)

- Drill Pipe Thread DataDokument4 SeitenDrill Pipe Thread Datakahutzed666Noch keine Bewertungen

- Downbeat 1.18Dokument116 SeitenDownbeat 1.18saltybuddha100% (1)

- (The Great Composers Series) Roy Blokker - The Music of Dmitri Shostakovich, The Symphonies-Associated Univ PR (1979) PDFDokument205 Seiten(The Great Composers Series) Roy Blokker - The Music of Dmitri Shostakovich, The Symphonies-Associated Univ PR (1979) PDFRichard Yin0% (1)

- Spiral Retaining Ring Install and RemovalDokument17 SeitenSpiral Retaining Ring Install and Removalkahutzed666Noch keine Bewertungen

- Engineering Drawing ManualDokument128 SeitenEngineering Drawing Manualadnan100% (6)

- Dark Side of Bollywood IndustryDokument13 SeitenDark Side of Bollywood IndustryAayushi ShahNoch keine Bewertungen

- Hydrogen Safety 871916Dokument389 SeitenHydrogen Safety 871916BustaDrives100% (1)

- Body in Movement - WorkshopDokument8 SeitenBody in Movement - WorkshopAndrew CareyNoch keine Bewertungen

- Spring CalculationsDokument1 SeiteSpring CalculationsROHAN DESAINoch keine Bewertungen

- Two Phase Relief SizingDokument9 SeitenTwo Phase Relief Sizingashirwad shetty75% (4)

- Fatigue ANalysis SN CurveDokument11 SeitenFatigue ANalysis SN CurveM Rafiq RajaNoch keine Bewertungen

- Fatigue ANalysis SN CurveDokument11 SeitenFatigue ANalysis SN CurveM Rafiq RajaNoch keine Bewertungen

- Cass Elliot PDFDokument3 SeitenCass Elliot PDFLoriNoch keine Bewertungen

- Aluminium Heat ExchangersDokument6 SeitenAluminium Heat ExchangersSachin KheveriaNoch keine Bewertungen

- Bali Tour Packages 7 Days and 6 Nights Tours Itinerary and ArrangementDokument5 SeitenBali Tour Packages 7 Days and 6 Nights Tours Itinerary and ArrangementKumar ManvendraNoch keine Bewertungen

- Eisenstein's 'Montage of AttractionsDokument4 SeitenEisenstein's 'Montage of AttractionsALy AlexandraNoch keine Bewertungen

- Is Google Making Us Stupid EssayDokument5 SeitenIs Google Making Us Stupid Essayapi-252844849100% (4)

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDokument4 SeitenDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNoch keine Bewertungen

- Salzgitter S275J2 steel sheet mechanical propertiesDokument1 SeiteSalzgitter S275J2 steel sheet mechanical propertiesPalani KarthiNoch keine Bewertungen

- Primary Met Final SpreadsDokument5 SeitenPrimary Met Final SpreadsPablo GarciaNoch keine Bewertungen

- R of in Fine Welding With LaserDokument52 SeitenR of in Fine Welding With LaserMaher ShehabNoch keine Bewertungen

- FR4 4806Dokument2 SeitenFR4 4806Trasma_Yunita_1885Noch keine Bewertungen

- Capacitor Tantalio SMT 1206KEM T2005 T491Dokument24 SeitenCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaNoch keine Bewertungen

- 3M DP125Dokument7 Seiten3M DP125echobravo1Noch keine Bewertungen

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Dokument3 SeitenMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNoch keine Bewertungen

- DH 1400modDokument1 SeiteDH 1400modGopiNathNoch keine Bewertungen

- L111 SMCDokument0 SeitenL111 SMCozy1979Noch keine Bewertungen

- E DBL 008 Ol SteelceramicDokument4 SeitenE DBL 008 Ol SteelceramicCostas AggelidisNoch keine Bewertungen

- DH 1232NSDokument1 SeiteDH 1232NSGopiNathNoch keine Bewertungen

- Polyken 932 TapeDokument2 SeitenPolyken 932 TapeKyaw Kyaw AungNoch keine Bewertungen

- E Magnets UK Neodymium Data SheetDokument1 SeiteE Magnets UK Neodymium Data SheetAndre CoraucciNoch keine Bewertungen

- Catalogo Er70s3Dokument3 SeitenCatalogo Er70s3upedro26Noch keine Bewertungen

- Single Crystal Sapphire: 006/002/0710 Printed in Japan 006997Dokument8 SeitenSingle Crystal Sapphire: 006/002/0710 Printed in Japan 006997Edward PittsNoch keine Bewertungen

- Enhanced P L A P: Olyimide Aminate ND RepregDokument4 SeitenEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNoch keine Bewertungen

- S235J2 NDokument1 SeiteS235J2 Npraveenmenon86Noch keine Bewertungen

- 3M Scotch 50 51 Data SheetDokument4 Seiten3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNoch keine Bewertungen

- Damasteel Martensitic Damascus SteelDokument6 SeitenDamasteel Martensitic Damascus SteelsurintanNoch keine Bewertungen

- TDS Loctite 3355 PDFDokument3 SeitenTDS Loctite 3355 PDFffincher4203Noch keine Bewertungen

- A New Die Material For Longer Service LifeDokument12 SeitenA New Die Material For Longer Service LifeLuis SantosNoch keine Bewertungen

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDokument1 SeiteNon-Alloy Structural Steels: Mechanical Properties Available DimensionsOM PRAKASH PALNoch keine Bewertungen

- RO3035 Laminate Data Sheet PDFDokument2 SeitenRO3035 Laminate Data Sheet PDFrahul05singhaNoch keine Bewertungen

- Almit Technology Ltd Product Information Update July 2007Dokument2 SeitenAlmit Technology Ltd Product Information Update July 2007gcharalNoch keine Bewertungen

- Implant: Stainless SteelDokument2 SeitenImplant: Stainless SteelSachin GhalmeNoch keine Bewertungen

- RO4000 Laminates Data SheetDokument4 SeitenRO4000 Laminates Data SheetJavier De La VegaNoch keine Bewertungen

- C1e 010Dokument9 SeitenC1e 010Agung SumargoNoch keine Bewertungen

- General Information Theory - LindabDokument27 SeitenGeneral Information Theory - LindabaudithanNoch keine Bewertungen

- DI-MC 355: Product DescriptionDokument4 SeitenDI-MC 355: Product DescriptionvinodNoch keine Bewertungen

- Non Alloy Structural Steels S275J2 NDokument1 SeiteNon Alloy Structural Steels S275J2 Nserzo75Noch keine Bewertungen

- Impact: Wear Resistant SteelDokument6 SeitenImpact: Wear Resistant SteelmazuckNoch keine Bewertungen

- CCM03 MK III SIM/SAM Card ConnectorDokument2 SeitenCCM03 MK III SIM/SAM Card ConnectorDamianFrancucciNoch keine Bewertungen

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Dokument3 SeitenHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzNoch keine Bewertungen

- DS482Dokument3 SeitenDS482mariomatoNoch keine Bewertungen

- E 2209 AcdcDokument2 SeitenE 2209 AcdcLuis Alejandro Gonzalez SantanaNoch keine Bewertungen

- TT100 Ultrasonic Thickness GaugeDokument2 SeitenTT100 Ultrasonic Thickness GaugeDeny Arief RusamsiNoch keine Bewertungen

- Coating Thickness Meter 1Dokument20 SeitenCoating Thickness Meter 1allanNoch keine Bewertungen

- Super Duplex Stainless Steel 32750 Data SheetDokument2 SeitenSuper Duplex Stainless Steel 32750 Data SheetPrem EditsNoch keine Bewertungen

- Sap HireDokument2 SeitenSap HiretonisugusNoch keine Bewertungen

- Hysa9460 enDokument3 SeitenHysa9460 enengpontelliNoch keine Bewertungen

- Polyken 4000 PrimerlessDokument2 SeitenPolyken 4000 PrimerlessKyaw Kyaw AungNoch keine Bewertungen

- Otel de Scule - GBDokument37 SeitenOtel de Scule - GBColta VictorNoch keine Bewertungen

- Reference Flats and Mirrors 3404Dokument1 SeiteReference Flats and Mirrors 3404kirancallsNoch keine Bewertungen

- Metallized FilmsheetsDokument2 SeitenMetallized FilmsheetsGerardo LopezNoch keine Bewertungen

- Mitsu End MillDokument20 SeitenMitsu End MillTrịnh Văn PhậnNoch keine Bewertungen

- NexxZr Instructions For Use - EN - REV9Dokument10 SeitenNexxZr Instructions For Use - EN - REV9Devest Cad-CamNoch keine Bewertungen

- D+led-Ld5rDokument6 SeitenD+led-Ld5rJulia EchazarretaNoch keine Bewertungen

- Isoval 11 HKBDokument2 SeitenIsoval 11 HKBjalilemadiNoch keine Bewertungen

- S355MCDokument2 SeitenS355MCRodrigo Eduardo GomesNoch keine Bewertungen

- Loctite 222MS™: Technical Data SheetDokument4 SeitenLoctite 222MS™: Technical Data SheetbabshuagNoch keine Bewertungen

- Inductors: TSL Series TSL1315 Type For Power Line RadialDokument2 SeitenInductors: TSL Series TSL1315 Type For Power Line Radialcalvarez_5Noch keine Bewertungen

- CVD Diamond BookletDokument28 SeitenCVD Diamond BookletАндрей ВольхинNoch keine Bewertungen

- SL 012S PeDokument2 SeitenSL 012S PeNikhil KumarNoch keine Bewertungen

- Ertalyte TX Technical Data SheetDokument1 SeiteErtalyte TX Technical Data SheetLutfi IsmailNoch keine Bewertungen

- SS 6mo - 1.4547Dokument1 SeiteSS 6mo - 1.4547f_riseNoch keine Bewertungen

- PB Alumec EnglishDokument12 SeitenPB Alumec EnglishByron RodriguezNoch keine Bewertungen

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyVon EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNoch keine Bewertungen

- Spe 48856 PDFDokument6 SeitenSpe 48856 PDFkahutzed666Noch keine Bewertungen

- Spe71692 PDFDokument13 SeitenSpe71692 PDFkahutzed666Noch keine Bewertungen

- Coiled-Tubing Completion Procedure Reduces Cost and Time For Hydraulically Fractured WellsDokument8 SeitenCoiled-Tubing Completion Procedure Reduces Cost and Time For Hydraulically Fractured WellsKamran Haider TunioNoch keine Bewertungen

- Metric1801 1802Dokument1 SeiteMetric1801 1802stephendixNoch keine Bewertungen

- Liquid Pressure Test Pac PDFDokument6 SeitenLiquid Pressure Test Pac PDFkahutzed666Noch keine Bewertungen

- Tubingpatch PDFDokument3 SeitenTubingpatch PDFkahutzed666Noch keine Bewertungen

- ISO9001 QuickStartGuideDokument19 SeitenISO9001 QuickStartGuideHelder GuerreiroNoch keine Bewertungen

- CH 9 American National Unified Screw ThreadsDokument19 SeitenCH 9 American National Unified Screw Threadskahutzed666Noch keine Bewertungen

- ProfileDokument3 SeitenProfilekahutzed666Noch keine Bewertungen

- BOE Calculation - Paper PDFDokument1 SeiteBOE Calculation - Paper PDFkahutzed666Noch keine Bewertungen

- H03041Dokument2 SeitenH03041kahutzed666Noch keine Bewertungen

- American National Standard Vs Unified Inch StandardDokument4 SeitenAmerican National Standard Vs Unified Inch Standardkahutzed666Noch keine Bewertungen

- GallingDokument2 SeitenGallingkahutzed666100% (1)

- Calculus DerivativesDokument1 SeiteCalculus DerivativesAli FahemNoch keine Bewertungen

- (A305) Statik Atalet Momentleri Formülleri PDFDokument1 Seite(A305) Statik Atalet Momentleri Formülleri PDFberkantytuNoch keine Bewertungen

- Trigonometry PDFDokument1 SeiteTrigonometry PDFVanderson De Andrade SantosNoch keine Bewertungen

- Lubrication Hydraulic Fluid CleanlinessDokument20 SeitenLubrication Hydraulic Fluid Cleanlinesskahutzed666Noch keine Bewertungen

- How To Read A PatentDokument48 SeitenHow To Read A Patentkahutzed666Noch keine Bewertungen

- United States Patent (191: SiegelDokument14 SeitenUnited States Patent (191: Siegelkahutzed666Noch keine Bewertungen

- Oring Friction ForcesDokument7 SeitenOring Friction Forceskahutzed666Noch keine Bewertungen

- LOCATIONS AND CONTACT INFORMATION FOR SPARTAN THRU TUBING SERVICESDokument2 SeitenLOCATIONS AND CONTACT INFORMATION FOR SPARTAN THRU TUBING SERVICESkahutzed666Noch keine Bewertungen

- Gabriel CallingDokument1 SeiteGabriel CallingdiscoveryschoolNoch keine Bewertungen

- Atg Worksheet PastsimpleirregDokument2 SeitenAtg Worksheet PastsimpleirregFelicia Bratosin0% (1)

- Poseidon's Trident: A History of the Three-Pronged SpearDokument33 SeitenPoseidon's Trident: A History of the Three-Pronged Spearyahyaiyai01Noch keine Bewertungen

- PH-07 (KD 3.7) Recount (PG30) +keyDokument8 SeitenPH-07 (KD 3.7) Recount (PG30) +keyLahita AzizahNoch keine Bewertungen

- Lesson 1 Nominative and VocativeDokument10 SeitenLesson 1 Nominative and VocativeSeijuro HikoNoch keine Bewertungen

- For The LOVE of Figurative Language: Ms GilesDokument9 SeitenFor The LOVE of Figurative Language: Ms Gilesapi-488069675Noch keine Bewertungen

- The Importance and Beauty of Light in MosquesDokument5 SeitenThe Importance and Beauty of Light in MosquessidNoch keine Bewertungen

- Ray Bradbury Modern WorldDokument12 SeitenRay Bradbury Modern WorldDiana ChernyashchukNoch keine Bewertungen

- Art 7 (091319)Dokument4 SeitenArt 7 (091319)Alexander Tolentino Jr.Noch keine Bewertungen

- Hôtel Concorde Berlin: Latest Update: 05 October 2010Dokument9 SeitenHôtel Concorde Berlin: Latest Update: 05 October 2010Shashank JainNoch keine Bewertungen

- Collection of Ielts Speaking Part 2Dokument12 SeitenCollection of Ielts Speaking Part 2Hu MihiNoch keine Bewertungen

- Dental WaxesDokument23 SeitenDental Waxesdrgayen6042100% (1)

- Blacktown Council PART MDokument77 SeitenBlacktown Council PART Mterrykhtlan2918Noch keine Bewertungen

- Tongue TwistersDokument2 SeitenTongue TwistersBojan BojanicNoch keine Bewertungen

- How Many Miles To Babylon Teacher S Pack PDFDokument30 SeitenHow Many Miles To Babylon Teacher S Pack PDFmikecuchulainnNoch keine Bewertungen

- Chapter 8Dokument1 SeiteChapter 8dheerakalra1988Noch keine Bewertungen

- Camtasia Studio 201908 Crack + Keygen Full Download UpdatedDokument7 SeitenCamtasia Studio 201908 Crack + Keygen Full Download UpdatedAnwar Maulana0% (1)

- I Shall See Him by and by - Frank E. Graeff PDFDokument1 SeiteI Shall See Him by and by - Frank E. Graeff PDFEducational PurposesNoch keine Bewertungen

- Artikel Drama Lysistrata PDFDokument64 SeitenArtikel Drama Lysistrata PDFBala KurawaNoch keine Bewertungen

- Harry Potter TerminologyDokument2 SeitenHarry Potter TerminologyPeter BacomoNoch keine Bewertungen

- Douglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Dokument6 SeitenDouglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Luis Omar AmundarayNoch keine Bewertungen

- Theocritus Idyll 07 NotesDokument2 SeitenTheocritus Idyll 07 Notespm5rNoch keine Bewertungen