Beruflich Dokumente

Kultur Dokumente

Wilson Conversion Chart

Hochgeladen von

Guru SamyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wilson Conversion Chart

Hochgeladen von

Guru SamyCopyright:

Verfügbare Formate

Conversion Chart

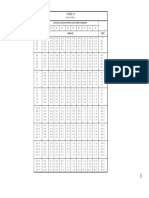

Cylindrical Correction Chart 53

Cylindrical work corrections to be added to observed

Rockwell number for scales indicated

15-N 30-N 45-N

15

30

45

150 60 100 150

kg

kg

kg

kg

kg

kg

kg 1/16 N

N

N

Brale Brale Brale ball Brale Brale

Brale

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

92.0

91.5

91.0

90.5

90.0

89.5

89.0

88.5

88.0

87.0

86.5

86.0

85.6

85.0

84.5

83.9

83.4

82.8

82.3

81.8

81.2

80.7

80.1

79.6

79.0

78.5

78.0

77.4

76.8

76.3

75.9

75.2

74.7

74.1

73.6

73.1

72.5

72.0

71.5

70.9

70.4

69.9

69.4

68.9

68.4

67.9

67.4

66.8

66.3

65.8

65.3

64.6

64.3

63.8

63.3

62.8

62.4

62.0

61.5

61.0

60.5

86.5

85.5

84.5

84.0

83.0

82.5

81.5

81.0

80.0

79.5

78.5

78.0

76.9

76.1

75.4

74.5

73.8

73.0

72.2

71.5

70.7

69.9

69.2

68.5

67.7

66.9

66.1

65.4

64.6

63.8

63.1

62.1

61.4

60.8

60.0

59.2

58.5

57.7

56.9

56.2

55.4

54.6

53.8

53.1

52.3

51.5

50.8

50.0

49.2

48.4

47.7

47.0

46.1

45.2

44.6

43.8

43.1

42.1

41.6

40.9

40.1

NA

92.0

91.0

90.0

89.0

88.0

87.0

86.0

84.5

83.5

82.5

81.0

96.5

96.3

96.0

95.8

95.5

95.3

95.0

94.8

94.5

94.3

94.0

93.5

93.2

92.9

92.5

92.2

91.8

91.4

91.1

90.7

90.2

89.8

89.3

88.9

88.3

87.9

87.4

86.9

86.4

85.9

85.5

85.0

84.5

83.9

83.5

83.0

82.5

82.0

81.5

80.9

80.4

79.9

79.4

78.8

78.3

77.7

77.2

76.6

76.1

75.6

75.0

74.5

73.9

73.3

72.8

72.2

71.6

71.0

70.5

69.9

69.4

92.0

91.5

91.0

90.5

90.0

89.0

88.5

88.0

87.0

86.5

86.0

85.0

84.4

83.6

82.8

81.9

81.1

80.1

79.3

78.4

77.5

76.6

75.7

74.8

73.9

73.0

72.0

71.2

70.2

69.4

68.5

67.6

66.7

65.8

64.8

64.0

63.1

62.2

61.3

60.4

59.5

58.6

57.7

56.8

55.9

55.0

54.2

53.3

52.1

51.3

50.4

49.5

48.6

47.7

46.8

45.9

45.0

44.0

43.2

42.3

41.5

87.0

86.5

85.5

84.5

83.5

82.5

81.5

80.5

79.5

78.5

77.5

76.5

75.4

74.2

73.3

72.0

71.0

69.9

68.8

67.7

66.6

65.5

64.3

63.2

62.0

60.9

59.8

58.6

57.4

56.1

55.0

53.8

52.5

51.4

50.3

49.0

47.8

46.7

45.5

44.3

43.1

41.9

40.8

39.6

38.4

37.2

36.1

34.9

33.7

32.5

31.3

30.1

28.9

27.8

26.7

25.5

24.3

23.1

22.0

20.7

19.6

Tensile

Vickers Knoop Brinell Strength

HV

HK

HB

KSI

500 3000

kg

1000

gm

10 kg

10

lbs/

and

mm

sq in

over

ball

1865

1787

1710

1633

1556

1478

1400

1323

1245

1160

1076

972

1004

946

940

920

900

895

865

870

NA

832

846

739

800

822

722

772

799

706

746

776

688

720

754

670

697

732

654

NA

674

710

634

351

653

690

615

338

633

670

595

325

613

650

577

313

595

630

560

301

577

612

543

292

560

594

525

283

544

576

512

273

528

558

496

264

513

542

481

255

498

526

469

246

484

510

455

238

471

495

443

229

458

480

432

221

446

466

421

215

434

452

409

208

423

438

400

201

412

426

390

194

402

414

381

188

392

402

371

182

382

391

362

177

372

380

353

171

363

370

344

166

354

360

336

161

345

351

327

156

336

342

319

152

327

334

311

149

318

326

301

146

310

318

294

141

302

311

286

138

294

304

279

135

286

297

271

131

279

290

264

128

272

284

258

125

266

278

253

123

260

272

247

119

254

266

243

117

248

261

237

115

243

256

231

112

238

251

226

110

NOTE 2

Superficial

NOTE 1

Rockwell

Note

1: A 10 mm steel ball was used for 450 BHN and below. A 10 mm carbide ball was used above 450 BHN.

2: The tensile strength relation to hardness is not exact, even for steel, unless it is determined for a specific material.

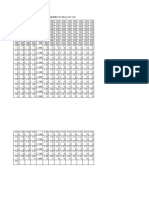

Hardness vs Minimum Thickness Chart 55

Any greater

thickness and

hardness can be

safely tested on

indicated scale

Rockwell

Superficial

Hardness Scales

15N

15

kgf

Thickness

inches (mm)

.006 (0.15)

.008 (0.20)

.010 (0.25)

.012 (0.30)

.014 (0.36)

.016 (0.41)

.018 (0.46)

.020 (0.51)

.022 (0.56)

.024 (0.61)

.026 (0.66)

.028 (0.71)

.030 (0.76)

.032 (0.81)

.034 (0.86)

.036 (0.91)

.038 (0.96)

.040 (1.02)

Any greater

thickness and

hardness can be

safely tested on

indicated scale

92

90

88

83

76

68

45N

45

kgf

77

74

72

68

63

58

51

37

20

Rockwell

Superficial

Hardness Scales

15-T

15

kgf

Thickness

inches (mm)

.010 (0.25)

.012 (0.30)

.014 (0.36)

.016 (0.41)

.018 (0.46)

.020 (0.51)

.022 (0.56)

.024 (0.61)

.026 (0.66)

.028 (0.71)

.030 (0.76)

.032 (0.81)

.034 (0.86)

.036 (0.91)

.038 (0.96)

.040 (1.02)

30N

30

kgf

N Brale

Indenter

82

78.5

74

66

57

47

Rockwell

Regular

Hardness Scales

91

86

81

75

68

30-T

45-T

30

45

kgf

kgf

1/16-in Ball

Indenter

80

72

71

64

62

55

53

45

43

34

31

18

A

60

kgf

86

84

82

79

76

71

67

60

D

C

100 150

kgf

kgf

Brale

Indenter

77

75

69

72

67

68

65

63

62

58

57

51

52

43

45

37

28

20

Rockwell

Regular

Hardness Scales

F

B

G

60 100 150

kgf kgf

kgf

1/16-in Ball

Indenter

98 94

94

91 87

87

85 80

76

77 71

68

69 62

59

52

50

40

42

28

31

22

X = No minimum hardness. These are approximate numbers only.

1.800.695.4273 | 1.781.575.6000

Microficial

WMN

Scales C, D, A

Brale Diamond Indenter

Diameter of Specimen - inches (mm)

Observed 1/8 1/4 3/8 1/2 5/8 3/4 7/8 1 1-1/4 1-1/2

Reading (3.2) (6.4) (10) (13) (16) (19) (22) (25) (32) (38)

90

NA 0.5 0

0

0

0

0

0

0

0

85

0.5 0.5 0.5 0

0

0

0

0

0

80

0.5 0.5 0.5 0.5 0.5 0

0

0

0

75

1.0 0.5 0.5 0.5 0.5 0.5 0

0

0

70

1.0 1.0 0.5 0.5 0.5 0.5 0.5

0

0

65

1.5 1.0 1.0 0.5 0.5 0.5 0.5

0

0

60

1.5 1.0 1.0 0.5 0.5 0.5 0.5

0

0

55

2.0 1.5 1.0 1.0 0.5 0.5 0.5 0.5

0

50

2.5 2.0 1.5 1.0 1.0 0.5 0.5 0.5 0.5

45

3.0 2.0 1.5 1.0 1.0 1.0 0.5 0.5 0.5

40

3.5 2.5 2.0 1.5 1.0 1.0 1.0 0.5 0.5

35

4.0 3.0 2.0 1.5 1.5 1.0 1.0 0.5 0.5

30

5.0 3.5 2.5 2.0 1.5 1.5 1.0 1.0 0.5

25

5.5 4.0 3.0 2.5 2.0 1.5 1.0 1.0 1.0

20

6.0 4.5 3.5 2.5 2.0 1.5 1.5 1.0 1.0

Scales B, F, G

1000

gm

953

949

945

942

938

934

930

926

922

917

913

909

904

900

896

891

887

883

879

874

870

865

861

856

851

847

842

837

832

827

822

817

812

807

802

798

793

788

783

778

773

768

762

757

751

746

741

736

730

725

720

1/16-in Ball Indenter

Diameter of Specimen - inches (mm)

Observed 1/8 1/4 3/8 1/2 5/8 3/4 7/8

Reading (3.2) (6.4) (10) (13) (16) (19) (22)

100

NA 3.5 2.5 1.5 1.5 1.0 1.0

90

4.0 3.0 2.0 1.5 1.5 1.5

80

5.0 3.5 2.5 2.0 1.5 1.5

70

6.0 4.0 3.0 2.5 2.0 2.0

60

7.0 5.0 3.5 3.0 2.5 2.0

50

8.0 5.5 4.0 3.5 3.0 2.5

40

9.0 6.0 4.5 4.0 3.0 2.5

30

10.0 6.5 5.0 4.5 3.5 3.0

20

11.0 7.5 5.5 4.5 4.0 3.5

10

12.0 8.0 6.0 5.0 4.0 3.5

0

12.5 8.5 6.5 5.5 4.5 3.5

Scales 15-N, 30-N, 45-N

1 1-1/4 1-1/2

(25) (32) (38)

0.5 NA

NA

1.0

1.5

1.5

2.0

2.0

2.5

2.5

3.0

3.0

3.0

N Brale Diamond Indenter

Diameter of Specimen - inches (mm)

Observed

Reading

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

1/8 1/4 3/8 1/2 5/8 3/4 7/8 1 1-1/4 1-1/2

(3.2) (6.4) (10) (13) (16) (19) (22) (25) (32) (38)

0

0

0

0

0

0

0

0

NA

NA

0.5 0.5 0.5 0.5 0

0

0

0

1.0 0.5 0.5 0.5 0.5 0

0

0

1.5 1.0 0.5 0.5 0.5 0.5 0

0

2.0 1.0 1.0 0.5 0.5 0.5 0.5 0.5

2.5 1.5 1.0 0.5 0.5 0.5 0.5 0.5

3.0 1.5 1.0 1.0 1.0 0.5 0.5 0.5

3.5 2.0 1.5 1.0 1.0 0.5 0.5 0.5

3.5 2.0 1.5 1.0 1.0 1.0 1.0 0.5

4.0 2.0 1.5 1.0 1.0 1.0 1.0 1.0

4.5 2.5 1.5 1.5 1.0 1.0 1.0 1.0

5.0 2.5 2.0 1.5 1.0 1.0 1.0 1.0

5.5 3.0 2.0 1.5 1.5 1.0 1.0 1.0

5.5 3.0 2.0 1.5 1.5 1.5 1.5 1.0

6.0 3.0 2.0 1.5 1.5 1.5 1.5 1.5

Scales 15-T, 30-T, 45-T

1/16-in Ball Indenter

Diameter of Specimen - inches (mm)

Observed

Reading

90

80

70

60

50

40

30

20

1/8

(3.2)

1.5

3.0

5.0

6.5

8.5

10.0

11.5

13.0

1/4

(6.4)

1.0

2.0

3.5

4.5

5.5

6.5

7.5

9.0

3/8

(10)

1.0

1.5

2.5

3.0

4.0

4.5

5.0

6.0

1/2

(13)

0.5

1.5

2.0

2.5

3.0

3.5

3.5

4.5

5/8

(16)

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.5

3/4

(19)

0.5

1.0

1.0

1.5

2.0

2.5

2.5

3.0

7/8

(22)

0.5

1.0

1.0

1.5

2.0

2.0

2.0

2.0

1 1-1/4 1-1/2

(25) (32) (38)

0.5 NA

NA

0.5

1.0

1.5

1.5

2.0

2.0

2.0

These corrections are approximate only and represent the averages to the nearest 1/2 Rockwell number.

Worldwide Service Network | 1-800-473-7838

Wilson Instruments is an Instron ITW company and is backed by Instrons

professional service force. It is the industrys largest and most responsive

group, including factory trained and certified service engineers, application

engineers, and service specialists. Instron field personnel expertise is just a

phone call away.

Services include:

Calibration and Certification

Preventative Maintenance

Emergency Service

Installation and Relocation

On-site Parts and Accessories

Application Support and Solutions

On-site Training

Hardness Products

Wilson Instruments offers a full range of Wilson testing products and

technology to meet virtually any hardness testing application and budget.

Rockwell Testers

Knoop and Vickers Testers

Image Analysis and Automatic Systems

Soft Steel, Grey and Malleable Cast Iron and Most Non-Ferrous Metals

Rockwell

B

Superficial

E

15-T

30-T

Knoop

45-T

100

60

150

60 150 15

30

45

60 100

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg 1/8 1/8 1/8 1/16 1/16 1/16

1/16 1/16 1/16 Brale

ball

ball

ball

ball ball ball ball

ball

ball

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

NA

99.6

99.1

98.5

98.0

97.4

96.8

96.2

95.6

95.1

94.5

93.9

93.4

92.8

92.2

91.7

91.1

90.5

90.0

89.4

88.8

88.2

87.7

87.1

86.5

86.0

85.4

84.8

84.3

83.7

83.1

82.6

82.0

81.4

80.8

80.3

79.7

79.1

78.6

78.0

77.4

76.9

76.3

75.7

75.2

74.6

74.0

73.5

73.0

72.5

72.0

71.0

70.5

70.0

69.5

69.0

68.5

68.0

67.0

66.5

66.0

65.5

65.0

64.5

64.0

63.5

63.0

62.0

61.5

61.0

60.5

60.0

59.5

59.0

58.0

57.5

57.0

82.5

81.0

79.0

77.5

76.0

74.0

72.5

71.0

69.0

67.5

66.0

64.0

62.5

61.0

59.0

57.5

56.0

54.0

52.5

51.0

49.0

47.5

46.0

44.0

42.5

41.0

39.0

37.5

36.0

34.5

32.5

31.0

29.5

28.0

26.5

25.0

23.5

22.0

20.5

19.0

17.5

16.0

14.5

13.0

11.5

10.0

8.5

7.0

5.5

4.0

2.5

NA

61.5

60.9

60.2

59.5

58.9

58.3

57.6

57.0

56.4

55.8

55.2

54.6

54.0

53.4

52.8

52.3

51.7

51.1

50.6

50.0

49.5

48.9

48.4

47.9

47.3

46.8

46.3

45.8

45.3

44.8

44.3

43.8

43.3

42.8

42.3

41.8

41.4

40.9

40.4

40.0

39.5

39.0

38.6

38.1

37.7

37.2

36.8

36.3

35.9

35.5

35.0

34.6

34.1

33.7

33.3

32.9

32.4

32.0

31.6

31.2

30.7

30.3

29.9

29.5

29.1

28.7

28.2

27.8

27.4

27.0

26.6

26.0

25.5

25.0

24.5

24.3

24.0

23.5

23.0

22.5

22.0

21.5

21.3

21.0

20.5

20.0

NA

NA

100

99.5

99.0

98.0

97.5

97.0

96.0

95.5

95.0

94.5

93.5

93.0

92.5

92.0

91.0

90.5

90.0

89.5

89.0

88.0

87.5

87.0

86.5

85.5

85.0

84.5

84.0

83.5

82.5

82.0

81.5

81.0

80.0

79.5

79.0

78.5

78.0

77.0

76.5

76.0

75.5

75.0

74.0

73.5

73.0

72.5

72.0

71.0

70.5

70.0

69.5

68.5

68.0

67.5

67.0

66.5

65.5

65.0

64.5

64.0

63.5

62.5

62.0

61.5

61.0

60.5

60.0

59.0

58.5

58.0

57.5

57.0

NA

100

99.5

99.0

98.8

98.5

98.0

97.8

97.5

97.0

96.5

96.3

96.0

95.5

95.3

95.0

94.5

94.3

94.0

93.5

93.0

92.8

92.5

92.0

91.8

91.5

91.0

90.5

90.3

90.0

89.5

89.3

89.0

88.5

88.0

87.8

87.5

87.0

NA

100

99.5

98.5

98.0

97.0

96.5

95.5

94.5

94.0

93.0

92.0

91.0

90.5

89.5

88.5

88.0

87.0

86.0

85.0

84.5

83.5

82.5

81.5

81.0

80.0

79.0

78.0

77.5

76.5

75.5

74.5

74.0

73.0

72.0

71.0

70.5

69.5

68.5

68.0

67.0

66.0

65.0

64.5

63.5

62.5

61.5

61.0

60.0

59.0

58.0

57.5

56.5

55.5

54.5

54.0

53.0

52.0

51.5

50.5

49.5

48.5

48.0

47.0

46.0

45.0

44.5

43.5

42.5

41.5

41.0

40.0

39.0

38.0

37.5

36.5

35.5

35.0

34.0

33.0

32.0

31.5

30.5

29.5

29.0

28.0

27.0

26.0

25.5

24.5

23.5

23.0

22.0

21.0

93.1

92.8

92.5

92.1

91.8

91.5

91.2

90.8

90.5

90.2

89.9

89.5

89.2

88.9

88.6

88.2

87.9

87.6

87.3

86.9

86.6

86.3

86.0

85.6

85.3

85.0

84.7

84.3

84.0

83.7

83.4

83.0

82.7

82.4

82.1

81.8

81.4

81.1

80.8

80.5

80.1

79.8

79.5

79.2

78.8

78.5

78.2

77.9

77.5

77.2

76.9

76.6

76.2

75.9

75.6

75.3

74.9

74.6

74.3

74.0

73.6

73.3

73.0

72.7

72.3

72.0

71.7

71.4

71.0

70.7

70.4

70.0

69.3

69.5

69.0

68.8

68.5

68.0

67.8

67.5

67.3

67.0

66.5

66.3

66.0

65.5

65.3

65.0

64.5

64.3

64.0

63.8

63.5

63.0

62.8

62.5

62.0

61.8

61.5

61.0

60.5

83.1

82.5

81.8

81.1

80.4

79.8

79.1

78.4

77.8

77.1

76.4

75.8

75.1

74.4

73.8

73.1

72.4

71.8

71.1

70.4

69.7

69.1

68.4

67.7

67.1

66.4

65.7

65.1

64.4

63.7

63.1

62.4

61.7

61.0

60.4

59.7

59.0

58.4

57.7

57.0

56.4

55.7

55.0

54.4

53.7

53.0

52.4

51.7

51.0

50.3

49.7

49.0

48.3

47.7

47.0

46.3

45.7

45.0

44.3

43.7

43.0

42.3

41.6

41.0

40.3

39.6

39.0

38.3

37.6

37.0

36.3

35.6

34.5

34.0

33.0

32.5

32.0

31.0

30.5

29.5

29.0

28.5

27.5

27.0

26.0

25.5

25.0

24.0

23.5

23.0

22.0

21.5

20.5

20.0

19.5

18.5

18.0

17.0

16.5

16.0

15.0

72.9

71.9

70.9

69.9

68.9

67.9

66.9

65.9

64.8

63.8

62.8

61.8

60.8

59.8

58.8

57.8

56.8

55.8

54.8

53.8

52.8

51.8

50.8

49.8

48.8

47.8

46.8

45.8

44.8

43.8

42.8

41.8

40.8

39.8

38.7

37.7

36.7

35.7

34.7

33.7

32.7

31.7

30.7

29.7

28.7

27.7

26.7

25.7

24.7

23.7

22.7

21.7

20.7

19.7

18.7

17.7

16.7

15.7

14.7

13.6

12.6

11.6

10.6

9.6

8.6

7.6

6.6

5.6

4.6

3.6

2.6

1.0

NA

HK

500

gm

and

over

251

246

241

236

231

226

221

216

211

206

201

196

192

188

184

180

176

173

170

167

164

161

158

155

152

150

147

145

143

141

139

137

135

133

131

129

127

125

124

122

120

118

117

115

114

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

87

86

85

84

83

82

82

81

81

80

79

78

78

77

76

75

75

74

73

72

71

71

70

69

69

69

68

68

63

63

Brinell

HB

500

kg

10

mm

ball

201

195

189

184

179

175

171

167

163

160

157

154

151

148

145

142

140

137

135

133

130

128

126

124

122

120

118

116

114

112

110

109

107

106

104

102

101

99

98

96

95

94

92

91

90

89

87

86

85

84

83

82

81

80

80

79

78

77

76

75

75

74

73

72

72

71

70

69

69

68

67

66

66

65

65

64

64

63

62

62

61

61

60

60

59

59

59

58

58

57

57

57

56

56

55

55

55

54

54

54

53

HB

HV

Tensile MicroStrength ficial

KSI

WMN

3000

kg

10 kg

1000

lbs/

sq in

1000

gm

240

234

228

222

216

210

205

200

195

190

185

180

176

172

169

165

162

159

156

153

150

147

144

141

139

137

135

132

130

127

125

123

121

119

117

116

114

112

110

108

107

106

104

103

101

100

NA

116

114

109

104

102

100

98

94

92

90

89

88

86

84

83

82

81

80

77

73

72

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

NA

730

725

719

713

707

701

696

690

684

679

674

668

662

656

651

646

640

634

629

624

618

612

607

602

596

592

587

581

576

571

566

561

556

551

546

542

537

532

527

522

517

512

507

502

497

492

487

482

477

472

468

463

458

453

448

444

439

435

430

426

422

417

413

409

404

401

396

392

388

384

380

376

372

369

365

361

357

353

350

346

343

339

335

332

329

325

322

318

314

311

308

304

300

297

293

289

286

283

279

276

272

NOTE 2

Hardened Steel and Hardened Alloys

The values shown are approximate only. This chart is intended primarily as a reference guide.

Brinell Testers

Universal Hardness Testers

Shore Durometers for Rubber and Plastic

Portable Testers

Custom Solutions

Test Blocks, Indenters, and Accessories

Conversions

All values, except WMN, are consistent with ASTM E140 Tables 1 and 2, and

ASTM A370 Tables 3A and 3B, where applicable. WMN or Wilson Microficial

Numbers were developed by Wilson Instruments in the Wilson Standards

laboratory and are not derived from ASTM.

Cylindrical Corrections Values are consistent with ASTM E18 Table 6,7,13, and 14

Hardness vs. Minimum Thickness Values are consistent with ASTM E18 Tables

4, 5, 11, and 12 except for D and G scale values, which are obtained from

indentation hardness testing by Vincent E. Lysaght.

Originator of the Rockwell Tester

Americas | Europe | Asia

www.wilson-hardness.com

Das könnte Ihnen auch gefallen

- IBM System 360 RPG Debugging Template and Keypunch CardVon EverandIBM System 360 RPG Debugging Template and Keypunch CardNoch keine Bewertungen

- Problems: 7.17 ReferencesDokument2 SeitenProblems: 7.17 ReferencesAhmad Shuaib Khawari ,141305Noch keine Bewertungen

- Th. of FailureDokument3 SeitenTh. of Failureraja50% (2)

- Normas de Roscas y NormalizacionDokument1 SeiteNormas de Roscas y NormalizacionProyectos IngemetzaNoch keine Bewertungen

- Shaft Keys Couplings Extra Lecture PDFDokument16 SeitenShaft Keys Couplings Extra Lecture PDFHardik ParmarNoch keine Bewertungen

- DeberDokument2 SeitenDeberJuan SuarezNoch keine Bewertungen

- MLE1101 - Tutorial 4 - Suggested SolutionsDokument7 SeitenMLE1101 - Tutorial 4 - Suggested SolutionsYin HauNoch keine Bewertungen

- 유체역학 6 PDFDokument127 Seiten유체역학 6 PDFChan YuNoch keine Bewertungen

- Richard Finch-Welder's Handbook - A Guide To Plasma Cutting, Oxyacetylene, ARC, MIG, and TIG welding-HPBooks (2007) PDFDokument5 SeitenRichard Finch-Welder's Handbook - A Guide To Plasma Cutting, Oxyacetylene, ARC, MIG, and TIG welding-HPBooks (2007) PDFMedina SivacNoch keine Bewertungen

- ASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeDokument3 SeitenASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeGautam Tyagi100% (1)

- Assignment 2 Fluctuating LoadDokument3 SeitenAssignment 2 Fluctuating Loadabhishek chaurasiyaNoch keine Bewertungen

- Hardness Testing of Metallic MaterialsDokument4 SeitenHardness Testing of Metallic MaterialsAshan Marambe100% (1)

- Brinell TestDokument4 SeitenBrinell TestashprakNoch keine Bewertungen

- VelocitytutorialDokument4 SeitenVelocitytutorialManoz Thapa KajiNoch keine Bewertungen

- AUTOCOLLIMATORDokument6 SeitenAUTOCOLLIMATORAhmed Almujabber100% (1)

- HW2 SolutionDokument7 SeitenHW2 SolutionAnson ChanNoch keine Bewertungen

- Thermo CalibrationDokument10 SeitenThermo CalibrationAngelo De AsisNoch keine Bewertungen

- Deber 1 PLC BasicoDokument11 SeitenDeber 1 PLC BasicoFher JaramilloNoch keine Bewertungen

- MaterialsDokument4 SeitenMaterialsSilvio VarricchioNoch keine Bewertungen

- 2 - 3 Involute Spur Gear 1Dokument13 Seiten2 - 3 Involute Spur Gear 1jiteshpaul100% (1)

- Norma Astm A255Dokument21 SeitenNorma Astm A255Carlos Fernando Luna Carlosama100% (1)

- SplinesDokument4 SeitenSplinesthirumalaikumaranNoch keine Bewertungen

- ME 308: Machine Design II: Second Semester (142) Problem Set # 2 Topics Covered (13.1 - 13.14)Dokument3 SeitenME 308: Machine Design II: Second Semester (142) Problem Set # 2 Topics Covered (13.1 - 13.14)abdulwahabNoch keine Bewertungen

- ASTM Hardness Conversion ChartDokument3 SeitenASTM Hardness Conversion ChartJose Daniel De la CruzNoch keine Bewertungen

- Aisi 1040Dokument2 SeitenAisi 1040Xin Yu100% (1)

- Examples of Welded JointsDokument12 SeitenExamples of Welded JointsAdugna GosaNoch keine Bewertungen

- Coefficient For Static Friction of Steel ChartDokument2 SeitenCoefficient For Static Friction of Steel ChartAnonymous dWa1xtpKmfNoch keine Bewertungen

- Mitsui Tafmer A SeriesDokument1 SeiteMitsui Tafmer A Seriesavip2uNoch keine Bewertungen

- Balncing KitDokument4 SeitenBalncing KitRul RtNoch keine Bewertungen

- Backing (Strip)Dokument3 SeitenBacking (Strip)Zariq BahrinNoch keine Bewertungen

- Diametral PitchDokument2 SeitenDiametral Pitchbrpnaidu2157Noch keine Bewertungen

- Strength of Materials - Task 1. Chapter 3Dokument3 SeitenStrength of Materials - Task 1. Chapter 3NEIVER ALEVIS CASTRO JULIONoch keine Bewertungen

- Lab 3 MeasurementDokument21 SeitenLab 3 MeasurementAbdul AzizNoch keine Bewertungen

- Grades of Steel ChartDokument3 SeitenGrades of Steel ChartKimNoch keine Bewertungen

- ICE All ExercisesDokument10 SeitenICE All ExercisesB Ninh100% (1)

- 2 CepasDokument12 Seiten2 CepasEby RocíoNoch keine Bewertungen

- Table 19 - Table of OffsetsDokument1 SeiteTable 19 - Table of OffsetsMarcelo MilicevickNoch keine Bewertungen

- DIAGRAMA DE ALTURAS CORTE Y RELLENO REV-01 - Con AdecuacionDokument22 SeitenDIAGRAMA DE ALTURAS CORTE Y RELLENO REV-01 - Con AdecuacionLuis Miguel Benites ParcoNoch keine Bewertungen

- La Instrucţiunile Nr. 317 AnexaDokument4 SeitenLa Instrucţiunile Nr. 317 AnexaAlina MirelaNoch keine Bewertungen

- La Instrucţiunile Nr. 317 AnexaDokument4 SeitenLa Instrucţiunile Nr. 317 AnexaAlina MirelaNoch keine Bewertungen

- Yatay Yükün Üçgen Yayılı Da Ilı I Durumunda y Katsayısı (Standart Büküm Noktası Yüksekli I)Dokument2 SeitenYatay Yükün Üçgen Yayılı Da Ilı I Durumunda y Katsayısı (Standart Büküm Noktası Yüksekli I)ZaferArazNoch keine Bewertungen

- Espectro de Pseudo-Aceleraciones Rne E.030Dokument17 SeitenEspectro de Pseudo-Aceleraciones Rne E.030Gerson CarrascoNoch keine Bewertungen

- RBX10L840 Arr22sDokument7 SeitenRBX10L840 Arr22sflorencio vazquezNoch keine Bewertungen

- Socket Head Cap ScrewsDokument16 SeitenSocket Head Cap ScrewsyauctionNoch keine Bewertungen

- 2º Corte - Grupo G PDFDokument1 Seite2º Corte - Grupo G PDFDaniel HurtadoNoch keine Bewertungen

- SDFGXHCKLDokument34.725 SeitenSDFGXHCKLbrintopvNoch keine Bewertungen

- Programming ComputerDokument6 SeitenProgramming ComputeribnikhairaniNoch keine Bewertungen

- Spec ZDokument11 SeitenSpec ZMert CetinNoch keine Bewertungen

- 317 Anexa 8 040216Dokument1 Seite317 Anexa 8 040216Alina MirelaNoch keine Bewertungen

- 317 Anexa 8 040216Dokument1 Seite317 Anexa 8 040216Alina MirelaNoch keine Bewertungen

- Standard Normal Tail AreaDokument1 SeiteStandard Normal Tail AreajohnNoch keine Bewertungen

- DATA ANTOINE Crude Oil BunyuDokument12 SeitenDATA ANTOINE Crude Oil BunyuwynneralphNoch keine Bewertungen

- 1B UskDokument36 Seiten1B UskIqbal MaulanaNoch keine Bewertungen

- IUI - Perdas de PressãoDokument1 SeiteIUI - Perdas de PressãoMarcio ChristoNoch keine Bewertungen

- Negative To PositiveDokument2 SeitenNegative To PositiveOliver Barbequel PartoNoch keine Bewertungen

- Baza Date ReunitaDokument28 SeitenBaza Date Reunitaorbit_roNoch keine Bewertungen

- Fracionamento ADokument1 SeiteFracionamento AborbalsNoch keine Bewertungen

- PPPDokument1 SeitePPPMuhammad ThirafiNoch keine Bewertungen

- Plantilla ColumnasDokument39 SeitenPlantilla ColumnasSebastián BadillaNoch keine Bewertungen

- Reto Ahorro 365 DiasDokument2 SeitenReto Ahorro 365 DiasPAMELA VARGAS MILLANNoch keine Bewertungen

- 100 Excel Tips - EwB PDFDokument106 Seiten100 Excel Tips - EwB PDFAbhijit SahaNoch keine Bewertungen

- Premier Cooling TowerDokument1 SeitePremier Cooling TowerGuru SamyNoch keine Bewertungen

- OxidationDokument23 SeitenOxidationGuru SamyNoch keine Bewertungen

- ForgingDokument10 SeitenForgingGuru SamyNoch keine Bewertungen

- Maths IIIDokument7 SeitenMaths IIIGuru SamyNoch keine Bewertungen

- Curriculum Vitae: ObjectiveDokument4 SeitenCurriculum Vitae: ObjectiveGuru SamyNoch keine Bewertungen

- Curriculum Vitae: ObjectiveDokument4 SeitenCurriculum Vitae: ObjectiveGuru SamyNoch keine Bewertungen

- Surface Treatment-An OverviewDokument20 SeitenSurface Treatment-An OverviewGuru SamyNoch keine Bewertungen

- Comprehensive Industry Document On Electroplating IndustriesDokument92 SeitenComprehensive Industry Document On Electroplating Industrieskaranahuja18Noch keine Bewertungen

- The Metallography of Impact FatigueDokument6 SeitenThe Metallography of Impact FatigueGuru SamyNoch keine Bewertungen

- Hexavalent Chromium PresentationDokument58 SeitenHexavalent Chromium PresentationGuru SamyNoch keine Bewertungen

- Slurry Erosion Behaviour of Uncoated and Coated MaterialsDokument13 SeitenSlurry Erosion Behaviour of Uncoated and Coated MaterialsGuru SamyNoch keine Bewertungen

- Hard Chrome PlatingDokument2 SeitenHard Chrome PlatingGuru SamyNoch keine Bewertungen

- Advances in Tribology and WearDokument31 SeitenAdvances in Tribology and WearGuru SamyNoch keine Bewertungen

- 5th National Tribological Congress MeetDokument104 Seiten5th National Tribological Congress MeetGuru Samy0% (1)

- Case Hardened Part PerformanceDokument5 SeitenCase Hardened Part PerformanceGuru SamyNoch keine Bewertungen

- Requirements For The Valve Train - Lotus EnggDokument22 SeitenRequirements For The Valve Train - Lotus EnggGuru SamyNoch keine Bewertungen

- SAE Ferrous Materials Standards Manual - 2004Dokument3 SeitenSAE Ferrous Materials Standards Manual - 2004Xin Yu50% (2)

- Atlas of MicrostructuresDokument46 SeitenAtlas of MicrostructuresSerkan Apay100% (1)

- Aerospace Material Specification-AMS 2759Dokument11 SeitenAerospace Material Specification-AMS 2759Guru Samy50% (2)

- Automatic Vickers Case Depth Measurement-Edition 6Dokument6 SeitenAutomatic Vickers Case Depth Measurement-Edition 6Guru SamyNoch keine Bewertungen

- SAE Ferrous Materials Standards Manual - 2004Dokument3 SeitenSAE Ferrous Materials Standards Manual - 2004Xin Yu50% (2)

- 8-16 Metallurgy For Heat TreatmentDokument9 Seiten8-16 Metallurgy For Heat TreatmentvishalNoch keine Bewertungen

- Case Hardened Part PerformanceDokument5 SeitenCase Hardened Part PerformanceGuru SamyNoch keine Bewertungen

- Case Hardened Part PerformanceDokument5 SeitenCase Hardened Part PerformanceGuru SamyNoch keine Bewertungen

- Crack Propagation of Rolling Contact Fatigue - 2007Dokument12 SeitenCrack Propagation of Rolling Contact Fatigue - 2007Geraldo Rossoni SisquiniNoch keine Bewertungen

- Fanuc LATHE CNC Program Manual Gcodetraining 588Dokument104 SeitenFanuc LATHE CNC Program Manual Gcodetraining 588DOBJAN75% (12)

- IC Engine Exhaust EmissionsDokument38 SeitenIC Engine Exhaust EmissionsGuru SamyNoch keine Bewertungen

- DIN-EN1676 - Aluminium Ingots For Remelting Spec PDFDokument11 SeitenDIN-EN1676 - Aluminium Ingots For Remelting Spec PDFGuru SamyNoch keine Bewertungen

- G Code Quick Guide PDFDokument7 SeitenG Code Quick Guide PDFTamil Selvan0% (1)

- 1en 02 PDFDokument96 Seiten1en 02 PDFAndrey100% (2)

- Citrus Information Kit-Update: Reprint - Information Current in 1998Dokument53 SeitenCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNoch keine Bewertungen

- Brochure - OasisDokument24 SeitenBrochure - OasisVivek RNoch keine Bewertungen

- 3E Hand Over NotesDokument3 Seiten3E Hand Over NotesAshutosh MaiidNoch keine Bewertungen

- Speaking RubricDokument1 SeiteSpeaking RubricxespejoNoch keine Bewertungen

- ENSC1001 Unit Outline 2014Dokument12 SeitenENSC1001 Unit Outline 2014TheColonel999Noch keine Bewertungen

- 2023 2024 Syllabus PDFDokument23 Seiten2023 2024 Syllabus PDFRika DianaNoch keine Bewertungen

- Group Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanDokument18 SeitenGroup Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanNurul Hana BalqisNoch keine Bewertungen

- Using Your Digital Assets On Q-GlobalDokument3 SeitenUsing Your Digital Assets On Q-GlobalRemik BuczekNoch keine Bewertungen

- Prometric Questions-1 AnswersDokument45 SeitenPrometric Questions-1 AnswersNina Grace Joy Marayag-Alvarez100% (1)

- RESEARCHDokument5 SeitenRESEARCHroseve cabalunaNoch keine Bewertungen

- Literature Review - Part Time Job Among StudentDokument3 SeitenLiterature Review - Part Time Job Among StudentMarria65% (20)

- Kaun Banega Crorepati Computer C++ ProjectDokument20 SeitenKaun Banega Crorepati Computer C++ ProjectDhanya SudheerNoch keine Bewertungen

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDokument64 SeitenUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091Noch keine Bewertungen

- Unit-5 Harmonics & FiltersDokument25 SeitenUnit-5 Harmonics & FiltersBhanu100% (1)

- New Microsoft Word DocumentDokument3 SeitenNew Microsoft Word DocumentAditya ShanbhagNoch keine Bewertungen

- Nursing Assessment in Family Nursing PracticeDokument22 SeitenNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganNoch keine Bewertungen

- Chapter 3 Extension - Game Theory-StDokument25 SeitenChapter 3 Extension - Game Theory-StQuynh Chau TranNoch keine Bewertungen

- 1id Abstracts Season 2 Episode 6Dokument406 Seiten1id Abstracts Season 2 Episode 6Jennifer BrownNoch keine Bewertungen

- Ishrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19Dokument4 SeitenIshrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19DejanNoch keine Bewertungen

- Assessment - UK Forestry Data ICT THEORY For CAT1Dokument13 SeitenAssessment - UK Forestry Data ICT THEORY For CAT1Joanna AchemaNoch keine Bewertungen

- Charter of The New UrbanismDokument4 SeitenCharter of The New UrbanismBarabas SandraNoch keine Bewertungen

- CHAPTER I Lesson II Seven Environmental PrinciplesDokument17 SeitenCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotNoch keine Bewertungen

- Oral Communication in ContextDokument19 SeitenOral Communication in ContextAzory ZelleNoch keine Bewertungen

- Request For Proposals/quotationsDokument24 SeitenRequest For Proposals/quotationsKarl Anthony Rigoroso MargateNoch keine Bewertungen

- Circuit Construction: Assignment 3Dokument45 SeitenCircuit Construction: Assignment 3ali morisyNoch keine Bewertungen

- Ims DB DCDokument90 SeitenIms DB DCpvnkraju100% (1)

- BLG311 Cell Biology: Course Outline (Fall 2020)Dokument11 SeitenBLG311 Cell Biology: Course Outline (Fall 2020)Emilija BjelajacNoch keine Bewertungen

- High Speed Power TransferDokument33 SeitenHigh Speed Power TransferJAYKUMAR SINGHNoch keine Bewertungen

- QSasDokument50 SeitenQSasArvin Delos ReyesNoch keine Bewertungen