Beruflich Dokumente

Kultur Dokumente

Growth of Copper Real

Hochgeladen von

Lambert StrongOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Growth of Copper Real

Hochgeladen von

Lambert StrongCopyright:

Verfügbare Formate

Growth of Copper (II) SulphatePentahydrate (CuSO4 .5H2O) from Aqueous Solution.

Introduction

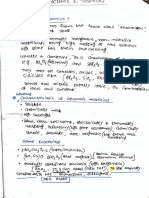

Crystals play an important role in modern technology and their importance in the field of pharmaceutical, agriculture and materials science cannot be over emphasized. The physical and chemical properties of crystals determine their uses. Usually crystal growth aims at producing crystals with the desired quality for specific applications. There are several techniques used to grow crystals but each techniques aims at producing a crystal with such quality good enough to be used for the desired application. Crystal growth may be achieved using simple cheap techniques or complex and relatively expensive methods. The growth rate and crystal sizes also vary with the method used. Crystals may be produced in the solid, liquid or vapour phase and usually involves a controlled or tailored phase transformation. Based on the phase transformation process, crystal growth techniques are classified as solid growth, vapour growth, melt growth and solution growth. Solid Growth - Solid-to-Solid phase transformation Liquid Growth - Liquid to Solid phase transformation Vapour Growth - Vapour to Solid phase transformation Crystals will grow from a melt much more rapidly than the will grow from the vapour phase or from solution. This is simply because the density of the material in the melt is comparable to that in the crystal, so the atoms or molecules are essentially there already to grow the crystal. For vapour and solution growth, the density of the atoms or molecules in the mother phase is much lower, and the growth rate depends on the rate at which they arrive at the surface of the crystal. For the commercial growth of crystals, the faster the crystals of acceptable quality can be grown the better. This is also true for non-commercial growth of experimental crystals. So melt growth is the preferred method. However there are various reasons why many crystals cannot be grown from the melt as we shall see below. Crystal growth involves two successive processes referred to as nucleation and growth respectively. Nucleation is a process whereby tiny fragments called seeds crystals are produced, this usually occurs when components of a solution start to precipitate out, forming nuclei which attract more precipitate. The seed crystal then forms the base upon which the growth occurs. Nucleation can occur spontaneously mostly due to changes in pressure and temperature in which case it is referred to as homogeneous or it can be induced or aided in which case it is referred to as heterogeneous. The two processes involved in crystal grow i.e. nucleation and growth will be discussed in more detail. Nucleation For a crystal to grow, a seed capable of maintaining a stable condition in a solution, melt or vapour phase has to be produced first. Nucleation requires the formation of a 3d nucleus. In this experiment Copper (II) Sulphate Pentahydrate was grown using the temperature reduction method. This method is a sub-group of the solution growth methods. As mentioned above, crystal growth from solution is a slow process and the method is mostly used for materials which cannot be grown from a melt. Some materials decompose or sublime below

their melting point and cannot be growth from melts. This is true for Copper (II) Sulphate Pentahydrate, therefore solution growth is the most appropriate method to use.

Aim of Experiment.

The aim of the experiment is to grow a single crystal of Copper (II) Sulphate Pentahydrate from an aqueous solution by temperature reduction method.

Theory

Growth of crystals from low temperature aqueous solution is controlled by the temperature and concentration of the solution. Materials, which possess high solubility and whose solubility is temperature dependent, can be grown easily by solution method. This method is simpler and cheaper compared with other methods. But growth process is slow and it takes a long time for crystallization. There are several methods in solution growth depending on the solvents and the solubility of the solute. These include; Temperature reduction method Isothermal evaporation method salting out

Copper (II) Sulphate Pentahydrate was grown by low temperature solution growth method. As mentioned above, this method is applicable for materials with moderate to high solubility and even more important is that the solubility should be highly temperature dependent. The solubility of Copper (II) Sulphate Pentahydrate is very temperature dependent. At 0C the solubility is about 250g/l of water and at 100C the solubility increases to more than 2000g/l of water (see fig. 1).

Fig 1.The Solubility curve of Copper (II) SulphatePentahydrate in Water.

This method is suitable to grow single crystals from starting materials which are either unstable or undergo phase transformation under high temperatures. Copper (II) Sulphate Pentahydrate as is a salt with a triclinic crystal structures, dehydrates at 150C and decomposes at 650C. Other growth methods such as growth from melts, vapours or solid to solid transformation will not be suitable to grow Copper (II) Sulphate Pentahydrate because these other methods require much higher temperatures which may decompose or dehydrate the material. The experiment was performed as follows;

Equipment

Fume hood, growth apparatus with control unit, bright lamp (e.g. cold-light lamp), drying cabinet with temperature control, various beakers (300 2000 ml) with appropriate cover glasses (watch glasses), crystallizing dish, heating plate with magnetic rotation, glass rod, thermometer (up to 80 C), filter paper with matching funnel, laboratory stand, clamps etc., nylon thread, latex gloves, lint-free paper towels, Teflon tweezers, plastic tins for storage.

Chemical

1000g copper (II) sulphate pentahydrate, several litres of 18 Mcm H2O, detergents, alcohol (e.g. isopropanol)

Procedure

The experiment was performed stepwise as follows: Cleaning Preparation of growth apparatus Growth of seed crystals Preparation of saturated solution and the determination of saturation point. Growth of crystals End of growth, preparation of grown crystal, determination of growth rate End of Experiment.

Cleaning

In order to avoid parasitic nucleation all the devices used in this experiment were freed from all solid particles. This was achieved by thoroughly cleaning all the device parts as follows: Flushing with soap water and rinsing with plenty of water Repeatedly rinsing with 18 Mcm H2O using a wash bottle Finally washing down with deionised water Dripping and drying in an oven at suitable temperatures

Growth Apparatus Set-up and Preparation

The growth apparatus used for this experiment is shown in the diagram below and it was prepared a s follows:

The outer vessel was filled with water up to about 1-2 cm below the aluminum ring. The water level was tried to be kept constant by replenishing it from time to time. The pump was started and the thermostat was set so the water get a uniform temperature of about 50C. This is the growth temperature. The crystallizing vessels together with all the stirring parts were thoroughly cleaned initially with tab water then with 18 Mcm H2O. The vessels and the other parts were then left to drain The parts were rapidly assembled to avoid dust from getting into the vessel.

Growth of Seed Crystals

While the growth apparatus gets a uniform temperature a solution for the seed crystal was prepared. The solution was prepared as follows: 30g of Copper (II) Sulphate Pentahydrate was mixed with 100ml of 18 Mcm H2O in a 300ml cooking cup The mixture was placed in a heating plate and heated to a temperature of about 50C and occasional up to 60C to get all the Copper (II) Sulphate Pentahydrate into solution. During the heating the solution was constantly stirred to help dissolution and keep a uniform temperature throughout the solution. The solution was then left to stay overnight at room temperature. The solution was covered to prevent dust or other solid particles from getting inside as this might lead to parasitic nucleation. The next day some seed crystals were formed. The solution was filtered over the crystals into a crystallising dish The biggest of the seed crystal was selected to be used for the growth. A fishing line was tight around the seed crystal to enable it to be suspended in the growth solution.

Preparation of Saturated solution and the determination of saturated point.

The saturated solution was prepared in the following way: A 3l flask , suction filter, and funnel were cleaned and heated (without the sealing cuffs) to about 85C A temperature of 50C was chosen as the growth temperature and the solubility Copper (II) Pentahydrate at this temperature was determined using the solubility curves. Based on this calculation, 0,657kg (per litre of water) of Copper (II) Pentahydrate is need to make a saturated solution at 50C.

The mixture of the 0,657kg of Copper (II) pentahydrate and 1000ml of water was then heated to about 60C on a heating plate with a Teflon stirrer. The cooking cup was covered throughout the dissolution time. A membrane pump was then used to filter the solution and the filtered solution was then poured into the crystallising vessel in the growth apparatus.

The saturation point was determined by the streaking method using a crystal of lower quality. The principle of the streaking method is shown schematically below.

The test seed crystals and the attachment cord were clean with alcohol and briefly dipped in deionised water to roughen the surface of the crystal. The crystal was then introduced into the saturated solution and observed with a lamp from behind the growth apparatus. The observation was to check for the three possible scenarios above. Alternatively the crystal was left to stay in the saturated solution over night at the growth temperature. If the solution is not saturated, the test crystal will dissolve, if the solution is over saturated, the test crystal will grow and if the size does not change significantly, it means the solution has the right saturation for this temperature. The test crystal did not show any significant change in size after 24 hours and we assumed that the saturation point for the solution at the growth temperature was reached.

Growth of Crystal

After being convinced that the saturation point of the growth solution is correct, the test crystal was removed and replaced by the seed crystal. The seed crystal was also dipped in deionised water to roughen the surface. Suspended on a nylon cord, the seed crystal was slowly lowered into the saturated solution such that it was roughly in the middle of the vessel with the saturated solution without touching the walls or bottom of the vessel. After making sure that the seed crystals was in the desired position we proceeded with temperature reduction. The switch was adjusted to the temperature reduction mode and the temperature reducer was turned to position 1. The temperature was reduced at a 0,2 interval after every few days until the growth process was completed. At the end of the growth period the growth apparatus was switched off and the crystal was left to stay in the solution for more one night. This is to prevent thermal shock of the crystal. The crystal was then removed and sprayed with a vanish coating to prevent it from absorbing moisture. The crystal was measured and the growth rate was determined.

Results and Discussions The experiment lasted for four weeks in total. The first two days were used in the preparation of the seed crystal, growth apparatus, growth solution and the determination of the saturation of the growth solution. The rest period was used for the growth. The diagrams below show both the seed crystal and the grown crystal. The seed crystal has the dimension of 2,5cm by 3,5 cm and the grown crystal has the dimension of 4,5cm by 5,5cm.

6 5 4 Growth [cm] 3 2 1 0 0 10 Time [days] 20 30

short axis long axis

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Cameroon GCE Ordinary Level 2017Dokument496 SeitenCameroon GCE Ordinary Level 2017Metz GreyNoch keine Bewertungen

- Paper 1Dokument295 SeitenPaper 1Shreyas TiwariNoch keine Bewertungen

- Fluid Mechanics Chapter 1-5Dokument32 SeitenFluid Mechanics Chapter 1-5Kristine Ann Reclosado38% (8)

- Children Memory Verses From The BibleDokument1 SeiteChildren Memory Verses From The BibleLambert StrongNoch keine Bewertungen

- Worship Songs EmeDokument2 SeitenWorship Songs EmeLambert StrongNoch keine Bewertungen

- Exercise 4 MatDokument7 SeitenExercise 4 MatLambert StrongNoch keine Bewertungen

- BBC Wuppertal Kids 2017: Song1Dokument2 SeitenBBC Wuppertal Kids 2017: Song1Lambert StrongNoch keine Bewertungen

- Structure ChemistryDokument19 SeitenStructure ChemistryLambert StrongNoch keine Bewertungen

- Blessed Baptist Church: Wuppertal Charity and ThanksgivingDokument1 SeiteBlessed Baptist Church: Wuppertal Charity and ThanksgivingLambert StrongNoch keine Bewertungen

- Introduction AnkaDokument6 SeitenIntroduction AnkaLambert StrongNoch keine Bewertungen

- Xcal RXNDokument11 SeitenXcal RXNLambert StrongNoch keine Bewertungen

- Blessed Basptist Church Wuppertal Harvest Thanksgiving: Psalms 105:1 " Oh, Give Thanks To The LORD!"Dokument1 SeiteBlessed Basptist Church Wuppertal Harvest Thanksgiving: Psalms 105:1 " Oh, Give Thanks To The LORD!"Lambert StrongNoch keine Bewertungen

- Ep 364 Solid State Physics: Course Coordinator Prof. Dr. Beşire GönülDokument139 SeitenEp 364 Solid State Physics: Course Coordinator Prof. Dr. Beşire GönülLambert StrongNoch keine Bewertungen

- Optical GlassDokument55 SeitenOptical GlassLambert StrongNoch keine Bewertungen

- Application For KielDokument1 SeiteApplication For KielLambert StrongNoch keine Bewertungen

- Matlab 2 PDFDokument3 SeitenMatlab 2 PDFLambert StrongNoch keine Bewertungen

- Tutor:Hess: Growth of Copper (Ii) Sulphate Pentahydrate (Cuso 5H O) From Aqueous SolutionDokument11 SeitenTutor:Hess: Growth of Copper (Ii) Sulphate Pentahydrate (Cuso 5H O) From Aqueous SolutionLambert StrongNoch keine Bewertungen

- Basic Elements of CrystallographyDokument207 SeitenBasic Elements of CrystallographyErnesto Rodriguez86% (7)

- Z5 Float ZoneDokument113 SeitenZ5 Float ZoneLambert StrongNoch keine Bewertungen

- Growth of Copper (Ii) Sulphate Pentahydrate (Cuso 5H O) From Aqueous SolutionDokument2 SeitenGrowth of Copper (Ii) Sulphate Pentahydrate (Cuso 5H O) From Aqueous SolutionLambert StrongNoch keine Bewertungen

- Lecture2 MartinDokument46 SeitenLecture2 MartinLambert StrongNoch keine Bewertungen

- Waste Managment Cottbus - PPTX (Automatisch Gespeichert)Dokument1 SeiteWaste Managment Cottbus - PPTX (Automatisch Gespeichert)Lambert StrongNoch keine Bewertungen

- Interpretation of The Magnetic AnomaliesDokument24 SeitenInterpretation of The Magnetic AnomaliesLambert StrongNoch keine Bewertungen

- Copper: T7011B Mining Economy and Risk Evaluation Assignment 1, Part 1Dokument4 SeitenCopper: T7011B Mining Economy and Risk Evaluation Assignment 1, Part 1Lambert StrongNoch keine Bewertungen

- Article WJPR 1467266667Dokument10 SeitenArticle WJPR 1467266667Atthapu ThirupathaiahNoch keine Bewertungen

- Effect of Flake Ice On Concrete CoolingDokument1 SeiteEffect of Flake Ice On Concrete CoolingGianni TogniNoch keine Bewertungen

- BR Int LD Id Inspiration 55-70plusDokument11 SeitenBR Int LD Id Inspiration 55-70plustarkett tNoch keine Bewertungen

- Nanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsDokument19 SeitenNanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsPRAVEEN MNoch keine Bewertungen

- Pioglitazone NaopaticlesDokument11 SeitenPioglitazone NaopaticlesAtiq Ur-RahmanNoch keine Bewertungen

- Welding Technology NotesDokument89 SeitenWelding Technology NotesSanjay JangraNoch keine Bewertungen

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDokument4 SeitenSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosSyafrian AzmiNoch keine Bewertungen

- Chiroptical Spectroscopy: Theory and Applications in Organic ChemistryDokument32 SeitenChiroptical Spectroscopy: Theory and Applications in Organic ChemistryDavid SantiagoNoch keine Bewertungen

- Koerner. On The Creep GeosynteticDokument6 SeitenKoerner. On The Creep GeosynteticSergio Xexo Gonzalez RuizNoch keine Bewertungen

- Durability Studies On Concrete With Fly Ash & GGBS: A.H.L.Swaroop, K.Venkateswararao, Prof P KodandaramaraoDokument5 SeitenDurability Studies On Concrete With Fly Ash & GGBS: A.H.L.Swaroop, K.Venkateswararao, Prof P Kodandaramaraoபுருஷோத்தமன் சரவணன்Noch keine Bewertungen

- Stepan Pol Ps 2352Dokument2 SeitenStepan Pol Ps 2352A MahmoodNoch keine Bewertungen

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDokument3 SeitenPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesNoch keine Bewertungen

- 2018 10 08 ICSG Factbook Copper 2018Dokument66 Seiten2018 10 08 ICSG Factbook Copper 2018treNoch keine Bewertungen

- Solid-State Kinetic ModelsDokument14 SeitenSolid-State Kinetic Modelsleizar_death64Noch keine Bewertungen

- Clay Notes (4th Sem)Dokument21 SeitenClay Notes (4th Sem)SamNoch keine Bewertungen

- SigmazincDokument8 SeitenSigmazincHaresh BhavnaniNoch keine Bewertungen

- Proposed OS&E Requirement - Measuring Ozone DosageDokument3 SeitenProposed OS&E Requirement - Measuring Ozone DosageProteina QuitinaseNoch keine Bewertungen

- NESC Diploma - MillwrightDokument2 SeitenNESC Diploma - MillwrightjamesNoch keine Bewertungen

- Anatomi Dan Fisiologi Tumbuhan: Ihsan Tria Pramanda, M.SDokument19 SeitenAnatomi Dan Fisiologi Tumbuhan: Ihsan Tria Pramanda, M.SReva RahmafitriNoch keine Bewertungen

- Carnauba-Super-Micropowder 2442 P 5: ApplicationDokument1 SeiteCarnauba-Super-Micropowder 2442 P 5: Application333cubi333Noch keine Bewertungen

- Industrial Crops & Products: SciencedirectDokument8 SeitenIndustrial Crops & Products: SciencedirectJyotsana DwivediNoch keine Bewertungen

- Endothermic and Exothermic Reactions WorksheetDokument4 SeitenEndothermic and Exothermic Reactions Worksheetabdulhakim100% (1)

- 50 Easy and Free FertilizersDokument12 Seiten50 Easy and Free FertilizersScott Odam100% (1)

- Biology Remedial Module PDFDokument185 SeitenBiology Remedial Module PDFBetseha Merawi67% (3)

- Product Information: Synpower™ Motor Oil Sae 5W-40Dokument2 SeitenProduct Information: Synpower™ Motor Oil Sae 5W-40Iulia DanaNoch keine Bewertungen

- 11.drug StudyDokument1 Seite11.drug StudyFreisanChenMandumotanNoch keine Bewertungen

- TDS OF H-408 Silicone Adjuvant For AgricultureDokument2 SeitenTDS OF H-408 Silicone Adjuvant For AgricultureAda FuNoch keine Bewertungen

- Component in Making Fiber Board As Substitute For HardiflexDokument9 SeitenComponent in Making Fiber Board As Substitute For Hardiflexxiniac_1Noch keine Bewertungen