Beruflich Dokumente

Kultur Dokumente

Concrete Weigh Pit Notesff

Hochgeladen von

Herman HutabaratCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrete Weigh Pit Notesff

Hochgeladen von

Herman HutabaratCopyright:

Verfügbare Formate

TNZ S/5P NOTES: 1987

NOTES ON CONCRETE WEIGH PIT STANDARD

These notes are for the guidance of supervising officers and must not be included in the contract documents. 1. SCOPE These notes cover the requirements for the construction of approaches and the concrete single axle weigh pit for use with Telub scales model 10T and 1203 on state highways, see drawings: 0/189/1/8004/1 State Highway Single Axle Weigh Pit Layout and Construction Details 0/189/1/7004/1 State Highway Single Axle Weigh Pit Swing Arm Barrier Details

2.

CONCRETE SUBBASE AND PAVEMENT AREA 2.1 General Design The concrete weigh pit subbase and approach exit and waiting area pavement layers shall be designed in accordance with TNZ S/4. The concrete slab shall be 150mm thick. The design loading shall not be less than 2 x 104 EDA. Where modified materials are to be incorporated in the pavement the design shall conform with RRU Technical Recommendations TR2, TR5 and TR7, whichever is appropriate. The design CBR is defined in section 2.2 of these notes. The provision of a seal cost shall be subject to the approval of the District Highways Engineer. 2.2 Bearing Strength Bearing strength determinations shall consist of sets of three CBR tests on samples randomly selected from the subgrade. The tests shall consist of soaked CBRs carried out according to NZS 4402 Part 2P: 1981 Test 18(A). The design CBR (Cd) shall be determined as follows:

SP/NS5P:87XXXX

NOTES ON SPECIFICATIONS FOR CONCRETE WEIGH PITS

Page 1 of 3

TNZ S/5P NOTES: 1987 Cd = c (1.3 x S ) where c = mean CBR, S = standard deviation 2.3 Construction All construction, pavement layers and surfacings shall be in accordance with the relevant TNZ specifications.

3.

CONCRETE 3.1 General All concrete shall be in accordance with NZS 3109: 1980 with a minimum compressive strength of 20MPa at 28 days. Construction joints shall be provided only where shown on the drawings. PVC blinding is used between subbase and in situ concrete and all joints in PVC shall be sealed to prevent grout leakage. All visible surfaces shall have a smooth finish in accordance with class U2 of NZS 3114: 1980. 3.2 Reinforcing Steel All reinforcement shall be welded reinforcing fabric mesh type 665 in grade 485 steel. At construction joints every second bar crossing the joint shall be terminated 50mm each side of the joint. 3.3 Tolerances The tolerances shown in the specification and drawings must be achieved to ensure that the facility complies with the Ministry of Transport requirements for weighing heavy vehicles. 3.4 Gradients The maximum gradient allowable on weigh pit approach, exit and waiting area to be 3% unless otherwise approved by the District Highways Engineer. The concrete ramps, aprons and weigh pit recess shall be level in the longitudinal direction. 3.5 Crossfall The crossfall shall be 2% to ensure adequate surface runoff.

SP/NSP:87XXXX

NOTES ON SPECIFICATIONS FOR CONCRETE WEIGH PITS

Page 2 of 3

TNZ S/5P NOTES: 1987 4. DRAINAGE It is essential to keep the subbase layer as free of water as possible. A drainage system around the perimeter of the weigh pit site may be required to control local runoff. Subsoil drainage is required between the weigh pit site and the adjacent roadway to intercept subbase or subgrade water which may percolate through to the weigh pit subbase. Between the weigh pit site and the adjacent roadway a dished channel shall be constructed to take surface runoff from the roadway and weigh pit area. The subsoil drainage system and the dished channel shall drain to common sumps. Piped culverts shall be used from the sumps to the overall drainage system used. Alternative sump and drainage channel details may be used if approved by the District Highways Engineer.

5.

SWING ARM BARRIER A removable swing arm barrier shall be provided to stop traffic from running over the weigh pit recess when not in use. A lock shall be provided.

SP/NSP:87XXXX

NOTES ON SPECIFICATIONS FOR CONCRETE WEIGH PITS

Page 3 of 3

Das könnte Ihnen auch gefallen

- Herman Pardamean Hutabarat: Mechanical EngineerDokument3 SeitenHerman Pardamean Hutabarat: Mechanical EngineerHerman HutabaratNoch keine Bewertungen

- Duration 4 Days Fee Rp. 4.500.000: ObjectiveDokument1 SeiteDuration 4 Days Fee Rp. 4.500.000: ObjectiveHerman HutabaratNoch keine Bewertungen

- Tips and Trick To Avoid Fake Recruitment On Behalf of PERTAMINADokument14 SeitenTips and Trick To Avoid Fake Recruitment On Behalf of PERTAMINAHerman HutabaratNoch keine Bewertungen

- Book SetDokument1 SeiteBook SetHerman HutabaratNoch keine Bewertungen

- FormcompDokument1 SeiteFormcomp123456mkNoch keine Bewertungen

- Dove Holy Spirit PowerPoint TemplatesDokument48 SeitenDove Holy Spirit PowerPoint TemplatesChittaNoch keine Bewertungen

- Form Request Man PowerDokument1 SeiteForm Request Man PowerHerman HutabaratNoch keine Bewertungen

- Ceklist Rev 1Dokument1 SeiteCeklist Rev 1Herman HutabaratNoch keine Bewertungen

- Ceklist Rev 1Dokument1 SeiteCeklist Rev 1Herman HutabaratNoch keine Bewertungen

- Load Chart FT 5 TonDokument1 SeiteLoad Chart FT 5 TonHerman HutabaratNoch keine Bewertungen

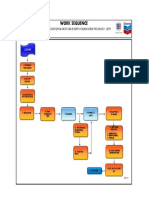

- Work Sequence: Coating Application 36 Inch Cgs 5 Duri To Dumai Area Package 2 - 2019Dokument1 SeiteWork Sequence: Coating Application 36 Inch Cgs 5 Duri To Dumai Area Package 2 - 2019Herman HutabaratNoch keine Bewertungen

- Accident PreventionDokument11 SeitenAccident PreventionHerman HutabaratNoch keine Bewertungen

- WG's Process Engineers' Codes & StandardsDokument7 SeitenWG's Process Engineers' Codes & StandardsHerman HutabaratNoch keine Bewertungen

- 1-7 - Ornamental Designs ModelDokument1 Seite1-7 - Ornamental Designs ModelHerman HutabaratNoch keine Bewertungen

- Accident Reporting & InvestigationDokument26 SeitenAccident Reporting & InvestigationHerman HutabaratNoch keine Bewertungen

- FormcompDokument1 SeiteFormcomp123456mkNoch keine Bewertungen

- Halliburton Job Application Receipt Warning Against FraudDokument1 SeiteHalliburton Job Application Receipt Warning Against FraudHerman HutabaratNoch keine Bewertungen

- NI Tutorial 5097Dokument2 SeitenNI Tutorial 5097Herman HutabaratNoch keine Bewertungen

- SymbolsDokument1 SeiteSymbolsbarmarwanNoch keine Bewertungen

- Baca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveDokument1 SeiteBaca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveHerman HutabaratNoch keine Bewertungen

- Form Pendaftaran.1Dokument2 SeitenForm Pendaftaran.1Veronika ChaidirNoch keine Bewertungen

- Tooling Approval Checklist For Plastic Moulds0Dokument1 SeiteTooling Approval Checklist For Plastic Moulds0Herman Hutabarat0% (1)

- Beam & Column Selection CalculatorDokument63 SeitenBeam & Column Selection CalculatorVivek Prajapati100% (1)

- Danareksa Management Trainee ApplicationDokument1 SeiteDanareksa Management Trainee ApplicationHerman HutabaratNoch keine Bewertungen

- Baca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveDokument1 SeiteBaca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveHerman HutabaratNoch keine Bewertungen

- 1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsDokument2 Seiten1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsTKASHIQUE100% (1)

- MalDokument1 SeiteMalHerman HutabaratNoch keine Bewertungen

- Calculation of Water Flow Rates For Different Pipe Sizes - US UnitsDokument4 SeitenCalculation of Water Flow Rates For Different Pipe Sizes - US UnitsRyan KaneNoch keine Bewertungen

- SymbolsDokument1 SeiteSymbolsbarmarwanNoch keine Bewertungen

- Friction FactorDokument6 SeitenFriction Factorrajeshsapkota123Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Sustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Dokument408 SeitenSustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Randall WestNoch keine Bewertungen

- Gatk Pipeline Presentation: From Fastq Data To High Confident VariantsDokument8 SeitenGatk Pipeline Presentation: From Fastq Data To High Confident VariantsSampreeth ReddyNoch keine Bewertungen

- Design Process at LEGODokument5 SeitenDesign Process at LEGOkapsarcNoch keine Bewertungen

- Agitators: Robert L. Bates, President Chemineer, IncDokument24 SeitenAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiNoch keine Bewertungen

- DownloadDokument11 SeitenDownloadAnonymous ffje1rpaNoch keine Bewertungen

- 42U System Cabinet GuideDokument68 Seiten42U System Cabinet GuideGerman AndersNoch keine Bewertungen

- Tender Evaluation Template GuideDokument15 SeitenTender Evaluation Template GuideKhalid NaeemNoch keine Bewertungen

- Cost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDDokument59 SeitenCost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDranzlorenzoo100% (1)

- Adapting Cognitive Behavioral Techniques To Address Anxiety and Depression in Cognitively Able Emerging Adults On The Autism SpectrumDokument3 SeitenAdapting Cognitive Behavioral Techniques To Address Anxiety and Depression in Cognitively Able Emerging Adults On The Autism SpectrumVini PezzinNoch keine Bewertungen

- Analogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiDokument235 SeitenAnalogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiAl-FarabiNoch keine Bewertungen

- RRR Media Kit April 2018Dokument12 SeitenRRR Media Kit April 2018SilasNoch keine Bewertungen

- STR File Varun 3Dokument61 SeitenSTR File Varun 3Varun mendirattaNoch keine Bewertungen

- Defender 90 110 Workshop Manual 5 WiringDokument112 SeitenDefender 90 110 Workshop Manual 5 WiringChris Woodhouse50% (2)

- Open MPDokument30 SeitenOpen MPmacngocthanNoch keine Bewertungen

- July 4th G11 AssignmentDokument5 SeitenJuly 4th G11 Assignmentmargo.nicole.schwartzNoch keine Bewertungen

- Bhajan Songs PDFDokument36 SeitenBhajan Songs PDFsilphansi67% (6)

- Solution Manual For Contemporary Project Management 4th EditionDokument15 SeitenSolution Manual For Contemporary Project Management 4th EditionDanaAllendzcfa100% (77)

- Unit 01 Family Life Lesson 1 Getting Started - 2Dokument39 SeitenUnit 01 Family Life Lesson 1 Getting Started - 2Minh Đức NghiêmNoch keine Bewertungen

- Double Burden of Malnutrition 2017Dokument31 SeitenDouble Burden of Malnutrition 2017Gîrneţ AlinaNoch keine Bewertungen

- Broom Manufacture Machine: StartDokument62 SeitenBroom Manufacture Machine: StartHaziq PazliNoch keine Bewertungen

- Educating The PosthumanDokument50 SeitenEducating The PosthumanCatherine BrugelNoch keine Bewertungen

- Financial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelDokument35 SeitenFinancial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelRagava KarthiNoch keine Bewertungen

- Vsip - Info - Ga16de Ecu Pinout PDF FreeDokument4 SeitenVsip - Info - Ga16de Ecu Pinout PDF FreeCameron VeldmanNoch keine Bewertungen

- Antenatal AssessmentDokument9 SeitenAntenatal Assessmentjyoti singhNoch keine Bewertungen

- Operation Manual 11-3000psi Shear Ram BopDokument30 SeitenOperation Manual 11-3000psi Shear Ram BopBoedi SyafiqNoch keine Bewertungen

- Hearing God Through Biblical Meditation - 1 PDFDokument20 SeitenHearing God Through Biblical Meditation - 1 PDFAlexander PeñaNoch keine Bewertungen

- Math 2 Unit 9 - Probability: Lesson 1: "Sample Spaces, Subsets, and Basic Probability"Dokument87 SeitenMath 2 Unit 9 - Probability: Lesson 1: "Sample Spaces, Subsets, and Basic Probability"Anonymous BUG9KZ3100% (1)

- EJC H2 Math P1 With Solution PDFDokument23 SeitenEJC H2 Math P1 With Solution PDFKipp SohNoch keine Bewertungen

- Carmina GadelicaDokument37 SeitenCarmina GadelicaoniricsNoch keine Bewertungen

- Ukraine and Russia E IRDokument287 SeitenUkraine and Russia E IRtatgirNoch keine Bewertungen