Beruflich Dokumente

Kultur Dokumente

UDS 110 Depentaniser Debutanizer PDF

Hochgeladen von

mujeebmeharOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UDS 110 Depentaniser Debutanizer PDF

Hochgeladen von

mujeebmeharCopyright:

Verfügbare Formate

De-Pentanizer & De-Butanizer

De-Pentanizer & De-Butanizer

2005 Honeywell - All Rights Reserved UDS-110.03.R350.01

De-Pentanizer & De-Butanizer

Workshop

Separation of light products is typical of Refinery operations. In this module, two columns will be modeled to separate pentanes and butanes. Because the Condenser temperature in the De-butanizer is below zero, the process stream will need to be cooled. The Propane Refrigeration Loop from the previous module will be used to cool the process stream, showing how templates can be linked into UniSim Design cases.

Learning Objectives

Once you have completed this section, you will be able to: Build columns using the Input Experts Use the Spreadsheet Link Templates

Prerequisites

Before beginning this module you need to have completed the Getting Started and the Propane Refrigeration Loop modules.

Process Overview

De-Pentanizer & De-Butanizer

Column Overview

De-pentanizer

De-butanizer

De-Pentanizer & De-Butanizer

Building the Simulation

For this module you will continue building on the case you worked on in Module 1 by adding two distillation columns. 1. Open the case you saved at the end of module 1. Make sure the temperature, pressure and flowrate for Feed stream are the following:

In this cell... Temperature Pressure Molar Flow Enter... 30C (86F) 700 kPa (100 psia) 100 kgmole/h (220 lbmole/h)

Adding the First Column: De-Pentanizer

The De-pentanizer will be modelled with a Distillation column. The Column is a special type of Sub-Flowsheet, which contains equipment and streams, and exchanges information with the parent Flowsheet through the connected streams. UniSim Design has several basic Column templates depending on the type of equipment your Column requires:

Basic Column Types Absorber Liquid-Liquid Extractor Reboiled Absorber Refluxed Absorber Distillation Description Tray Section Only Tray Section Only Tray Section and a bottom stage reboiler Tray Section and an overhead condenser Tray Section with both reboiler and condenser

There are 12 ideal stages in the De-pentanizer, 10 in the tray section plus the Reboiler and Condenser. 1. Double-click on the Distillation Column icon in the Object Palette. The first Input Expert view appears.

Distillation Column icon

De-Pentanizer & De-Butanizer

2. Input the following information into the first input expert page.

In this field... Column Name Input Expert is a tool that help to ensure all required information is entered. Once you are familiar with the column view, they can be turned off in your preference file. Inlet Stream Inlet Stage Condenser Energy Stream Condenser Type Overhead Vapour Outlet Reboiler Energy Stream Bottoms Liquid Outlet Figure 1 Enter... De-Pentanizer Feed 5_Main TS Cond1 Q Full Reflux Ovhd Vap Prod Reb1 Q Pentanes+

3. Click the Next button to proceed to the next page. The Next button is only available when all of the necessary information has been supplied. 4. Supply the following information to the Pressure Estimates page.

In this cell... Condenser Pressure Reboiler Pressure Enter... 650 kPa (94 psia) 700 kPa (101 psia)

De-Pentanizer & De-Butanizer

Figure 2

5. Click the Next button to proceed to the next page. 6. On this page, enter the temperature estimates. The Condenser temperature estimate will be 10C (50F), and the reboiler temperature estimate will be 120C (248F). Temperature estimates are not required for the column to solve but they will aid in convergence.

Figure 3

7. Click the Next button to continue.

De-Pentanizer & De-Butanizer

8. On the last page supply a value of 2 for the Reflux Ratio.

Figure 4

9. Click the Done button. UniSim Design will open the Column Property View window. Access the Monitor page on the Design tab.

Figure 5

Two specifications must be filled so that the Degrees of Freedom are 0. You already have specified the Reflux Ratio. In this case you will use the i-C5 purity instead of the Ovhd Vap Rate.

De-Pentanizer & De-Butanizer

10. You need to deactivate the Ovhd Vap Rate by clicking on the Active check box. Now only the Reflux Ratio checkbox is checked and the Degrees of Freedom is 1. 11. To add a specification, click the Add Spec button.

Figure 6

12. Select Column Component Fraction and click the Add Spec(s) button. 13. Provide the following information.

In this cell... Name Target Type Draw Basis Spec Value Components Figure 7 Enter... iC5 Comp Fraction Stream Pentanes+ @Col1 Mole Fraction 0.27 i-Pentane

10

De-Pentanizer & De-Butanizer

14. When you are done, close the window to go back to the Monitor page of the Design tab. Check the Active ratio button for the Comp Fraction iC5 specification. 15. Click the Run button to begin calculations. Once the column has converged, you can view the results on the Performance tab.

Figure 8

What is the flowrate of the Pentanes+ Stream? ___________________________

Adding the Second Column: De-Butanizer

The De-butanizer column is also modelled as a distillation column, with 17 stages, 15 trays in the column, plus the reboiler and condenser. The objective of this column is to produce a bottom product that has a molar fraction of butanes (both i-C4 and n-C4) of 0.97. 1. Double click on the Distillation Column button on the Object

10

De-Pentanizer & De-Butanizer

11

Palette and enter the following information:

In this cell... Connections Name No. of Stage Feed Stream/Stage Condenser Type Overhead Vapour Product Bottom Product Condenser Duty Reboiler Duty Pressure Condenser Reboiler Temperature Estimates Condenser Reboiler Specification Reflux Ratio Component Recovery (i-butane) 2 0.97 -20C (-4F) 50C (122F) 550 kPa (80 psia) 600 kPa (87 psia) De-butanizer 15 Ovhd Vap Prod / 9 Full Reflux Light Products Butanes Cond2 Q Reb2 Q Enter...

What is the Molar Flow of Light Products streams? _________________________ And the flowrate of i-C4 and n-C4 in Light Products? i-C4_________, n-C4__________ What is the molar fraction of butanes in Light Products? _________________________ What is the recovery of butanes? _________________________ Save your case as Crude3.usc.

Save your case!

11

12

De-Pentanizer & De-Butanizer

Using the Spreadsheet

To answer the previous questions you had to add the fraction of i-C4 and n-C4 somewhere outside the simulation. UniSim Design has a Spreadsheet operation, which allows you to import stream or operation variables, perform calculations, and export calculated results. You are going to create a spreadsheet to calculate the molar fraction both of pentanes and butanes in their respectively streams and their recoveries. 1. To install a Spreadsheet and display its property view, double-click on the Spreadsheet icon in the Object Palette.

Spreadsheet icon

2. Click the Add Import button, and the Select Import view will appear. 3. Choose the Object, Variable, and Variable Specific as shown:

In this field... Object Variable Variable Specifics Figure 9 Select... Feed Comp Molar Flow i-Pentane

Notice that UniSim Design assigned the imported variable to Spreadsheet cell A1, by default. Change this cell location to B1. The reason for doing so will become apparent on the Spreadsheet tab. 4. Before continuing you need to add more rows to the spreadsheet. Do this by clicking in the Parameters tab and entering 16 in the Number of Rows field.

12

De-Pentanizer & De-Butanizer

13

5. In many ways, the UniSim Design Spreadsheet behaves similarly to commercial spreadsheets packages; you enter data in the cells, and calculated results are returned. You can introduce the variables directly in the spreadsheet. Change to the Spreadsheet tab. 6. Right-click in the cell where you want to import the variable. Do this in cell D1. The following view will appear:

Figure 10

7. Select Import Variable. 8. Select the Object, Variable, and Variable Specific as shown:

In this field... Object Variable Variable Specifics Select... Feed Comp Molar Flow n-Pentane

9. Enter the following names in the spreadsheet:

In this cell... A3 A4 A5 A6 A7 A10 A12 A13 A14 A15 A16 C5 C7 C14 C16 Enter... PENTANES+ iC5 Frac nC5 Frac iC5 Flow nC5 Flow iC4 Ovhd Vap Flow BUTANES iC4 Frac nC4 Frac iC4 Flow nC4 Flow Pentane Frac Pentane Recovery Butane Frac Butane Recovery

13

14

De-Pentanizer & De-Butanizer

10. Complete the rest of the spreadsheet by importing the following values into the specified cell.

Cell B4 B5 B6 B7 B10 B13 B14 B15 B16 D10 Object Pentanes+ Pentanes+ Pentanes+ Pentanes+ Ovhd Vap Prod Butanes Butanes Butanes Butanes Ovhd Vap Prod Figure 11 Variable Comp Mole Frac Comp Mole Frac Comp Molar Flow Comp Molar Flow Comp Molar Flow Comp Mole Frac Comp Mole Frac Comp Molar Flow Comp Molar Flow Comp Molar Flow Variable Specifics i-Pentane n-Pentane i-Pentane n-Pentane i-Butane i-Butane n-Butane i-Butane n-Butane n-Butane

You can move to a cell by clicking it, or by clicking the arrow keys. The values are those corresponding the variable named to the left. Import them. Fractions and Flows are in molar basis 11. To enter the formulas place the cursor on the cell and write it. Remember to use a "=" symbol before mathematical operations. Enter the following formulas

Cell D5 D7 D14 D16 Formula =b4+b5 =(b6+b7)/(b1+d1)*100 =b13+b14 =(b15+b16)/(b10+d10)*100

14

De-Pentanizer & De-Butanizer

15

Figure 12

Clicking in the Function Help button you can see all the operations that are available in UniSim Design. Once the cell is completed, you can export the variable to the simulation. This is done by clicking with the right button in the cell. The spreadsheet allows you to use your own correlations, for example, for pressures drop, etc.

What is the pentanes recovery? _____________________________________________ And that of butanes? _____________________________

Save your case as Crude3_Recovery.usc

Save your case!

15

16

De-Pentanizer & De-Butanizer

Another easy way to view the component recovery is to go to the Performance-Summary view of the column properties, and then select the Recovery radio button. From this view, the users can find the component recovery for each individual component.

Figure 13

16

De-Pentanizer & De-Butanizer

17

Linking Templates

Once you have completed the recovery fractionation train you can link it to the Propane Loop Template, and use the Propane Loop to refrigerate the De-butanizer. The duty of the Condenser, Cond2 Q, in this module, will be linked to the duty of the Chiller, Chill-Q in the Propane Refrigeration Loop template. 1. Double-click on the Sub-Flowsheet icon on the Object Palette. 2. Select the Read an Existing Template button.

Sub-Flowsheet icon

3. Open the template file saved in the Propane Refrigeration Loop module, C3loop.tpl. 4. The Sub-Flowsheet Operation view appears. Click the SubFlowsheet Environment button at the bottom of the view. 5. The PFD of the Propane Refrigeration Loop appears. Double-click on the energy stream of the Chiller, Chill-Q. 6. Delete the Heat Flow value of the stream by pressing the DELETE key on the keyboard.

To connect the template without conflicts, the heat flow value of Chiller-Q is deleted in the template prior to connecting the internal and external energy stream. This is to prevent over specifying the flowsheet; if the heat flow value of Chiller-Q is not deleted, a consistent error will occur as there are two different heat flow values for the same energy stream.

Figure 14

7. Close the Energy stream view. Click the Enter Parent Simulation Environment icon on the toolbar to return to the Sub-Flowsheet Operation view.

Enter Parent Simulation

17

18

De-Pentanizer & De-Butanizer

8. In the Feed Connections to Sub-Flowsheet group, connect the External Stream, Cond2 Q, to the Internal Stream Chill Q.

Figure 15

Once the connection is complete, both streams, (Internal and External) will have the same name and heat flow value, that of the External stream.

What is the flowrate of propane in the Refrigeration Loop? _________________________________________ What is the compressor duty? _________________________________________

18

Advanced Modelling

19

Advanced Modelling

The Column is a special type of SubFlowsheet in UniSim Design. SubFlowsheets contain equipment and streams, and exchange information with the Parent Flowsheet through the connected streams. From the Main Environment, the Column appears as a single, multifeed multi-product operation. In many cases, you can treat the Column in exactly that manner. The Column SubFlowsheet provides a number of advantages: Isolation of the Column Solver. The Column Build Environment allows you to make changes and focus on the Column without the re-calculation of the entire Flowsheet. Optional use of different Fluid Packages. UniSim Design allows you to specify a unique (different from the Main Environment) fluid package for the Column SubFlowsheet. This may be useful in instances when a different fluid package is better suited to the Column (Gas Plant using PR may contain an Amine Contactor that needs to use the Amines Property Package), or the Column does not use all of the components used in the Main Flowsheet and so by decreasing the number of components in the column you may speed up column convergence. Construction of custom templates. In addition to the default column configurations which are available as templates, you may define column setups with varying degrees of complexity. Complex custom columns and multiple columns may be simulated within a single SubFlowsheet using various combinations of SubFlowsheet equipment. Custom column examples include replacement of the standard Condenser with a Heat Exchanger, or the standard kettle reboiler with a thermosyphon reboiler. Ability to solve multiple towers simultaneously. The Column SubFlowsheet uses a simultaneous solver whereby all operations within the SubFlowsheet are solved simultaneously. The simultaneous solver permits the user to install multiple interconnected columns within the SubFlowsheet without the need for Recycle blocks.

The presence of the green "Up Arrow" button in the Button Bar and the Environment: Name (COL1) indicates that you are in the Column SubFlowsheet. It is also written at the right in the Icons bar.

19

20

Advanced Modelling

Enter Parent Simulation Environment icon

You can enter the Column SubFlowsheet by clicking the Column Environment button on the Column Property View. Once inside the Column Environment you can return to the Parent Environment by clicking either the Parent Environment button on the Column Runner view or the Enter Parent Simulation Environment icon in the toolbar.

Exploring with the Simulation

Exercise 1

Study the influence of the number of stages on the propane fraction in bottoms. Increase the number of stages until the propane recovery in the tower overhead is higher than 0.998.

Exercise 2

What is the Molar Enthalpy for streams Reflux and Boilup? Reflux___________,Boilup__________________

20

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Fire Hazards & Control Techniques in RefineriesDokument47 SeitenFire Hazards & Control Techniques in Refineriesmujeebmehar57% (7)

- Presentation Slides For Tank Construction and MaintenanceDokument71 SeitenPresentation Slides For Tank Construction and Maintenancemujeebmehar86% (14)

- Assignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaDokument4 SeitenAssignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaPaulo PimentaNoch keine Bewertungen

- AP PHYSICS B 1988 MC + AnswersDokument17 SeitenAP PHYSICS B 1988 MC + AnswersbastardNoch keine Bewertungen

- DHDS Block OperationsDokument77 SeitenDHDS Block Operationsmujeebmehar100% (2)

- O M Manual W818 PDFDokument71 SeitenO M Manual W818 PDFmujeebmehar100% (1)

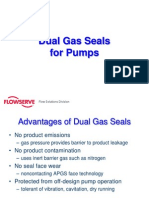

- Flowserve Pump Gas SealsDokument37 SeitenFlowserve Pump Gas Sealsmujeebmehar50% (2)

- CommunicationDokument53 SeitenCommunicationmujeebmeharNoch keine Bewertungen

- Crude Oil - Selection - Planning-IMA-17.01.12-by T.AdhikariDokument54 SeitenCrude Oil - Selection - Planning-IMA-17.01.12-by T.Adhikarimujeebmehar100% (1)

- AVU II Skill Development 2008 09 PDFDokument43 SeitenAVU II Skill Development 2008 09 PDFsudhirkumar99Noch keine Bewertungen

- CRUDE OIL OPERATING MANUAL FOR PARADIP REFINERYDokument43 SeitenCRUDE OIL OPERATING MANUAL FOR PARADIP REFINERYmujeebmehar70% (10)

- Boiler DraftDokument10 SeitenBoiler DraftShiju JohnNoch keine Bewertungen

- Flowserve Pump Gas SealsDokument37 SeitenFlowserve Pump Gas Sealsmujeebmehar50% (2)

- HEAT EXCHANGERS MDokument143 SeitenHEAT EXCHANGERS Mmujeebmehar67% (3)

- Pictorial PresentationDokument27 SeitenPictorial PresentationmujeebmeharNoch keine Bewertungen

- AVUDokument22 SeitenAVUmujeebmeharNoch keine Bewertungen

- UDS-110-Propane Refrigeration Loop PDFDokument28 SeitenUDS-110-Propane Refrigeration Loop PDFmujeebmehar100% (1)

- Column & Vessel - NSDokument144 SeitenColumn & Vessel - NSmujeebtalibNoch keine Bewertungen

- Crude Cost and Qga Impact On GRMDokument48 SeitenCrude Cost and Qga Impact On GRMmujeebmehar100% (1)

- BASIC REFINING OPERATIONS & DISTILLATIONDokument40 SeitenBASIC REFINING OPERATIONS & DISTILLATIONmujeebmehar100% (1)

- Cdu Presentation 13 07 2010Dokument38 SeitenCdu Presentation 13 07 2010mujeebmeharNoch keine Bewertungen

- QC of Various Stream1Dokument5 SeitenQC of Various Stream1mujeebmeharNoch keine Bewertungen

- PipingDokument102 SeitenPipingmujeebmehar100% (1)

- Cdu Presentation 13 07 2010Dokument38 SeitenCdu Presentation 13 07 2010mujeebmeharNoch keine Bewertungen

- HEAT EXCHANGERS MDokument143 SeitenHEAT EXCHANGERS Mmujeebmehar67% (3)

- Failure & Distress of StructuresDokument41 SeitenFailure & Distress of Structuresahmadfaiz2012Noch keine Bewertungen

- Training On Soil & Foundation Engineering, IMA) 2012 PDFDokument52 SeitenTraining On Soil & Foundation Engineering, IMA) 2012 PDFmujeebmeharNoch keine Bewertungen

- BASIC REFINING OPERATIONS & DISTILLATIONDokument40 SeitenBASIC REFINING OPERATIONS & DISTILLATIONmujeebmehar100% (1)

- Accident Prevention & Behaviour Based Safety ManagementDokument65 SeitenAccident Prevention & Behaviour Based Safety Managementmujeebmehar100% (2)

- Basics of WeldingDokument88 SeitenBasics of Weldingmujeebmehar100% (1)

- Flowserve Pump Gas SealsDokument37 SeitenFlowserve Pump Gas Sealsmujeebmehar50% (2)

- Diagonalization Practice ProblemDokument6 SeitenDiagonalization Practice ProblemawekeuNoch keine Bewertungen

- Data Sheet Otdr Fho5000 enDokument2 SeitenData Sheet Otdr Fho5000 enJulio RoDriguezNoch keine Bewertungen

- Overview Aerodynamics 2017Dokument10 SeitenOverview Aerodynamics 2017marcoNoch keine Bewertungen

- Avr GeneralDokument67 SeitenAvr GeneralRukma Goud Shakkari100% (2)

- Assg 03 1Dokument7 SeitenAssg 03 1Abdul ShakoorNoch keine Bewertungen

- Light SourcesDokument5 SeitenLight Sources123vidyaNoch keine Bewertungen

- How To Do Great WorkDokument64 SeitenHow To Do Great WorkMohan GuntiNoch keine Bewertungen

- Fjbzr6wn50 - Class 7 Timetable - Fua 2024Dokument2 SeitenFjbzr6wn50 - Class 7 Timetable - Fua 2024mrs.prernajainNoch keine Bewertungen

- Determining Dielectric Constants Using A Parallel Plate CapacitorDokument5 SeitenDetermining Dielectric Constants Using A Parallel Plate CapacitorAhmAd GhAziNoch keine Bewertungen

- The Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru ODokument8 SeitenThe Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru OAnggit Tri AtmajaNoch keine Bewertungen

- Activity MergedDokument9 SeitenActivity MergedSoham MondalNoch keine Bewertungen

- Astm F1717-21Dokument11 SeitenAstm F1717-21wenhsiaochuanNoch keine Bewertungen

- Terjemahan BukuDokument2 SeitenTerjemahan BukuSeprianNoch keine Bewertungen

- Marsh FunnelDokument2 SeitenMarsh Funnel123shripadNoch keine Bewertungen

- Signature RedactedDokument49 SeitenSignature RedactedG Pavan KumarNoch keine Bewertungen

- Acids and Bases: Answers To Worked ExamplesDokument12 SeitenAcids and Bases: Answers To Worked ExamplesDana CapbunNoch keine Bewertungen

- 1117 1 M-Ary Signals PART 1Dokument11 Seiten1117 1 M-Ary Signals PART 1PARKSANGWOOKNoch keine Bewertungen

- Applications of Nano Biotechnology in Wastewater Treatment PDFDokument9 SeitenApplications of Nano Biotechnology in Wastewater Treatment PDFswaroop_exlncNoch keine Bewertungen

- Manifest Your Desires with The Quantum CookbookDokument14 SeitenManifest Your Desires with The Quantum CookbookAgarta1111Noch keine Bewertungen

- Hough Transform in Matlab: - If We Find An Edge Point at (Ix, Iy), We Loop Through All Possible Values of ThetaDokument11 SeitenHough Transform in Matlab: - If We Find An Edge Point at (Ix, Iy), We Loop Through All Possible Values of ThetaLe QuyenNoch keine Bewertungen

- LaminateDokument154 SeitenLaminateAbhishek VaggarNoch keine Bewertungen

- Lab 6 SpectrophotometerDokument11 SeitenLab 6 SpectrophotometerChing Wai YongNoch keine Bewertungen

- Air Preheater Technical PaperDokument21 SeitenAir Preheater Technical Paperchekoti koushikNoch keine Bewertungen

- Electrical and Optical Properties of Indium-Tin Oxide (ITO) Films by Ion-Assisted Deposition (IAD) at Room TemperatureDokument6 SeitenElectrical and Optical Properties of Indium-Tin Oxide (ITO) Films by Ion-Assisted Deposition (IAD) at Room Temperaturereza mirzakhaniNoch keine Bewertungen

- Making and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForDokument8 SeitenMaking and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForAhmed AbidNoch keine Bewertungen

- Mid-Term Math Exam for Grade 5Dokument18 SeitenMid-Term Math Exam for Grade 5李安逸Noch keine Bewertungen

- S P I C e J e T Q U e S T I o N SDokument43 SeitenS P I C e J e T Q U e S T I o N SDharavGosaliaNoch keine Bewertungen

- Noise Margin Definition ExplainedDokument10 SeitenNoise Margin Definition ExplainedAnil BhardwajNoch keine Bewertungen