Beruflich Dokumente

Kultur Dokumente

STRESS ANALYSIS OF FLUE GAS DUCTS

Hochgeladen von

Sergio SmithOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

STRESS ANALYSIS OF FLUE GAS DUCTS

Hochgeladen von

Sergio SmithCopyright:

Verfügbare Formate

STRESS ANALYSIS - FLUE GAS DUCT

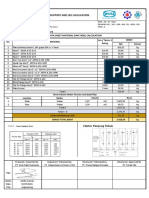

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 1 of 11

STRESS ANALYSIS OF FLUE GAS DUCTS

CLIENT

UROMIA PETROCHEMICAL COMPANY 150 TPD SULPHURIC ACID PLANT

PROJECT :

A Rev.

02-OCT-12 Issue date

FOR APPROVAL DESCRIPTION

KAUTILYA PREPARED BY

K.S. CHKD. BY

V.S. APPR. BY

INDEX

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 2 of 11

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

Introduction...3 References.3 Generic Pipe Stress Model Input....3 4 Specifications of Piping Components.4 5 Methodology...6 7 Allowable Nozzle Loads...8 Considerations & Assumptions.9 Results & Discussions.10 Recommendations...10

Appendices A1 A2 A3 Stress Isometric CAESAR II Model CAESAR II Report

1.0

INTRODUCTION

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 3 of 11

This report covers the Stress Analysis of following Flue Gas Ducts: 36"-SO2-5001-A10-H-200 12"-SO2-5003-A10-H-150 12"-SO2-5002-A10-H-150 The analysis has been performed through CAESAR-II Ver-5.10. The applicable Load cases has been presented in Section-5.4 of this report. Refer appendix-A3 for the detailed CAESAR report. The purpose of this analysis is to identify the possible causes of failures and provide recommendations which will help to mitigate these failures. Used Code & Standards: 1.1 ASME B31.3-2004 : Process Piping Code 1.2 ASME B36.10M-2004 : Welded & Seamless Wrought Steel Pipe 1.3 ASME B16.9-2003 : Factory-Made Wrought Butt-Welded Fittings 1.4 EJMA, 9th Ed.: Standards of the Expansion Joint Manufacturers Association, Inc. 2.0 2.1 2.2 2.3 2.4 2.5 2.6 REFERENCES 10001-PA-DI-A2-EPP-1010 : P&ID T-210-KSJ-ISO-101 : Isometric Drawing TIE-SK-01 : Drwg. for Mitered Bends KSJ-SAU-150-M-DUCT : Ducting Layout PMS (Piping Material Specifications) released by KSJ Version 5.10 CAESAR II Applications Guide; 1985-2008 COADE, Inc.

3.0 GENERIC PIPE STRESS MODEL INPUT Operating Condition: Operating Temperature T1 Operating Pressure P1 Design Condition: Design Temperature Design Pressure Line Size Nominal Pipe Thickness Pipe Longitudinal Joint Efficiency Corrosion Allowance Mechanical Allowance Mill Tolerance Pipe Material Pipe Density Insulation Material Insulation Thickness T2 P2 tn Ej CA c MT

= = = = = = = = = = = = = = =

480 0C 0.3 Kg/cm2, g = 0.2942 Bar, g 510 0C 0.45 Kg/cm2, g = 0.4413 Bar, g 36 NPS & 12 NPS 8 mm - 36 NPS STD Sch - 12 NPS 0.85 2 mm Nil 2.5% Eqvt. to ASTM A285 Gr. C 7833 Kg/m3 Mineral Wool 100 mm

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant Insulation Density Fluid Specific Gravity 4.0 4.1 SPECIFICATIONS OF PIPING COMPONENTS Fittings: NPS 36" 36" 12 12 Description 900 Elbow 90 Elbow 90 Elbow Tee

0 0

Rev-A

Page- 4 of 11

= ~

150 Kg/m3 0

Type Mitered Mitered

Bending Radius 1.5 D 1.0 D

No. of Cuts 4 4

Butt-Welded (ASME B16.9) Butt-Welded (ASME B16.9)

4.2

Expansion Joints: Nominal Size = 36 Bellow Effective ID Expansion Joint Type Make Style MAWP No. of Convolutions Maximum Angular Movement Bending Stiffness Overall Length Nominal Size = 12 Bellow Effective ID Expansion Joint Type Make Style MAWP No. of Convolutions Maximum Angular Movement Bending Stiffness Overall Length De = = = = = = = = = = = = = = = = = = 948.5 mm Gimbal type Senior Flexonics AG 3.5 Kg/cm2 8 100 320 N-m/Deg 330 mm 267 mm 355.6 mm Gimbal type Senior Flexonics AG 3.5 Kg/cm2 8 100 78 N-m/Deg 330 mm 333 mm

N fb

(Welded Ends) (Flanged Ends)

De

N fb

(Welded Ends) (Flanged Ends)

4.3

Valves:

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant 4.3.1 Butterfly Valve Nominal Size Mounting Dimension Weight Butterfly Valve Nominal Size Mounting Dimension Weight

Rev-A

Page- 5 of 11

= = = = = =

36 950 mm 3158 N 12 300 mm 980 N

4.3.1

5.0

METHODOLOGY

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant 5.1

Rev-A

Page- 6 of 11

General The software used for the stress analysis is Caesar II software package, version 5.10, by Coade Inc. The program analyses flexibility under the assumption that displacement strains will produce proportional stress over a sufficiently wide range. CAESAR automatically calculates the Stress Intensification Factor (SIF) for all fittings (including bends and tees) to accommodate complex stress distribution at fittings. Nomenclature 5.2.1 Coordinate System: The direction of X, Y, and Z coordinates are as defined below: X = Positive in south direction Y = Positive in vertical upwards direction Z = Positive in west direction 5.2.2 Support Types: Nomenclature for support used in analysis: ANC = Translational and Rotational movements restrained +Y = Vertical downward movement is restrained GUIDE = Guided support, lateral movements are restrained for horizontal pipe; horizontal direction movements are restrained for vertical pipe

5.2

5.3

Allowable Stresses Piping material was considered as Carbon Steel equivalent to ASTM A285 Gr. C. Appendix-A of ASME Code B31.3 provides the value of Allowable Stress for ASTM A285 Gr. C upto 593 0C. Hence, Code Allowable Stresses are as follows: Allowable Stress at Cold condition = Sc = 18300 Psi Allowable Stress at Optg. condition = Sh1 = 6600 Psi Allowable Stress at Design condition = Sh2 = 4500 Psi Load Cases Case No 1 2 3 4 5 6 Load Case W + T1 + P1 W + T2 + P2 W + P1 W + P2 L1 - L3 L2 - L4 Type OPE OPE SUS SUS EXP EXP Output Disp / Forces Disp / Forces Disp / Force/Stress Disp / Force/Stress Disp / Force/Stress Disp / Force/Stress

5.4

5.5

Where: W : Pipe and contents weight T1 : Operating Temperature P1 : Operating Pressure T2 : Design Temperature P2 : Design Pressure OPE : Operating Load Case SUS : Sustained Load Case EXP : Displacement Stress Range Load Case CAESAR Output Flexibility Analysis has been performed as per the guidelines of Appendix-S, ASME B31.3-2004. CAESAR output included the following in-line with the requirements of Appendix-S, B31.3:

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 7 of 11

5.4.1

Operating Load Case: The operating load case is used to determine the operating

Position of the piping and reaction loads for any attached equipment, anchors, supports, guides, or stops. Hence, nodal movements and restraint loads are included in CAESAR output for operating load cases (W + P1 +T1 & W + P2 + T2).

5.4.2

and

Sustained Load Case: Sustained stresses due to the axial force, internal pressure,

intensified bending moment are combined to determine the sustained longitudinal stress, SL. So, Nodal Stresses for sustained load case (W + P1 & W + P2) are included in CAESAR output and are compared with Allowable Code Stress.

5.4.3

Displacement Stress Range Load Case : The displacement stress range, SE, is based on

the temperature range from the installation to maximum metal temperature for the thermal cycles under analysis. Hence, CAESAR output includes Displacement Stress Range for Expansion load case (L1 L3 & L2 L4) and is compared with the Allowable Stress range, SA, where SA is calculated automatically according to the following relationship defined in para. 302.3.5(d) of ASME B31.3-2004: SA = f (1.25Sc + 0.25Sh)

6.0

ALLOWABLE NOZZLE LOADS

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 8 of 11

Allowable Nozzle Forces and Moments from Thermal displacement and Deadweight are estimated from the following equations: Axial force (Tension or compression) Tangential force (in plane of flange) Longitudinal force (in plane of flange) Torsional Moment Circumferential Bending moment Longitudinal Bending moment Fa = 2000 x B x D FO = 1500 x B x D FL = 2000 x B x D MT = 150 x B x D2 MO = 100 x B x D2 ML = 130 x B x D2 (N) (N) (N) (Nm) (Nm) (Nm)

D = Nominal Dia. of Nozzle in inches B = Factor dependent upon Nozzle Flange rating = 0.6 ( for Class 150#)

Hence, for 36, 24 and 12 Nozzle, the Allowable loads are as under:

D (Inch) 36 24 12

0.6 0.6 0.6

Fa (N) 4320 0 2880 0 1440 0

Fo (N) 3240 0 2160 0 1080 0

FL (N) 4320 0 2880 0 1440 0

MT (N.m) 11664 0 51840 12960

Mo (N.m) 7776 0 3456 0 8640

ML (N.m) 101088 44928 11232

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 9 of 11

7.0 7.1 7.2

CONSIDERATIONS & ASSUMPTIONS Vessels are refractory lines; so, vessel expansion is neglected in comparison to Duct. Hence, no displacement is considered for the vessel Nozzles. *Gimbal type Expansion Joints allow only the Angular movement. Hence, very large value was considered for the Axial and Lateral stiffness for these Expansion Joints during the CAESAR input. As per the classical approach in CAESAR, Gimbal type Expansion Joints are modeled with zero length. As the flowing Fluid is Flue Gas, so, Fluid density is negligible and considered as zero during the CAESAR input Coefficient of Frictions at Guides is taken as 0.3. Valves has been modeled as Rigid Elements in CAESAR Wind & Seismic Loads not considered during Analysis. Flanged Joints not analysed. Dynamic Analysis Not applicable Hydrotest load case Not Applicable

7.3 7.4 7.5 7.6 7.7 7.8 7.9

* Refer Page 5.22 in Version 5.10 CAESAR II Applications Guide; 1985-2008 COADE, Inc.

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 10 of 11

8.0

RESULTS & DISCUSSION

The Results obtained from CAESAR are as follows: 8.1 Load on Nozzles From the Restraints summary report obtained from CAESAR-II it is clear that Loads on the following Nozzles are within permissible limits (as estimated in section-6 of this report): Node-10 : Nozzle N1 of R-9205 Node-210: Nozzle N2 of FT-9204 Node-1300: Nozzle N9 of R-9205 Node-1380: Nozzle N10 of R-9205 Load on Supports From the Restraints summary report obtained from CAESAR-II it is observed that Load on any of the supports is less than 5 Metric ton. Rotation at Gimbal type Expansion Joint As evident from the above Nodal movements table obtained from CAESER-II, Rotation at any of the Gimbal type Expansion Joints is less than 10 Deg. Nodal Stresses & Code compliance The Nodal Stresses are listed in CAESAR output (Appendix A2). The nodal stresses are found to be less than Allowable Stress.

8.2

8.3

8.4

9.0

RECOMMENDATIONS

1. Before designing the Supports, Support Designer need to check the Nodal movements at Supports (listed in

the CAESAR output). Support need to be designed to allow the Nodal movements at the corresponding support. 2. Supports to be designed according to the Support load tabulated in Restraint load table obtained from CAESAR-II analysis.

STRESS ANALYSIS - FLUE GAS DUCT

Doc No. : TIE/12/KSJ/CAE/02 Project : 150 TPD Sulphuric Acid Plant

Rev-A

Page- 11 of 11

Appendices

A1 A2 A3

Stress Isometric CAESAR II Model CAESAR II Report

Das könnte Ihnen auch gefallen

- Prakash Engineering Services Steam Pipeline Stress Analysis ProposalDokument1 SeitePrakash Engineering Services Steam Pipeline Stress Analysis Proposalprakash07343Noch keine Bewertungen

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDokument32 Seiten202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluNoch keine Bewertungen

- Piping To Nozzle To VesselDokument38 SeitenPiping To Nozzle To VesselBaskar Kannaiah0% (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Von EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Noch keine Bewertungen

- CAESAR Stress Analysis of GRPDokument3 SeitenCAESAR Stress Analysis of GRPA.Subin DasNoch keine Bewertungen

- PO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDDokument18 SeitenPO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDUmair RazaNoch keine Bewertungen

- Coiled Tubing Wellbore Maintenance ManualDokument33 SeitenCoiled Tubing Wellbore Maintenance Manualanthony lakpahNoch keine Bewertungen

- Fatigue Analysis Using CAESAR IIDokument7 SeitenFatigue Analysis Using CAESAR IIayoungaNoch keine Bewertungen

- Heater Catalog 0618Dokument576 SeitenHeater Catalog 0618abasakNoch keine Bewertungen

- Stress Design Basis Rev 0 PDFDokument15 SeitenStress Design Basis Rev 0 PDFaprabhakar15100% (1)

- Stress Concentration Roark-Ch06Dokument42 SeitenStress Concentration Roark-Ch06marisNoch keine Bewertungen

- P01-E06 Rev 3 Mar 2022 Pipe Support Criteria For Metallic PipingDokument17 SeitenP01-E06 Rev 3 Mar 2022 Pipe Support Criteria For Metallic PipingMohamed AdelNoch keine Bewertungen

- Hendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFDokument930 SeitenHendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFÂn HồngNoch keine Bewertungen

- TRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Dokument228 SeitenTRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Jorge Cuadros Blas100% (4)

- Allowable Pipe Spans LoadsDokument84 SeitenAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- Modeling Thin-Walled Pipe in CAESAR IIDokument2 SeitenModeling Thin-Walled Pipe in CAESAR IIbee4manu100% (1)

- NMB Rwhp4a Pip Bod 40000 - 01 SFSB Commented Code BDokument38 SeitenNMB Rwhp4a Pip Bod 40000 - 01 SFSB Commented Code BChanNoch keine Bewertungen

- Caesar Wrc107and297Dokument3 SeitenCaesar Wrc107and297spiritizNoch keine Bewertungen

- SGP Stress Analysis ReportDokument14 SeitenSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- Asme Calculation For Renewal-A-317-Id Based - Rev-2Dokument29 SeitenAsme Calculation For Renewal-A-317-Id Based - Rev-2ariya100% (1)

- Example From Theory To Caesar II PDFDokument12 SeitenExample From Theory To Caesar II PDFIskandar Hasibuan100% (1)

- Modeling For Caesar Ii Piping Stress AnalysisDokument37 SeitenModeling For Caesar Ii Piping Stress Analysisrajeevfa100% (1)

- DN02 SM L FD 0002Dokument27 SeitenDN02 SM L FD 0002Bharuk Mech100% (1)

- Nozzle Calculation - Primary Reformer Stack-R0Dokument22 SeitenNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Autopipe Msrs Example1XzDokument29 SeitenAutopipe Msrs Example1XzFabio MiguelNoch keine Bewertungen

- Taller3 Modeling Concepts in Buried Pipe AnalysisDokument29 SeitenTaller3 Modeling Concepts in Buried Pipe AnalysisFSAAVEDRAF100% (1)

- Geological Models in Epithermal Porphyry Exploration Terry Leach LegacyDokument11 SeitenGeological Models in Epithermal Porphyry Exploration Terry Leach LegacyMatias Reinoso100% (2)

- Chemicals Safety PresentationDokument39 SeitenChemicals Safety Presentatione cube100% (1)

- Nozzle Calculation - Auxiliary Boiler Stack-R0Dokument13 SeitenNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainNoch keine Bewertungen

- Calcs 4Dokument19 SeitenCalcs 4Syariful Maliki NejstaršíNoch keine Bewertungen

- Sample CalculationDokument35 SeitenSample CalculationYoesbar Sofyan100% (1)

- Mechanical Calculation Storage Tank 110 KL (T-04)Dokument4 SeitenMechanical Calculation Storage Tank 110 KL (T-04)Priyo Jati WahyonoNoch keine Bewertungen

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDokument8 Seiten8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNoch keine Bewertungen

- DT & DP - Flange Rating and Pipe Sizing R2 PDFDokument11 SeitenDT & DP - Flange Rating and Pipe Sizing R2 PDFroyNoch keine Bewertungen

- M0237 01 RBP PD RP 3013Dokument159 SeitenM0237 01 RBP PD RP 3013harishNoch keine Bewertungen

- BVS-01 Stress AnalysisDokument11 SeitenBVS-01 Stress AnalysisSiva baalan100% (1)

- Stress ReportDokument6 SeitenStress Reportasif_vzaNoch keine Bewertungen

- Hydraulics: Pressure Transducer With LMS™ Amesim™ Student EditionDokument5 SeitenHydraulics: Pressure Transducer With LMS™ Amesim™ Student EditionSergio SmithNoch keine Bewertungen

- System design: Calculating pipe expansion and contractionDokument3 SeitenSystem design: Calculating pipe expansion and contractionreach_arindomNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Stress Analysis On Offshore PlatformsDokument45 SeitenStress Analysis On Offshore PlatformsMalarNoch keine Bewertungen

- CPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and MoreDokument8 SeitenCPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and Morejunhe898Noch keine Bewertungen

- Mechanical Engineering News BulletinDokument16 SeitenMechanical Engineering News BulletinAshok KumarNoch keine Bewertungen

- Engg & Piping Design Guide (FRP Pipe)Dokument36 SeitenEngg & Piping Design Guide (FRP Pipe)karuna346Noch keine Bewertungen

- Shimadzu System GC CatalogDokument48 SeitenShimadzu System GC CatalogTerry Osenbach100% (1)

- Chapter 8 EXERGYDokument37 SeitenChapter 8 EXERGYzabidullahNoch keine Bewertungen

- Two Phase Flow RegimeDokument4 SeitenTwo Phase Flow RegimeRafael ReyesNoch keine Bewertungen

- Conductimetric Analysis of Water Soluble Ionic Contamination of Blasting AbrasivesDokument3 SeitenConductimetric Analysis of Water Soluble Ionic Contamination of Blasting AbrasivesCristhian CoariteNoch keine Bewertungen

- Case Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFDokument15 SeitenCase Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFJafer SayedNoch keine Bewertungen

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDokument17 SeitenSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantNoch keine Bewertungen

- JET - DR1 - GI - 001 - Reva Issued 20130110 PDFDokument1 SeiteJET - DR1 - GI - 001 - Reva Issued 20130110 PDFFadria HandayaniNoch keine Bewertungen

- PSV Reaction Force - Closed SystemDokument5 SeitenPSV Reaction Force - Closed SystemWayne MonneryNoch keine Bewertungen

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDokument3 SeitenSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusNoch keine Bewertungen

- Pipe Stress Analysis Training Complete CourseDokument24 SeitenPipe Stress Analysis Training Complete CourseFábio GamaNoch keine Bewertungen

- EJMA Example 06Dokument5 SeitenEJMA Example 06Mayank GodhaNoch keine Bewertungen

- Piping Stress CriteriaDokument11 SeitenPiping Stress CriteriasbrencuNoch keine Bewertungen

- TEMA Shell Bundle Entrance and Exit AreasDokument3 SeitenTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNoch keine Bewertungen

- Discharge Nozzle Load Analysis for Fire Water Pump P-05ADokument22 SeitenDischarge Nozzle Load Analysis for Fire Water Pump P-05ASeptian FirdausNoch keine Bewertungen

- CAEPIPE Users ManualDokument257 SeitenCAEPIPE Users ManualFATIMA TORRADO CASASNoch keine Bewertungen

- Dynamic Analysis of Slug by Advance Input MethodDokument53 SeitenDynamic Analysis of Slug by Advance Input MethodYogesh PangareNoch keine Bewertungen

- FE107 Experimental ResultsDokument11 SeitenFE107 Experimental ResultsEsapermana RiyanNoch keine Bewertungen

- WRC 107 WRC 297 Co MP PDFDokument11 SeitenWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- ClydeBergemannSootblowers PrinceGeorge06Dokument36 SeitenClydeBergemannSootblowers PrinceGeorge06Arun YogaNoch keine Bewertungen

- API 676 pump nozzle load increaseDokument2 SeitenAPI 676 pump nozzle load increaseAshok KumarNoch keine Bewertungen

- Hot Tapping Split Tee SpecificationDokument19 SeitenHot Tapping Split Tee SpecificationAli ClubistNoch keine Bewertungen

- Metal Backing Flange GuidelinesDokument19 SeitenMetal Backing Flange GuidelinesDang Hieu NguyenNoch keine Bewertungen

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidDokument19 SeitenRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidThinh NguyenNoch keine Bewertungen

- PVM Su 1322 H.1 PDFDokument22 SeitenPVM Su 1322 H.1 PDFJEEVITHANoch keine Bewertungen

- Cross Country Piping Stress AnalysisDokument8 SeitenCross Country Piping Stress Analysisprabu2001Noch keine Bewertungen

- Fibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFDokument122 SeitenFibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFA.Subin DasNoch keine Bewertungen

- Advance Nema Sm23Dokument7 SeitenAdvance Nema Sm23Afrizal ManafNoch keine Bewertungen

- TH 3358 PDFDokument84 SeitenTH 3358 PDFSergio SmithNoch keine Bewertungen

- The Flow of Real FluidsDokument35 SeitenThe Flow of Real Fluidsbakhtyar21Noch keine Bewertungen

- Cubic CurveDokument2 SeitenCubic CurveSergio SmithNoch keine Bewertungen

- PDIL Walk-in Interviews for Engineers on Contract BasisDokument13 SeitenPDIL Walk-in Interviews for Engineers on Contract BasisSergio SmithNoch keine Bewertungen

- LearningDokument1 SeiteLearningSergio SmithNoch keine Bewertungen

- Quqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaDokument1 SeiteQuqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaSergio SmithNoch keine Bewertungen

- Boundary Value Problems: Second Order BVPDokument4 SeitenBoundary Value Problems: Second Order BVPmakfirsefaNoch keine Bewertungen

- Uses of Magnets: By-Aditi Vi-BDokument5 SeitenUses of Magnets: By-Aditi Vi-BSergio SmithNoch keine Bewertungen

- Uses of Magnets: By-Aditi Vi-BDokument5 SeitenUses of Magnets: By-Aditi Vi-BSergio SmithNoch keine Bewertungen

- Numerical Methods for Diff Eq & Machine DesignDokument1 SeiteNumerical Methods for Diff Eq & Machine DesignSergio SmithNoch keine Bewertungen

- Hydraulic Hose Training GuideDokument22 SeitenHydraulic Hose Training GuideSergio SmithNoch keine Bewertungen

- Quqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaDokument1 SeiteQuqntity: Keyboard 2 600 Mouse 4 800 BBBBBBB BBBB Aaaaaa AaaaaaSergio SmithNoch keine Bewertungen

- LearningDokument1 SeiteLearningSergio SmithNoch keine Bewertungen

- Modal ParametersDokument8 SeitenModal ParametersSergio SmithNoch keine Bewertungen

- Linear Weight CalculatorDokument8 SeitenLinear Weight CalculatorSergio SmithNoch keine Bewertungen

- Diff Eqn SolverDokument1 SeiteDiff Eqn SolverSergio SmithNoch keine Bewertungen

- Te2401 Part1Dokument193 SeitenTe2401 Part1Jami BurnettNoch keine Bewertungen

- Direct Numerical Integration MethodsDokument19 SeitenDirect Numerical Integration MethodsallentvmNoch keine Bewertungen

- Numerical Methods for Diff Eq & Machine DesignDokument1 SeiteNumerical Methods for Diff Eq & Machine DesignSergio SmithNoch keine Bewertungen

- Pipe Connection Size Moment CalculationDokument1 SeitePipe Connection Size Moment CalculationSergio SmithNoch keine Bewertungen

- Towards East Towards NorthDokument3 SeitenTowards East Towards NorthSergio SmithNoch keine Bewertungen

- Pipe Connection Size Moment CalculationDokument1 SeitePipe Connection Size Moment CalculationSergio SmithNoch keine Bewertungen

- Matrix MarioDokument1 SeiteMatrix MarioSergio SmithNoch keine Bewertungen

- CodeDokument17 SeitenCodeSergio SmithNoch keine Bewertungen

- Pipe Connection Size Moment CalculationDokument1 SeitePipe Connection Size Moment CalculationSergio SmithNoch keine Bewertungen

- Rigid StiffnessDokument28 SeitenRigid StiffnessvsvineeshNoch keine Bewertungen

- Static ForceDokument1 SeiteStatic ForceSergio SmithNoch keine Bewertungen

- Martin EricksonDokument1 SeiteMartin EricksonSergio SmithNoch keine Bewertungen

- Haldia Institute of Technology Engineering Chemistry Laboratory (CH 191 &CH 291)Dokument29 SeitenHaldia Institute of Technology Engineering Chemistry Laboratory (CH 191 &CH 291)Shresth Sanskar100% (1)

- Oxidative WearDokument17 SeitenOxidative WearManish Kumar SinghNoch keine Bewertungen

- Material QuizDokument22 SeitenMaterial QuizMr Nerd100% (3)

- A Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsDokument10 SeitenA Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsseenisitNoch keine Bewertungen

- What Are HerbicidesDokument14 SeitenWhat Are HerbicidesBabatunde Alim OluwafẹmiNoch keine Bewertungen

- Resins Word DocumentDokument8 SeitenResins Word DocumentHarish KakraniNoch keine Bewertungen

- Pen Type Visual Fault Locator: SpecificationsDokument1 SeitePen Type Visual Fault Locator: SpecificationsHuy DuNoch keine Bewertungen

- Artículo Toxic JuiceDokument6 SeitenArtículo Toxic JuiceSonia Fernández PradosNoch keine Bewertungen

- VWR® Symphony® Analysis PackagesDokument3 SeitenVWR® Symphony® Analysis Packageslusoegyi 1919Noch keine Bewertungen

- Optical Properties of Semiconductor NanocrystalsDokument259 SeitenOptical Properties of Semiconductor Nanocrystalsanhthigl25Noch keine Bewertungen

- Shot Peenning and Grit Blasting Effect On Surface Integrity PDFDokument6 SeitenShot Peenning and Grit Blasting Effect On Surface Integrity PDFmanuNoch keine Bewertungen

- Carga de Bolas - Molino KopperDokument4 SeitenCarga de Bolas - Molino KopperIngridkferNoch keine Bewertungen

- Benzene Structure and Delocalised Model ExplainedDokument8 SeitenBenzene Structure and Delocalised Model ExplainedHisham Jafar AliNoch keine Bewertungen

- Media File Sheehan Perf of HDG in Coastal Envs PDFDokument18 SeitenMedia File Sheehan Perf of HDG in Coastal Envs PDFFrankie ChanNoch keine Bewertungen

- Caustic Potash SpecificationDokument1 SeiteCaustic Potash SpecificationJayakumar ANoch keine Bewertungen

- MSc Surveying and Water Resources TopicsDokument3 SeitenMSc Surveying and Water Resources TopicsNirjhor KabirNoch keine Bewertungen

- Third Order Elastic ConstantsDokument3 SeitenThird Order Elastic ConstantsElango PaulchamyNoch keine Bewertungen

- Air Wipe ArgentinaDokument2 SeitenAir Wipe ArgentinaalfdusNoch keine Bewertungen

- What Is Calcium Oxalate PrecipitationDokument3 SeitenWhat Is Calcium Oxalate PrecipitationluismiguelmmercadoNoch keine Bewertungen

- AFLAS Technical DatasheetDokument13 SeitenAFLAS Technical DatasheetManual SourceNoch keine Bewertungen

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokument38 SeitenBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen