Beruflich Dokumente

Kultur Dokumente

Astm A182 - Astm A182

Hochgeladen von

phresendeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Astm A182 - Astm A182

Hochgeladen von

phresendeCopyright:

Verfügbare Formate

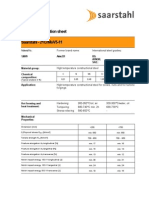

ASTM A182 FLANGES ANSI B16.

5 INDEX

CLASS 150 STAINLESS STEEL FLANGES ANSI B16.5

39

CLASS 150 STAINLESS STEEL FLANGES ANSI B16.5

40

CLASS 300 STAINLESS STEEL FLANGES ANSI B16.5

41

CLASS 300 STAINLESS STEEL FLANGES ANSI B16.5

42

CLASS 600 STAINLESS STEEL FLANGES ANSI B16.5

43

CLASS 600 STAINLESS STEEL FLANGES ANSI B16.5

44

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 150 STAINLESS STEEL FLANGES ANSI B16.5

WELDING NECK

LAP JOINT

SLIP-ON

X

B3

X

B2

X

H

B1

Y

1/16"

1/16"

F

O.D

37.

5

1/16"

O.D.

O.D.

unit : inch

BORE DIAMETER (B)

HUB DIA.

FLANGE

(B1)

(B2)

FLANGE THICKNESS HUB DIA. RAISED

AT

WELDING SLIP-ON

(B3)

(Q)

DIAMETER

AT BASE FACE DIA. WELDING

NECK

AND

LAP

AND

SOCKET

MIN.

(O.D.)

(X)

(F)

POINT

JOINT

SOCKET

WELD

MIN.

(1)

(H)

WELD

MIN.

(2)

1/ 2

3.50

0.44

1.19

1.38

0.84

0.62

0.88

0.90

3/ 4

3.88

0.50

1.50

1.69

1.05

0.82

1.09

1.11

4.25

0.56

1.94

2.00

1.32

1.05

1.36

1.38

1 1/ 4

4.62

0.62

2.31

2.50

1.66

1.38

1.70

1.72

1 1/ 2

5.00

0.69

2.56

2.88

1.90

1.61

1.95

1.97

6.00

0.75

3.06

3.62

2.38

2.07

2.44

2.46

2 1/ 2

7.00

0.88

3.56

4.12

2.88

2.47

2.94

2.97

7.50

0.94

4.25

5.00

3.50

3.07

3.57

3.60

31/ 2

8.50

0.94

4.81

5.50

4.00

3.55

4.07

4.10

9.00

0.94

5.31

6.19

4.50

4.03

4.57

4.60

10.00

0.94

6.44

7.31

5.56

5.05

5.66

5.69

11.00

1.00

7.56

8.50

6.63

6.07

6.72

6.75

13.50

1.12

9.69

10.62

8.63

7.98

8.72

8.75

10

16.00

1.19

12.00

12.75

10.75

10.02

10.88

10.92

12

19.00

1.25

14.38

15.00

12.75

12.00

12.88

12.92

14

21.00

1.38

15.75

16.25

14.00

13.25

14.14

14.18

16

23.50

1.14

18.00

18.50

16.00

15.25

16.16

16.19

18

25.00

1.56

19.88

21.00

18.00

17.25

18.18

18.20

20

27.50

1.69

22.00

23.00

20.00

19.25

20.20

20.25

24

32.00

1.88

26.12

27.25

24.00

23.25

24.25

24.25

39

COUNTER

BORE OF

THREADED

FLANGE

(C)

NO COUNTER BORE REQUIRED ON 150# THREADED FLANGES

N OM.

PIPE

SIZE

LENGTH THROUGH HUB (Y)

DEPTH

OF

SOCKET

(D)

SLIP-ON

WELDING SOCKET

WELD

AND

NECK

THREADED

LAP

JOINT

0.38

1.88

0.62

0.62

0.44

2.06

0.62

0.62

0.50

2.19

0.69

0.69

0.56

2.25

0.81

0.81

0.62

2.44

0.88

0.88

0.69

2.50

1.00

1.00

0.75

2.75

1.12

1.12

0.81

2.75

1.19

1.19

0.88

2.81

1.25

1.25

0.94

3.00

1.31

1.31

0.94

3.50

1.44

1.44

1.06

3.50

1.56

1.56

1.25

4.00

1.75

1.75

1.31

4.00

1.94

1.94

1.56

4.50

2.19

2.19

1.63

5.00

2.25

3.12

1.75

5.00

2.50

3.44

1.94

5.50

2.69

3.81

2.12

5.69

2.88

4.06

2.50

6.00

3.25

4.38

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 150 STAINLESS STEEL FLANGES ANSI B16.5

SOCKET WELD

BLIND

THREADED

X

B2

Y

Q

F

O.D

1/16"

F

O.D

1/16"

Q

1/16"

B1

F

O.D.

unit : inch

RADIUS

NOM.

MIN.

(R)

PIPE THREAD

LAP

SIZE LENGTH JOINT

DRILLING

DIAMETER

OF BOLT

CIRCLE

BOLTING

NO.

DIA.

DIA.

OF

OF

OF

HOLES HOLES BOLTS

MACHINE

BOLT

LENGTH

APPROXIMATE WEIGHT EACH

STUD BOLT

LENGTH

Raised

Face

.06"

Raised

Face

.06"

Ring

Joint

POUNDS

NOM.

PIPE

SIZE

WELDING

NECK

SLIP-ON.

SOCKET

WELD

AND

THREADED

LAP

JOINT

BLIND

1/ 2

0.62

0.12

2.38

0.62

1/ 2

2.00

2.50

1/ 2

1.25

1.00

1.00

1.25

3/ 4

0.62

0.12

2.75

0.62

1/ 2

2.25

2.50

3/ 4

2.00

1.50

1.50

1.50

0.69

0.12

3.12

0.62

1/ 2

2.25

2.75

3.25

2.50

2.00

2.00

2.00

1 1/ 4

0.81

0.19

3.50

0.62

1/ 2

2.50

2.75

3.25

1 1/ 4

3.00

3.00

3.00

3.00

1 1/ 2

0.88

0.25

3.88

0.62

1/ 2

2.50

3.00

3.50

1 1/ 2

4.50

3.00

3.50

4.00

1.00

0.31

4.75

0.75

5/ 8

2.75

3.25

3.75

6.00

5.25

5.00

6.50

2 1/ 2

1.12

0.31

5.50

0.75

5/ 8

3.00

3.50

4.00

2 1/ 2

10.00

8.00

7.00

9.50

1.19

0.38

6.00

0.75

5/ 8

3.25

3.75

4.25

12.00

9.00

9.25

12.50

3 1/ 2

1.25

0.38

7.00

0.75

5/ 8

3.25

3.75

4.25

3 1/ 2

12.00

11.00

11.00

13.00

1.31

0.44

7.50

0.75

5/ 8

3.25

3.75

4.25

16.50

12.50

12.50

17.00

1.44

0.50

8.50

0.88

3/ 4

3.25

4.00

4.50

19.00

15.00

15.00

20.00

1.56

0.50

9.50

0.88

3/ 4

3.50

4.00

4.50

25.00

19.00

19.00

26.50

1.75

0.50

11.75

0.88

3/ 4

3.75

4.25

4.75

39.00

30.00

30.00

45.00

10

1.94

0.50

14.25

12

1.00

7/ 8

4.00

4.75

5.25

10

52.00

43.00

43.00

70.00

12

2.19

0.50

17.00

12

1.00

7/ 8

4.25

4.75

5.25

12

80.00

64.00

64.00

110.00

14

2.25

0.50

18.75

12

1.12

4.50

5.25

5.75

14

110.00

90.00

105.00

140.00

16

2.50

0.50

21.25

16

1.12

4.75

5.50

6.00

16

140.00

98.00

140.00

180.00

18

2.69

0.50

22.75

16

1.25

1 1/ 8

5.00

6.00

6.50

18

150.00

130.00

160.00

220.00

20

2.88

0.50

25.00

20

1.25

1 1/ 8

5.50

6.25

6.75

20

180.00

165.00

195.00

285.00

24

3.25

0.50

29.50

20

1.38

1 1/ 4

6.00

7.00

7.50

24

260.00

220.00

275.00

430.00

40

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 300 STAINLESS STEEL FLANGES ANSI B16.5

WELDING NECK

LAP JOINT

SLIP-ON

X

B3

X

B2

X

H

B1

Y

1/16"

1/16"

F

O.D

37.

5

1/16"

O.D.

O.D.

unit : inch

N OM.

PIPE

SIZE

BORE DIAMETER (B)

HUB DIA.

FLANGE

(B1)

(B2)

FLANGE THICKNESS HUB DIA. RAISED

AT

WELDING SLIP-ON

(B3)

(Q)

DIAMETER

AT BASE FACE DIA. WELDING

NECK

AND

LAP

AND

SOCKET

MIN.

(O.D.)

(X)

(F)

POINT

JOINT

SOCKET

WELD

MIN.

(1)

(H)

WELD

MIN.

(2)

LENGTH THROUGH HUB (Y)

COUNTER

BORE OF

THREADED

FLANGE

(C)

MIN.

DEPTH

OF

SOCKET

(D)

WELDING

NECK

SLIP-ON

SOCKET

WELD

AND

THREADED

LAP

JOINT

1/ 2

3.75

0.56

1.50

1.38

0.84

0.62

0.88

0.90

0.93

0.38

2.06

0.88

0.88

3/ 4

4.62

0.62

1.88

1.69

1.05

0.82

1.09

1.11

1.14

0.44

2.25

1.00

1.00

4.88

0.69

2.12

2.00

1.32

1.05

1.36

1.38

1.41

0.50

2.44

1.06

1.06

1 1/ 4

5.25

0.75

2.50

2.50

1.66

1.38

1.70

1.72

1.75

0.56

2.56

1.06

1.06

1 1/ 2

6.12

0.81

2.75

2.88

1.90

1.61

1.95

1.97

1.99

0.62

2.69

1.19

1.19

6.50

0.88

3.31

3.62

2.38

2.07

2.44

2.46

2.50

0.69

2.75

1.31

1.31

2 1/ 2

7.50

1.00

3.94

4.12

2.88

2.47

2.94

2.97

3.00

0.75

3.00

1.50

1.50

8.25

1.12

4.62

5.00

3.50

3.07

3.57

3.60

3.63

0.81

3.12

1.69

1.69

31/ 2

9.00

1.19

5.25

5.50

4.00

3.55

4.07

4.10

4.13

3.19

1.75

1.75

10.00

1.25

5.75

6.19

4.50

4.03

4.57

4.60

4.63

3.38

1.88

1.88

11.00

1.38

7.00

7.31

5.56

5.05

5.66

5.69

5.69

3.88

2.00

2.00

12.50

1.44

8.12

8.50

6.63

6.07

6.72

6.75

6.75

3.88

2.06

2.06

15.00

1.62

10.25

10.62

8.63

7.98

8.72

8.75

8.75

4.38

2.44

2.44

10

17.50

1.88

12.62

12.75

10.75

10.02

10.88

10.92

10.88

4.62

2.62

3.75

12

20.50

2.00

14.75

15.00

12.75

12.00

12.88

12.92

12.94

5.12

2.88

4.00

14

23.00

2.12

16.75

16.25

14.00

13.25

14.14

14.18

14.19

5.62

3.00

4.38

16

25.50

2.25

19.00

18.50

16.00

15.25

16.16

16.19

16.19

5.75

3.25

4.75

18

28.00

2.38

21.00

21.00

18.00

17.25

18.18

18.20

18.19

6.25

3.50

5.12

20

30.50

2.50

23.12

23.00

20.00

19.25

20.20

20.25

20.19

6.38

3.75

5.50

24

36.00

2.75

27.62

27.25

24.00

23.25

24.25

24.25

24.19

6.62

4.19

6.00

41

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 300 STAINLESS STEEL FLANGES ANSI B16.5

SOCKET WELD

BLIND

THREADED

X

B2

Y

Q

F

O.D

1/16"

F

O.D

1/16"

Q

1/16"

B1

F

O.D.

unit : inch

RADIUS

NOM.

MIN.

(R)

PIPE THREAD

LAP

SIZE LENGTH JOINT

DRILLING

DIAMETER

OF BOLT

CIRCLE

BOLTING

NO.

DIA.

DIA.

OF

OF

OF

HOLES HOLES BOLTS

MACHINE

BOLT

LENGTH

APPROXIMATE WEIGHT EACH

STUD BOLT

LENGTH

Raised

Face

.06"

Raised

Face

.06"

Ring

Joint

POUNDS

NOM.

PIPE

SIZE

WELDING

NECK

SLIP-ON.

SOCKET

WELD

AND

THREADED

LAP

JOINT

BLIND

1/ 2

0.62

0.12

2.62

0.62

1/ 2

2.25

2.75

3.00

1/ 2

3/ 4

0.62

0.12

3.25

0.75

5/ 8

2.50

3.00

3.50

3/ 4

0.69

0.12

3.50

0.75

5/ 8

2.75

3.25

3.75

1 1/ 4

0.81

0.19

3.88

0.75

5/ 8

2.75

3.25

3.75

1 1/ 4

1 1/ 2

0.88

0.25

4.50

0.88

3/ 4

3.00

3.75

4.25

1 1/ 2

1.00

0.31

5.00

0.75

5/ 8

3.00

3.50

4.25

2 1/ 2

1.12

0.31

5.88

0.88

3/ 4

3.50

4.00

4.75

2 1/ 2

12

10

10

12

1.19

0.38

6.62

0.88

3/ 4

3.75

4.25

5.00

15

13

13

16

3 1/ 2

1.25

0.38

7.25

0.88

3/ 4

3.75

4.50

5.25

3 1/ 2

18

17

17

21

1.31

0.44

7.88

0.88

5/ 8

4.00

4.50

5.25

25

22

22

27

1.44

0.50

9.25

0.88

3/ 4

4.25

4.75

5.50

32

28

28

35

1.56

0.50

10.62

12

0.75

3/ 4

4.25

5.00

5.75

42

39

39

50

1.75

0.50

13.00

12

0.88

7/ 8

4.75

5.50

6.25

67

58

58

81

10

1.94

0.50

15.25

16

1.00

5.50

6.25

7.00

10

91

81

91

125

12

2.19

0.50

17.25

16

1.00

1 1/ 8

6.00

6.75

7.50

12

140

115

140

185

14

2.25

0.50

20.25

20

1.12

1 1/ 8

6.25

7.00

7.75

14

180

165

190

250

16

2.50

0.50

22.50

20

1.12

1 1/ 4

6.50

7.50

8.25

16

250

190

250

295

18

2.69

0.50

24.75

24

1.25

1 1/ 4

6.75

7.75

8.50

18

320

250

295

395

20

2.88

0.50

27.00

24

1.25

1 1/ 4

7.25

8.25

9.00

20

400

315

370

505

24

3.25

0.50

32.00

24

1.38

1 1/ 2

8.00

9.25

10.25

24

580

475

550

790

42

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 600 STAINLESS STEEL FLANGES ANSI B16.5

WELDING NECK

LAP JOINT

SLIP-ON

X

B3

X

B2

X

H

B1

Y

1/16"

1/16"

F

O.D

37.

5

1/16"

O.D.

O.D.

unit : inch

N OM.

PIPE

SIZE

BORE DIAMETER (B)

HUB DIA.

FLANGE

(B1)

(B2)

FLANGE THICKNESS HUB DIA. RAISED

AT

WELDING SLIP-ON

(B3)

(Q)

DIAMETER

AT BASE FACE DIA. WELDING

NECK

AND

LAP

SOCKET

AND

MIN.

(O.D.)

(X)

(F)

POINT

JOINT

WELD

SOCKET

MIN.

MIN.

(1)

(H)

WELD

(2)

LENGTH THROUGH HUB (Y)

COUNTER

BORE OF

THREADED

FLANGE

(C)

MIN.

DEPTH

OF

SOCKET

(D)

WELDING

NECK

SLIP-ON

SOCKET

WELD

AND

THREADED

LAP

JOINT

3.75

0.56

1.50

1.38

0.84

0.88

0.90

0.93

0.38

2.06

0.88

0.88

3/ 4

4.62

0.62

1.88

1.69

1.05

1.09

1.11

1.14

0.44

2.25

1.00

1.00

4.88

0.69

2.12

2.00

1.32

1.36

1.38

1.41

0.50

2.44

1.06

1.06

1 1/ 4

5.25

0.81

2.50

2.50

1.66

1.70

1.72

1.75

0.56

2.62

1.12

1.12

1 1/ 2

6.12

0.88

2.75

2.88

1.90

1.95

1.97

1.99

0.62

2.75

1.25

1.25

6.50

1.00

3.31

3.62

2.38

2.44

2.46

2.50

0.69

2.88

1.44

1.44

2 1/ 2

7.50

1.12

3.94

4.12

2.88

2.94

2.97

3.00

0.75

3.12

1.62

1.62

8.25

1.25

4.62

5.00

3.50

3.57

3.60

3.63

0.81

3.25

1.81

1.81

31/ 2

9.00

1.38

5.25

5.50

4.00

4.07

4.10

4.13

3.38

1.94

1.94

10.75

1.50

6.00

6.19

4.50

4.57

4.60

4.63

4.00

2.12

2.12

13.00

1.75

7.44

7.31

5.56

5.66

5.69

5.69

4.50

2.38

2.38

14.00

1.88

8.75

8.50

6.63

6.72

6.75

6.75

4.62

2.62

2.62

16.50

2.19

10.75

10.62

8.63

8.72

8.75

8.75

5.25

3.00

3.00

10

20.00

2.50

13.50

12.75

10.75

10.88

10.92

10.88

6.00

3.38

4.38

12

22.00

2.62

15.75

15.00

12.75

12.88

12.92

12.94

6.12

3.62

4.62

14

23.75

2.75

17.00

16.25

14.00

14.14

14.18

14.19

6.50

3.69

5.00

16

27.00

3.00

19.50

18.50

16.00

16.16

16.19

16.19

7.00

4.19

5.50

18

29.25

3.25

21.50

21.00

18.00

18.18

18.20

18.19

7.25

4.62

6.00

20

32.00

3.50

24.00

23.00

20.00

20.20

20.25

20.19

7.50

5.00

6.50

24

37.00

4.00

28.25

27.25

24.00

24.25

24.25

24.19

8.00

5.50

7.25

TO BE SPECIFIED BY PURCHASER

1/ 2

43

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

ASTM A182 FLANGES ANSI B16.5

CLASS 600 STAINLESS STEEL FLANGES ANSI B16.5

SOCKET WELD

BLIND

THREADED

X

B2

Y

Q

F

O.D

1/16"

F

O.D

1/16"

Q

1/16"

B1

F

O.D.

unit : inch

DRILLING

NOM.

PIPE

SIZE

RADIUS

MIN.

(R)

THREAD LAP DIAMETER

LENGTH JOINT OF BOLT

CIRCLE

BOLTING

NO.

DIA.

DIA.

OF

OF

OF

HOLES HOLES BOLTS

MACHINE

BOLT

LENGTH

APPROXIMATE WEIGHT EACH

STUD BOLT

LENGTH

Raised

Face

.06"

Raised

Face

.06"

Ring

Joint

POUNDS

NOM.

PIPE

SIZE

WELDING

NECK

SLIP-ON.

SOCKET

WELD

AND

THREADED

LAP

JOINT

BLIND

1/ 2

0.62

0.12

2.62

0.62

1/ 2

3.25

3.00

3.00

1/ 2

3/ 4

0.62

0.12

3.25

0.75

5/ 8

3.50

3.25

3.50

3/ 4

0.69

0.12

3.50

0.75

5/ 8

3.75

3.50

3.75

1 1/ 4

0.81

0.19

3.88

0.75

5/ 8

4.00

3.75

4.00

1 1/ 4

1 1/ 2

0.88

0.25

4.50

0.88

3/ 4

4.25

4.00

4.25

1 1/ 2

1.12

0.31

5.00

0.75

5/ 8

4.25

4.00

4.50

12

10

2 1/ 2

1.25

0.31

5.88

0.88

3/ 4

4.75

4.50

5.00

2 1/ 2

18

13

12

15

1.38

0.38

6.62

0.88

3/ 4

5.00

4.75

5.25

23

16

15

20

3 1/ 2

1.56

0.38

7.25

1.00

7/ 8

5.50

5.25

5.75

3 1/ 2

26

21

20

29

1.62

0.44

8.50

1.00

7/ 8

5.75

5.50

6.00

42

37

36

41

1.88

0.44

10.50

1.12

6.50

6.25

6.75

68

63

61

68

2.00

0.50

11.50

12

1.12

6.75

6.50

7.00

81

80

78

86

2.25

0.50

13.75

12

1.25

1 1/ 8

7.75

7.50

7.75

120

115

110

140

10

2.56

0.50

17.00

16

1.38

1 1/ 4

8.50

8.25

8.75

10

190

170

170

230

12

2.75

0.50

19.25

20

1.38

1 1/ 4

8.75

8.50

9.00

12

225

200

200

295

14

2.88

0.50

20.75

20

1.50

1 3/ 8

9.25

9.00

9.50

14

280

230

250

355

16

3.06

0.50

23.75

20

1.62

1 1/ 2

10.00

9.75

10.25

16

390

330

365

495

18

3.12

0.50

25.75

20

1.75

1 5/ 8

10.75

10.50

11.00

18

475

400

435

630

20

3.25

0.50

28.50

24

1.75

1 5/ 8

11.50

11.25

11.75

20

590

510

570

810

24

3.62

0.50

33.00

24

2.00

1 7/ 8

13.00

12.75

13.25

24

830

730

810

1250

44

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

Das könnte Ihnen auch gefallen

- 7050 Aluminum Sheet SuppliersDokument12 Seiten7050 Aluminum Sheet Supplierssanghvi overseas incNoch keine Bewertungen

- As 2331.3.9-2001 Methods of Test For Metallic and Related Coatings Corrosion and Related Property Tests - MetDokument2 SeitenAs 2331.3.9-2001 Methods of Test For Metallic and Related Coatings Corrosion and Related Property Tests - MetSAI Global - APACNoch keine Bewertungen

- Is 1501 Part 1Dokument114 SeitenIs 1501 Part 1Mohit DhimaanNoch keine Bewertungen

- 1 2714Dokument1 Seite1 2714K Mohana PraneshNoch keine Bewertungen

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDokument16 SeitenA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNoch keine Bewertungen

- ANSI FlangeDokument10 SeitenANSI FlangemechftpNoch keine Bewertungen

- Iso 27509 2020Dokument15 SeitenIso 27509 2020T KelvinNoch keine Bewertungen

- ASTM Specs FittingsDokument10 SeitenASTM Specs FittingskhaireddinNoch keine Bewertungen

- ISO 898 Grade 10.9Dokument2 SeitenISO 898 Grade 10.9Mihaela NastaseNoch keine Bewertungen

- Asme Section Ii A-2 Sa-815 Sa-815mDokument10 SeitenAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNoch keine Bewertungen

- Induction BendingDokument2 SeitenInduction BendingshaonaaNoch keine Bewertungen

- JIS Standard ValveDokument8 SeitenJIS Standard ValveJong JavaNoch keine Bewertungen

- Flexivity of Thermostat Metals: Standard Test Methods ForDokument7 SeitenFlexivity of Thermostat Metals: Standard Test Methods ForAnurag YadavNoch keine Bewertungen

- Purchase Spec. For Nozzles Swage (Sa106b)Dokument4 SeitenPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNoch keine Bewertungen

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Dokument3 SeitenHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitNoch keine Bewertungen

- ASME 193 and 193MDokument4 SeitenASME 193 and 193MGauravNoch keine Bewertungen

- Stainless Steel Grade AISI 321Dokument2 SeitenStainless Steel Grade AISI 321Mitul RawatNoch keine Bewertungen

- GTAW Welding of CP Titanium and Ti6Al4VDokument1 SeiteGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNoch keine Bewertungen

- Grating Weight - CalculationDokument1 SeiteGrating Weight - CalculationMuthuram NNoch keine Bewertungen

- Equivalent Material Cross Valve CastDokument2 SeitenEquivalent Material Cross Valve CastsviswaNoch keine Bewertungen

- Grades of Steel ChartDokument3 SeitenGrades of Steel ChartKimNoch keine Bewertungen

- En 13121-3:2008+a1:2010 (E)Dokument1 SeiteEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITENoch keine Bewertungen

- VALVES J70530 Catalogue HiResDokument76 SeitenVALVES J70530 Catalogue HiResandreNoch keine Bewertungen

- Steelmet Industries Grade C MN Si CR Ni en EqvtDokument34 SeitenSteelmet Industries Grade C MN Si CR Ni en Eqvtdesign1983Noch keine Bewertungen

- Pipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MDokument6 SeitenPipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MAmlan SahaNoch keine Bewertungen

- 12 Valves SpecificationsDokument19 Seiten12 Valves Specificationsshaliq28100% (1)

- 21 CR Mo V511Dokument1 Seite21 CR Mo V511uksrajNoch keine Bewertungen

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Dokument5 SeitenCarbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Ton PhichitNoch keine Bewertungen

- Pump Material SpecificationDokument6 SeitenPump Material SpecificationshripaddixitNoch keine Bewertungen

- 3 2 Purchase Material SpecificationDokument1 Seite3 2 Purchase Material Specificationanon_376696588Noch keine Bewertungen

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDokument4 SeitenASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNoch keine Bewertungen

- Tube Bundle DrawingDokument1 SeiteTube Bundle DrawingVeera ManiNoch keine Bewertungen

- AISI 4340 Alloy Steel Properties and ApplicationsDokument4 SeitenAISI 4340 Alloy Steel Properties and ApplicationsJourdyPradityaNoch keine Bewertungen

- Fabory Fasteners ASTM StudboltDokument13 SeitenFabory Fasteners ASTM StudboltJohan ConradieNoch keine Bewertungen

- Astm A192 Asme Sa192 PDFDokument4 SeitenAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- DIN 3015 ClampsDokument20 SeitenDIN 3015 ClampsRasheshNoch keine Bewertungen

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Dokument3 SeitenSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNoch keine Bewertungen

- 1.4462 PropertiesDokument1 Seite1.4462 PropertiesutreshwarmiskinNoch keine Bewertungen

- All Materials DocumentsDokument1 SeiteAll Materials DocumentsHarnish BariaNoch keine Bewertungen

- Asme Ix Int Vol26Dokument17 SeitenAsme Ix Int Vol26Julio CastilhosNoch keine Bewertungen

- A 789 - A 789MDokument4 SeitenA 789 - A 789MJGD123Noch keine Bewertungen

- Sa 299Dokument3 SeitenSa 299Web LogueandoNoch keine Bewertungen

- Astm Nos. For Piping CommoditiesDokument1 SeiteAstm Nos. For Piping CommoditiesHitesh MhatreNoch keine Bewertungen

- Heat Resisting AlloysDokument3 SeitenHeat Resisting AlloysElMacheteDelHuesoNoch keine Bewertungen

- Astm A234-A234m-06Dokument8 SeitenAstm A234-A234m-06NadhiraNoch keine Bewertungen

- ASME Material SpectDokument46 SeitenASME Material SpectPankajDhobleNoch keine Bewertungen

- Asme-Bpvc Sec IV Int Vol 44Dokument7 SeitenAsme-Bpvc Sec IV Int Vol 44mostafa aliNoch keine Bewertungen

- Material P NumberDokument11 SeitenMaterial P NumberChaitanya Sai TNoch keine Bewertungen

- WELDOLET SIZING CHARTDokument8 SeitenWELDOLET SIZING CHARTSubramanian Shanmuga SundaramNoch keine Bewertungen

- Orbital Tube Welding PDFDokument7 SeitenOrbital Tube Welding PDFnarutothunderjet216100% (1)

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Dokument3 SeitenASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNoch keine Bewertungen

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDokument50 SeitenSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNoch keine Bewertungen

- Hollow Bar 304L Φ80ΧΦ50Dokument6 SeitenHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Material Comparisons For Astm and JisDokument2 SeitenMaterial Comparisons For Astm and JisNitesh GargNoch keine Bewertungen

- DIN 3015 Clamp Technical OverviewDokument17 SeitenDIN 3015 Clamp Technical OverviewBalderas Rosas WilibaldoNoch keine Bewertungen

- TK PIPING PQ KoreaDokument35 SeitenTK PIPING PQ Koreaphuhai haizaNoch keine Bewertungen

- ABZ ValveDokument8 SeitenABZ ValveJavierfox98Noch keine Bewertungen

- OzLinc Flanges CatalogueDokument12 SeitenOzLinc Flanges CatalogueKarenNoch keine Bewertungen

- ASV 10 20 BrochureDokument8 SeitenASV 10 20 BrochureThomas Duane DavidsonNoch keine Bewertungen

- En-353GF Head & Lower HalfDokument22 SeitenEn-353GF Head & Lower HalfVaeco Đoàn Tncs HcmNoch keine Bewertungen

- Piping OverviewDokument28 SeitenPiping Overviewعزت عبد المنعمNoch keine Bewertungen

- American Homes and Gardens 1905 Jul-DecDokument396 SeitenAmerican Homes and Gardens 1905 Jul-DecNickiedeposieNoch keine Bewertungen

- Piping HandbookDokument78 SeitenPiping HandbookAurinho9292% (12)

- Piping Material SelectionDokument3 SeitenPiping Material SelectionRifka AisyahNoch keine Bewertungen

- " Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsDokument1 Seite" Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsJCSNoch keine Bewertungen

- Engineering Design Verification InspectionsDokument20 SeitenEngineering Design Verification InspectionsixoteeNoch keine Bewertungen

- amm 467 349Dokument6 Seitenamm 467 349Dinesh JagadisanNoch keine Bewertungen

- Stock Register StoreDokument1.218 SeitenStock Register StoreSantanu Kumar SahuNoch keine Bewertungen

- Creep and Shrinkage Analysis in Strand7 R2.4Dokument18 SeitenCreep and Shrinkage Analysis in Strand7 R2.4caojin259Noch keine Bewertungen

- Vulkem NEM - Data SheetDokument2 SeitenVulkem NEM - Data SheetRobertNoch keine Bewertungen

- Report Case StudyDokument12 SeitenReport Case StudyAnisalya Jamri100% (1)

- Preliminary Design of BeamDokument4 SeitenPreliminary Design of BeamSaroj DwaNoch keine Bewertungen

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDokument6 SeitenEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљNoch keine Bewertungen

- Standard Pipe NipplesDokument1 SeiteStandard Pipe NippleschadNoch keine Bewertungen

- Accessories For Dosage and Application PDFDokument7 SeitenAccessories For Dosage and Application PDFmochkurniawanNoch keine Bewertungen

- AnnexureDokument16 SeitenAnnexureAmirNoch keine Bewertungen

- Rego-Fix Er Recool enDokument28 SeitenRego-Fix Er Recool endavicocasteNoch keine Bewertungen

- Design of Guyed Mast TowerDokument5 SeitenDesign of Guyed Mast TowerShai KoiNoch keine Bewertungen

- 1pf2gf - Pgf-Int-Gp-Re10213Dokument20 Seiten1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingNoch keine Bewertungen

- Behaviour of Masonry StructuresDokument27 SeitenBehaviour of Masonry StructuresvarshaNoch keine Bewertungen

- CeracoatDerincoat Information SheetDokument5 SeitenCeracoatDerincoat Information SheetMahesh MishraNoch keine Bewertungen

- Vernacular ArchitectureDokument22 SeitenVernacular ArchitectureSharmae Rongavilla100% (1)

- Jib Cranes Brochure PDFDokument28 SeitenJib Cranes Brochure PDFJESUSCALVILLONoch keine Bewertungen

- Portfolio 2013Dokument29 SeitenPortfolio 2013mucupNoch keine Bewertungen

- Wiring Design & CalculationsDokument36 SeitenWiring Design & CalculationsSerrano Ivan Jasper100% (1)

- Mechanic Documents: Drawings and Parts ListsDokument21 SeitenMechanic Documents: Drawings and Parts ListsisnaldoNoch keine Bewertungen

- Welded Connections DesignDokument35 SeitenWelded Connections DesignBelkacem AchourNoch keine Bewertungen

- Losses in Bends FittingsDokument26 SeitenLosses in Bends FittingsKunalNoch keine Bewertungen

- Essential Masonry ToolsDokument4 SeitenEssential Masonry ToolsKamonGwgNoch keine Bewertungen